Professional Documents

Culture Documents

Cummins Hylyzer 250 Specsheet

Uploaded by

amsukdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cummins Hylyzer 250 Specsheet

Uploaded by

amsukdCopyright:

Available Formats

HyLYZER®

WATER ELECTROLYZERS

HyLYZER® is Cummins' globally proven modular water

electrolyzer system designed for easy on-site installation inside

or out, with simple interconnectivity to scale up, and an unrivaled

record for reliability, low maintenance and on-site safety.

Recommended for projects between 200 - 500 Nm3/h.

Proven technology, compliant with highest safety standards

Turnkey solution

Exceptionally compact

30 bar pressurized stacks

FEATURES

HyLYZER® - 200 HyLYZER® - 250

Technology PEM

Hydrogen production 200 Nm3/h (431 kg/day) 250 Nm3/h (539 kg/day)

H2 delivery pressure 30 barg (435 psig) without a compressor

H2 quality 99.998%

max impurities O2 < 2 ppm, N2 < 12 ppm (higher purities optional); Atm. Dew point: -75°C

Reprinted with the permission of Hydrogenics Corporation;

Copyright © Hydrogenics Corporation 2020. All rights reserved.

cummins.com/hydrogen

TECHNICAL SPECIFICATIONS

HyLYZER® - 200 HyLYZER® - 250

Operating range 5-100%

40 to 48 kWh/kg

DC power consumption at stack

(3.6 to 4.3 kWh/Nm3)

System specific consumption* ≤ 55 kWh/kg

Utilities required to

Electrical power, potable water, nitrogen for purging requirements

operate the plant

6 to 36kV± 10% - 50/60 Hz - 1.4 MVA 6 to 36kV± 10% - 50/60 Hz - 1.7 MVA

Rectifier specifications

97% efficiency 97% efficiency

Auxiliary installed power 125 kVA

Scope of supply includes a water treatment plant with reverse osmosis that

Potable water consumption requires 1.2 to 1.5 L/Nm3 [13 to 17 L/kg of H2] to produce 0.8 L/Nm3 of demin

water for the electrolysis process

Total footprint

18 m x 11 m (~ 198 m2)

(including maintenance area)

Product setup Outdoor (40ft + 20ft ISO container)

Installation environment Outdoors -20°C to 40°C / -4°F to 104°F

*System specific consumption considers: the standard scope of supply (refer to BOS and BOP tables); 100% Load capacity; Beginning Of Life;

1% increase per annum (at ≥8500 hours operation)

STACK AND BALANCE-OF-STACK (BOS)

Outdoor Indoor

Cell stacks and gas generation system ■

Power rectifiers ■

Control panel ■

Water polishing system ■

BALANCE-OF-PLANT (BOP)

Outdoor Indoor

Rectifier cooling ■

Gas cooling ■

Electrolysis cooling ■

Water purification system ■

Instrument air compressor ■

Hydrogen purification system ■

Applicable Codes and Standards Pressure Equipment Directive 2014/68/EU, Low Voltage Directive 2014/35/EU, Machinery Directive 2006/42/EC, Electro-Magnetic Compatibility

2014/30/EU, ATEX Directive 2014/34/EU, IEC 61511, IEC 61508, IEC 60079-10-1, NFPA 2, NFPA 497, National Electrical Code (NEC), ANSI/NFPA 70, ASME B31.3-2016, ASME Boiler

and Pressure Vessel Code 2017, CSA C22.1 and C22.2, CSA B51 2019, CAN/BNQ 1784-000/2007. Other jurisdictions available on request.

The content of this document may contain technical inaccuracies or typographical errors. Cummins reserves the right to make changes or updates at any time without prior notice.

Copying or distributing in whole or in part of the content without consent of Cummins is not allowed.

cummins.com

Bulletin 5676516 Produced in the U.K. 6/21

©2021 Hydrogenics Corporation

You might also like

- Hampton Machine Tool CoDocument13 pagesHampton Machine Tool CoArdi del Rosario100% (12)

- Fundamental Analysis For InvestorsDocument213 pagesFundamental Analysis For InvestorsTheVagabond Harshal100% (19)

- Stock Receiving and Storage ProceduresDocument18 pagesStock Receiving and Storage ProceduresAnuu BhattiNo ratings yet

