Professional Documents

Culture Documents

Plant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.

Uploaded by

Letlape SamuelOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plant and Equipment Risk Management Form: Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.

Uploaded by

Letlape SamuelCopyright:

Available Formats

1.

Hazard Management Details – General

Plant/Equipment Item: High Pressure Water Cleaner Make/Model No.: Serial No.:

School / Work Location: Region:

Name of Person(s) Conducting Activity: Date Conducted:

Description of Use: Summary of Key Risks:

(refer to appropriate subsections)

A high-pressure water cleaner is a

mechanical sprayer that uses Impact (from back spray)

high-pressure water to clean

Pressurised content

vehicles, buildings, roads etc.

Electricity

Ergonomics

Slips/trips/falls

Plant and Equipment Risk Management Form

Last Updated: 2 February 2023

Plant and Equipment Risk Management Form

2. Documentation

Relevant Legislation/Standards Y/N Comments

Is plant required to be registered? Y N

Is a user license required? Y N

Key Reference material AS/NZS 3160 Approval and test specification – Hand-held electrical power tools

AS/NZS 60745.1 Hand-held motor-operated electric tools – Safety – General requirements

AS 4024.1 Safety of machinery

AS/NZS 3760 In service safety inspection and testing of electrical equipment.

AS/NZS 60745.2 Hand-held motor-operated electric tools – Safety – Particular requirements for

hedge trimmers

Plant Documentation Y/N Comments

Are operator’s manuals accessible? Y N

Is this a restricted use item? Y N

Does this item require safe use Y N

documents/test?

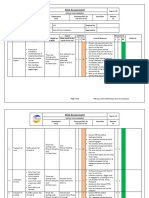

3. Hazard Identification

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

ENTANGLEMENT Y N

Can anyone’s hair, clothing, gloves, cleaning

brushes, tools, rags or other materials

become entangled with moving parts of the

plant or materials?

High Pressure Water Cleaner Risk Management Form Page | 2

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

IMPACT AND CUTTING INJURIES Potential for impact from Ensure high pressure cleaner is

Can anyone be crushed/cut/struck etc. due back spray containing operated and maintained in

to: water and/or debris. accordance with manufacturer’s

instructions.

Material falling off the plant? Y N

Strike with uncontrolled

Uncontrolled/unexpected movement of Y N Minor Unlikely Low hose or coupling. Wear appropriate PPE (e.g.

plant/load? goggles and water proof clothing

etc.).

Lack of capacity to slow, stop or Y N

immobilise plant?

The plant tipping or rolling over? Y N

Parts of the plant disintegrating or Y N

collapsing?

Contact with moving parts during testing, Y N

inspection, operation, maintenance,

cleaning or repair?

Being thrown off or under the plant? Y N

Contact with sharp or flying objects? Y N Minor Possible Medium

(e.g. work pieces being ejected)

The mobility of the plant? Y N

Inappropriate parts and accessories Y N

being used?

Other Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

High Pressure Water Cleaner Risk Management Form Page | 3

Plant and Equipment Risk Management Form

Cons Like Risk

Level

SHEARING Y N

Can anyone’s body parts be sheared

between two parts of plant, or between a

part of the plant and a work piece or

structure?

PRESSURISED CONTENT Y N Minor Possible Medium Excess pressure and/or Ensure equipment is operated

Can anyone come into contact with fluids or damaged accessories may and maintained in accordance

gases under high pressure, due to plant cause blow out of air or with manufacturer’s instructions.

failure or misuse of the plant? water.

Ensure equipment is not directed

Misuse of equipment can at people or animals.

lead to contact with

pressurised content.

ELECTRICITY The high pressure cleaner Ensure the high pressure

Can anyone be injured or burnt due to: can pose an electrical cleaner is not directed at live

hazard if improperly used, electrical equipment.

Live electrical conductors? (e.g. exposed Y N

directed at live electrical

wires)

equipment or has Ensure equipment is serviced on

Working in close proximity to electrical Y N damaged or frayed a regular basis in accordance

conductors? electrical cables. with manufacturer’s operating

instructions, tested and tagged

Access to electricity? Y N

and appropriate isolation

procedures (e.g. lock out tags)

Damaged or poorly maintained electrical Y N are in place.

leads, cables or switches?

Water near electrical equipment? Y N Moderate Possible Medium Ensure the power cord or

extension cables are not

damaged by running over,

Lack of isolation procedures? Y N

pinching, dragging or similar.

