Professional Documents

Culture Documents

Capsu LES: Pharma Ceutics 2

Uploaded by

Mirumbi Kefa MomanyiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capsu LES: Pharma Ceutics 2

Uploaded by

Mirumbi Kefa MomanyiCopyright:

Available Formats

CAPSU

LES

Pharma

ceutics

2

Dr. Kabara

Dr. kabara capsules Page 1

CAPSULES

These are the solid dosage forms of medicaments in which the drug is enclosed

in a practically tasteless hard or soft container /shell made up of a suitable form

of gelatin.

It’s an edible package made from gelatin and is filled with medicines to produce

a unit oral dosage form.

Types of capsules

There are two types.

1. Hard capsules ‘two piece’ – They have two pieces in the form of cylinders

closed at one end. The shorter piece ‘cap’ fits over the open end of the longer

piece ‘body.’ Hard capsules are used for filling solid substances.

2. Soft capsules – “One Piece” – They are used for filling liquids and semi

solids.

Some capsules are administered through the rectum or vagina and may be better

than suppositories.

Advantages of Capsules

1. They are tasteless, colourless and can be easily administered.

2. They are elegant or attractive in appearance.

3. Drugs with unpleasant colour or taste can be enclosed in a tasteless shell.

4. They can be filled quickly and conveniently.

5. They physicians can change the dose and the combination of drugs to suit

individual patients. This is an advantage over tablets.

6. They are economical.

7. They are easy to handle and carry

Capsules Dr. kabara Page 2

Disadvantages

1. Hygroscopic drugs are unsuitable in capsules as they absorb the water

present in capsules making the shell brittle hence it crumbles into pieces.

2. Concentrated solutions that require previous dilution are unsuitable for

capsules. If administered as such, they lead to irritation of the stomach.

GELATIN

It is the major component from which capsules are made. It has 5 basic

properties.

1. It is non toxic and can be used for food stuffs.

2. It is readily soluble in biological fluids at body temperature.

3. It is a good film forming material and produces a strong flexible film.

(The wall thickness of a hard gelatin capsule is about 100µm

4. Gelatin solution of high concentration- 40% w/v is mobile at 500c.Other

biological polymers e.g. Agar are not

5. A gelatin solution in water or in a water plasticizer blend undergoes a

reversible change from solution to gel at a few degrees above ambient.

For other dosage forms forming films, large quantities of heat is required to

cause change of state.

Gelatin is prepared by hydrolysis of collagen the main protein constituent of

connective tissue.

The raw materials include animal skins and bones.

Types of Gelatin

There are two main types:

1. Type A – Produced by acid hydrolysis

2. Type B – produced by basic hydrolysis

Acid hydrolysis takes 7-10 days. It is used on animal skins that require less pre-

treatment compared to bones.

Capsules Dr. kabara Page 3

Basic hydrolysis takes 70-100 days and is used for bovine bones. The bones are first

decalcified by washing in acid to give a soft sponge like material called ossein.

Calcium phosphates are produced as byproducts. Ossein is then soaked in lime

pits for several weeks.

After hydrolysis, gelatin is extracted from the treated material using hot water.

The first extract contains gelatin with the highest physical properties. As the

temperature is raised, the quality of gelatin falls.

The weak solution of gelatin is concentrated in a series of evaporates then chilled

to form a gel. The gel is extruded to form stands which are dried in a fluidized

bed drier. The dried material is then graded and blended.

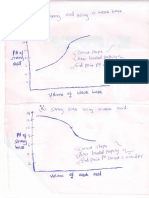

Bloom Strength and viscosity

Bloom strength is a measure of gel rigidity. It is determined by preparing a

standard gel ( 6.66 w/v) and maturing it at 100.

It is defined as the force in grams required topush a standard plunger 4mm into

the gel.

Gelatin used in hard capsule manufacture is of ahigher bloom strength (200 –

250gms) than that for soft capsules 150grams.

Student assignment

Read on colourants

Sizes of Capsules

Capsule shells are supplied in a number of sizes ranging from 000 to 5.

0 is the largest while 5 is the smallest.

