Professional Documents

Culture Documents

Kitchen Hood Suppression System

Uploaded by

Aziz UllahOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kitchen Hood Suppression System

Uploaded by

Aziz UllahCopyright:

Available Formats

Kitchen Hood Suppression System

Commissioning / Handing Over Report

Installation date: ________________________ Commissioning date: ________________

TYPE OF SYSTEM:

Wet Chemical Systems

Dry Chemical Systems

UL 300 Wet System

Client Name: ___Kitchen Hood Studio_________________________

Project Name: ___Khaadi Dolmen City Mall_____________________

Client P.O. No.: ________________ _____________________________

Consultant Name: __ SEM Engineers______________________________

Contractor Name: __ Kitchen Hood Studio__________________________

Representatives:

Were the following present to witness the test:

A. Client / Representative ☐ Yes ☐ No ☐ N/A

B. Consultant / Representative ☐ Yes ☐ No ☐ N/A

C. Contractor / Representative ☐ Yes ☐ No ☐ N/A

CLIENT’S REPRESENTATIVE NAME & SIGNATURE CONSULTANT REPRESENTATIVE NAME & SIGNATURE

COMMENTS COMMENTS

CONTRACTOR REPRESENTATIVE NAME & SIGNATURE ZARA ENGINEERS REPRESENTATIVE NAME & SIGNATURE

COMMENTS COMMENTS

I state that the information on this form is correct

at the time and place of my inspection and that all

equipment testes at this time were left in

operational condition upon completion of this

inspection except as noted.

Note: For further detail see attached reports.

APPLIANCE COVERAGE, NOZZLES, AND PIPING

1 All cooking appliances that can produce grease laden vapors are completely under the range hood. ☐ Yes ☐ No

2 All cooking appliances have the required number and type of nozzles to provide adequate fire protection. ☐ Yes ☐ No

3 All nozzles are properly positioned. ☐ Yes ☐ No

4 All piping and conduit are immobilized with proper hangers and brackets ☐ Yes ☐ No

SYSTEM CONTROLS

1 All system controls and components are accessible and free from obstructions. ☐ Yes ☐ No

2 The system is operational from the terminal link (last fusible link). ☐ Yes ☐ No

3 The fusible links were replaced. ☐ Yes ☐ No

4 The manual (remote) pull is configured correctly and is operational. ☐ Yes ☐ No

5 The operation of the fusible link line is not impaired by grease. ☐ Yes ☐ No

6 The micro switch that controls the gas and/or electrical power to the appliance’s functions properly. ☐ Yes ☐ No

CYLINDERS AND EXTINGUISHING AGENT

1 The extinguishing agent in the cylinders conforms to the manufacturer’s requirements for this system. ☐ Yes ☐ No

The system has adequate supply of extinguishing agent as required to meet the demand for complete coverage of the

2 ☐ Yes ☐ No

cooking appliances.

3 The cylinders are filled with the correct volume of extinguishing agent. ☐ Yes ☐ No

4 If present, the cylinder gauge is in the operational range. ☐ Yes ☐ No

5 The hydrostatic testing of the agent cylinder(s) is up-to-date. ☐ Yes ☐ No

SYSTEM SECURITY AND MONITORING

1 The tamper seals on the suppression system were installed. ☐ Yes ☐ No

2 The suppression system is connected to the fire alarm panel. (Only select N/A if there is no fire alarm system) ☐ Yes ☐ No

FINAL CHECKS, TAGGING, AND REPORTS

1 A current red, green tag was placed on the panel ☐ Yes ☐ No

The color of the tag is:

2 ☐ Green ☐ Red

Handing Over (To Client)

Except as noted, the system is occupied with the same occupancy classification and hazard of control as the last inspection. Also, the system has

remained in service without modification and has been free of the actuation of devices and alarms.

Name: _______________________________________________ Signature / Date: ______________________________________________

You might also like

- Welder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamFrom EverandWelder Practice Questions: Welder Practice Questions Similar to Red Seal or AWS Welder ExamNo ratings yet

- 2013.04 - Mechanical CodeDocument500 pages2013.04 - Mechanical CodebillyNo ratings yet

- Boom Lift - Man Lift Inspection ChecklistsDocument3 pagesBoom Lift - Man Lift Inspection ChecklistsAgung Tri SugihartoNo ratings yet

- PennBarry Fumex Catalog FXDocument32 pagesPennBarry Fumex Catalog FXArmando MantillaNo ratings yet

- Rig Safety Audit ChecklistDocument23 pagesRig Safety Audit ChecklistKACEM100% (5)

- Jumping Compactor Inspection ChecklistDocument1 pageJumping Compactor Inspection Checklistarunjith rNo ratings yet