Other Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

High Pressure Water Cleaner Risk Management Form Page | 4

Plant and Equipment Risk Management Form

Cons Like Risk

Level

ERGONOMICS Repetitive and sustained Ensure appropriate manual

Can anyone be injured due to: use of the high pressure handling techniques are

cleaner could pose a applied when handling the

Poorly designed workstation? Y N

manual handling hazard. high pressure cleaner.

Repetitive body movement? Y N Minor Possible Medium

Ensure appropriate rest

breaks are taken.

Constrained body posture or the Y N

need for excessive effort?

Design deficiency causing Y N

psychological stress?

Inadequate or poorly placed lighting? Y N

Does the plant impact on the Y N

surrounding workplace and create

potential hazards? (Consider

potential impact on the design and

layout of the workplace)

Is the location of the plant Y N

inappropriate? (Consider potential

effects due to environmental

conditions and terrain)

Other Y N

High Pressure Water Cleaner Risk Management Form Page | 5

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

RADIATION Y N

Can anyone using the plant, or in the vicinity

of the plant suffer injury or illness due to

exposure to radiation in the form of any of

the following:

infra-red radiation

ultra violet light

microwaves

NOISE Y N

Can anyone using the plant, or in the vicinity

of the plant, suffer injury due to exposure to

noise?

VIBRATION Y N

Can anyone be injured or suffer ill-health

from exposure to vibration?

FRICTION Y N

Can anyone be burnt due to contact with

moving parts, materials or surfaces of the

plant?

SUFFOCATION Y N

Can anyone be suffocated due to lack of

oxygen, or atmospheric contamination?

CONDITION Y N

Is a hazard likely due to the age and

condition of the plant? (Consider how hard

the machine has been worked, and whether

it is used constantly or rarely).

Can anyone be injured as a result of the Y N

plant not serviced appropriately and/or

maintained in line with manufacturer’s

recommendations?

High Pressure Water Cleaner Risk Management Form Page | 6

Plant and Equipment Risk Management Form

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

SLIPS/TRIPS/FALLS Cleaning operations Ensure that appropriate

Can anyone using the plant, or in the which produce and/or housekeeping practices are

vicinity of the plant, slip, trip or fall due allow the build-up of maintained to minimise the

to: liquid materials or risk of a slip, trip or fall.

failure to immediately

Uneven, slippery or steep work Y N Minor Possible Medium

clean up spills could Ensure appropriate footwear

surfaces?

result in a slip, trip or is worn.

Poor housekeeping, e.g. spillage in Y N Minor Possible Medium fall hazard.

the vicinity?

Obstacles being placed in the vicinity Y N

of the plant?

Inappropriate or poorly maintained Y N

floor or walking surfaces (i.e. lack of

a slip-resistant surface, unprotected

holes, penetrations or gaps?)

If operating or maintaining plant at

height can anyone slip, trip or fall due to:

Use of work platforms, stairs or Y N

ladders?

Lack of guardrails or other suitable Y N

edge protection?

Other Y N

Hazards Inspected Risk Assessment Description of Risk Control Measures

Cons Like Risk

Level

High Pressure Water Cleaner Risk Management Form Page | 7

Plant and Equipment Risk Management Form

FIRE AND EXPLOSION Y N

Can anyone be injured by fire?

Can anyone be injured by explosion Y N

of gases, vapours, liquids, dusts, or

other substances?

TEMPERATURE/MOISTURE Y N

Can anyone come into contact with

objects at high or low temperatures?

Can anyone suffer ill-health due to Y N

exposure to high or low

temperatures?

Can anyone be injured or suffer ill- Y N

health due to exposure to moisture?

OTHER

Can anyone be injured or suffer ill-health

from exposure to:

Chemicals? Y N

Toxic gases or vapours? Y N

Fumes/Dusts? Y N

Other? (please specify) Y N

4. Risk Assessment Signoff

Authorised By: Signature: Date:

High Pressure Water Cleaner Risk Management Form Page | 8

Plant and Equipment Risk Management Form

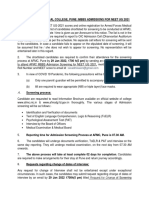

1. Consequence - Evaluate the consequences of a risk occurring according 2. Likelihood - Evaluate the likelihood of an incident occurring according to the

to the ratings in the top row ratings in the left hand column

Descriptor Level Definition

Descriptor Level Definition

Rare 1 May occur somewhere, sometime (“once in a life time /

Insignificant 1 No injury once in a hundred years”)

Minor 2 Injury/ ill health requiring first aid Unlikely 2 May occur somewhere within the Department over an

extended period of time

Moderate 3 Injury/ill health requiring medical

attention Possible 3 May occur several times across the Department or a

Major 4 Injury/ill health requiring hospital region over a period of time

admission Likely 4 May be anticipated multiple times over a period of time

Severe 5 Fatality May occur once every few repetitions of the activity or

event

3. Risk level - Calculate the level of risk by finding the intersection between the Almost 5 Prone to occur regularly

likelihood and the consequences Certain It is anticipated for each repetition of the activity of event

4. Risk Level/Rating and Actions

Likelihoo Consequence

d Descripto Definition

Insignificant Minor Moderate Major Severe r

Almost Medium High Extreme Extreme Extreme

Certain Extreme: Notify Workplace Manager and/or Management OHS

Nominee immediately. Corrective actions should be taken

Likely Medium Medium High Extreme Extreme immediately. Cease associated activity.