The amount of medicament that can be filled in a particular size of capsule

depends on the density of the material to be filled.

For powders, the weight equals to body volume x tapped bulk density.

For liquids, the fill weight is equal to specific gravity x the capsule volume x 0.8

Capsules Dr. kabara Page 4

Shapes of Capsules

Capsule shape has remained unchanged since its invention. Self locking

capsules were introduced in the 1960’s. This was to overcome spilling caused by

vibration that caused the capsule to come apart.

They have indents on the inside of the cap and the outside of the body.

When the capsule is closed after filling, they form a fit that holds them together

during mechanical handling.

Packaging and Storage of Capsules

Capsules should be packed in well closed glass or plastic containers and stored

in a cool place.

These containers are better than cardboard boxes as they are more convenient to

handle and transport.

They also protect the capsules from moisture and dust.

To prevent the capsules from rattling, a tuft of cotton is placed over and under

the capsules.

In containers with very hygroscopic capsules, a packet containing desiccant like

silica gel or anhydrous CaCl2 is placed to prevent absorption of excessive

moisture by the capsule.

Capsules are packaged in strip packs which provide sanitary handling of

medicines and eases counting and identification.

Filling of Hard Gelatin Capsules

Each ingredient is weighed and finely powdered. They are mixed by trituration

to form a uniform powder.

The mixed powder is placed on a paper and spread with a spatula so as to make

a small pile.

Remove the cap from the capsule and hold it in the left hand.

Press the body repeatedly into the powder until it is filled.

Insert the cap on the body and weigh the capsule

Capsules Dr. kabara Page 5

Each capsule of the same size must be kept in the other pan as a tare to ensure

the exact quantity of drug is filled.

The type of material to be filled:

-Should not react with gelatin

-Should not contain a high level of free moisture

-Should have a volume of the drug which doesn’t exceed the size of the capsule

available.

Substances to be avoided include:

-Formaldehyde which causes cross linking reaction that make the capsule

insoluble

-Substances containing free water which may be absorbed by gelatin causing it to

soften and distort.

Types of Materials for Filling Hard Gelatin Capsules

1. Dry solids – Powders

Pellets

Granules

Tablets

2. Semi solids Thermosoftening mixtures

- Thixotropic

- Pastes

3. Liquids - Non-aqueous liquids (without water)

Student assignment:

Read on the hand operated gelatin capsule filling machine

Hand operated and electrically operated machines are used for filling the

capsules for quick dispensing.

Capsules Dr. kabara Page 6

Hand operated hard gelatin capsule filling machines consists of the following;

1. A bed 200 or 300 holes

2. A capsule loading tray

3. A pin plate having 200 of 300 pins corresponding the number of holes

of the bed and capsule loading tray

4. A lever

5. A handle

6. A plate fitted with rubber top.

The machines are generally supplied with additional loading trays, beds and pin

plates with various sizes of the capsules.

The machines are very simple to operate and can be dismantled and resembled.

Even unskilled workers can fill the capsule contents without much difficulty.

Small quantities of capsules can be cleared by wiping each capsule with surgical

gauze or clean cloth.

On large scale they can be rolled lightly in the folds of a clean towel or cloth

forward and backward until cleaned.

FORMULATION

Formulations must meet basic requirements.

1. Be capable of being filled uniformly to give a stable product.

2. Must release active contents in a form available for absorption by the

patient.

3. They must comply with official standards.

Powder Formulation

The capsule fill is a mixture of active ingredients and the excipients.

The powder selected depends on

1. The properties of the active ingredients

2. The dose, solubility, particle size and shape

3. The size of the capsule to be used.

Capsules Dr. kabara Page 7

Types of Excipients

i. Diluents – To give the plug forming properties.

ii. Lubricants – to reduce powder to metal adhesion

iii. Glidants- To improve powder flow. (by reducing interparticulate

friction)

iv. Wetting agents – to improve water penetration

v. Disintegrants – to produce disruption of the powder mass

vi. Stabilizers – to improve product stability

There are three main factors in powder formulation

1. Good flow – using free flowing diluents and glidants

2. No adhesion – using a lubricant

3. Cohesion – using plug forming diluents

Good flow contributes to uniform filling of capsules.