- Scania Technical Data - Issue-13Document51 pagesScania Technical Data - Issue-13kman548No ratings yet

- NEW BUILD 270FT LCT FOR SALEDocument13 pagesNEW BUILD 270FT LCT FOR SALErafetguzelsoy100% (1)

- CARTEX Operating Manual Incl - Sctional DRWG Rev 4Document11 pagesCARTEX Operating Manual Incl - Sctional DRWG Rev 4keyur1109No ratings yet

- Three Phase Synchronous Motor Features and SpecificationsDocument25 pagesThree Phase Synchronous Motor Features and Specificationsjcpp_18No ratings yet

- Trolling Actuator MM9001 Rev 9-03Document78 pagesTrolling Actuator MM9001 Rev 9-03momo99No ratings yet

- Cummins Hystat 30 SpecsheetDocument2 pagesCummins Hystat 30 SpecsheetamsukdNo ratings yet

- Marine Eng Est Time Between OverhaulsDocument6 pagesMarine Eng Est Time Between OverhaulsagvassNo ratings yet

- DSG DIG Installation Service and MaintenanceDocument142 pagesDSG DIG Installation Service and MaintenanceAlbert ArtellsNo ratings yet

- MSDS RocketDocument2 pagesMSDS Rocketbudhi saputroNo ratings yet

- Azi FactDocument2 pagesAzi FactpropulziNo ratings yet

- SB LT32575Document14 pagesSB LT32575zzapiecheNo ratings yet

- Propulsion Trends in Container VesselsDocument28 pagesPropulsion Trends in Container VesselsFuchsbauNo ratings yet

- Marine Sewage Treatment UnitDocument9 pagesMarine Sewage Treatment UnitArvin SinghNo ratings yet

- (Micfil) Produkt ModularDocument9 pages(Micfil) Produkt ModularAbdulrahman Al HuribyNo ratings yet

- MR 14002-Extended Light Load Specific TurbochargerDocument16 pagesMR 14002-Extended Light Load Specific TurbochargerVictor NoschangNo ratings yet

- MTU Submarine Charging Unit 12V 4000Document4 pagesMTU Submarine Charging Unit 12V 4000selleriverketNo ratings yet

- Compound Geaquello E950Document2 pagesCompound Geaquello E950antonNo ratings yet

- A V228 StationaryDocument4 pagesA V228 StationaryMike FinazziNo ratings yet

- Marine Engine Program 2014 PDFDocument164 pagesMarine Engine Program 2014 PDFAlbertoJim90No ratings yet

- PIM130B1 - Daihatsu DT Series Archived JUN PDFDocument5 pagesPIM130B1 - Daihatsu DT Series Archived JUN PDFAnonymous XGsiY6rNo ratings yet

- IACS Ur-M59Document4 pagesIACS Ur-M59Seong Ju KangNo ratings yet

- ERS M22 PC4 FerryDocument2 pagesERS M22 PC4 FerryouakgoodNo ratings yet

- KG2Document3 pagesKG2anon_697917996No ratings yet

- BUKH DV36 Diesel Engine Workshop ManualDocument196 pagesBUKH DV36 Diesel Engine Workshop Manualasaturday85No ratings yet

- Separ Filter IndustrialDocument25 pagesSepar Filter IndustrialNatanael HernandezNo ratings yet

- محطات إنتاج الطاقة الكهربائية في السودانDocument6 pagesمحطات إنتاج الطاقة الكهربائية في السودانTruuth SeekerNo ratings yet

- Vapor Emission Control System Manual Usc PDFDocument100 pagesVapor Emission Control System Manual Usc PDFNestor MospanNo ratings yet

- MTU Marine Spec 16V4000M93 PDFDocument2 pagesMTU Marine Spec 16V4000M93 PDFsmithworkNo ratings yet

- PERKÿNS SABRE 6TG2AM AYRDIMCI MOTORDocument2 pagesPERKÿNS SABRE 6TG2AM AYRDIMCI MOTORRiki Akbar100% (1)

- 300-5617 Cooler Parts 2Document2 pages300-5617 Cooler Parts 2harikrishnanpd3327No ratings yet

- Fuel Oil SystemDocument5 pagesFuel Oil SystemyattoakaiNo ratings yet

- S70me-C8 5Document365 pagesS70me-C8 5Kostas Mournianakis100% (1)

