Professional Documents

Culture Documents

Property Comparison Chart PDF

Uploaded by

mecano1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Property Comparison Chart PDF

Uploaded by

mecano1Copyright:

Available Formats

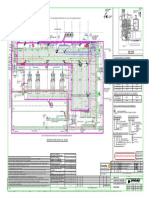

PROPERTY COMPARISON CHART - page 2 www.redwoodplastics.

com

COEFFICIENT THERMAL HEAT DEFLECTION MAX. OPERATING DIELECTRIC DIELECTRIC 24hr. WATER THERMAL

PROPERTY

OF FRICTION EXPANSION TEMPERATURE AT TEMPERATURE STRENGTH CONSTANT ABSORPTION CONDUCTIVITY

combination with other products. Users are advised to make their own tests to determine the safety and suitability of each such product or product combination for their own purposes. Unless otherwise agreed in writing, we sell the products without warranty, and buyers and users assume all responsibility and liability for the

We cannot anticipate all conditions under which this information and our products, or the products of other manufacturers in combination with our products, may be used. We accept no responsibility for the results obtained by the application of this information or the safety and suitability of our products, whether alone or in

Printed in Canada

UNITS in/in-°F °F (°C) @ 264psi °F (°C) V/mil at 1Khz % BTU-in/ft²-hr-°F

ASTM TEST Against Steel E-831 or D696* D-3418 or D-648* UL-94 D-149 D-150 D-570 F-433, C-177*

ACRYLIC (Cast Sheet) 3.9 200-215 (93-102)* 500 3.3 0.2

POLYCARBONATE 0.38 3.7 X 10-5 270 (132) 275 (135) 380 - 0.15 1.35*

PVC (Rigid) 1.2 - 5.6 158-162 (70-72) 160 (70) 350 - 500 4.0 - 8.0 0.04 - 0.4 -

PI (Polyimide) Unfilled - 27* 680 (360)* 700 3.41 0.4 1.53*

PI (Polyimide) Glass Fiber - - 660 (349)* 500 4.7 0.2 3.48*

PI (Polyimide) 25% Graphite 0.24 - 550 (288)* - - 0.6 11.3*

PI (Polyimide) 15% Graphite 0.24 - 680 (360)* 250 13.3 0.2 6.0*

THERMOPLASTICS

PI (Polyimide) - - 625 4.5 0.3 2.2*

loss or damage arising from the handling and use of our products, whether used alone or in combination with other products. For most recent technical information, phone in USA or Canada. CDN 1-800-667-0999. US 1-866-733-2684.

Laminates 660 (349)*

ACETAL (Copolymer) 0.15 5.4 X 10-5 205 (96)* 180 (82) 2,100 3.7 0.22 1.6*

ACETAL (Homopolymer) 0.15 4.7 X 10-5 277 (136)* 180 (82) 3,000 3.7 0.25 2.6*

PEEK (Unreinforced) 0.4 320 (160) 482 (250) 480 3.3 0.1 - 0.5 1.75

PEEK (30% Glass) 450 (232) 480 (249) 500 0.11 2.98

PEEK (30% Carbon) 0.2 518 (270) 482 (250) 32 0.06 6.4

PAI (Polyamide-imide) 0.2 - 0.35 0.8 - 2.0 520-540 (271-282) 500 (260) 700 - 0.3 - 0.4 1.8 - 3.7

PEI (Polyetherimide) 0.18 - 0.42 1.1 - 3.1 390-410 (199-210) 338 (170) 830 - 0.18 - 0.30 0.85

PTFE (Virgin) 0.04-0.06 610 0

PP (Polypropylene) HPP 6.2* 125 (52) 180 (82) 500-660 2.25 <0.01 0.76-0.81

PP (Polypropylene) HPP Filled 130-330 (54-165) 0.01-0.09 2.4-9*

PP (Polypropylene) CPP 6.6* 110 (43) 170 (77) 475 2.2-2.36 0.01-0.03

PP (Polypropylene) CPP Filled 116-280 (47-138) 0.01-0.02 3-9*

UHMW - Reprocessed 0.14 - 0.20 2 X 10-4 180 (82)