The powder bed from which the dose is measured needs to be homogenous and

packed reproducibly to achieve uniform fill weight.

Low dose active ingredients flow well when mixed with free flowing diluent e.g.

lactose.

When space is limited, glidants e.g. silica or lubricants e.g. magnesium stearate

are added.

Glidants and lubricants coat the surfaces of other ingredients.

Student assignment

Read on formulation and release of active ingredients

DIFFICULTY IN FILLING CAPSULES

1. Deliquescent /Hygroscopic powders

A gelatin capsule contains water which is extracted by a hygroscopic drug

rendering the capsule very brittle leading to cracking. This is overcome by

adding an absorbent like MgCO3 and or Mg0 (inside the capsule)

Capsules Dr. kabara Page 8

The capsule must be packed in a tightly closed glass capsule vial.

2. Eutetic mixtures – some substances when mixed tend to liquefy or form a

pasty mass due to the formation of a mixture with lower melting point than

ambient.

When filling these substances, each troublesome ingredient is mixed with an

absorbent separately then they are mixed together and filled in capsules.

The absorbent used are MgO and kaolin.

The substances can also be mixed together to form a eutectic mixture then an

absorbent like MgO or kaolin is added.

3. Addition of inert powders

Inert powders – (diluents) are added when the drug to be filled in a capsule is of

a very small quantity

The smallest capsule requires at least 65mg of the substance to fill it.

4. Filling of granular powders

Some powders lacking adhesiveness and most granular powders are difficult to

fill in capsules by punch method as they are not compressible and flow out of the

capsule as soon as they are lifted from the pile of the powder into which they are

punched.

To overcome this, non-adhesive powders should be moistened with alcohol and

the granular powders should be reduced to powder before filling into the

capsule.

5. Incompatible Ingredients.

Some manufacturers separate incompatible ingredients by placing one ingredient

in a smaller capsule then placing this smaller capsule in a larger capsule

containing the other ingredient of the formulation.

Forming one of the constituents as a pro-drug

Capsules Dr. kabara Page 9

Special Types of Capsules

a) Enteric coated capsules

These capsules do not disintegrate in the stomach or acidic media but break up

in the intestines or alkaline medium.

Enteric coating is given to various categories of drugs i.e.

(i) Those that cause irritation of the gastric mucosa and lead to nausea and

vomiting.

ii) Those that interfere with digestion e.g. tannins, silver nitrate and other

salts of heavy metals.

iii) Those which are unstable in the gastric fluids.

iv) Those that are specially needed for the treatment of the intestines e.g.

santonin a vermicide or antihelmintic.

v) Those which are required to produce delayed action of the drug.

Substances used for enteric coating of capsules include cellulose acetate

phthalate or a mixture of waxes with fatty acids of their esters.

b. Sustained release capsules

They release the drug slowly and continuously for a prolonged duration of

action. This maintains the MEC of the drug in the blood at a constant level

throughout the treatment period.

The finely powdered drug is converted into pellets of suitable size (1- 2mm

diameter.)

The pellets are divided into a number of groups e.g. ten groups. The first group

is kept untreated to produce rapid therapeutic effect.

The other groups are coated with selected materials one group after another to

produce thickness of varying degrees e.g. group 2 -2 coatings group 3 – 3

coatings etc.

The total thickness of these coatings should be 0.1mm.

All of the groups, both coated and uncoated are filled into the capsules. Materials

used for coating include;

Capsules Dr. kabara Page 10

-Cellulose esters

-Fats

-Keratin

-Mixtures of bees wax

-Cernouba wax with gylceryl monostearate

c. Rectal Capsules

Soft gelatin capsules may be used as substitutes for rectal of vaginal

suppositories

Different shapes and sizes are used.

They are generally wider at one end.

The movement of the sphincter muscles forces the capsule forward into the

rectum.

Liquids and solids can be filled in rectal capsules but the base in which the

medicament is incorporated must be non-toxic, non irritant and compatible with

the capsule shell.

d. Capsule for packing ophthalmic ointments

Ophthalmic ointments must be sterile and non irritant and remain so until the

whole product is used up.