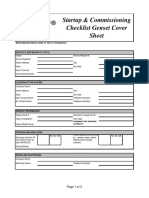

- Genset Startup and Commissioning Checklist C 175Document3 pagesGenset Startup and Commissioning Checklist C 175Dwi Mulyanti Dwimulyantishop100% (1)

- Electrical Pump & Motor Inspection ChecklistDocument1 pageElectrical Pump & Motor Inspection ChecklistJIJESH GOKULDASNo ratings yet

- Checklist - Transformer Location Inspection ChecklistDocument3 pagesChecklist - Transformer Location Inspection ChecklistSachin wakeNo ratings yet

- Commercial Kitchen Inspection ChecklistDocument2 pagesCommercial Kitchen Inspection ChecklistDaoud TuffahaNo ratings yet

- AC7102.4 Rev DDocument25 pagesAC7102.4 Rev DVijay Yadav100% (1)

- Exhaust Hoods Design Guide Selecting SizingDocument11 pagesExhaust Hoods Design Guide Selecting Sizingmayur bargeNo ratings yet

- Pressure Vessel Compliance ChecklistDocument3 pagesPressure Vessel Compliance Checklistpineda44444100% (2)

- Barford TR5048 Manual + Parts List 2021 WITH MULCHDocument62 pagesBarford TR5048 Manual + Parts List 2021 WITH MULCHpggmarquesNo ratings yet

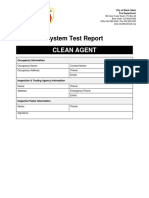

- Clean Agent System Test Report-1Document96 pagesClean Agent System Test Report-1bayrammtnNo ratings yet

- The Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1From EverandThe Concise Calibration & Test Equipment Management Guide: The Concise Collection, #1Rating: 4.5 out of 5 stars4.5/5 (2)

- LAWA Basic Commissioning Forms - CompleteDocument53 pagesLAWA Basic Commissioning Forms - Completemohammed_hatem0% (1)

- Smoke Control in Malls PDFDocument4 pagesSmoke Control in Malls PDFmukeshsinghtomarNo ratings yet

- HT MotorDocument25 pagesHT MotorgaladrialNo ratings yet

- Commercial Kitchen VentilationDocument59 pagesCommercial Kitchen VentilationPrabhjot BediNo ratings yet

- Kitchen Hoods: As 1668.2 - Conventional FryingDocument2 pagesKitchen Hoods: As 1668.2 - Conventional Fryingamo3330No ratings yet

- ACCUREX Hoods & Accessories PDFDocument48 pagesACCUREX Hoods & Accessories PDFdavid0775No ratings yet

- Gas Facilities Audit ChecklistDocument2 pagesGas Facilities Audit ChecklistEddie TaiNo ratings yet

- Fire Pump System Test ReportDocument12 pagesFire Pump System Test Reportcoolsummer1112143100% (2)

- AC7102.4 Rev DDocument25 pagesAC7102.4 Rev DVijay YadavNo ratings yet

- Update On The Latest SCDF Fire Code PDFDocument55 pagesUpdate On The Latest SCDF Fire Code PDFMaung AyeNo ratings yet

- Tunnel Oven PDFDocument20 pagesTunnel Oven PDFCarlos Ney100% (1)

- 5fec8c0179132328730e3526 - Fulcrum Checklist - Welding Safety Inspection ChecklistDocument5 pages5fec8c0179132328730e3526 - Fulcrum Checklist - Welding Safety Inspection ChecklistkuldeepNo ratings yet

- Start-Up Checklist For 30Xv Liquid Chillers (Remove and Use For Job File)Document8 pagesStart-Up Checklist For 30Xv Liquid Chillers (Remove and Use For Job File)MauricioNo ratings yet

- IQOQThermometerDocument9 pagesIQOQThermometerrizvi ahmadiNo ratings yet

- York Comissioning FormDocument6 pagesYork Comissioning Formfopoku2k2No ratings yet

- Its BPV Form 12 Guarded Status Steam Plants ChecklistDocument4 pagesIts BPV Form 12 Guarded Status Steam Plants ChecklistchristophermrequintoNo ratings yet

- 30RAP-6T - Check ListDocument2 pages30RAP-6T - Check ListGaray Valdovinos AlanNo ratings yet

- TP - 008 - F - Contractor Materials Test Certificate For Piping Alterations and Relocation of Heads 11.5.2021Document2 pagesTP - 008 - F - Contractor Materials Test Certificate For Piping Alterations and Relocation of Heads 11.5.2021Don WaiteNo ratings yet

- 049a AHU Checklist TemplateDocument10 pages049a AHU Checklist Templatemohamedelshrpeni0No ratings yet

- Maintenance MUGUNTHANDocument6 pagesMaintenance MUGUNTHANMugun ThanNo ratings yet

