Professional Documents

Culture Documents

Plant and Equipment Risk Management Form: 1. Hazard Management Details - General

Uploaded by

Jigar VekariyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plant and Equipment Risk Management Form: 1. Hazard Management Details - General

Uploaded by

Jigar VekariyaCopyright:

Available Formats

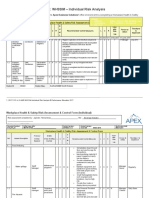

1.

Hazard Management Details – General

Plant/Equipment Item: Air Compressor (Mobile) Make/Model No.: Serial No.:

School / Work Location: Region:

Name of Person(s) Conducting Activity: Date Conducted:

Description of Use: Summary of Key Risks:

(refer to appropriate subsections)

An air compressor takes in air at

atmospheric pressure and Impact and cutting

compresses it to a higher

Pressurised content

pressure.

Electricity

Common uses for air compressors Ergonomics

is to supply high-pressure air for Noise

conveying, paint spraying, inflating Slips/trips/falls

tyres, cleaning, pneumatic tools

etc.

Plant and Equipment Risk Management Form

Last Updated: 29 August 2018

Plant and Equipment Risk Management Form

2. Documentation

Relevant Legislation/Standards Y/N Comments

Is plant required to be registered? Y N

Is a user license required? Y N

Key Reference material AS 4343 Pressure equipment - Hazard levels

AS/NZS 3760 In service safety inspection and testing of electrical equipment

Plant Documentation Y/N Comments

Are operator’s manuals accessible? Y N

Is this a restricted use item? Y N

Does this item require safe use Y N

documents/test?

3. Hazard Identification

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ENTANGLEMENT

Can anyone’s hair, clothing, gloves,

cleaning brushes, tools, rags or other Y N

materials become entangled with moving

parts of the plant or materials?

Air Compressor Risk Management Form Page | 2

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

IMPACT AND CUTTING INJURIES Strike with uncontrolled Ensure air compressor is

Can anyone be crushed/cut/struck etc. hose or coupling. operated and maintained in

due to: accordance with

Material falling off the plant? Y N manufacturer’s instructions.

Uncontrolled/unexpected movement Moderate Possible Medium

Y N

of plant/load?

Lack of capacity to slow, stop or

Y N

immobilise plant?

The plant tipping or rolling over? Y N

Parts of the plant disintegrating or

Y N

collapsing?

Contact with moving parts during

testing, inspection, operation, Y N

maintenance, cleaning or repair?

Being thrown off or under the plant? Y N

Contact with sharp or flying objects?

Y N

(e.g. work pieces being ejected)

The mobility of the plant? Y N Moderate Possible Medium

Inappropriate parts and accessories

Y N

being used?

Other Y N

Air Compressor Risk Management Form Page | 3

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SHEARING

Can anyone’s body parts be sheared

between two parts of plant, or between a Y N

part of the plant and a work piece or

structure?

PRESSURISED CONTENT Moderate Possibl Medium Damaged hoses and Ensure air compressor is

Can anyone come into contact with e accessories may cause operated and maintained in

fluids or gases under high pressure, due Y N

blow out. accordance with the

to plant failure or misuse of the plant? manufacturer’s instructions.

ELECTRICITY Damaged or frayed Operator to check for

Can anyone be injured or burnt due to: electrical cords pose an damaged electrical cords

Live electrical conductors? (e.g. electrical hazard. prior to use.

Y N

exposed wires)

Working in close proximity to Ensure equipment is serviced

Y N

electrical conductors? on a regular basis, tested and

Access to electricity? tagged and appropriate

Y N isolation procedures (e.g. lock

Damaged or poorly maintained Major Unlikely Medium out tags) are in place.

Y N

electrical leads, cables or switches?

Water near electrical equipment?

Y N

Lack of isolation procedures?

Y N

Other

Y N

Air Compressor Risk Management Form Page | 4

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ERGONOMICS Moving or handling the Ensure appropriate manual

Can anyone be injured due to: air compressor may handling techniques are

Poorly designed workstation? present a manual applied when moving or

Y N

handling risk. handling the air compressor.

Repetitive body movement?

Y N

Constrained body posture or the Moderate Unlikely Medium

Y N

need for excessive effort?