The best method is to pack into single dose containers. Soft gelatin capsules are

used.

Just before application, the capsule is punctured with a sterile needle and the

contents instilled into the eye and the shell discarded.

Standardization of Capsules

Capsules should be subjected to the following test

i. Shape and size

ii. Colour

iii. Thickness of capsule shell

iv. Locking test for semi solids and liquid ingredients for soft

capsules

Capsules Dr. kabara Page 11

v. Disintegration test

vi. Weight variation test

vii. Percentage of medicament test

The control tests in the official books are;

1. Disintegration test

A tablet disintegration apparatus is used. One capsule is placed in each tube

which is then suspended in beakers to move up and down for 30 minutes.

The capsules pass the test if no residue of drug or other fragments of the shell

remain on a screen mesh no. 10.

2. Weight variation test

20 capsules are taken at random and weighed. Their average weight is

calculated then each capsule weighed individually. The capsules pass the test if

the weight of individual capsules falls within 90-100% of average weight.

3. Contents uniformity tests

This is applicable to all capsules for oral administration.

A sample of the contents is assayed as described in the monographs. The values

calculated must comply with the prescribed standards.

Student assignment

Read on soft gelatin capsules

SOFT GELATIN CAPSULES

They are also referred to as soft gels.

They consist of a liquid of semi-solid matrix inside a one piece of outer gelatin

shell.

They are soft and elastic in nature prepared from gelatin and water to which

glycerine, sorbitol or propylene glycol is added as a plasticizer making the

capsule flexible.

They contain a preservative to prevent the growth of bacteria of fungi. The

shapes include spherical, oval, cylindrical etc.

Capsules Dr. kabara Page 12

Contents vary from 0.1mm to 30mm.

Soft gelatin capsules are formed and filled in one continous operation of semi-

automatic machines.

They are hermatically sealed.

They are used for filling liquids and semi-solids e.g cod liver oil, Vitamin A,

Vitamin D and Multi vitamins.

Uses

1. They also contain eye, ear, nose, throat preparations

2. Opthalmic ointments are packed in unit dose capsules

3. They are also substitutes for suppositories

Preparation of soft capsules

These methods are used

1. Plate process

2. Rotary die process

1. Plate process

A warmed sheet of plasticized gelatin is placed over a plate having a no. of

depressions or moulds. The sheet is drawn into these depressions by applying a

vacuum

A measured quantity of liquid medicament is poured over then another shit of

gelatin is placed on.

Over these another plate of the mould is placed and pressure is then applied to

the combined plates.

The capsules are then simultaneously shaped, filled and sealed into individual

units.

2. Rotary die process

The filled capsules are produced continuously and automatically. Two

continuous sheets of gelatin are supplied to the two die rolls of the machine that

has a number of matching dies and rotates at the same speed and in opposite

directions.

Capsules Dr. kabara Page 13

As the gelatin sheet comes in between the rollers, the material to be filled is

injected through a metering device.

The pressure exerted by the material forces the gelatin sheet to go into the

cavities of the die rolls to form two halves of the capsule and fill them.

The heat and pressure exerted by the die falls seals and cuts out the capsules.

The finished capsules are then passed through a series of napha baths to remove

lubricants and then dried.

The rotary machines can produce 2500 – 30,000 capsules per hour.

Capsules Dr. kabara Page 14

You might also like

- CAPSULES EditedDocument14 pagesCAPSULES Editedmelvin karanjaNo ratings yet

- TSDF Unit 3 FinalDocument19 pagesTSDF Unit 3 FinalLittle SparkNo ratings yet

- Types, Manufacture, Formulation of Capsules 1Document26 pagesTypes, Manufacture, Formulation of Capsules 1chill streamNo ratings yet

- Differences Between Soft and Hard CapsulesDocument8 pagesDifferences Between Soft and Hard CapsulesMahmuda Akter Marzia 2014151649No ratings yet