- Ariston Genus 23-27-30 MFFI - 27RFFiDocument76 pagesAriston Genus 23-27-30 MFFI - 27RFFipvale23No ratings yet

- Confined Space Entry Permit Rev 01Document3 pagesConfined Space Entry Permit Rev 01Neel Vadera100% (1)

- NGK Generator Honda EngineDocument31 pagesNGK Generator Honda EnginebcqbaoNo ratings yet

- Welding Safety Inspection ChecklistDocument6 pagesWelding Safety Inspection ChecklistDan AlbertNo ratings yet

- Manual LlenadoraDocument17 pagesManual LlenadoraFabrizio RinaldiNo ratings yet

- DT12 Automatic Dissolution Tester Quality Inspection Test: PT Andaru Persada MandiriDocument16 pagesDT12 Automatic Dissolution Tester Quality Inspection Test: PT Andaru Persada MandiriunicahayNo ratings yet

- AIP Preventive Mainteanace Week 3 March 31-2023 Inspection ReportDocument24 pagesAIP Preventive Mainteanace Week 3 March 31-2023 Inspection Reportyibelta abebeNo ratings yet

- Preventive Maintenance Suven Life Sciences LimitedDocument5 pagesPreventive Maintenance Suven Life Sciences LimitedvjchandrarNo ratings yet

- Manual de DRESSER Meter B3Document32 pagesManual de DRESSER Meter B3Maxx MamaniNo ratings yet

- HVAC Refrigeration EquipmentDocument1 pageHVAC Refrigeration EquipmentmonpetitchatshopNo ratings yet

- Informe Inspc JLG MastilDocument1 pageInforme Inspc JLG Mastilanmec20No ratings yet

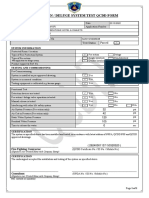

- Preaction TX GFDocument1 pagePreaction TX GFMelvin FNo ratings yet

- NAV 04 Calibration and Use of Measuring and Test EquipmentDocument5 pagesNAV 04 Calibration and Use of Measuring and Test Equipmentaaqipaper100% (1)

- Annual Sprinkler Inspection FormDocument4 pagesAnnual Sprinkler Inspection FormBryan NavarroNo ratings yet

- Standard Check List: Station: Sheet 1 of 1 Instrument: Flame Scanner SCL REF 1.8.5Document2 pagesStandard Check List: Station: Sheet 1 of 1 Instrument: Flame Scanner SCL REF 1.8.5ROUNAK MANDALNo ratings yet

- De Nora - Maintenece ChecklistDocument6 pagesDe Nora - Maintenece ChecklistBenjamin MillerNo ratings yet

- 30RAP Start-Up ProcedureDocument12 pages30RAP Start-Up ProcedureHunter BercowNo ratings yet

- Alera Operator Manual Rev 1.2Document278 pagesAlera Operator Manual Rev 1.2SIELAB C.A.No ratings yet

- Cold Cutting Guideline ChecklistDocument2 pagesCold Cutting Guideline Checklisttahatekri100% (1)

- Dresser Instalacion MantDocument28 pagesDresser Instalacion MantosmarNo ratings yet

- Eltek Sgs Pvt. LTD.: Fault Analysis Report of Field Feed Back ComplaintDocument1 pageEltek Sgs Pvt. LTD.: Fault Analysis Report of Field Feed Back Complaintsantosh kumarNo ratings yet

- MonitoringDocument1 pageMonitoringRey GeraldinoNo ratings yet

- Drying Cabinet ManualDocument10 pagesDrying Cabinet ManualwalfsNo ratings yet

- G-GD-PRS 005 Annex 9 MOC PSSRDocument4 pagesG-GD-PRS 005 Annex 9 MOC PSSRPhụng LêNo ratings yet

- AIP-Aug-PM - Inspection ReopertDocument16 pagesAIP-Aug-PM - Inspection Reopertyibelta abebeNo ratings yet

- Elevator Inspection ChecksheetDocument3 pagesElevator Inspection ChecksheetHimTex /JaswinderNo ratings yet

- Manual Hi Cart Meter ManualDocument24 pagesManual Hi Cart Meter ManualcartarNo ratings yet

- PRIMUS - Installation Qualification Checklist 2.20 - 2019Document7 pagesPRIMUS - Installation Qualification Checklist 2.20 - 2019Noé Amargo BarbosaNo ratings yet

- Checklist - Transformer Location Inspection ChecklistDocument3 pagesChecklist - Transformer Location Inspection ChecklistSachin wakeNo ratings yet

- Boss 107 Installation M1.1 PDFDocument16 pagesBoss 107 Installation M1.1 PDFEduardo E Hernandez AguirreNo ratings yet

- Checklist Alarm Check ValveDocument1 pageChecklist Alarm Check ValveMuhammad Zafarullah SialviNo ratings yet

