Professional Documents

Culture Documents

2.2 Quality System With Quality Assurance Guidelines

Uploaded by

Rashad MallakOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.2 Quality System With Quality Assurance Guidelines

Uploaded by

Rashad MallakCopyright:

Available Formats

QUALITY CONTROL, INSPECTION AND TESTING

2.2 Quality System with Quality Assurance Guidelines

2.2.1 Quality Control System

2.2.1.1 Operation of the System

The Project Manager is responsible for the administration, monitoring and

development of the system and ensures the compliance of the ADVCON to the

specific requirements of construction of academic buildings for JIC as stipulated

in the contract scope of works. The Quality Assurance Manager will directly

report to the ADVCON Management for the activities he is performing.

The Technical Department under the close supervision of the Project

Manager produces the Quality Control Plan which comprises of specific

work procedures, work instructions and Quality Inspection and Test Plans

(QITP) to become the ADVCON – Quality control working documents.

The particular conditions of the contract identify the involvement of the

OWNER Representative in the inspection regime for the works and for the

layout of the Quality Inspection & Test Plan (QITP). ADVCON QA

Manager and Officers together with the Engineer will conduct inspection

system to ensure that ADVCON is complying with the agreed

requirements.

The Engineer will be entitled, during the manufacture, fabrication or

preparation to inspect and test the materials and Plants to be supplied

under the Contract. If materials or Plant are being manufactured,

fabricated or prepared in workshops or places other than those of the

Contractor, the Contractor shall obtain permission for the Engineer to

carry out such inspection and testing in those workshops or places. Such

inspection or testing shall not release the Contractor from any obligation

under the Contract.

If, as per the agreed inspection and testing system the Engineer found some

defects on any work/s that was being undertaken or material/s that was delivered

on site and the Plant were not as per the Contract or specifications (General &

Special), the Engineer has the authority to reject / hold any of this defective works

or materials that were out of the said specifications.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 1

QUALITY CONTROL, INSPECTION AND TESTING

The Engineer shall inform the ADVCON in writing of these defaults in the

earliest time possible, so that the ADVCON can rectify it without affecting the

progress of

the works. In any case, the ADVCON will bear all expenditures incurred by these

rectifications.

Implementation of activities are defined and documented by the ADVCON

Project Management established quality plans, work procedures and instructions,

method statements and standard details.

This system will be continuously monitored by the Quality Engineers to form the

basis for continued development and improvement of the ADVCON quality

management capability.

The inter-relationship among various departments is depicted in the

Organizational Chart.

2.2.1.2 Allocation of Qualified staff to verify the system

The ADVCON Project Management provides adequate resources and

assigns suitably trained and experienced personnel to carry out the

verification procedures detailed in this Quality Control system, its quality

of work procedures, standard work instructions / method statements and

Project Quality Inspection & Test Plans (QITP).

The Project Manager shall plan and delegate operational Quality

Assurance Responsibilities to suitably trained and experienced staff, who

shall carry out verification routines under his guidance and control in

accordance with the Project Quality Plan. All of these responsibilities for

ensuring that ADVCON services fully satisfy the OWNER expectations

and satisfying the OWNER quality requirements.

2.2.2 General View of the Quality Control System

The Quality Control System adopted by ADVCON Project Management is based

on ISO 9002; 1994(E) model for quality assurances as specified in the condition of

contract, technical specifications and other related documents and will form as

the working documents of ADVCON Project Management Quality Control

Program.

2.2.2.1 Site Operation Control

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 2

QUALITY CONTROL, INSPECTION AND TESTING

To identify and plan the production process in which directly affect quality and

to ensure that these processes are carried out under controlled conditions, i.e. use

of established procedures defining the manner of productions, use of suitable

equipment’s and instruments in compliance with the standards and quality

plans, monitoring and approval of the process by the Project Management

Consultant, the OWNER representative.

2.2.2.2 Procurement

Relates to the documented procedures established to ensure that

purchased products conforms to specified requirements of the contracted

scope of works, to relevant technical specifications, drawings and other

standard codes.

2.2.2.3 Materials Identification and Traceability

Where appropriate, it relates to the established procedures for identifying

the products by suitable method from receipt and during all stages of

production delivery and installations.

2.2.2.4 Document and Data Control

The documented procedures, QAC-XXXX, QAC-XXXX to control all documents

and data that relates to the requirements of project technical specification,

contract documents and relevant internationally accepted standard codes

2.2.2.5 Review of Engineering and Technical Submittal

Details the review carried out to ensure that all technical requirements are clearly

defined and documented; capability is assessed and assured to meet the specified

contract or other requirements.

2.2.2.6 Inspection and Testing

The inspection and test procedure detail the provisions to be made for inspecting

supplies and work activities to verify the compliance with the project

specifications.

2.2.2.7 Calibration of Measuring & Testing Equipment’s & Instruments

The calibration procedure establishes the routine checking that are carried out on

measuring equipment/instruments to established that it is performing within the

acceptable limits define in the manufacturer’s original specifications.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 3

QUALITY CONTROL, INSPECTION AND TESTING

2.2.2.8 Inspection and Test Status

The process for inspection and test status has been incorporated into the control

of non-conformance and procedure of receipt, storage and handling of incoming

materials.

2.2.2.9 Control of Non-Conformance (Products Related)

The procedure describes the system for identifying, segregating and proposing

remedial action to be taken on non-conforming products found in the

Engineering, Procurement and Construction process carried to ensure that

defective work is not built into the service provided and thereby reducing the

compounding cost of repair (immediate action).

2.2.2.10 Corrective and Preventive Action (Process Related)

The procedure is used as the process for continuously improving the quality

system and ensures that effective action is taken to prevent problems. To detect

and eliminate potential causes of problems and where the problems occur. To

ensure that effective corrective action is taken.

2.2.2.11 Receipt, Storage and Handling Of Materials

The procedure establishes authorization levels required to receive materials. The

procedure also identifies the controls required for storing various types of

materials to prevent deterioration and the method of handling required avoiding

damages.

2.2.2.12 Quality Records

The quality records QAC-XXXX, procedure sets out the process for identifying,

preparing and maintaining quality records relating to the processes carried out

by ADVCON Project Management of quality and verify the effective operation of

the quality control system.

2.2.3 Site Operation Control

It is the policy of ADVCON to formally plan those activities which directly affect

quality.

Formal approved written procedures/method statements shall be utilized to

ensure compliance with contractual requirements.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 4

QUALITY CONTROL, INSPECTION AND TESTING

The standard of our workmanship shall be closely monitored by Supervisors and

Quality Inspectors.

Non-Destructive Testing shall be employed as required to demonstrate

compliance to the OWNER requirements, conditions of contract, engineering

standards and all applicable codes.

Personnel having control of special processes shall be trained to the standard

necessary to perform their duties.