- Tailshaft Condition Monitoring TCM - Notation - Guide-July12Document2 pagesTailshaft Condition Monitoring TCM - Notation - Guide-July12Marlon Alejandro Arboleda TapiaNo ratings yet

- Power System PDFDocument24 pagesPower System PDFlethanhtu0105No ratings yet

- Twin Disc Arneson Surface Drives Performance & BenefitsDocument12 pagesTwin Disc Arneson Surface Drives Performance & BenefitsWoodsy12No ratings yet

- Ship Survey Status: Tirumala GasDocument27 pagesShip Survey Status: Tirumala GasHoa LuuNo ratings yet

- KTA50G12 & G14 Engine Parts CatalogueDocument161 pagesKTA50G12 & G14 Engine Parts CataloguePedro Jim Farley Guedes Mesquita100% (1)

- 12-385 Item 01 - MonitorDocument20 pages12-385 Item 01 - Monitorleokareyxoxoers100% (1)

- Daihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Operation)Document114 pagesDaihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Operation)andriy.b1979No ratings yet

- HIMSEN Catalog 2010Document46 pagesHIMSEN Catalog 2010A87_navjNo ratings yet

- Caterpillar C32 Genset Test SpecDocument3 pagesCaterpillar C32 Genset Test SpecHendra MechanicNo ratings yet

- 220Document1 page220fahmi wibowoNo ratings yet

- 600@1800 Kta19 M3 Tontek PowerDocument3 pages600@1800 Kta19 M3 Tontek PowerStenny LumiNo ratings yet

- 6N18,+6N21,+8N21,+Air starting equipment,+Starting equipment,+Air motor,+TDI,+45MA,+Pinion gear,+Service,+Work,+Assembly,+Caution,+Service newsDocument2 pages6N18,+6N21,+8N21,+Air starting equipment,+Starting equipment,+Air motor,+TDI,+45MA,+Pinion gear,+Service,+Work,+Assembly,+Caution,+Service newsengdpaliNo ratings yet

- Catalog Motoare MAN 2Document120 pagesCatalog Motoare MAN 2Licente NavaleNo ratings yet

- Wartsila 20121 PDFDocument53 pagesWartsila 20121 PDFDan Alin Mircea100% (1)

- Work Boats: SVA/SVAL 630 - 1400 - 3,000 - 20,000 KWDocument8 pagesWork Boats: SVA/SVAL 630 - 1400 - 3,000 - 20,000 KWJulia FalconeNo ratings yet

- 1000kva - Data Sheet - XCRP Qst30Document4 pages1000kva - Data Sheet - XCRP Qst30b400013No ratings yet

- D2842 Heavy DutyDocument4 pagesD2842 Heavy Dutym_najman100% (2)

- DJ110Z Waterjet ManualDocument111 pagesDJ110Z Waterjet ManualĐặng Minh100% (1)

- Daihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformanceDocument8 pagesDaihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformancePrince ChaudharyNo ratings yet

- Acinonyx Investment Limited Belize Yacht Renovation CLASSIFIED REPORT LeakedDocument18 pagesAcinonyx Investment Limited Belize Yacht Renovation CLASSIFIED REPORT LeakedPour La Nation100% (1)

- Noble Corporation: Noble Analyst Day Singapore May 17-18, 2011Document27 pagesNoble Corporation: Noble Analyst Day Singapore May 17-18, 2011Andi ayuNo ratings yet

- Technical Data of Engine: MAN D2840 LE 201: EP 520 Rating at 0.8PF Prime Rating Standby RatingDocument1 pageTechnical Data of Engine: MAN D2840 LE 201: EP 520 Rating at 0.8PF Prime Rating Standby Rating02031989No ratings yet

- PM Speed Adjusting Motor For PSGDocument2 pagesPM Speed Adjusting Motor For PSGFathima Regin100% (2)

- Technical Sales Document: - Product DataDocument27 pagesTechnical Sales Document: - Product DataLuis AyalaNo ratings yet

- Engine Performance Report, LOW LOADDocument2 pagesEngine Performance Report, LOW LOADAsm Faysal100% (1)

- Cummins Hylyzer 500 SpecsheetDocument2 pagesCummins Hylyzer 500 SpecsheetamsukdNo ratings yet