Possible Low Medium Medium High Extreme High: Notify Workplace Manager and/or Management OHS

Unlikely Low Low Medium Medium High Nominee immediately. Corrective actions should be taken

within 48 hours of notification.

Rare Low Low Low Medium Medium

Medium: Notify Nominated employee, HSR / OHS Committee.

Nominated employee, OHS Representative / OHS Committee

is to follow up that corrective action is taken within 7 days.

Low Notify Nominated employee, HSR / OHS Committee.

Nominated employee, HSR / OHS Committee is to follow up

that corrective action is taken within a reasonable time.

High Pressure Water Cleaner Risk Management Form Page | 9

You might also like

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument10 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralsamNo ratings yet

- Mobile Air Compressor Risk ManagementDocument9 pagesMobile Air Compressor Risk ManagementJigar VekariyaNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument9 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralJigar VekariyaNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument11 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - Generalum erNo ratings yet

- Stivuitor ElectricDocument10 pagesStivuitor ElectricDan DumbravescuNo ratings yet

- Air Compressor Risk MG T FormDocument8 pagesAir Compressor Risk MG T FormFateh AliyaNo ratings yet

- Scissor Lift Risk ManagementDocument11 pagesScissor Lift Risk ManagementAlejandro Campomar100% (1)

- Air Compressor Risk MG T FormDocument8 pagesAir Compressor Risk MG T Formashraf100% (1)

- Plant and Equipment Risk Assessment Fgoc - NewDocument12 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- Plant and Equipment Risk Assessment Fgoc - NewDocument13 pagesPlant and Equipment Risk Assessment Fgoc - Newmajid khanNo ratings yet

- Evaluare Risk MotoferastrauDocument10 pagesEvaluare Risk MotoferastrauDan DumbravescuNo ratings yet

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument9 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDan Dumbravescu100% (1)

- Plant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralDocument11 pagesPlant and Equipment Risk Management Form: 1. Hazard Management Details - GeneralAlejandro CampomarNo ratings yet

- 17-Using Portable Power ToolsDocument2 pages17-Using Portable Power Toolshsse.maltaNo ratings yet

- Safe Work Procedure: Last Updated: 22 August 2018Document2 pagesSafe Work Procedure: Last Updated: 22 August 2018Dan DumbravescuNo ratings yet

- RISK ASSESSMENT Cleaning TankDocument5 pagesRISK ASSESSMENT Cleaning TankYoussef HdiaNo ratings yet

- Safety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Document12 pagesSafety - Preventing Serious Injury and Fatalities - Chevrons Field Guide - Part 1Priyo DjatmikoNo ratings yet

- Environmental Health Risk AssessmentDocument7 pagesEnvironmental Health Risk Assessmentdu dungNo ratings yet

- Maintenance Job Hazard AnalysisDocument9 pagesMaintenance Job Hazard Analysisjherson gravidesNo ratings yet

- Electrical Equipment 2010Document3 pagesElectrical Equipment 2010victorNo ratings yet

- TIP-HSE-P02-01-F01 Risk Assessment R0Document10 pagesTIP-HSE-P02-01-F01 Risk Assessment R0Vijayakumar KarunanidhiNo ratings yet

- Generator RADocument16 pagesGenerator RABaher MohamedNo ratings yet

- RiskDocument4 pagesRiskansarmulla711No ratings yet

- JSA For RCC, Foundation & Generator Installation (R-00)Document14 pagesJSA For RCC, Foundation & Generator Installation (R-00)Suju RajanNo ratings yet

- Swift TS06E Risk AssessmentDocument9 pagesSwift TS06E Risk AssessmentsouravrobinNo ratings yet

- Risk assessment formDocument3 pagesRisk assessment formJalagandeeswaran KalimuthuNo ratings yet

- Heights Safe Working atDocument7 pagesHeights Safe Working atHendrias Ari SujarwoNo ratings yet

- CNC Maching Ceneter Risk MGT FormDocument8 pagesCNC Maching Ceneter Risk MGT FormAhsan RiazNo ratings yet