Design deficiency causing

Y N

psychological stress?

Inadequate or poorly placed lighting?

Y N

Does the plant impact on the

surrounding workplace and create

potential hazards? (Consider Y N

potential impact on the design and

layout of the workplace)

Is the location of the plant

inappropriate? (Consider potential

Y N

effects due to environmental

conditions and terrain)

Other

Y N

Air Compressor Risk Management Form Page | 5

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

RADIATION

Can anyone using the plant, or in the

vicinity of the plant suffer injury or illness

due to exposure to radiation in the form

of any of the following: Y N

infra-red radiation

ultra violet light

microwaves

NOISE Moderate Unlikely Medium The air compressor may Ensure appropriate hearing

Can anyone using the plant, or in the produce high levels of protection is worn if working

vicinity of the plant, suffer injury due to Y N noise. in close proximity to the air

exposure to noise? compressor.

VIBRATION

Can anyone be injured or suffer ill-health Y N

from exposure to vibration?

FRICTION

Can anyone be burnt due to contact with

Y N

moving parts, materials or surfaces of

the plant?

SUFFOCATION

Can anyone be suffocated due to lack of Y N

oxygen, or atmospheric contamination?

CONDITION

Is a hazard likely due to the age and

condition of the plant? (Consider how Y N

hard the machine has been worked, and

whether it is used constantly or rarely).

Can anyone be injured as a result of

the plant not serviced appropriately

Y N

and/or maintained in line with

manufacturer’s recommendations?

Air Compressor Risk Management Form Page | 6

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SLIPS/TRIPS/FALLS Poor housekeeping Ensure appropriate cleaning

Can anyone using the plant, or in the practices allowing the and housekeeping practices

vicinity of the plant, slip, trip or fall due build-up of waste are maintained to minimise

to: materials or failure to the risk of a slip/trip/falls

Uneven, slippery or steep work immediately clean up hazard.

Y N

surfaces? spills could result in a

Poor housekeeping, e.g. spillage in Minor Possible Medium slip hazard.

Y N

the vicinity?

Obstacles being placed in the vicinity Minor Possible Medium Inappropriate placement

Y N

of the plant? of objects (e.g. spare

Inappropriate or poorly maintained material, electrical

floor or walking surfaces (i.e. lack of cords, bags etc.) in the

Y N immediate vicinity of the

a slip-resistant surface, unprotected

holes, penetrations or gaps?) equipment may result in

If operating or maintaining plant at a trip hazard.

height can anyone slip, trip or fall due to:

Use of work platforms, stairs or

Y N

ladders?

Lack of guardrails or other suitable

Y N

edge protection?

Other

Y N

Air Compressor Risk Management Form Page | 7

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

FIRE AND EXPLOSION

Y N

Can anyone be injured by fire?

Can anyone be injured by

explosion of gases, vapours, liquids, Y N

dusts, or other substances?

TEMPERATURE/MOISTURE

Can anyone come into contact with Y N

objects at high or low temperatures?

Can anyone suffer ill-health due to

exposure to high or low Y N

temperatures?

Can anyone be injured or suffer ill-

Y N

health due to exposure to moisture?

OTHER

Can anyone be injured or suffer ill-health

from exposure to:

Chemicals? Y N

Toxic gases or vapours? Y N

Fumes/Dusts? Y N

Other? (please specify) Y N

4. Risk Assessment Signoff

Authorised By: Signature: Date:

Air Compressor Risk Management Form Page | 8

Plant and Equipment Risk Management Form

1. Consequence - Evaluate the consequences of a risk occurring according 2. Likelihood - Evaluate the likelihood of an incident occurring according to the

to the ratings in the top row ratings in the left hand column

Descriptor Leve Definition

Descriptor Level Definition l

Rare 1 May occur somewhere, sometime (“once in a life time /

Insignificant 1 No injury once in a hundred years”)