- HyLYZER 400 - 500Document2 pagesHyLYZER 400 - 500Lukas MarconNo ratings yet

- Vedant Fashions: Connecting To The Roots With Style!Document50 pagesVedant Fashions: Connecting To The Roots With Style!amsukdNo ratings yet

- HDFC Securities On Aether Industries Another Feather in Its Cap!Document6 pagesHDFC Securities On Aether Industries Another Feather in Its Cap!amsukdNo ratings yet

- Centrum Rural Pulse 2023 - Outcome of 2 Day ConferenceDocument20 pagesCentrum Rural Pulse 2023 - Outcome of 2 Day ConferenceamsukdNo ratings yet

- ET WealthDocument24 pagesET WealthamsukdNo ratings yet

- Nirmal Bang On Pharmaceutical Sector Key Prescription Trends inDocument7 pagesNirmal Bang On Pharmaceutical Sector Key Prescription Trends inamsukdNo ratings yet

- ICICI Direct On AU Small Finance Bank Reverse Arbitrage OpportunityDocument5 pagesICICI Direct On AU Small Finance Bank Reverse Arbitrage OpportunityamsukdNo ratings yet

- Mirae Asset Capital Initiating Coverage On Varun BeveragesDocument32 pagesMirae Asset Capital Initiating Coverage On Varun BeveragesamsukdNo ratings yet

- Sharekhan On Power Grid Corporation of India Pick Up in TransmissionDocument9 pagesSharekhan On Power Grid Corporation of India Pick Up in TransmissionamsukdNo ratings yet

- BC Fly H2-Trailer-filling Diaphragm 210930 enDocument2 pagesBC Fly H2-Trailer-filling Diaphragm 210930 enamsukdNo ratings yet

- AnandRathi On HG Infra On The Road To A Better Future RetainingDocument12 pagesAnandRathi On HG Infra On The Road To A Better Future RetainingamsukdNo ratings yet

- Looking To Buy Top IT Stocks Wait For A Quarter To Get BargainsDocument3 pagesLooking To Buy Top IT Stocks Wait For A Quarter To Get BargainsamsukdNo ratings yet

- Time TechnoplastDocument24 pagesTime TechnoplastamsukdNo ratings yet

- AnandRathi On Affle India Pain in Developed Markets Continues MaintainingDocument6 pagesAnandRathi On Affle India Pain in Developed Markets Continues MaintainingamsukdNo ratings yet

- Compressor Solutions For Hydrogen Mobility EnergyDocument2 pagesCompressor Solutions For Hydrogen Mobility EnergyamsukdNo ratings yet

- BC Fly H2-Trailer-filling Diaphragm 210930 enDocument2 pagesBC Fly H2-Trailer-filling Diaphragm 210930 enamsukdNo ratings yet

- Compressor Solutions For Hydrogen Mobility EnergyDocument2 pagesCompressor Solutions For Hydrogen Mobility EnergyamsukdNo ratings yet

- EdgeReport AFFLE CaseStudy 23 12 2022 883Document36 pagesEdgeReport AFFLE CaseStudy 23 12 2022 883amsukdNo ratings yet

- Clean ScienceDocument21 pagesClean ScienceamsukdNo ratings yet

- Pharmaceutical Sector Key Prescription Trends Update 16 DecemberDocument6 pagesPharmaceutical Sector Key Prescription Trends Update 16 DecemberamsukdNo ratings yet

- Energy Magazine Dec2022Document72 pagesEnergy Magazine Dec2022amsukdNo ratings yet

- Psu Banks ThematicDocument25 pagesPsu Banks ThematicamsukdNo ratings yet

- PersistentDocument36 pagesPersistentamsukdNo ratings yet

- IOL Chemicals Q2FY23 Investor Presentation InsightsDocument31 pagesIOL Chemicals Q2FY23 Investor Presentation InsightsamsukdNo ratings yet

- Indian PSUs Theme2023Document12 pagesIndian PSUs Theme2023amsukdNo ratings yet

- Emkey On Shriram FinanceDocument18 pagesEmkey On Shriram FinanceamsukdNo ratings yet

- Clean ScienceDocument6 pagesClean ScienceamsukdNo ratings yet

- Nirmal Bang On United SpiritsDocument6 pagesNirmal Bang On United SpiritsamsukdNo ratings yet

- Clean Science ICDocument35 pagesClean Science ICErr DatabaseNo ratings yet

- Grid Integrated Electrolysis Oct 31 2016Document66 pagesGrid Integrated Electrolysis Oct 31 2016amsukdNo ratings yet