UHMW - Virgin 0.14 - 0.20 2 X 10-4 115 (46) 180 (82) 40 2.3 - 2.35

Natural Extruded 0.25 4 X 10-5 194 (90) 220 (104) 600 3.9 1.2 1.7

Natural Cast 0.26-0.42 5.5 X 10-5 200-250 (93-121) 0.6-1.2

NYLONS

Natural Oil 0.12-0.19 5.5 X 10-5 200-250 (93-121) 0.6-1.2

Blue 0.22-0.42 5.5 X 10-5 200-250 (93-121) 0.6-1.2

MD 0.36-0.42 5.5 X 10-5 200-250 (93-121) 0.6-1.2

MD-Oil 0.13-0.20 5.5 X 10-5 200-250 (93-121) 0.2-0.5

Oil 0.17-0.19 5.5 X 10 -5

200-250 (93-121) 0.6-1.2

SL 0.08-0.14 5.5 X 10-5 200-250 (93-121) 0.30

TIVAR® 88 0.12 2 X 10-4 180 (82)

SPECIALTY

TIVAR® Dryslide 0.15 2 X 10-4 180 (82)

SYNSTEEL 0.205

TUFFKAST 0.30-0.40 5.5 X 10-5 220-250 (104-121) 500-600 0.3-0.5

TUFFKAST 010 0.08-0.13 5.5 X 10 -5

220-250 (104-121) 500-600 0.2-.035

TUFFKAST 015 0.13-0.15 5.5 X 10-5 220-250 (104-121) 500-600 0.2

FRP GRATING 0.035 0.45

ARC VOLUME SURFACE MAX. OPERATING DIELECTRIC DIELECTRIC 24hr. WATER DISSIPATION

PROPERTY

RESISTANCE RESITIVITY RESITIVITY TEMPERATURE STRENGTH CONSTANT ABSORPTION FACTOR

UNITS seconds meg-ohm-cm meg-ohms °F (°C) Vpm 106 cycles/sec % 106 cycles/sec

ASTM TEST D-495 D-229 D-229 D-229 D-229 D-229 D-229

LAMINATES

PHENOLIC XXX Paper - 3 x 10 7

7 x 10 5

284 (140) 600 5.2 0.4 0.037

PHENOLIC LE Fine Weave Fabric - 7 x 104 6 x 104 257 (125) 350 5.1 0.7-1.9 0.065

PHENOLIC CE Med. Weave - - - 257 (125) 200 - 1.1 -

PHENOLIC G-5 Glass Cloth 180 6 x 107 6 x 106 284 (140) 300 6.3 0.4 0.019

PHENOLIC G-9 Glass Cloth 180 1.5 x 107 1.5 x 107 284 (140) - 7.2 0.2 0.018

PHENOLIC G-10 Glass Cloth 100 6 x 106 1 x 106 266 (130) 550 5.0 0.05 0.032

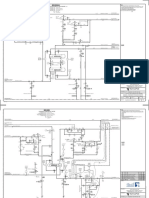

BAYSHORE BELL BRITTLE 300% POST CURE

PROPERTY POT LIFE NCO

REBOUND POINT MODULUS @ 100°C

UNITS % °F Minutes psi % Hours

ASTM TEST D-638

Deadplate 3 970 4.85

POLYURETHANE

54A 23 4 1150 3.2 16

6060 30 6 - 3.6 16

70A 30 -80 5-7 1020 4.05 16

80A 30 -80

430 42 -80 5 2100 4.2 16

500 40 -80 3 2600 6.25 16

Extreme 28 6 3447 5.19 16

600 40

750 45 -70

750SXL 43 -58

SPS-2000 46 -13

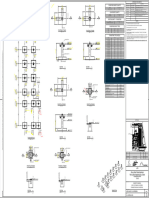

PROPERTY COMPARISON CHART - page 1 www.redwoodplastics.com

SPECIFIC TENSILE TENSILE ELONGATION FLEXURAL FLEXURAL IZOD IMPACT

PROPERTY GRAVITY HARDNESS

STRENGTH MODULUS AT BREAK STRENGTH MODULUS NOTCHED

combination with other products. Users are advised to make their own tests to determine the safety and suitability of each such product or product combination for their own purposes. Unless otherwise agreed in writing, we sell the products without warranty, and buyers and users assume all responsibility and liability for the