- CapsuleskncopDocument181 pagesCapsuleskncopboozokaranNo ratings yet

- ProjectDocument27 pagesProjectAbhishek YadavNo ratings yet

- Hard Gelatin CapsulesDocument58 pagesHard Gelatin Capsulesas.jessy0608No ratings yet

- Tablet, Granules, CapsulesDocument49 pagesTablet, Granules, CapsulesRubab SyedNo ratings yet

- Capsules: Mr. Jadhav R. SDocument40 pagesCapsules: Mr. Jadhav R. SRx Ram JadhavNo ratings yet

- Capsules .Document40 pagesCapsules .Phar MacyNo ratings yet

- Capsule Mod 2Document9 pagesCapsule Mod 2Manasvi MehtaNo ratings yet

- CapsuleDocument71 pagesCapsuleMuhammad TalhaNo ratings yet

- Capsules: An Overview of Types, Manufacturing, and ApplicationsDocument63 pagesCapsules: An Overview of Types, Manufacturing, and ApplicationsSubha ShankareeNo ratings yet

- Unit 2 CapsuleDocument104 pagesUnit 2 Capsuleabdullah2020No ratings yet

- Pharm 200 Activity 4Document4 pagesPharm 200 Activity 4Pot-Pot LoboNo ratings yet

- Capsules 6396Document18 pagesCapsules 6396MUHAMMAD ZOHAIBNo ratings yet

- Capsule Manufacturing TechnologyDocument2 pagesCapsule Manufacturing TechnologycoooleNo ratings yet

- CapsulesDocument38 pagesCapsulesanburajjNo ratings yet

- CapsuleDocument44 pagesCapsuleBharat JainNo ratings yet

- Capsules and It's Technology PDFDocument7 pagesCapsules and It's Technology PDFlouish9175841No ratings yet

- Capsules: Hari Kesh MeenaDocument100 pagesCapsules: Hari Kesh MeenaDevesh Sharma100% (1)

- CapsulesDocument25 pagesCapsulesKhara TeanoTanNo ratings yet

- 7CAPSULES Answers PDFDocument7 pages7CAPSULES Answers PDFPATRICIA ROSE SORIANONo ratings yet

- Capsules A Dosage FormDocument5 pagesCapsules A Dosage FormVijayaraj SurendranNo ratings yet

- CapsulesDocument29 pagesCapsulesShakeel IjazNo ratings yet

- 5 - CapsulesDocument20 pages5 - CapsulesAl-Homam SalahNo ratings yet

- Capsules Explained: Types, Materials, Manufacturing & ApplicationsDocument35 pagesCapsules Explained: Types, Materials, Manufacturing & Applicationsde_rigorry67% (3)

- Capsules by Pabitra SubediDocument20 pagesCapsules by Pabitra Subedisanjeev khanalNo ratings yet

- Capsule ManufacturingDocument22 pagesCapsule ManufacturingHasna AthiyahNo ratings yet

- Evaluation Parameters of Hard and Soft Gelatin Capsule and Their Manufacturing ProcessDocument17 pagesEvaluation Parameters of Hard and Soft Gelatin Capsule and Their Manufacturing ProcessRahul VermaNo ratings yet

- CapsulesDocument50 pagesCapsulesneha_dand1591No ratings yet

- Capsules ReportDocument31 pagesCapsules ReportkdvillanuevaNo ratings yet

- A Review - Capsule Shell Material From Gelatin To Non Animal OriginDocument30 pagesA Review - Capsule Shell Material From Gelatin To Non Animal OriginAyten Güllüce100% (1)

- Castor Oil CapsuleDocument36 pagesCastor Oil CapsuleRye M. BirungNo ratings yet

- Preparation # 5 Aspirin CapsulesDocument12 pagesPreparation # 5 Aspirin CapsulesIvy Rose OrozcoNo ratings yet

- SuppositoryDocument12 pagesSuppositoryKhushboo100% (2)

- Capsules - 2 Slides Per PageDocument26 pagesCapsules - 2 Slides Per PageTaj PolinNo ratings yet

- Capsule Filling and QC - DiscoveryDocument5 pagesCapsule Filling and QC - DiscoveryXiao HuiNo ratings yet