Our equipment/instrument is maintained in line with the manufacturers

recommended requirements and all legislative requirements to ensure the quality

of works.

Procedures which describe the activities and responsibilities with regard to Site

Operation Control are located in the Quality Work Procedures File found in

separate binder. This file shall be issued under controlled conditions.

2.2.4 Procurement

Materials required for the project are procured based on the material submittals

made by the Technical Department as per PROC-XXXX. Orders for the various

materials and services are made on the approved vendor by the Procurement

Section.

2.2.4.1 Requirements for Vendors / Suppliers

The vendor / supplier is required to submit to ADVCON a catalogue or

brochures showing the capability of their product for the assessment of the

Quality Control Manager and the approval of the Engineer. Any material,

instruments or equipment will be scrutinizing by the Quality Control Manager

for their capability as per the required quality or working performance, then to

be submitted to the Engineer for approval prior for the purchase of any material,

instruments or equipment’s necessary for the project. This materials, instruments

or equipment must be as per the required specifications as required from the

contract and it must pass the standards required by the OWNER through its

representative the Engineer. All necessary documents i.e. testing and calibration

certificates must be available together with the products.

2.2.4.2 Purchasing Data

The specific requirements of the materials procured are given in the BOQ of the

contract. These requirements are verified by the user departments and

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 5

QUALITY CONTROL, INSPECTION AND TESTING

procurement is initiated. These specifications are also approved by the OWNER’s

representative for every procurement action.

Purchasing documents are reviewed and approved for the adequacy of specified

requirements prior to release by Technical Department for their relevant material

as per PROC-XXXX. Where verification of purchased products at our storage is

proposed, verification arrangements and the method of product release are

specified in the purchasing documents PROC-XXXX.

2.2.5 Materials Identification and Traceability

The ADVCON is not a manufacturer. The ADVANCE COMPANY procures all

their equipment and materials from the vendors and suppliers.

Since the ADVCON has no requirements for identification of materials, they will

just accept the Supplier’s system of identification of his materials, items or goods.

Documented procedures are established and maintained for identifying the

product by suitable means from receipt through installation, testing and final

hand-over.

The following quality Procedures explains our methods, requirements and

responsibilities.

PROC – XXXX -Materials Identification and Traceability

QAC-XXXX -Inspection and Test Status

(If any data appear enigmatical, it will be defined after award of contract)

2.2.6 Document and Data Control

Documented procedure QAC-XXXX, QAC-XXXX controls the documents and

data relate to the requirements of ISO 9002/1994(E). The documents include

OWNER’s drawings, Standards and Technical Specifications, Procedures,

Method Statement, Quality Inspection Test Plan.

2.2.6.1 Document and Data Approval and Issue

A master list identifying the current status of documents is readily available with

ADVCON Project Management Staff to preclude the use of invalid and/or

obsolete documents. These documents are guided as per the procedure and

ensure that:

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 6

QUALITY CONTROL, INSPECTION AND TESTING

a) The documents and data are reviewed for adequacy and approved

before issue.

b) The pertinent issues of appropriate documents are available at all

locations where operations essential to the effective functioning of

the quality system are performed.

c) Invalid and/or obsolete documents are promptly removed from all

points of issue or use, or otherwise protected against unintended

use.

d) Any obsolete documents retained for legal and/or knowledge

preservation purposes are suitably identified.

e) Documents for all work testing that was been conducted by the

Laboratories will be kept and filed in a manner that the OWNER

and concerned authorities be accessible at all times for retrieval and

for review.

The procedure QAC-XXXX and QAC-XXXX ensures technical data and

documents from/to OWNER/external agencies are properly identified and

distributed to the concerned.

2.2.6.2 Document and Data Changes

Changes to documents and data are reviewed and approved by the same

functions that prepared and issued the initial documents, the concerned to have

access to pertinent background information upon which to base their review and

approval. The amendment history is available with the function that prepared

the original documents.

2.2.7 Design Control

The OWNER’s design and contract drawings will receive by ADVCON Technical

Department as per Procedure QAC-XXXX. The Technical Manager reviews these

drawings for its completeness (QAC-XXX) and if necessary, seeks clarification as

per QAC-XXXX Request for information. Then the design depicted in the contract

drawings and specifications are transferred into detailed construction shop

drawings required for execution.

Updated shop drawings are submitted to the OWNER for approval. As the

design and construction evolves, necessary revisions are made in the shop

drawings as per the procedure.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 7

QUALITY CONTROL, INSPECTION AND TESTING

Temporary work drawings & shop drawings for all works will be done

progressively as per the natural ground cross sections being surveyed by the

ADVCON surveyors and upon the acceptance of the Consultant’s surveyor and

upon approval of the Engineer and according to the drawing of the project.

As the design and construction evolves, revisions are being made for the work

drawings and shop drawings as per the requirements of the Engineer. This

drawing will be reviewed by the Engineer’s Technical staff and upon reviewing

and found out it needs corrections or revisions, The ADVCON technical people

will rectify the subject as per the corrections made by the people concerned and

to be re-submitted to the Engineer for final approval. No work is to be done

without the approved work drawings and shop drawings by the Engineer.

As-built drawings will be prepared upon completion in part or in whole of the

Project, which to be submitted to the OWNER through its representative, the

Engineer of the project, for approval.

2.2.8 Inspection and Test Plan

All inspection and testing, QAC-XXX, shall be carried out in accordance with the

ADVCON Project Management’s standard documented procedures.

All work inspection and testing is to be carried out in accordance with OWNER

Specifications.

See attached Appendix B for the abovementioned testing specifications as

required for the completion of the said project in a proper way.

The Engineer and its supervision staff will witness and supervised the testing to

be done for the required

2.2.8.1 Receiving Inspection

Receiving and testing requirements are listed in the Project Quality Control

Inspection and Test Plan/s (QITPs).

All materials and equipment shall be inspected and verified as conforming to

contractual requirements on receipt. The level and extent of the inspection shall

be governed by the type of material/equipment.

When materials or components are released for urgent use before the receiving

inspection is completed it shall be positively identified and recorded as not

inspected. Such items shall be inspected before installation or use.

2.2.8.2 In-Process Inspection and Test

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 8

QUALITY CONTROL, INSPECTION AND TESTING

All inspection and testing shall be undertaken by ADVCON in a controlled

manner. Use shall be made of documented procedures and approved quality

control inspection and test plans.

2.2.8.3 Final Inspection and Test

All materials shall undergo final inspection and test to ensure that they comply

and function with the design criteria and the actual operating conditions. All

quality related documentation shall be reviewed and verified as being correct

and, if required shall be made available to the OWNER.

2.2.8.4 Inspection and Test Records

Quality records, QAC-XXXX, pertaining to completed items shall be maintained.