- Annexure - Equipment Inspection Check Sheet EESLDocument13 pagesAnnexure - Equipment Inspection Check Sheet EESLaravindappiNo ratings yet

- 049b Pump ChecklistDocument13 pages049b Pump ChecklistRamy AdelNo ratings yet

- En Tor-3Document71 pagesEn Tor-3Multitech InternationalNo ratings yet

- Helix FIRST V 3602-1-5-16-E-S-400-50 (8.8 Lsec, 33 M)Document4 pagesHelix FIRST V 3602-1-5-16-E-S-400-50 (8.8 Lsec, 33 M)Aziz UllahNo ratings yet

- Tender Text: Pos - No Quant. Description PG Up / Eur TP / EurDocument4 pagesTender Text: Pos - No Quant. Description PG Up / Eur TP / EurAziz UllahNo ratings yet

- Medana CH1-L.1604-1-E-E-10T (60 USGPM, 100 FT.)Document4 pagesMedana CH1-L.1604-1-E-E-10T (60 USGPM, 100 FT.)Aziz UllahNo ratings yet

- AGN 50-200-15-2-P5 (51 m3hr, 210 FT.)Document4 pagesAGN 50-200-15-2-P5 (51 m3hr, 210 FT.)Aziz UllahNo ratings yet

- Extracted Pages From FOAM-SYSTEMDocument1 pageExtracted Pages From FOAM-SYSTEMAziz UllahNo ratings yet

- Pre - Start Up Checklist: S.No. DescriptionDocument2 pagesPre - Start Up Checklist: S.No. DescriptionAziz UllahNo ratings yet

- Extracted Pages From FOAM-SYSTEMDocument1 pageExtracted Pages From FOAM-SYSTEMAziz UllahNo ratings yet

- General Notes: D.P.W.HDocument1 pageGeneral Notes: D.P.W.HJemil Rose SamosNo ratings yet

- 380 Melb Sales Manual 15march2019Document15 pages380 Melb Sales Manual 15march2019Tamara SisilNo ratings yet

- CMC 2010Document389 pagesCMC 2010tyger089No ratings yet

- Checklist NFPA 96Document56 pagesChecklist NFPA 96Carlos VagnoniNo ratings yet

- PPC-Catalogue BookletDocument11 pagesPPC-Catalogue BookletSibashis DharNo ratings yet

- Chapter 7 Notes (6 Slides Per Page) (B - W)Document11 pagesChapter 7 Notes (6 Slides Per Page) (B - W)Nabil JefriNo ratings yet

- Dual User Guide V2.0Document33 pagesDual User Guide V2.0JC MartinezNo ratings yet

- Manual For The Installation, Use and Maintenance of Decorative Hoods Üzembehelyezési, Használati És Karbantartási Útmutató Konyhai SzagelszívókhozDocument8 pagesManual For The Installation, Use and Maintenance of Decorative Hoods Üzembehelyezési, Használati És Karbantartási Útmutató Konyhai Szagelszívókhozpannika763299No ratings yet

- Pricing and Profit Calculating For Daraz by Peel - PKDocument29 pagesPricing and Profit Calculating For Daraz by Peel - PKMuhammad Mehran Khan AttariNo ratings yet

- R 102 Manual PDFDocument141 pagesR 102 Manual PDFEvi SceradorNo ratings yet

- Kitchen Hood Cleaning Checklist-1-2Document2 pagesKitchen Hood Cleaning Checklist-1-2zaimNo ratings yet

- SS 350 DSH WebDocument2 pagesSS 350 DSH WebDavid RivardNo ratings yet

- 08 - Kitchen Exhaust Systems - 2.10Document3 pages08 - Kitchen Exhaust Systems - 2.10Anonymous BbZceWkVnNo ratings yet

- Halton KVL-2 With UnderhangDocument7 pagesHalton KVL-2 With Underhanging_ballesterosNo ratings yet

- Fixed AssetDocument81 pagesFixed Assetphạm giangNo ratings yet

- NRC98DV Installation Manual 2017Document42 pagesNRC98DV Installation Manual 2017tankerueNo ratings yet

- Ikea Catalogue enDocument165 pagesIkea Catalogue enVulturu AlinaNo ratings yet

- RydAiR Kitchen Exhaust 4 Pgs HI ResDocument4 pagesRydAiR Kitchen Exhaust 4 Pgs HI Resnashal kkNo ratings yet

- 2021 Designer Inclusions Brochure Coral HomesDocument25 pages2021 Designer Inclusions Brochure Coral Homeskmae dizonNo ratings yet

- The World's Most Extensive Selection of Ductless Fume Hoods.Document9 pagesThe World's Most Extensive Selection of Ductless Fume Hoods.Alejandro Ceron GuerreroNo ratings yet