Minor 2 Injury/ ill health requiring first aid Unlikely 2 May occur somewhere within the Department over

an extended period of time

Moderate 3 Injury/ill health requiring medical

attention Possible 3 May occur several times across the Department or a

region over a period of time

Major 4 Injury/ill health requiring hospital

admission Likely 4 May be anticipated multiple times over a period of time

May occur once every few repetitions of the activity or

Severe 5 Fatality event

Almost 5 Prone to occur regularly

3. Risk level - Calculate the level of risk by finding the intersection between the

Certain It is anticipated for each repetition of the activity of event

likelihood and the consequences

Likelihoo Consequence 4. Risk Level/Rating and Actions

d Insignificant Minor Moderate Major Severe Descripto Definition

Almost Medium High Extreme Extreme Extreme r

Certain

Likely Medium Medium High Extreme Extreme Extreme: Notify Workplace Manager and/or Management OHS

Possible Low Medium Medium High Extreme Nominee immediately. Corrective actions should be taken

Unlikely Low Low Medium Medium High immediately. Cease associated activity.

Rare Low Low Low Medium Medium High: Notify Workplace Manager and/or Management OHS

Nominee immediately. Corrective actions should be taken

within 48 hours of notification.

Medium: Notify Nominated employee, HSR / OHS Committee.

Nominated employee, OHS Representative / OHS Committee

is to follow up that corrective action is taken within 7 days.

Low Notify Nominated employee, HSR / OHS Committee.

Nominated employee, HSR / OHS Committee is to follow up

that corrective action is taken within a reasonable time.

Air Compressor Risk Management Form Page | 9

You might also like

- The Handbook of Safety Engineering: Principles and ApplicationsFrom EverandThe Handbook of Safety Engineering: Principles and ApplicationsRating: 4 out of 5 stars4/5 (1)

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument9 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralJigar VekariyaNo ratings yet

- Plant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.Document9 pagesPlant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.Letlape SamuelNo ratings yet

- Hydraulic Press Risk MG T FormDocument10 pagesHydraulic Press Risk MG T FormAndrei VNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument10 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralsamNo ratings yet

- Air Compressor Risk MG T FormDocument8 pagesAir Compressor Risk MG T Formashraf100% (1)

- Air Compressor Risk MG T FormDocument8 pagesAir Compressor Risk MG T FormFateh AliyaNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument11 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro Campomar100% (1)

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument11 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - Generalum erNo ratings yet

- Stivuitor ElectricDocument10 pagesStivuitor ElectricDan DumbravescuNo ratings yet

- Evaluare Risk MotoferastrauDocument10 pagesEvaluare Risk MotoferastrauDan DumbravescuNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument12 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument11 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro CampomarNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument9 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDan Dumbravescu100% (1)

- HIRARC ElectricalDocument8 pagesHIRARC Electricalsandip jitNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- Plant Risk Assessment FormDocument9 pagesPlant Risk Assessment FormSufika FaniNo ratings yet

- Pera Air CompressorDocument6 pagesPera Air Compressorabdulhanansamo65No ratings yet

- JSA Template HVH CoverDocument10 pagesJSA Template HVH CoverAisha purconNo ratings yet

- Risk Assessment - PPE - Floatation DevicesDocument1 pageRisk Assessment - PPE - Floatation Devicesbearingworks123No ratings yet

- Anup 000768Document8 pagesAnup 000768rhp1989No ratings yet

- Jsa-Installation Roof Truss Steel Structure For ShelterDocument10 pagesJsa-Installation Roof Truss Steel Structure For ShelterAisha purconNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- Screen Cutting Tool - Reviewed - Photo AddedDocument4 pagesScreen Cutting Tool - Reviewed - Photo AddedAchuuNo ratings yet

- FAHU Risk AssessmentDocument2 pagesFAHU Risk AssessmentRaqib NawazNo ratings yet

- RISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Document1 pageRISK/IMPACT ASSESSMENT (To Be Used Both Occupation Health, Safety & Environment)Sijo RajanNo ratings yet

- Handling Precautions For SMC ProductsDocument92 pagesHandling Precautions For SMC ProductsmilanNo ratings yet

- Sharma Riya AwewhssimcfDocument4 pagesSharma Riya AwewhssimcfMax kaoNo ratings yet

- TIP-HSE-P02-01-F01 Risk Assessment R0Document10 pagesTIP-HSE-P02-01-F01 Risk Assessment R0Vijayakumar KarunanidhiNo ratings yet