These records shall show the results of all agreed inspections.

The following Quality Procedures illustrate the requirements and responsibilities

associated with this activity.

PROC-XXXX -Materials Control

QAC-XXXX -Inspection and Test Status

(If any data appear enigmatical, it will be defined after award of contract)

2.2.9 Calibration of measuring Inspection and Test Equipment

The ADVCON employs an independent Specialist Testing Laboratory for its

resource to ensure that the required quality standards of all inspection and test

equipment are met. The ADVCON ensures that the specialized equipment used

by the Independent Laboratory for testing shall be maintained to the required

standards of calibration and contractual requirements.

Calibration and Maintenance documentations will be kept by ADVCON as

reference for the assurance that the Test Equipment’s were being maintained and

calibrated in continuous sequence to ensure the good performance of these

equipment’s.

Survey instruments will be maintained and calibrated by the supplier/s or any of

its approved maintenance establishment to ensure the good performance of these

measuring instruments once a year or whenever these instruments need

maintenance or calibration. If unforeseen incident happens and the survey

instruments was damaged, the ADVCON will at once send the instrument to the

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 9

QUALITY CONTROL, INSPECTION AND TESTING

qualified technician for repair/s, as this may affect the progress of the survey

works.

The ADVCON ’s approved sub-contracted testing laboratories, which carry out

the calibration of instruments, shall have test equipment traceable to the

applicable International Standards and provide Certified Records of Calibration

where necessary.

2.2.10 Inspection and Test Status

Items purchased from a supplier shall be either inspected at the Supplier’s

premises by ADVCON Project Management Staff or subjected to the required

level of inspection on receipt. The Supplier has the responsibility to comply with

ADVCON ’s requirements for inspection and testing of all material, components

and items manufactured or produced by him according to the agreed contractual

requirements.

No items shall be dispatched from any facility without the prior written authority

of the ADVCON Project Management.

The ADVCON Project Management fabricates or installed system shall be

inspected and tested as required by the documented Quality Control Inspection

and Test Plan (QITP) or other approved procedures.

The ADVCON Quality Procedure QAC-XXXX Inspection and Test Status

describe the methods of maintaining the inspection status of all products.

2.2.11 Control of Non-Conformance

The ADVCON Project Management (Technical Department) shall control all

known Non-Conformances QAC-XXX. Non-Conformances can be described as

items, materials or services which do not meet the approved specification or

requirements.

All known Non-Conformances shall be reported to The ADVCON Management

(Technical Department) for review and disposition. Non-conformances reported

shall be reviewed by The ADVCON Technical Department and agreements shall

be reached with regard to their disposition according to the findings made after

each review.

Non-Conformances shall NOT be left outstanding and should be resolved as

soon as practically possible. Records shall be kept of all Non-Conformances by

the Technical Department and these records shall form part of the final document

package.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 10

QUALITY CONTROL, INSPECTION AND TESTING

All Vendors and Suppliers shall report all Non-Conformances to ADVCON

Project Management. All Vendors and Suppliers shall submit their Non-

Conformance procedure to ADVCON Project Management for review and

approval.

All Non-conformance procedures from all parties, vendors and suppliers

Shall comply with the ADVCON procedure and shall as a minimum detail the

following;

a) How Non-Conformances are reported?

b) Who is responsible for addressing and evaluating them?

c) What method of control exists to respond to them?

d) The steps taken to ensure that they do not re-occur.

The decision on the acceptance of Non-Conformance resolution is normally at the

discretion of ADVCON Project Management or by the OWNER as deemed

required.

The following are normal resolutions taken by ADVCON (or OWNER) after

reviews of Non-conformances of materials, items and /or goods supplied.

Acceptance as is (may require a formal concession).

Reworking of the items to achieve an acceptable standard.

Rejecting or scraping of the items.

Any re-work to items, etc. shall be fully recorded. Re-inspection should always

be performed.

Where corrective action is required the Vendor/Supplier shall propose such

action and ADVCON Project Management shall give written approval prior to

any re-work. All corrective actions shall be recorded.

Systems shall be available to identify, document, segregate (when practical) and

assess the disposition of non-conforming products or services. Individuals and

departments affected by non-conforming items shall be advised as soon as

practically possible.

The following Quality Procedures are applicable to all parts of the work.

PROC-XXX -Materials Control

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 11

QUALITY CONTROL, INSPECTION AND TESTING

QAC-XXX -Inspection and Test Status

QAC-XXX -Control of Non- Conforming Products

The register of all Non-Conformances shall be reviewed by The ADVCON

Project Management on a monthly basis.

(If any data appear enigmatical, it will be defined after award of contract)

2.2.12 Corrective and Preventive Action Procedure

Corrective and Preventive Action, QAC-XXXX, will be done by The ADVCON

Project Management on an as going, as required basis in an effort to constantly

improve the Management’s system with its internal and external operations.

Corrective and Preventive Action forms part of ADVCON Project Management’s

Quality System activities in all facets of its operations and endeavors.

Internal procedures are in place to ensure that all The ADVCON Project

Management Staff and personnel are aware of the actions which are necessary if

and when situations arise which require corrective action.

These procedures also ensure that Preventive Action is taken by the Management

to alleviate such situations from re-occurring.

OWNER’s site instructions or issued Non-conformance item lists (if any) will be

analyzed by the ADVCON Project Management appropriate personnel to ensure

that an understanding of such situations is reached and that assurances can be

given to the OWNER on all as-going works.

All such actions that arise throughout the year are recorded. These, then form

part of management’s annual review cycle. If a decision is reached that further

action is required at a later date then this will be carried out.

Effective corrective actions require the following:

A reliable reporting system.

The analysis of the reports.

To conduct an in-depth investigation to locate the root causes.

To ensure the required level of control I applied to prevent the recurrence

of the original non-conformance.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 12

QUALITY CONTROL, INSPECTION AND TESTING

Quality Procedures QAC-XXXX Corrective and Preventive Action and QAC-

XXXX Investigation report describe how ADVCON Project Management

implements and controls these activities.

2.2.13 Receipt, Storage and Hauling of Incoming Materials

2.2.13.1 Handling

Procedures are in place for the handling of all materials and equipment.

The ADVCON Project Management provides suitable handling and

rigging equipment to allow the safe manipulation of all materials and

items. This assists in preventing damage and deterioration to all products.

For special items, ADVCON shall seek the advice and instruction from the

supplier regarding handling procedures.

2.2.13.2 Storage

The ADVCON Project Management shall provide suitable storage facilities for

protection, identification and control of all materials and equipment according to

the Supplier recommendation.

2.2.13.3 Packaging

All items shall be stored in accordance with the ADVCON Project Management

standard procedures. Special items shall be packed and marked in accordance

with the Supplier’s instructions. Items shall be packed and marked in accordance

with the OWNER’s requirements.