- Preparation # I. Objectives:: Pharmaceutical Dosage Forms Laboratory ManualDocument2 pagesPreparation # I. Objectives:: Pharmaceutical Dosage Forms Laboratory Manuallalag yanNo ratings yet

- Modern PharmaceuticsChapter-11Hard and Soft Shell CapsulesDocument46 pagesModern PharmaceuticsChapter-11Hard and Soft Shell CapsulesFaysal MasoodNo ratings yet

- Pharma Tech CapsuleDocument11 pagesPharma Tech Capsulekk4486No ratings yet

- Capsules: Types, Advantages, Disadvantages, PreparationDocument2 pagesCapsules: Types, Advantages, Disadvantages, PreparationMnemo SyneNo ratings yet

- 10-Capsules - DR FakharDocument71 pages10-Capsules - DR Fakharawais khanNo ratings yet

- Capsules: Types, Manufacture and AdvantagesDocument100 pagesCapsules: Types, Manufacture and Advantagesprinceamit100% (1)

- Industrial Pharmacy CapsulesDocument8 pagesIndustrial Pharmacy CapsulesMustafa Salah MahdiNo ratings yet

- Capsules and It's Technology: An Overview: ArticleDocument8 pagesCapsules and It's Technology: An Overview: ArticleR TicoaluNo ratings yet

- Capsules - Remington - The Science and Practice of PharmacyDocument8 pagesCapsules - Remington - The Science and Practice of Pharmacyjuananzaldo266No ratings yet

- Soft Gelatin CapsulesDocument29 pagesSoft Gelatin CapsulesAsif KhanNo ratings yet

- Preparation and Packaging of CapsulesDocument17 pagesPreparation and Packaging of CapsulesRaed JaafariNo ratings yet

- Capsules:: Hard: Solid Filling Material Soft: Semisolid-Liquid MaterialDocument4 pagesCapsules:: Hard: Solid Filling Material Soft: Semisolid-Liquid MaterialAhmed AldumainiNo ratings yet

- CapsulesDocument35 pagesCapsulesRochelle AntigNo ratings yet

- Assignment 5 - CapsulesDocument5 pagesAssignment 5 - CapsulesJackie GanacNo ratings yet

- Hard Gelatin CapsuleDocument26 pagesHard Gelatin Capsuleaman kumarNo ratings yet

- Assignment 5 - CapsulesDocument5 pagesAssignment 5 - CapsulesJackie GanacNo ratings yet

- Tablet Types, Properties, and Manufacturing MethodsDocument7 pagesTablet Types, Properties, and Manufacturing MethodsTrisha ArgaoNo ratings yet

- Modern Pharmaceutics-338-383Document47 pagesModern Pharmaceutics-338-383Glendiita YepezNo ratings yet

- Freeze Drying Mastery For Beginners: Complete Guide to Long-Term Food Storage, Save Money, Reduce Waste and Keep Your Pantry StockedFrom EverandFreeze Drying Mastery For Beginners: Complete Guide to Long-Term Food Storage, Save Money, Reduce Waste and Keep Your Pantry StockedNo ratings yet

- Paleo Canning And Preserving Recipes Three Ps of Preserving – Pick, Prepare, and PreserveFrom EverandPaleo Canning And Preserving Recipes Three Ps of Preserving – Pick, Prepare, and PreserveNo ratings yet

- Adrenergic Receptors 2Document2 pagesAdrenergic Receptors 2Mirumbi Kefa MomanyiNo ratings yet

- Ch.01 Introduction To ComputersDocument10 pagesCh.01 Introduction To ComputersSam Daka100% (1)

- Parenteral Preparations AssignmentDocument3 pagesParenteral Preparations AssignmentMirumbi Kefa MomanyiNo ratings yet

- Adrenergic Drugs IDocument3 pagesAdrenergic Drugs IMirumbi Kefa MomanyiNo ratings yet

- Suppositories As A Dosage FormDocument11 pagesSuppositories As A Dosage FormMirumbi Kefa MomanyiNo ratings yet