- Pera Air CompressorDocument6 pagesPera Air CompressorJigar VekariyaNo ratings yet

- Turbine SafetyDocument54 pagesTurbine SafetyAkashNo ratings yet

- Environmental Health Risk AssessmentDocument7 pagesEnvironmental Health Risk Assessmentdu dungNo ratings yet

- RiskDocument4 pagesRiskansarmulla711No ratings yet

- HIRA-Air ConditioningDocument2 pagesHIRA-Air Conditioningtumelo makgabutlaneNo ratings yet

- Central Luzon Doctors Hospital HAZARD IDDocument6 pagesCentral Luzon Doctors Hospital HAZARD IDOsfmc LogisticsNo ratings yet

- Generator RADocument16 pagesGenerator RABaher MohamedNo ratings yet

- Safe Work Procedure: Last Updated: 22 August 2018Document2 pagesSafe Work Procedure: Last Updated: 22 August 2018Dan DumbravescuNo ratings yet

- 13-25-645 00 SM Safety Manual, Rotary, GDDocument48 pages13-25-645 00 SM Safety Manual, Rotary, GDSESKNo ratings yet

- Engineering Principles - PEO 19 2023Document54 pagesEngineering Principles - PEO 19 2023Christopher RedfernNo ratings yet

- Shop Safety Equipment Hazard Analysis and Management TemplateDocument4 pagesShop Safety Equipment Hazard Analysis and Management TemplateAmir MuhaiminNo ratings yet

- 04 Hazards Identification, Assessment and Controls (Participant Rev1)Document31 pages04 Hazards Identification, Assessment and Controls (Participant Rev1)ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- H59 P75 D7 Disaster Management PlanDocument22 pagesH59 P75 D7 Disaster Management PlanBrijgopal YadavNo ratings yet

- HiraDocument18 pagesHiraPanchdev KumarNo ratings yet

- Risk Management ReportDocument18 pagesRisk Management ReportVictor AlarcónNo ratings yet

- Safety Management Plan: For Limestone Mine of Ultratech Cement LimitedDocument22 pagesSafety Management Plan: For Limestone Mine of Ultratech Cement LimitedsunilsinghmNo ratings yet

- DEK 265-Horizon Operations ManualDocument28 pagesDEK 265-Horizon Operations ManualDavid ElectrónicNo ratings yet

- Hse For Engineers-PresentDocument30 pagesHse For Engineers-PresentMalayalam musical CollectionNo ratings yet

- Report Hirarc - Case Study 2Document16 pagesReport Hirarc - Case Study 2Wan Feris75% (4)

- FIELD GUIDE Preventing Serious Injury & FatalitiesGO1965Document16 pagesFIELD GUIDE Preventing Serious Injury & FatalitiesGO1965ekoimampNo ratings yet

- JHA MaintenanceDocument9 pagesJHA Maintenancejherson gravidesNo ratings yet

- Job Safety Analysis - N2 PurgingDocument3 pagesJob Safety Analysis - N2 Purgingbenjamin alingNo ratings yet

- Ra SPMS 180512Document20 pagesRa SPMS 180512AnoopNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- Machine Guarding SafetyDocument31 pagesMachine Guarding SafetyAnonymous iI88LtNo ratings yet

- SMO Blank ChecklistDocument2 pagesSMO Blank ChecklistPaeto KsdNo ratings yet

- Hazard Identification Risk Evaluation Risk ControlDocument20 pagesHazard Identification Risk Evaluation Risk ControlNyadroh Clement MchammondsNo ratings yet

- AWE Individual Health Safety Risk Assessment Control Form 2Document5 pagesAWE Individual Health Safety Risk Assessment Control Form 2RAMIYA PANNUNo ratings yet

- CNC Maching Ceneter Risk MGT FormDocument8 pagesCNC Maching Ceneter Risk MGT FormAhsan RiazNo ratings yet

- v1.0 AWE Individual Health Safety Risk Assessment Control FormDocument3 pagesv1.0 AWE Individual Health Safety Risk Assessment Control FormZoma ShaikhNo ratings yet

- Le - Cpar Week 1Document3 pagesLe - Cpar Week 1Reniña Lucena CarpioNo ratings yet