2.2.13.4 Preservation

Items shall be in accordance with the ADVCON Project Management standard

procedure. Environmentally sensitive products shall be segregated and

monitored to ensure that no deterioration is allowed to happen.

Special items shall be stored to ensure that their preservation is in line with

manufactures instructions.

2.2.13.5 Delivery

The ADVCON Project Management shall employ experienced companies to

transport all products. Clear written instructions shall be given to ensure that

products are properly protected at all times. Inspection shall take place at the

point of dispatch by The ADVCON Project Management Staff, their agents or the

vendor / supplier.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 13

QUALITY CONTROL, INSPECTION AND TESTING

A receiving inspection shall take place at their final destination point.

Vendors and suppliers employed by The ADVCON Project Management shall

have similar procedures which comply with the Management’s requirements for

handling, storing, packing and delivery.

All P. O’s shall contain explicit and concise instructions to Vendors and Suppliers

with reference with the above both their works for internal control, during

shipping and upon receipt.

2.2.13.6 Procedure

Quality Procedures Materials Control, PROC-XXXX relate to the requirements

and responsibilities of ADVCON Project Management Staff when handling or

storing any material.

2.2.14 Control of Quality Records

Records to be kept for the project shall be agreed with the OWNER. This

information shall form part of the ADVCON Project Management’s Project

Quality Plan which are then transferred to applicable Quality Control Inspection

and Test Plans (QITP’s), ADVCON ’s Vendors and Suppliers.

The following registers/files shall be maintained as a minimum by The ADVCON

Project Management Staff.

Title Register Number Responsibility

Non-Conformance -QAC-XXXX QC Manager

Register

Corrective Action –QAC-XXXX QC Manager

Inspection and Test Plan -QAC-XXXX QC Manager /

Supervisors

Purchase Order Register -PROC-XXXX Procurement

Manager

(If any data appear enigmatical, it will be defined after award of contract)

The ADVCON must maintain all quality records and files and must be stored

correctly and in a manner that these records and files be safe from losses or

damages and at any time shall be readily retrievable.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 14

QUALITY CONTROL, INSPECTION AND TESTING

All records must legible and identifiable to any specific work location/s. These

records must comply with all existing and contractual requirements from the

OWNER. Records relating to the Quality shall be maintained live for as long as a

project is on-going. Thereafter they shall be removed to an archive file or as

agreed to in contracts with the OWNERs.

2.2.15 Quality Auditing

The Quality Assurance Manager must delegate a competent person for the

purpose of internal auditing of all records for quality aspects of the said project.

He must see to it that all quality activities had been properly done and in

accordance with the required standard and procedure as stated in this Quality

Control Plan and as required from the contract.

He must see to it that all documents and records and all test results are being

properly documented and recorded and be kept in orderly and safe manner so

that it will always be ready for review and retrieval upon request by any

personnel from the ADVANCE COMPANY, the Engineer or the OWNER.

2.2.16 Training

As required, any personnel working with the Quality Control Team must be an

efficient and a competent person to avoid any mistake on their job. In case a

member of the team is not that competent to perform his job, then training must

be implied.

Any member who is assigned for assessing any kinds of equipment, heavy

or light, must be trained regarding the equipment, its parts and its use, so

that he may know the proper part/s to be used and its quality in case

repair is being done, so that, that equipment will be performed well upon

resuming its work.

A member assigned for the sampling and testing of the work on site or in

the Laboratory needs to be trained properly regarding the work he is

performing to avoid any mistakes that may affect the quality of the work.

2.2.17 Statistical Techniques

All materials, manufactured articles, and machinery incorporated in the

Permanent Works shall meet all quality requirements of the contract. They must,

in all cases, be approved by the Engineer prior to their inclusion in the Work.

The ADVCON shall, before placing any purchase order for materials,

manufactured articles, and machinery to be a part of the permanent works,

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 15

QUALITY CONTROL, INSPECTION AND TESTING

submit for the approval of the Engineer, a complete description of such items, the

names of the firms from which he proposes to obtain such items, together with

copies of all test records proving compliance with Contract provisions. No such

items shall be ordered from any firm without the approval of the Engineer.

2.2.12.1 Sampling and Testing

All materials shall be presented to the Engineer for inspection, testing and

acceptance before incorporation into the Work. All materials being used

are subject to inspection, testing or rejection at any time prior to

incorporation into the Work.

2.2.12.1.1 Sampling

All sampling must be in accordance with the standard/s stated in the contract.

Materials subject to statistical based acceptance shall be sampled randomly which

provides that all units being produced have an equal chance of being selected for

sampling and testing.

When sampling a material for statistical acceptance, the samples must be selected

using and approved random number selection procedure detailed in the

following paragraph or other random number selection procedure approved by

the Engineer. At least five (5) random samples from a lot of materials are needed

to make an acceptance statistical evaluation.

2.2.12.1.2 Random Sampling

All published sampling tables are prepared on the assumption that samples are

drawn at random; i.e., at any one time each of the remaining uninspected units of

product has an equal chance of being the next unit selected for the sample. To

conduct sampling requires that (1) random numbers are generated and (2)

random numbers be applied to the product at hand.

Random sampling shall be used for selecting when or where to take a sample. In

large lots, the method recommended by the M.O.T. is stratified (proportional)

random sampling because it prevents groupings of samples by using sub lots and

spreading the sample over the entire lot.

2.2.12.2 Quality Control Chart

The quality of materials and construction shall be controlled using control charts

based on statistical techniques. The control charts shall be prepared and kept

current daily by the ADVCON. These charts shall be submitted, if required, to the

Engineer every month for review and approval. The charts shall be drawn in the

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 16

QUALITY CONTROL, INSPECTION AND TESTING

form of graphs with property characteristics on the vertical axis and test numbers

on the horizontal axis.

Target line, upper and lower control and warning limits shall be drawn as

directed by the Engineer. The Engineer will divide the work and the materials

into lots. Each lot will be evaluated separately.

Guidance for Quality Assurance Project Plans

2.2.18 An Overview of Quality Assurance Project Plans

What is a QA Project Plan?

A QA Project Plan describes the activities of an environmental data operations

project involved with the acquisition of environmental information whether

generated from direct measurements activities, collected from other sources, or

compiled from computerized databases and information systems.

What is the purpose of the QA Project Plan?

The QA Project Plan documents the results of a project’s technical planning

process, providing in one place a clear, concise, and complete plan for the

environmental data operation and its quality objectives and identifying key

project personnel.

What is the difference between a Quality Management Plan and a QA Project

Plan?

A Quality Management Plan describes an organization’s quality system, i.e., its

systematic approach to quality assurance, while a QA Project Plan describes the

necessary QA procedures, quality control (QC) activities, and other technical

activities that will be implemented for a specific project or program.