We cannot anticipate all conditions under which this information and our products, or the products of other manufacturers in combination with our products, may be used. We accept no responsibility for the results obtained by the application of this information or the safety and suitability of our products, whether alone or in

Printed in Canada

UNITS g/cm 3

psi psi % psi psi ft-lb/in² scale as noted

ASTM TEST D-792 D-638 D-638 D-638 D-790 D-790 D-256 D-785

ACRYLIC (Cast Sheet) 1.19 10,500 4.5 5 16,500 4.5 0.4 M100-102

POLYCARBONATE 1.2 9000 345,000 130 14,200 345,000 17.0 R118, M70

0.4 - 2.0 D65-85, M89,

PVC (Rigid) 1.30 - 1.58 6,000 - 8,000 3.5 - 10 50 - 150 3-8 R107

PI (Polyimide) Unfilled 1.34 20,300 4 29,700 58.0 1.4 M110

PI (Polyimide) Glass Fiber 1.9 27,000 <1 50,000 32.5 17 M20

PI (Polyimide) 25% Graphite 1.45 5,700 <1 12,800 9 0.25 M110

PI (Polyimide) 15% Graphite 1.51 9,500 4.5 16,000 5.5 0.8 M88

THERMOPLASTICS

PI (Polyimide) Laminates 1.95 50,000 <1 70,000 40 13 -

loss or damage arising from the handling and use of our products, whether used alone or in combination with other products. For most recent technical information, phone in USA or Canada. CDN 1-800-667-0999. US 1-866-733-2684.

ACETAL (Copolymer) 1.41 8,800 400,000 55 13,000 400,000 1.3 M80

ACETAL (Homopolymer) 1.42 10,000 450,000 40 14,100 450,000 1.5 M94

R126, D85,

PEEK (Unreinforced) 1.32 14,000-16,000 500,000-630,000 40 24,700 5.3 1.6 M99-100

R126, D89,

PEEK (30% Glass) 1.49 14,000 1000 2.2 23,000 10 0.8 M103

PEEK (30% Carbon) 1.44 19,000 1100 5 25,750 12.5 1.03 D93, M102

1.4 - 1.6 10,000-23,000 400 - 1200 3 - 10 20,000-30,000 600 - 1,000 0.5 - 2.5 E66-E94, D90,

PAI (Polyamide-imide) M106-125

1.3 - 1.5 16,500-17,000 480 - 850 2 - 80 20,000 500 - 900 0.5 - 1.0 R125, D86,

PEI (Polyetherimide) M112-115

PTFE (Virgin) 2982-4970 250-400 809 49,700 D60-65

PP (Polypropylene) HPP 0.90 - 0.91 4,500 - 6,000 16,500 - 22,500 12 7000 17,000-25,000 1.9 R92

PP (Polypropylene) HPP Filled 0.97 - 1.27 3,500 - 16,000 37,500 - 100,000 1.5 - 80 21,000-100,000 0.6 - 12 R75-117

PP (Polypropylene) CPP 0.89 - 0.91 4,000 - 5,500 13,000 - 18,000 23 5400 13,000-20,000 7.5 R80

PP (Polypropylene) CPP Filled 0.98 - 1.24 2,500 - 10,000 5,000 - 35,000 2.2 - 50 21,000-96,000 0.6 - 4.0 R81-105

UHMW - Reprocessed 0.930 - 0.940 3,500-5,200 100,000-150,000 200 - 400 100,000-150,000 No Break R64-68

UHMW - Virgin 0.930 - 0.940 4,800-6,200 100,000-150,000 350 - 400 100,000-150,000 No Break R64-68

Natural Extruded 1.14 12,000 420,000 60 15,000 410,000 0.6 - .09 D80

Natural Cast 1.15 10,500-12,000 350,000-460,000 20-60 12,500-17,000 330,000-500,000 D78-83

NYLONS

Natural Oil 1.14 10,000-14,000 350,000-435,000 20-60 12,500-15,000 350,000-450,000 D74-78

Blue 1.15 10,500-12,000 350,000-460,000 20-40 12,500-17,000 330,000-450,000 D78-83