- Book DownDocument17 pagesBook DownProf. Madya Dr. Umar Yusuf MadakiNo ratings yet

- Pedu 202Document44 pagesPedu 202Mejane MonterNo ratings yet

- M Tech Thesis Format RGPVDocument5 pagesM Tech Thesis Format RGPVhollyschulzgilbert100% (2)

- Soal Bahasa Inggris Uas 2020Document5 pagesSoal Bahasa Inggris Uas 2020Mukhlisin OfficialNo ratings yet

- Testing Effects of Acid Rain On StatuesDocument5 pagesTesting Effects of Acid Rain On StatuesDanielle LoneNo ratings yet

- Ideal Gas Law NotesDocument4 pagesIdeal Gas Law NotesPrincess Jean GalabinNo ratings yet

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaNo ratings yet

- Chapter09 Mathematics of CryptographyDocument14 pagesChapter09 Mathematics of CryptographytartarNo ratings yet

- Continuous Beams (Common But Special Case) : Msc. CourseDocument15 pagesContinuous Beams (Common But Special Case) : Msc. CourseRaffal NejimNo ratings yet

- Impact of In-Service Training On Economics Teachers' Productivity in Secondary SchoolsDocument27 pagesImpact of In-Service Training On Economics Teachers' Productivity in Secondary SchoolsOjo Oluwaseun JuliusNo ratings yet

- Temperature Sensitivity of A Quartz Crystal Microbalance For TGA in Space AnnotatedDocument5 pagesTemperature Sensitivity of A Quartz Crystal Microbalance For TGA in Space AnnotatedNg Zi XuanNo ratings yet

- International Environmnet Law in IndiaDocument17 pagesInternational Environmnet Law in IndiaAnushka TRivediNo ratings yet

- Module 2 Disciplines in Applied Social SciencesDocument10 pagesModule 2 Disciplines in Applied Social SciencesAhmadNo ratings yet

- Sanmati Engineering College Brochure PDFDocument22 pagesSanmati Engineering College Brochure PDFMES Sanmati Group Adv. Vaishali Jain EducationNo ratings yet

- Virtual In-House Research & Extension Proposal Review For 2022Document3 pagesVirtual In-House Research & Extension Proposal Review For 2022larry santosNo ratings yet

- Part 3Document232 pagesPart 3Bobby SharmaNo ratings yet

- 6D E25 Errata 2Document2 pages6D E25 Errata 2WildanNo ratings yet

- Palla: Vibrating MillDocument16 pagesPalla: Vibrating MillSanjeev AroraNo ratings yet

- Independentuniversity, Bangladesh: Summer 2020 Semester Courses and Class Schedule Undergraduate ProgrammeDocument49 pagesIndependentuniversity, Bangladesh: Summer 2020 Semester Courses and Class Schedule Undergraduate Programmeabid faisalNo ratings yet

- Life Buoy Presentation - S7Document11 pagesLife Buoy Presentation - S7tejas baldaniyaNo ratings yet

- 08 - Chapter 5Document78 pages08 - Chapter 5RashaNo ratings yet

- CSR Paper ResearchDocument14 pagesCSR Paper ResearchJacqueline GalletoNo ratings yet

- Summer Practice Report Format For CeDocument8 pagesSummer Practice Report Format For CesohrabNo ratings yet

- Eng NHKDocument10 pagesEng NHKkiran smNo ratings yet

- FurleyP Memmertd 2010 TheroleofworkingmemoryinsportsDocument25 pagesFurleyP Memmertd 2010 Theroleofworkingmemoryinsports蘇柏霖No ratings yet

- Chapter Three: Logic and LanguageDocument16 pagesChapter Three: Logic and LanguageTagayNo ratings yet

- 5 Tesla's Companion: Lillie B. Delaney Was Erased From HistoryDocument46 pages5 Tesla's Companion: Lillie B. Delaney Was Erased From HistoryJorge E. Azanza Baca100% (1)

- QHSE Training Answers FIELD PERSONNELDocument1 pageQHSE Training Answers FIELD PERSONNELMhanna AYNo ratings yet

- Magnetic Field 2Document4 pagesMagnetic Field 2Yzabella Jhoy AlbertoNo ratings yet