May I combine a Quality Management Plan and a QA Project Plan into one

document?

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 17

QUALITY CONTROL, INSPECTION AND TESTING

Yes. With permission of the QA Manager of the organization sponsoring the

work, these two documents may be combined into a single document for small

programs, grants, and contracts. The combined document should address

satisfactorily all the elements of both documents.

What are the benefits of a QA Project Plan?

The benefits of a QA Project Plan are to communicate, to all parties, the

specifications for implementation of the project design and to ensure that the

quality objectives are achieved for the project. It does not guarantee success every

time, but the prospects are much higher with a QA Project Plan than without one.

Up-front planning eliminates approaches that do not work well (or not at all),

which has the potential to reduce the cost of lost time and rework.

Implementation as prescribed, with appropriate QC practices employed,

increases efficiency and provides for early detection of problems, either in the

field or in the laboratory. This again can save time and money from the rework

and enable the ability to make decisions more expeditiously. For example,

following calibration procedures will help to assure the credibility and usability

of data generated by laboratory instruments.

When should a QA Project Plan be prepared?

A QA Project Plan is prepared either as part of or after the project planning

process. But in all cases, the QA Project Plan should be completed and approved

before the project is started.

How do I develop a QA Project Plan?

The following is a brief summary of the process:

ADVCON will find out what needs to be done, based on what is known

about the site or situation.

ADVCON will assemble a project team with the necessary expertise.

ADVCON WILL plan what can be done, or what will be done to obtain

data of known quality that are good enough to support the decisions to be

made or the study questions to be answered.

ADVCON will write the QA Project Plan.

ADVCON will submit the QA Project Plan for peer review, input, and

approval, revising it as needed.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 18

QUALITY CONTROL, INSPECTION AND TESTING

ADVCON will distribute the approved QA Project Plan to all pertinent

individuals involved with the project.

ADVCON will begin work while implementing the plan, but remember to:

o Document any changes in the QA Project Plan,

o Get re-approval before initiating the change, and then

o Distribute the updated version.

2.2.19 ADVCON Policy

You will find ADVCON policies and other tools and guidance on the Quality

Staff’s web site, that we will construct it to serve this part.

Should a QA Project Plan be approved before work begins?

Yes. All work involving the collection or use of environmental data, by or on

behalf of ADVCON, is to be done with an approved QA Project Plan. This policy

applies to work performed by or on behalf of ADVCON. A QA Project Plan

should generally be approved before any environmental data collection

operation starts. Examples of exceptions include:

Circumstances warrant immediate action to protect human health and/or

the environment, or

Operations are conducted under police powers.

Advance approval ensures that all of the planning steps, including connecting

actions with needs, are completed. Clear documentation increases the likelihood

that the project will achieve its intended results. If the plan is not approved

before work begins, a stop-work order may be issued.

Where can I get information on the graded approach to QA Project Plan

contents?

The term “graded approach” appears in the Quality Manual where it states that

the level of detail in the quality management plan should be “based on a

common sense, graded approach that establishes QA and QC activities

commensurate with the importance of the work, the available resources, and the

unique needs of the organization.” In referring to the QA Project Plan, the

Quality Manual states that ADVCON organizations may tailor these QA Project

Plan specifications in their own implementation documents to better fit their

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 19

QUALITY CONTROL, INSPECTION AND TESTING

specific needs. Therefore, consult with the project officer or QA Manager

regarding the application of the graded approach to your project.

When should I revise my QA Project Plan?

When changes affect the scope, implementation, or assessment of the

outcome, the plan is revised to keep project information current.

The Project Manager, with the assistance of the QA Manager, determines

the impact of any changes on the technical and quality objectives of the

project.

For long-term projects, such as multi-year monitoring programs, the QA

Project Plan is reviewed annually by the Project Manager to determine the

need for revision.

When should I submit a revised QA Project Plan for review?

When a substantive change is warranted, the originator of the QA Project Plan

revises the plan to document the change, and then submits the revised plan to the

approving authority. Implement the change only after the revision has been

approved. Send the revised plan to all the individuals cited in the distribution

list.

How long is a QA Project Plan kept after the project ends?

Document retention should comply with the approving organization’s

specifications first, and the specifications of the organization performing the

work second.

2.2.20 Content of QA Project Plan

What is generally contained in a QA Project Plan?

The QA Project Plan is divided into four basic element groups: Project

Management; Data Generation and Acquisition; Assessment and Oversight; and

Data Validation and Usability. Each group consists of standard elements, 24 in

all, that pertain to various aspects of the project.

A QA Project Plan that addresses the basic elements will define and

describe the following:

who will use the data;

what the project’s goals/objectives/questions or issues are;

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 20

QUALITY CONTROL, INSPECTION AND TESTING

what decision(s) will be made from the information obtained;

how, when, and where project information will be acquired or generated;

what possible problems may arise and what actions can be taken to

mitigate their impact on the project;

what type, quantity, and quality of data are specified;

how “good” those data have to be to support the decision to be made; and

how the data will be analyzed, assessed, and reported.

What if some of the 24 elements do not apply?

QA Project Plans will vary in their level of complexity, based both on the nature

of the work being performed (such as the collection of new data or the use of

previously collected information), available resources, and the intended use of

the data.

Following the principle of the graded approach, if an element is not applicable,

then indicate why it is not relevant.

Can additional information be specified beyond the standard 24 elements?

The organization sponsoring or overseeing the work may specify additional

information to clarify project specific information.

If this information is documented in other places, do I rewrite that information

into this QA Project Plan?

Referring to existing documents can reduce QA Project Plan preparation and

review time and length. Any documents prepared before the QA Project Plan,

such as standard operating procedures (SOPs), sampling and analysis plans

(SAPs), work plans, environmental site assessments, literature files, and data sets

from other projects, may be appended.

How long is a QA Project Plan?

A QA Project Plan should have enough information to describe project objectives

and details. The number of pages needed to address this information will vary

with the complexity of the project and intended use of the information. A plan

for some environmental data operations may involve a qualitative discussion of

the experimental process and its objectives, while a plan that describes a complex

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 21

QUALITY CONTROL, INSPECTION AND TESTING

environmental project may involve extensive documentation to adequately

describe activities.

May I use the same QA Project Plan for standard activities?

Multi-year projects, and projects conducted at multiple sites, having the same

project objectives and sampling and analytical processes, may be described in a

generic QA Project Plan. You may describe site specific activities in supplements,

for example, separate field sampling plans. Review generic plans annually to

determine if any changes are necessary.

2.2.21 QA Project Plans and ADVCON Quality System

How does the QA Project Plan fit into the ADVCON Quality System?