- Veterinary PharmaceuticsDocument15 pagesVeterinary PharmaceuticsMirumbi Kefa MomanyiNo ratings yet

- Parenteral PreparationsDocument11 pagesParenteral PreparationsMirumbi Kefa MomanyiNo ratings yet

- Pharmacy Calculations Review: Pharmacy Tech Topics™ Volume 16 Number 3 July 2011Document24 pagesPharmacy Calculations Review: Pharmacy Tech Topics™ Volume 16 Number 3 July 2011Mirumbi Kefa MomanyiNo ratings yet

- The Endocrine System: Hypothalamus Pituitary GlandDocument58 pagesThe Endocrine System: Hypothalamus Pituitary GlandMirumbi Kefa MomanyiNo ratings yet

- MKT Usp PDFDocument62 pagesMKT Usp PDFlouish9175841No ratings yet

- The Endocrine System: Hypothalamus Pituitary GlandDocument58 pagesThe Endocrine System: Hypothalamus Pituitary GlandMirumbi Kefa MomanyiNo ratings yet

- Unit 1 Introduction To Pharmaceutics: StructureDocument19 pagesUnit 1 Introduction To Pharmaceutics: StructureV VISHALAKSHINo ratings yet

- Aerosols .Document19 pagesAerosols .Mirumbi Kefa MomanyiNo ratings yet

- Davi ResearchDocument35 pagesDavi ResearchMirumbi Kefa MomanyiNo ratings yet

- Page 3Document1 pagePage 3Mirumbi Kefa MomanyiNo ratings yet

- Pharm Analysis PPR One MS Question 4 B AnswerDocument1 pagePharm Analysis PPR One MS Question 4 B AnswerMirumbi Kefa MomanyiNo ratings yet

- US06CCHE21 UNIT II AlkaloidsDocument36 pagesUS06CCHE21 UNIT II AlkaloidsMirumbi Kefa MomanyiNo ratings yet

- Page 8Document1 pagePage 8Mirumbi Kefa MomanyiNo ratings yet

- ") N Oj E:Htk Motu O: C... '.J. RVDocument1 page") N Oj E:Htk Motu O: C... '.J. RVMirumbi Kefa MomanyiNo ratings yet

- Page 10Document1 pagePage 10Mirumbi Kefa MomanyiNo ratings yet

- A"U"'5 ' - , Z,'J/" / ,: M '"":"GTHDocument1 pageA"U"'5 ' - , Z,'J/" / ,: M '"":"GTHMirumbi Kefa MomanyiNo ratings yet

- Page 11Document1 pagePage 11Mirumbi Kefa MomanyiNo ratings yet

- Types of Bonds in Drug Receptor InteractionDocument12 pagesTypes of Bonds in Drug Receptor InteractionMirumbi Kefa MomanyiNo ratings yet

- Pharm AnalysisDocument6 pagesPharm AnalysisMirumbi Kefa MomanyiNo ratings yet

- Tsblet Best RGDocument12 pagesTsblet Best RGMirumbi Kefa MomanyiNo ratings yet

- A.s - ZR .: 1:L1-. RR - ':: - 1-jDocument1 pageA.s - ZR .: 1:L1-. RR - ':: - 1-jMirumbi Kefa MomanyiNo ratings yet

- LAB REPORT Buffer and PH ExperimentDocument19 pagesLAB REPORT Buffer and PH ExperimentFelix YeboahNo ratings yet

- E1423 QR AnswersDocument14 pagesE1423 QR AnswersᎠᎻᏒᏬᏉ BRIDNo ratings yet

- .Explosives and Blasting Module - 1628404265000Document85 pages.Explosives and Blasting Module - 1628404265000Cristiano RonaldoNo ratings yet

- Artificial Lift MechanismDocument22 pagesArtificial Lift MechanismKaran MathurNo ratings yet

- Answer Key: Neet Booster Test Series (NBTS) For Neet-2021 Test - 5Document13 pagesAnswer Key: Neet Booster Test Series (NBTS) For Neet-2021 Test - 5anita tripathiNo ratings yet