- SMO Blank ChecklistDocument2 pagesSMO Blank ChecklistPaeto KsdNo ratings yet

- SFSDFSDDocument8 pagesSFSDFSDali shahNo ratings yet

- FIELD GUIDE Preventing Serious Injury & FatalitiesGO1965Document16 pagesFIELD GUIDE Preventing Serious Injury & FatalitiesGO1965ekoimampNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Hydro Test PipesDocument3 pagesHydro Test PipesVikram Kumar MvsNo ratings yet

- The Mechanical RiskDocument23 pagesThe Mechanical RiskSolomon AlemuNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- 340AJ Risk AssessmentDocument7 pages340AJ Risk AssessmentMyaIdzaharNo ratings yet

- HIRA-Air ConditioningDocument2 pagesHIRA-Air Conditioningtumelo makgabutlaneNo ratings yet

- Sharma Riya AwewhssimcfDocument4 pagesSharma Riya AwewhssimcfMax kaoNo ratings yet

- Job Safety Analysis For Concrete Casting (R-01)Document13 pagesJob Safety Analysis For Concrete Casting (R-01)Suju RajanNo ratings yet

- FAHU Risk AssessmentDocument2 pagesFAHU Risk AssessmentRaqib NawazNo ratings yet

- TRA Strainer Cleaning 01Document7 pagesTRA Strainer Cleaning 01Ijaz Hussain0% (1)

- JHA Welding Pipe BenderDocument2 pagesJHA Welding Pipe Bendermohammad arshadNo ratings yet

- Jsa-Installation Roof Truss Steel Structure For ShelterDocument10 pagesJsa-Installation Roof Truss Steel Structure For ShelterAisha purconNo ratings yet

- RA04 General Office EquipmentDocument3 pagesRA04 General Office EquipmentM Hammad KothariNo ratings yet

- LUM ENGINEERING WORKS SDN. BHD. HAZARD IDENTIFICATION ANALYSISDocument1 pageLUM ENGINEERING WORKS SDN. BHD. HAZARD IDENTIFICATION ANALYSISMahendren Jayapalan0% (1)

- Anup 000768Document8 pagesAnup 000768rhp1989No ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneMoaatazz Nouisri0% (1)

- Job Safety Analysis for Workover OperationsDocument5 pagesJob Safety Analysis for Workover OperationsAshok SureshNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- Hazard and Risk Management AssessmentDocument4 pagesHazard and Risk Management Assessmentansarmulla711No ratings yet

- AHA-002, Geotechnical WorkDocument5 pagesAHA-002, Geotechnical WorkBuddhikaNo ratings yet

- Major EMOC Risk Assessment and Control ChecklistDocument4 pagesMajor EMOC Risk Assessment and Control Checklisttejcd1234No ratings yet

- RISK ASSESSMENT Cleaning Tank in Waha CPFDocument8 pagesRISK ASSESSMENT Cleaning Tank in Waha CPFYoussef HdiaNo ratings yet

- JRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaDocument8 pagesJRA No 11-193 Hydro Testing On 28 Bar Pressure For (WP) Water Produce Lines at FEC AreaAijaz AhmedNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplateJUAN NICANOR ALIAGA GIRONNo ratings yet

- AHA-009, Construction & Removing FormsDocument4 pagesAHA-009, Construction & Removing FormsBuddhikaNo ratings yet

- JSA Epoxy Coating Machine ShopDocument10 pagesJSA Epoxy Coating Machine ShopMarhendra100% (1)

- Civil (Barbending Work)Document3 pagesCivil (Barbending Work)pavanNo ratings yet

- LWX-C5 英文维修手册 (带LOGO) LWLWX -C5 (SMC) -H-002 (A2)Document103 pagesLWX-C5 英文维修手册 (带LOGO) LWLWX -C5 (SMC) -H-002 (A2)Victor Blanco100% (1)

- Depression Associated With Dementia With Lewy Bodies (DLB) and The Effect of SomatotherapyDocument6 pagesDepression Associated With Dementia With Lewy Bodies (DLB) and The Effect of SomatotherapyRaluca ElenaNo ratings yet

- Daily Diary Stress and Mood Variation/TITLEDocument103 pagesDaily Diary Stress and Mood Variation/TITLEFilsa Putri AnwarNo ratings yet

- Cusa (Cavitron Ultrasonic Surgical Aspirator) "The New Armour of Periodontal Therapy"Document4 pagesCusa (Cavitron Ultrasonic Surgical Aspirator) "The New Armour of Periodontal Therapy"International Journal of Innovative Science and Research TechnologyNo ratings yet