ADVCON Quality System consists of three levels or tiers:

a policy level,

a program level,

and a project level

The Project Level addresses project-specific activities. The tools for this level

include:

Systematic Planning;

Quality Assurance Project Plans;

Standard Operating Procedures;

Technical Audits;

Data Verification and Validation; and

Data Quality Assessment.

What is the role of systematic planning in developing the QA Project Plan?

Systematic planning is a process in which you identify the problem to be

investigated or the decision to be made, and then define the project’s objectives,

the type, quantity and quality of information needed, the technical and quality

control activities, and the level of oversight that will ensure project criteria are

satisfied. ADVCON stresses systematic project planning.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 22

QUALITY CONTROL, INSPECTION AND TESTING

2.2.22 Developing, Reviewing, and approving QA Project Plan

Who is included in developing the QA Project Plan?

Project planning necessitates the coordinated efforts of many individuals, such as

those who will generate information and those who will use the information or

make decisions based on that information. These individuals include: decision

makers, project managers, regulators, stakeholders, modelers, risk assessors, and

technical staff (for example, hydrologists, chemists, data validates, samplers, and

statisticians). In addition, peer reviewers and individuals with varied expertise

ensure that technical areas are sufficiently addressed, thus helping to minimize

problems during implementation.

Who is responsible for ensuring that the Plan is written?

Those who are both involved in planning the project and experienced in

environmental data operations, prepare and/or assist in the preparation of the

QA Project Plan.

Who reviews the plan?

This varies with each organization. Reviewers with expertise in the project

specific areas, such as program managers (decision makers), QA staff

independent of project management, and project field and laboratory technical

staff, should review the plan.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 23

QUALITY CONTROL, INSPECTION AND TESTING

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 24

QUALITY CONTROL, INSPECTION AND TESTING

What is included in a QA Project Plan review?

Reviewers should:

Ensure that the information is accurate and complete;

Ensure that all appropriate elements are addressed;

Ensure that the plan identifies the project's technical and quality

objectives, and that the intended measurement and data acquisition

methods will satisfy these objectives;

Confirm that the planned assessment procedures will be adequate to

evaluate the project; and

Confirm that there is a process to identify any limitations on the use of the

data.

These reviewers may also use tools, such as a checklist, in their review.

Who approves the QA Project Plan?

The approving authority will vary with the individual organization. The

ADVCON organization’s Quality Management Plan establishes how, when, and

by whom development, review, approval, and effective oversight of QA Project

Plans should occur. This includes processes for extramural (non-ADVANCE

COMPANY) organizations that prepare QA Project Plans. For ADVCON

projects, the Project Manager or Project Officer, and the QA Manager usually

approve the QA Project Plan. For extramural projects, the responsible

organization’s Project Manager, or Principal Investigator, and QA Manager may

review and approve the QA Project Plan, and then submit it for OWNER

approval Quality Management Plan). It is also beneficial if other key staff, such as

the laboratory directors and prime contractors and subcontractors, sign the plan

to indicate their review and approval.

What types of approvals exist?

In situations where only non-critical deficiencies in a QA Project Plan have not

been resolved (such as a final organizational chart or a data analysis procedure

that will not be followed for weeks), conditional approval may be given to allow

the project to start while these deficiencies are being resolved. The plan is then

resubmitted for approval when the information is finalized. The concept of

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 25

QUALITY CONTROL, INSPECTION AND TESTING

conditional approval, however, will vary with individual organizations; some

organizations may not permit conditional approval of a QA Project Plan.

2.2.23 Distributing QA Project Plan

Who gets a copy of the QA Project Plan?

All personnel involved in the project should retain or have access to the current

version of the QA Project Plan. This may include the Project Manager, laboratory

manager, field team leader, modeler, QA Manager, data reviewers, and any

essential contractor and subcontractor personnel involved with the project.

2.2.24 Implementing the QA Project Plan

Who is responsible for implementing the QA Project Plan?

The organization performing the work is responsible for ensuring that the QA

Project Plan is implemented as written and approved, whether this work is

conducted by contract personnel or in-house personnel. Ultimately the Project

Manager is responsible for project activities. A clearly written QA Project Plan

will help the Project Manager implement the plan, because all project personnel

will understand the specifications before the start of data generation activities.

Breakfast & Bakery – Fit Out @ Riyadh, Saudi Arabia 26

You might also like

- QA QC ManualDocument25 pagesQA QC ManualWaldo At100% (1)

- PMP Experience SpreadsheetDocument321 pagesPMP Experience SpreadsheetRashad Mallak0% (1)

- PMP Experience SpreadsheetDocument321 pagesPMP Experience SpreadsheetRashad Mallak0% (1)

- Quality PlanDocument26 pagesQuality PlanAbu Muhammed KhwajaNo ratings yet

- QAQC ManualDocument33 pagesQAQC ManualNagender Shreeram100% (1)

- Quality Control PlanDocument13 pagesQuality Control PlanMohammad Taqi HamidiNo ratings yet

- K 3 Project Quality PlanDocument23 pagesK 3 Project Quality PlanJonathan JoeNo ratings yet

- The PMP® Exam Experience Verification WorksheetDocument14 pagesThe PMP® Exam Experience Verification WorksheetRashad MallakNo ratings yet

- Quality AssuranceDocument61 pagesQuality AssuranceSandeep RajurkarNo ratings yet

- Quality Assurance and ControlDocument55 pagesQuality Assurance and ControlACHESNo ratings yet

- QA QC PresentationDocument109 pagesQA QC Presentationklibi89% (9)

- 01.08 - Quality AssuranceDocument179 pages01.08 - Quality AssuranceKrishna KishoreNo ratings yet

- Sample Quality PlanDocument17 pagesSample Quality PlanKhaled Abdelbaki100% (1)

- Validation Master PlanDocument33 pagesValidation Master PlanisralmayoorNo ratings yet

- QAQC ManualDocument33 pagesQAQC ManualAtef RagabNo ratings yet

- QAQCDocument15 pagesQAQCflawlessy2k100% (1)

- Thermal Insulation Project Quality PlanDocument8 pagesThermal Insulation Project Quality PlantegoehNo ratings yet

- Scope of WorkDocument69 pagesScope of WorkRashad MallakNo ratings yet

- Construction QC PlanDocument13 pagesConstruction QC PlanAbdallah YounisNo ratings yet

- QA-QC PlanDocument18 pagesQA-QC PlanSen IMO67% (3)

- PMP Comprehensive NotesDocument29 pagesPMP Comprehensive NotesMohammed AhmedNo ratings yet

- PMP Comprehensive NotesDocument29 pagesPMP Comprehensive NotesMohammed AhmedNo ratings yet

- MOS - Concrete Repair WorksDocument6 pagesMOS - Concrete Repair Worksharun yucelNo ratings yet

- QC-QA PlanDocument22 pagesQC-QA Planfaisal ahmad100% (1)