- Biology and Diversity of Viruses, Bacteria and Fungi (Paper Code: Bot 501)Document25 pagesBiology and Diversity of Viruses, Bacteria and Fungi (Paper Code: Bot 501)Ajzm CompanyNo ratings yet

- Tutorial SessionDocument5 pagesTutorial SessionKhánh LinhNo ratings yet

- Chapter 10 Powders For Porous Powder Metallurgy TechnologyDocument12 pagesChapter 10 Powders For Porous Powder Metallurgy TechnologyUlises Quintana CarhuanchoNo ratings yet

- Fluid Thioglycollate Medium (Thioglycollate Medium W/ Indicator and Dextrose)Document1 pageFluid Thioglycollate Medium (Thioglycollate Medium W/ Indicator and Dextrose)sinaNo ratings yet

- University of Cambridge International Examinations International General Certificate of Secondary EducationDocument16 pagesUniversity of Cambridge International Examinations International General Certificate of Secondary EducationFranca OkechukwuNo ratings yet

- Introduction and General Tips To Prepare For Chemistry OlympiadDocument4 pagesIntroduction and General Tips To Prepare For Chemistry OlympiadfaridsidikNo ratings yet

- MSDS Material Safety Data SheetDocument5 pagesMSDS Material Safety Data Sheethhnp204No ratings yet

- Physical Properties of SolutionsDocument30 pagesPhysical Properties of SolutionsCalonanak Sithr2020No ratings yet

- Chem 210 Prac 3Document5 pagesChem 210 Prac 3Cebolakhe ZunguNo ratings yet

- Membranes: Fficient Method To Determine Membrane FF Using FluorescentDocument14 pagesMembranes: Fficient Method To Determine Membrane FF Using Fluorescentabid hossainNo ratings yet

- Solubility of KI Salt SolutionsDocument7 pagesSolubility of KI Salt SolutionscxcchemistryNo ratings yet

- Chem 44.1 Special SynthesisDocument86 pagesChem 44.1 Special SynthesisCarlo Joseph Moskito100% (2)

- Q2M3Document22 pagesQ2M3Sophia Jhayne AquinoNo ratings yet

- Colloidal Gold. Part I: Historical and Preparative Aspects, Morphology and StructureDocument6 pagesColloidal Gold. Part I: Historical and Preparative Aspects, Morphology and StructureRSL100% (1)

- Separation Techniques: Composed With Epsilon Notes in AndroidDocument7 pagesSeparation Techniques: Composed With Epsilon Notes in AndroidBrãñdøn DzîñgáíNo ratings yet

- Jensen and Barton, 2000Document36 pagesJensen and Barton, 2000CesarVargasSalasNo ratings yet

- Maharshi Arvind Instute of Pharmacy Mansarovar, JaipurDocument38 pagesMaharshi Arvind Instute of Pharmacy Mansarovar, Jaipurjasmin86modiNo ratings yet

- ASSIGNMENT CHM557-mergedDocument3 pagesASSIGNMENT CHM557-mergedAhmad ZakwanNo ratings yet

- 2016 AFPM Annual Meeting - Combating The Negative Effects of Iron in The FCCUDocument28 pages2016 AFPM Annual Meeting - Combating The Negative Effects of Iron in The FCCUsaleh4060No ratings yet

- Soil AnalysisDocument43 pagesSoil AnalysisPragya PandeyNo ratings yet

- Biology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014Document13 pagesBiology - Physics Chemistry MCQS: Gyanm'S General Awareness - November 2014santosh.manojNo ratings yet

- Chemical-Bonding Part 01Document1 pageChemical-Bonding Part 01Sampa SadhukhanNo ratings yet

- Chem 321 Lecture 7 - Gravimetric Analysis: Student Learning ObjectivesDocument6 pagesChem 321 Lecture 7 - Gravimetric Analysis: Student Learning ObjectivesrtyiookNo ratings yet

- Entropy and Gibbs Free Energy Explained in 40 CharactersDocument6 pagesEntropy and Gibbs Free Energy Explained in 40 CharactersZyriel SaavedraNo ratings yet

- Abstract RRMBOKDocument1 pageAbstract RRMBOKRafael FernandesNo ratings yet