MD 1.15 10,500-12,000 350,000-460,000 20-40 12,500-17,000 330,000-450,000 D80

MD-Oil 1.15 10,000-12,000 350,000-450,000 20-45 12,500-15,000 420,000 D80-84

Oil 1.14 10,000 350,000-435,000 20-40 12,500-13,000 350,000-450,000 D80

SL 1.13 10,000-12,000 350,000-460,000 20-45 12,500-15,500 430,000 D80-84

TIVAR® 88 0.93 3000 102,000 300 D69

SPECIALTY

TIVAR® Dryslide 0.93 2770 118,643 200 D68

SYNSTEEL > 1.8 2150 59 2300 R54

TUFFKAST 1.14 8,900-11,000 400,000 40-70 16,300 350,000 1.83-2.74

TUFFKAST 010 1.13 8,900-10,000 400,000 45-70 16,000 320,000 2-2.74

TUFFKAST 015 1.14 8,500-10,000 390,000 45-80 16,000 320,000 2-2.74

FRP GRATING 4351 0.36 4351 0.26 25

SPECIFIC TENSILE COMPRESSIVE BONDING FLEXURAL IZOD IMPACT

PROPERTY GRAVITY SHEAR HARDNESS

STRENGTH STRENGTH STRENGTH STRENGTH NOTCHED

UNITS g/cm3 psi psi lb psi psi ft-lb/in² scale as noted

ASTM TEST D-792 D-229 D-229 D-229 D-229 D-229 D-732 D-229

LAMINATES

PHENOLIC XXX Paper 1.34 15,000 36,000 950-1,200 20,000 7,000 0.5 110

PHENOLIC LE Fine Weave Fabric 1.34 14,000 38,000 1,800 22,000 11,000 1.5 100

PHENOLIC CE Med. Weave Fabric 1.37 13,000 37,000 2,000 19,000 10,000 1.8 105

PHENOLIC G-5 Glass Cloth 1.9 40,000 65,000 1,800 50,000 30,000 10.0 115

PHENOLIC G-9 Glass Cloth 1.9 45,000 65,000 1,700-2,300 55,000 - 13.0 120

PHENOLIC G-10 Glass Cloth 1.85 50,000 50,000 2,600 60,000 21,500 10.0 115

SPECIFIC TENSILE TENSILE ELONGATION TEAR COMPRESSION IZOD IMPACT

PROPERTY HARDNESS

GRAVITY STRENGTH MODULUS AT BREAK STRENGTH SET NOTCHED

UNITS psi psi psi % pli % ft-lb/in scale as noted

ASTM TEST D-792 D-412 D-412 D-412 D-470 SPLIT S-395 METHOD B D-746 D-676

Deadplate 1.21 3050 170 720 42 5 FLEXED 52A

POLYURETHANE

54A 1.23 4500 250 490 16 1.2 FLEXED 54A

6060 1.16 4400 300 480 22 6 FLEXED 62A

70A 1.05 2500 310 650 60 31 FLEXED 70A

80A 1.05 3000 700 575 85 35 FLEXED 80A

430 1.1 5000 1050 450 95 30 FLEXED 90A

500 1.14 7000 1800 420 155 37 FLEXED 95A

Extreme 1.21 7240 1687 430 143 30 - 96A

600 1.14 8300 3000 320 135 40 - 60D

208 17

750 1.2 6382 5348 157 43 75D

750SXL 1.16 5681 5364 114 152 - 25 75D

SPS-2000 1.16 5271 4921 147 122 - 31 75D

You might also like

- C32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpDocument4 pagesC32 Generator Set With EMCP 3 Electrical System: Sxc1-Up Wdr1-UpJosé100% (1)

- Instant Assessments for Data Tracking, Grade 2: MathFrom EverandInstant Assessments for Data Tracking, Grade 2: MathNo ratings yet

- D-1100-Pid-004 Cause and Effect ProcessDocument17 pagesD-1100-Pid-004 Cause and Effect ProcessRizky Perdana PutraNo ratings yet

- Attachment #2 Marked-Up P&id PDFDocument17 pagesAttachment #2 Marked-Up P&id PDFzhangNo ratings yet

- SS-1 Deep Well Earth PitDocument1 pageSS-1 Deep Well Earth PitM&N ProjectsNo ratings yet