- 560-S27 QUALITY CONTROL PROGRAM Rev.4Document27 pages560-S27 QUALITY CONTROL PROGRAM Rev.4AbdelmuneimNo ratings yet

- 6.0 Quality Assurance InsulationDocument15 pages6.0 Quality Assurance InsulationMukiara LuffyNo ratings yet

- Sample - Project Quality PlanDocument12 pagesSample - Project Quality PlanSuraj Mani100% (1)

- Mine Valuation Lect 2Document23 pagesMine Valuation Lect 2Munyaradzi MurapaNo ratings yet

- 12 Project Quality Plan 7.11.20 (Final)Document81 pages12 Project Quality Plan 7.11.20 (Final)Michael Patungan100% (1)

- Procedure For QADocument7 pagesProcedure For QASharif Khan100% (1)

- Criterion C and D 2 Grade 9 StandardDocument6 pagesCriterion C and D 2 Grade 9 StandardClayton HalimNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- Base Construction INC: Quality Assurance and Quality Control ManualDocument27 pagesBase Construction INC: Quality Assurance and Quality Control ManualLegend Anbu100% (1)

- Pr2 Module 1Document57 pagesPr2 Module 1Joseph ObraNo ratings yet

- 01 40 00 - Quality RequirementsDocument27 pages01 40 00 - Quality RequirementsshauhramNo ratings yet

- Road Construction Essentials QA/QC PlanDocument10 pagesRoad Construction Essentials QA/QC Planrafiullah amireeNo ratings yet

- Quality Management PlanDocument9 pagesQuality Management Planmurtada kamilNo ratings yet

- MOS Commisioning AreaDocument6 pagesMOS Commisioning Areaharun yucelNo ratings yet

- Various Methods of SamplingDocument9 pagesVarious Methods of SamplingAhmad Ali100% (1)

- Inspection and Testing: Assignment of QC Inspections and MonitoringDocument2 pagesInspection and Testing: Assignment of QC Inspections and MonitoringMith MithunNo ratings yet

- Qa QCDocument10 pagesQa QCBrain Dee Tech LtdNo ratings yet

- Quantitative ResearchDocument26 pagesQuantitative ResearchAntonio Jarligo Compra50% (2)

- QUALITY CONTROL PROCEDURE FOR INSTALLATION & TESTING OF FIRE FIGHTING PIPING SYSTEM AND ACCESSORIES - The Engineer's BlogDocument12 pagesQUALITY CONTROL PROCEDURE FOR INSTALLATION & TESTING OF FIRE FIGHTING PIPING SYSTEM AND ACCESSORIES - The Engineer's BlogNESTOR YUMULNo ratings yet

- Lec 3-Geotechnical Investigations and StudiesDocument31 pagesLec 3-Geotechnical Investigations and StudiesAlina RafeeqNo ratings yet

- Quality Assurance and Quality Control PlanDocument6 pagesQuality Assurance and Quality Control PlanTia KurniawatiNo ratings yet

- New Problem StatementDocument2 pagesNew Problem Statementrenuka rathore100% (2)

- Quality AssuranceDocument7 pagesQuality Assurancesuresh84123No ratings yet

- Appendix 1 Quality Assurance PlanDocument6 pagesAppendix 1 Quality Assurance PlanRio Marthin Tambunan100% (1)

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- 2.01 Project Charter TemplateDocument5 pages2.01 Project Charter TemplateFrancisco HernandezNo ratings yet

- 2.01 Project Charter TemplateDocument5 pages2.01 Project Charter TemplateFrancisco HernandezNo ratings yet

- Quality ManualDocument4 pagesQuality ManualAli IrvaliNo ratings yet

- Project Construction Quality Control RequirementsDocument10 pagesProject Construction Quality Control RequirementsNarayanan Menon100% (1)

- 2.2 Quality System With Quality Assurance GuidelinesDocument26 pages2.2 Quality System With Quality Assurance GuidelinesRashad MallakNo ratings yet

- QC ProgramDocument7 pagesQC ProgramHerbert HernandezNo ratings yet

- Technical Specification 2Document2 pagesTechnical Specification 2Buliga MarianNo ratings yet

- ITP ProcedureDocument35 pagesITP ProcedureArif Sameer KhanNo ratings yet

- Quality Assurance Acceptance Program Section 200 TocDocument21 pagesQuality Assurance Acceptance Program Section 200 TocephNo ratings yet

- Technical Specification 3Document2 pagesTechnical Specification 3Buliga MarianNo ratings yet

- Contrat Jesa 4582K/12: Annex N Quality RequirementsDocument33 pagesContrat Jesa 4582K/12: Annex N Quality RequirementsoundilahmedNo ratings yet

- VAL 030 Equipment Specification and Qualification SampleDocument2 pagesVAL 030 Equipment Specification and Qualification SampleSameh MostafaNo ratings yet

- Type 1 - Se Qaqc Gen PlanDocument24 pagesType 1 - Se Qaqc Gen PlansacdawoodNo ratings yet

- QA & Control Program (21042003)Document6 pagesQA & Control Program (21042003)jitendraNo ratings yet

- Section 014300 Quality Assurance - Rev0Document5 pagesSection 014300 Quality Assurance - Rev0Al LopezNo ratings yet

- Technical Specification 1Document2 pagesTechnical Specification 1Buliga Marian100% (1)

- Number Three Wind Farm Lewis County, New York Case 16-F-0328 May 2018 1 Project InformationDocument6 pagesNumber Three Wind Farm Lewis County, New York Case 16-F-0328 May 2018 1 Project Informationblackberry7130gNo ratings yet

- ANNEX - REQUIREMENTS FOR QUALITY MANAGEMENT - PMT Implementation ServicesDocument9 pagesANNEX - REQUIREMENTS FOR QUALITY MANAGEMENT - PMT Implementation ServicesJhon fredy orozco palaciosNo ratings yet

- QUALITYDocument51 pagesQUALITYSaud NawabNo ratings yet

- SUMARY TESTING QRO060 HYA 2022 EnglishDocument10 pagesSUMARY TESTING QRO060 HYA 2022 EnglishJavier Enrique Diaz ChacinNo ratings yet

- Section VII - Quality Management System Major BuildingsDocument5 pagesSection VII - Quality Management System Major BuildingsAyodele Oluwaseyi DinaNo ratings yet

- PQPDocument29 pagesPQPabelpedroramosNo ratings yet

- SECTION 01 45 00 Quality ControlDocument15 pagesSECTION 01 45 00 Quality ControlJuanPaoloYbañezNo ratings yet

- Purchasing & Contracting Department, Breakfast & Bakery, Riyadh, Saudi ArabiaDocument2 pagesPurchasing & Contracting Department, Breakfast & Bakery, Riyadh, Saudi ArabiaRashad MallakNo ratings yet