- Checklist Using Nasopharengeal and Oropharengeal SuctioningDocument4 pagesChecklist Using Nasopharengeal and Oropharengeal SuctioningKristine Louise JavierNo ratings yet

- The Baltimore SunDocument21 pagesThe Baltimore SunАгент ГусьNo ratings yet

- A Case Study of Hypertensive Cardiovascular Disease (HCVD) : School of Nursing and MidwiferyDocument13 pagesA Case Study of Hypertensive Cardiovascular Disease (HCVD) : School of Nursing and Midwiferyhsiria100% (2)

- RhetoricDocument32 pagesRhetoricDian ValerieNo ratings yet

- Cover Letter For Epidemiologist PositionDocument7 pagesCover Letter For Epidemiologist Positiongt7gb636100% (1)

- AFMC MBBS Admissions Screening Dates for NEET UG 2021Document33 pagesAFMC MBBS Admissions Screening Dates for NEET UG 2021robert hookeNo ratings yet

- Implementing of Rewards and Punishments Toward Students' Motivation in ELDocument13 pagesImplementing of Rewards and Punishments Toward Students' Motivation in ELAriska ChikaNo ratings yet

- International Journal of Obstetric AnesthesiaDocument6 pagesInternational Journal of Obstetric Anesthesiaanita pratiwiNo ratings yet

- Behavioral Perspective On Mental Health and IllnessDocument12 pagesBehavioral Perspective On Mental Health and IllnessMonisha LakshminarayananNo ratings yet

- Mac Cosmetic CatalogDocument39 pagesMac Cosmetic CatalogCamy Herstig60% (5)

- English File B2 2 Fourth Edition Student S Book and WorkbookDocument241 pagesEnglish File B2 2 Fourth Edition Student S Book and WorkbookPaula AlcañizNo ratings yet

- Townshend - Effectivness of Mindful Parents ProgramsDocument40 pagesTownshend - Effectivness of Mindful Parents ProgramsDavid ZNo ratings yet

- Antimicrobial Susceptibility Testing. Currently Used Methods and Devices and The Near Future in Clinical PracticeDocument34 pagesAntimicrobial Susceptibility Testing. Currently Used Methods and Devices and The Near Future in Clinical PracticeRodrigo Sánchez CrespoNo ratings yet

- Wa0002.Document9 pagesWa0002.SojiNo ratings yet

- Module 1Document26 pagesModule 1priya malikNo ratings yet

- Adhikari AP Et Al - 2020 - Kabat Intervention With FEFE - A Pre-Post StudyDocument6 pagesAdhikari AP Et Al - 2020 - Kabat Intervention With FEFE - A Pre-Post StudyManisha ChaudharyNo ratings yet

- Continual Improvement ProcedureDocument6 pagesContinual Improvement ProcedureRonald Sarillana100% (1)

- Revised - Ie18 Final UpdatedDocument120 pagesRevised - Ie18 Final UpdatedLUCAS AndrewsNo ratings yet

- 3 Month Study Plan For CSS Exam PreparationDocument1 page3 Month Study Plan For CSS Exam PreparationDanish AliNo ratings yet

- Test Bank For Burtons Microbiology For The Health Sciences 9 North Americanth Edition Paul G EngelkirkDocument10 pagesTest Bank For Burtons Microbiology For The Health Sciences 9 North Americanth Edition Paul G Engelkirkraphaelsophiep9f9100% (22)

- NAVTA Ovt Nov17 CERadiographDocument8 pagesNAVTA Ovt Nov17 CERadiographabazanhasan6705No ratings yet

- Emergency Management of Severe Burns (EMSB) : Dr. Amrin Amir LubisDocument17 pagesEmergency Management of Severe Burns (EMSB) : Dr. Amrin Amir Lubisamrin amir lubisNo ratings yet

- Verification of Medical Condition(s) : Instructions For The Customer Information For The DoctorDocument3 pagesVerification of Medical Condition(s) : Instructions For The Customer Information For The DoctorElise SloperNo ratings yet

- Requirements Checklist for Infrastructure Project PlansDocument6 pagesRequirements Checklist for Infrastructure Project PlansNheiljanmark Cayetano0% (1)

- General Topics: Anesthesia, Analgesia, and Sedation of Small MammalsDocument23 pagesGeneral Topics: Anesthesia, Analgesia, and Sedation of Small Mammalsdoja catNo ratings yet

- Anaphy SGD HeartDocument1 pageAnaphy SGD HeartbrylleNo ratings yet

- European Journal of PharmacologyDocument9 pagesEuropean Journal of PharmacologyDumitru RadulescuNo ratings yet