- Ed 6Document1 pageEd 6jesus123_321No ratings yet

- NPK 300 Z2 DW 4006 V - R5 - General Arrangement Drawing For Dryer Cyclone (81 D 322A) FCDocument4 pagesNPK 300 Z2 DW 4006 V - R5 - General Arrangement Drawing For Dryer Cyclone (81 D 322A) FCDangolNo ratings yet

- 1C16 (KSS021-D-540) - Column-R0.1Document1 page1C16 (KSS021-D-540) - Column-R0.1mo3azNo ratings yet

- 800 Col Line: Bill of Material Sketch ListDocument1 page800 Col Line: Bill of Material Sketch ListAcfMacNo ratings yet

- Acrex 2023 - Hall 1 & Hall 2 Floor Plan (09.01.2023)Document1 pageAcrex 2023 - Hall 1 & Hall 2 Floor Plan (09.01.2023)Lines art StudioNo ratings yet

- 1C17 (KSS021-D-541) - Column-R0.1Document1 page1C17 (KSS021-D-541) - Column-R0.1mo3azNo ratings yet

- 1C4 (KSS021-D-528) - Column-R1Document1 page1C4 (KSS021-D-528) - Column-R1mo3azNo ratings yet

- RF1 (KSS021-D-1311) - Rafter-R1Document1 pageRF1 (KSS021-D-1311) - Rafter-R1mo3azNo ratings yet

- Architectural Drawings 1Document13 pagesArchitectural Drawings 1Manish PandeyNo ratings yet

- Wh-1088pe DrawingDocument1 pageWh-1088pe Drawingom sai quality developmentNo ratings yet

- Crt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Document1 pageCrt-Npc-Dmm-Hva-Dwg-Sd-Gn-33501 - Equipment Capacity Schedule 1-6Shah MuzzamilNo ratings yet

- Plan 3Document4 pagesPlan 3rnz mrnNo ratings yet

- Col Line HDocument1 pageCol Line HAcfMacNo ratings yet

- NPK 300 j9 DW 4000 V Rev.3 Instrument Termination DiagramDocument4 pagesNPK 300 j9 DW 4000 V Rev.3 Instrument Termination Diagramzuhud3331No ratings yet

- 01 - Amort. Pulsação - 1# Sucção - LP-1Document1 page01 - Amort. Pulsação - 1# Sucção - LP-1joaofbragasNo ratings yet

- Foundation Plan and Anchor Locations: Section CDocument1 pageFoundation Plan and Anchor Locations: Section CJavier Guerra TriviñoNo ratings yet

- Phase-I: Job No. 26148Document1 pagePhase-I: Job No. 26148Rodrigo Andres CeledonNo ratings yet

- Data Sheet For Variable Speed Drives of Medium and Large PowerDocument6 pagesData Sheet For Variable Speed Drives of Medium and Large Powerbrome2014No ratings yet

- UB UD UF Standard Condensing Units With S.E.Document8 pagesUB UD UF Standard Condensing Units With S.E.Ion ZabetNo ratings yet

- BE Engineering Guide VDC Air Cooled CondenserDocument46 pagesBE Engineering Guide VDC Air Cooled Condensernauta007No ratings yet

- 4355 Aa DC 21i10pr09001 - 0Document1 page4355 Aa DC 21i10pr09001 - 0amit bagchiNo ratings yet

- Propiedad de Don Pollo Loreto S.A.C. P.E. #11055640Document1 pagePropiedad de Don Pollo Loreto S.A.C. P.E. #11055640Cecilia Mego GomezNo ratings yet

- PDF tps57 Manual DLDocument139 pagesPDF tps57 Manual DLLisandroNo ratings yet

- AMEC Future of OilsandsDocument16 pagesAMEC Future of OilsandsForexFFNo ratings yet

- NGP Door GasketingCatalogDocument52 pagesNGP Door GasketingCatalogcoregroup1No ratings yet

- Quality Control: Lap Joint DetailDocument2 pagesQuality Control: Lap Joint DetailariNo ratings yet

- LPS Juice Factory - Design.Document2 pagesLPS Juice Factory - Design.Bilal KhalidNo ratings yet