- Basic Concepts in Forest Valuation and Investment Analysis - EditiDocument336 pagesBasic Concepts in Forest Valuation and Investment Analysis - EditiAsfaw GelanNo ratings yet

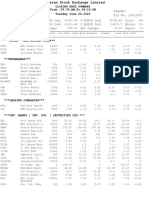

- Nse 20171006Document33 pagesNse 20171006BellwetherSataraNo ratings yet

- 外贸英语口语大全Document29 pages外贸英语口语大全ruipeng tangNo ratings yet

- Ir DBQ 2021Document5 pagesIr DBQ 2021Lizbeth HerreraNo ratings yet

- Retailer List UploadDocument64 pagesRetailer List UploadvarunjajooNo ratings yet

- Discussing Theories of the Term Structure of Interest RatesDocument12 pagesDiscussing Theories of the Term Structure of Interest RatesEdwin Lwandle NcubeNo ratings yet

- Economic System PresentationDocument19 pagesEconomic System PresentationVenkatesh NaraharisettyNo ratings yet

- Market Failure With Public GoodsDocument29 pagesMarket Failure With Public GoodsJefainNo ratings yet

- WP8 Inequality in Sub Saharan AfricaDocument36 pagesWP8 Inequality in Sub Saharan AfricaTsegaye BojagoNo ratings yet

- 50 Most Important Questions Economics SPCCDocument4 pages50 Most Important Questions Economics SPCCtwisha malhotraNo ratings yet

- TLE 10 - MODULE Cover PageDocument12 pagesTLE 10 - MODULE Cover PagePedro GenosasNo ratings yet

- MGAC CH 14 For Yahoo Group (Slide 1-12)Document12 pagesMGAC CH 14 For Yahoo Group (Slide 1-12)schatzchenNo ratings yet

- General Education LET QUESTIONDocument24 pagesGeneral Education LET QUESTIONAldrin Balacano GuevarraNo ratings yet

- Spartan+Trader+FX+Ebook+1 1+englishDocument110 pagesSpartan+Trader+FX+Ebook+1 1+englishLazaro da Silva100% (3)

- Apuntes - UD 3 - THE SECONDARY SECTORDocument7 pagesApuntes - UD 3 - THE SECONDARY SECTORKhronos HistoriaNo ratings yet

- GSFC Revision For Current Account Elegance 1 July 2019Document1 pageGSFC Revision For Current Account Elegance 1 July 2019Kim Jong YungNo ratings yet

- Tax Invoice/Bill of Supply/Cash MemoDocument1 pageTax Invoice/Bill of Supply/Cash MemoPrem ChanderNo ratings yet

- Private Equity and Private Debt Investments in IndiaDocument71 pagesPrivate Equity and Private Debt Investments in IndiaShashwat JainNo ratings yet

- Property Law ProjectDocument11 pagesProperty Law ProjectNikhil Hans100% (1)

- Republic of The Philippines Province of Bulacan: Municipality of San Ildefonso BarangayDocument4 pagesRepublic of The Philippines Province of Bulacan: Municipality of San Ildefonso BarangayEldie NazarNo ratings yet

- PDF DocumentssdreaDocument4 pagesPDF Documentssdrealuis rodriguezNo ratings yet

- Shipping & Billing Address: Neha Singh: Date: 23/02/2024Document2 pagesShipping & Billing Address: Neha Singh: Date: 23/02/2024tyrainternationalNo ratings yet

- Coi Ay 22-23Document2 pagesCoi Ay 22-23vikash pandeyNo ratings yet

- MRF Profile of CompanyDocument2 pagesMRF Profile of CompanyNarasimha AlandkarNo ratings yet

- Closingrates 202306junDocument20 pagesClosingrates 202306junTabrez IrfanNo ratings yet

- May 2009 Ifric UpdateDocument6 pagesMay 2009 Ifric UpdateNeji HergliNo ratings yet

- Discuss The Causes and Effects of Gentrification With Reference To Residential UrbanDocument6 pagesDiscuss The Causes and Effects of Gentrification With Reference To Residential UrbanRONNY WINGANo ratings yet

- Theory of Production (Economics)Document13 pagesTheory of Production (Economics)Keshvi LakhaniNo ratings yet