- Executive Summary: Breakfast & Bakery, Riyadh, Saudi ArabiaDocument4 pagesExecutive Summary: Breakfast & Bakery, Riyadh, Saudi ArabiaRashad MallakNo ratings yet

- Technical Approach For Built Up The ProjectDocument17 pagesTechnical Approach For Built Up The ProjectRashad MallakNo ratings yet

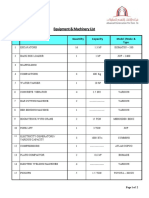

- Equipment & Machinery List: No. Item Quantity Capacity Model /make & TypeDocument2 pagesEquipment & Machinery List: No. Item Quantity Capacity Model /make & TypeRashad MallakNo ratings yet

- No Project Name Location Type Client Name Date Project Value (Sar)Document1 pageNo Project Name Location Type Client Name Date Project Value (Sar)Rashad MallakNo ratings yet

- Key Personnel ListDocument1 pageKey Personnel ListRashad MallakNo ratings yet

- 004 - Assets Request Process-REV01Document2 pages004 - Assets Request Process-REV01Rashad MallakNo ratings yet

- Key Personnel ExperienceDocument1 pageKey Personnel ExperienceRashad MallakNo ratings yet

- (Project Name) Project Charter: Project Title Project ScopeDocument2 pages(Project Name) Project Charter: Project Title Project ScopeRashad MallakNo ratings yet

- Project Management Systems: Recruitment ProcessDocument2 pagesProject Management Systems: Recruitment ProcessRashad MallakNo ratings yet

- 001 - Vendor Payment Request-REV02Document2 pages001 - Vendor Payment Request-REV02Rashad MallakNo ratings yet

- 001 - Vendor Payment Request-REV01Document2 pages001 - Vendor Payment Request-REV01Rashad MallakNo ratings yet

- 002 - Change Order Request-REV02Document2 pages002 - Change Order Request-REV02Rashad MallakNo ratings yet

- Project Management Systems: Procurement ProcessDocument2 pagesProject Management Systems: Procurement ProcessRashad MallakNo ratings yet

- PMP Exam Application SpreadsheetDocument49 pagesPMP Exam Application Spreadsheetanantvir100% (1)

- PMP Form Template v1.0Document5 pagesPMP Form Template v1.0Rashad MallakNo ratings yet

- PMP Exam Application SpreadsheetDocument49 pagesPMP Exam Application Spreadsheetanantvir100% (1)

- PMP Form Template v1.0Document5 pagesPMP Form Template v1.0Rashad MallakNo ratings yet

- Request# Status: Visitor Management SystemDocument1 pageRequest# Status: Visitor Management SystemRashad MallakNo ratings yet

- Request# Status: Visitor Management SystemDocument1 pageRequest# Status: Visitor Management SystemRashad MallakNo ratings yet

- Aitex LOI Nomex Test Report - 1Document6 pagesAitex LOI Nomex Test Report - 1Arun Vijayan M VNo ratings yet

- 2014teg Carreon FlorendoDocument8 pages2014teg Carreon FlorendoTina RosalesNo ratings yet

- Amr Project: Dinshaw's Ice Cream: Group - 8Document33 pagesAmr Project: Dinshaw's Ice Cream: Group - 8ATAUL KARIM BAIGNo ratings yet

- Methods of Sampling From A PopulationDocument3 pagesMethods of Sampling From A PopulationAiza San Pedro SantosNo ratings yet

- Group 5 Manuscript RevisedDocument67 pagesGroup 5 Manuscript RevisedangelNo ratings yet

- Chapter 1 To Chapter 5 + BibliographyDocument55 pagesChapter 1 To Chapter 5 + BibliographySecret Admirer100% (1)

- Full Download Elementary Statistics 8th Edition Weiss Test BankDocument35 pagesFull Download Elementary Statistics 8th Edition Weiss Test Bankonakeinonenfx100% (26)

- Customer Relationship Management ReportDocument65 pagesCustomer Relationship Management Reportsundar vigneshNo ratings yet

- Acurácia e Precisão PEDI-CATDocument7 pagesAcurácia e Precisão PEDI-CATLetícia AndradeNo ratings yet

- Summarizing Data-Measures of DispersionDocument47 pagesSummarizing Data-Measures of DispersionRakesh ChoudharyNo ratings yet

- Population and SampleDocument12 pagesPopulation and Sampleapi-3850829No ratings yet

- Sampling Theory of Surveys With ApplicationsDocument519 pagesSampling Theory of Surveys With ApplicationsAbhishek S SNo ratings yet

- Dwnload Full Applied Statistics From Bivariate Through Multivariate Techniques 2nd Edition Warner Solutions Manual PDFDocument36 pagesDwnload Full Applied Statistics From Bivariate Through Multivariate Techniques 2nd Edition Warner Solutions Manual PDFmaf0dlwood100% (18)

- Hubungan Pola Makan Dengan Status Gizi Pada Lansia: Tria Auliya Maratus Sholikhah, Elmie Muftiana, Sulistyo AndarmoyoDocument7 pagesHubungan Pola Makan Dengan Status Gizi Pada Lansia: Tria Auliya Maratus Sholikhah, Elmie Muftiana, Sulistyo Andarmoyosuci sevtiNo ratings yet

- Simple Random SampleDocument6 pagesSimple Random SampleKeerthi ShettyNo ratings yet

- Statistics: Federal Public Service CommissionDocument2 pagesStatistics: Federal Public Service CommissionA JawadNo ratings yet

- Designing Scoring Rubrics For Your ClassroomDocument9 pagesDesigning Scoring Rubrics For Your ClassroomAlissa QothrunnadaNo ratings yet

- Acoustic Survey Design and Analysis Procedure A Comprehensive Review of Current PracticeDocument136 pagesAcoustic Survey Design and Analysis Procedure A Comprehensive Review of Current Practiceluishiño solisNo ratings yet

- Vishal Chauhan Final Project Repor Ton BagzarDocument82 pagesVishal Chauhan Final Project Repor Ton BagzarAditya VermaNo ratings yet

- Faculty of Economics & Business: Guru Nanak Dev University AmritsarDocument107 pagesFaculty of Economics & Business: Guru Nanak Dev University AmritsarKaran SinghNo ratings yet

- Developing A Media PlanDocument14 pagesDeveloping A Media PlanNilu Kumar MishraNo ratings yet

- ISA530Document13 pagesISA530yejeebysrNo ratings yet

- Transport Modelling and Passenger Traffic Flow at Mostar International Airport, Bosnia and HerzegovinaDocument31 pagesTransport Modelling and Passenger Traffic Flow at Mostar International Airport, Bosnia and HerzegovinaLazar LukacNo ratings yet