- The Fastest Processing Capacity in The World A Multi-Purpose FCRDocument4 pagesThe Fastest Processing Capacity in The World A Multi-Purpose FCRlaboratorioelectroNo ratings yet

- Bods - Dehradun 15-12-2017Document5 pagesBods - Dehradun 15-12-2017designselvaNo ratings yet

- PEDWPRTS771025A1 - Main Compressor B Train 1 - 5Document1 pagePEDWPRTS771025A1 - Main Compressor B Train 1 - 5macielNo ratings yet

- Solar Reflective Shingles: The Heat Reflects Away, and Your Home Stays CoolDocument2 pagesSolar Reflective Shingles: The Heat Reflects Away, and Your Home Stays Coolvomawew647No ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- Parent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTDocument9 pagesParent: Customer Name: Project Name: 9281D4ASSEM 09281 D4 Certified: Approved For Construction Assy. WTmoneyphotocopyshopNo ratings yet

- NCGM XX XX D Aec DR 930 1103Document1 pageNCGM XX XX D Aec DR 930 1103yusufuNo ratings yet

- Workshop 2Document1 pageWorkshop 2Thamarai kannan SrinivasanNo ratings yet

- Drawing 3.Document1 pageDrawing 3.tiyaniNo ratings yet

- GGP 92 000000 MP 4033 93801 0001 GG300HBN0251 03 ModelDocument1 pageGGP 92 000000 MP 4033 93801 0001 GG300HBN0251 03 Modelchandana kumarNo ratings yet

- 4355-Aa-Dc-22i10pr0900i - Checkprint For SquadDocument1 page4355-Aa-Dc-22i10pr0900i - Checkprint For Squadamit bagchiNo ratings yet

- Arquitectura (2) Sistema de Control CONCENTRADORADocument12 pagesArquitectura (2) Sistema de Control CONCENTRADORAJORGEHNo ratings yet

- Rehau Awadukt Thermo 342100 UkDocument24 pagesRehau Awadukt Thermo 342100 UkpaolodownloadNo ratings yet

- XLP Pre L13 WL13P40Document2 pagesXLP Pre L13 WL13P40Aria NickbakhtNo ratings yet

- 0 - Armada Bathrust - IFC 24-04-2023Document12 pages0 - Armada Bathrust - IFC 24-04-2023Kenneth DomingoNo ratings yet

- E Dwgs MonarchTrading - PC S 011520Document11 pagesE Dwgs MonarchTrading - PC S 011520JesseNo ratings yet

- DFDFDDocument1 pageDFDFDPrince RanaNo ratings yet

- Petrol DoubleDocument1 pagePetrol DoubleKS CONSTRUCTIONSNo ratings yet

- MQ13 02 3210 3606 Loh 01 - R0 - RL1Document1 pageMQ13 02 3210 3606 Loh 01 - R0 - RL1Ruth Tecsi TCNo ratings yet

- Wondergraph 1920Document1 pageWondergraph 1920ARNo ratings yet

- Top-Title Bottom-Title: Entrance/Exit PlazaDocument1 pageTop-Title Bottom-Title: Entrance/Exit Plazaمعاذ كروبينNo ratings yet

- Darlington: Silicon NPN Triple Diffused Planar TransistorDocument2 pagesDarlington: Silicon NPN Triple Diffused Planar TransistorGilberto DiazNo ratings yet

- Group 2 Electrical Circuit: Frame/Engine Part Dashboard PartDocument7 pagesGroup 2 Electrical Circuit: Frame/Engine Part Dashboard PartAndré TarginoNo ratings yet

- Chauke Deon A1 PageDocument1 pageChauke Deon A1 PageanzaniNo ratings yet

- Model 72400 Servo Controlled Piston Pump: Parts InformationDocument20 pagesModel 72400 Servo Controlled Piston Pump: Parts InformationhidraulicavarginhadivulgacaoNo ratings yet

- Extracted Pages From PID BinderDocument15 pagesExtracted Pages From PID Bindermangesh patilNo ratings yet

- CGK063 BBCS Mechanical BinderDocument110 pagesCGK063 BBCS Mechanical BinderBack to SumateraNo ratings yet

- PPM LeaseplanDocument1 pagePPM LeaseplanGlobal Music StatsNo ratings yet