Professional Documents

Culture Documents

AIP-Aug-PM - Inspection Reopert

Uploaded by

yibelta abebe0 ratings0% found this document useful (0 votes)

2 views16 pagesOriginal Title

AIP-Aug-PM -Inspection reopert

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views16 pagesAIP-Aug-PM - Inspection Reopert

Uploaded by

yibelta abebeCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 16

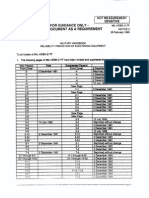

INDUSTRIAL PARKS DEVELOPMENT

CORPORATION

ADAMA INDUSTRIAL PARK

ENGINEERING AND MAINTENANCE DEPARTMENT

PREVENTIVE MAINTENANCE WEEK 4 INSPECTION REPORT

Daily transformer inspection of OSS

Daily transformer inspection checklist

CS Number:- AIP Location:- OSS Week:- Type:- Dry type transformer

W TEMP0C= Date:-31-07-2023 Enclosed( ) Open ( )

A=48,B=58.3,C=53

Humidity%= Feeder No:- OBFR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions It is dry type

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges. It is dry type

4 Visual inspection of oil leakages It is dry type

5 Check proper rotating direction of oil pumps. (If It is dry type

exist)

6 Check flow indicators of oil pumps. (If exist) It is dry type

7 Inspect cooling fans and radiators for cleanliness

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

DAILY TRANSFORMER INSPECTION OF POWER HOUSE

Daily transformer inspection checklist

CS Number:- AIP Location:- Power Week:- Type:- Dry type transformer

W,TEMP0C= house Date:-31-07-2023 Enclosed( ) Open ( )

A=39.5,B =38 C

=37.8

Humidity%= Feeder No:- PDR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions It is dry type

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges. It is dry type

4 Visual inspection of oil leakages It is dry type

5 Check proper rotating direction of oil pumps. (If It is dry type

exist)

6 Check flow indicators of oil pumps. (If exist) It is dry type

7 Inspect cooling fans and radiators for cleanliness

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Daily transformer inspection for waste water treatment plant

Daily transformer inspection checklist

CS Number:- AIP Location:- waste Week:- Type:- Oil immersed

TEMP0C= WT 55 Water Date:-31-7-2023 Enclosed( ) Open ( )

OT=55 treatment(ZLD)

Humidity%= Feeder No:- Inspected by:- Dead inspection is required

Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges.

4 Visual inspection of oil leakages

5 Check proper rotating direction of oil pumps. (If There is no oil pump motor

exist)

6 Check flow indicators of oil pumps. (If exist) There is no oil pump motor

7 Inspect cooling fans and radiators for cleanliness

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Monthly RMU inspection for OSS

Daily transformer inspection checklist

CS Number:- AIP Location:- OSS Week:- Type AC gas insulated switch gear

TEMP0C= Date:-1-8-2023 Enclosed( ) Open ( )

Humidity%= Feeder No:-OBFR 01 Inspected by:- Dead inspection is required

& 02 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Check bus and support enclosure for defects such

as cracked welds, chipped porcelain, cracked

insulation, etc., and free of dust accumulation.

2 Verify that all front panel mounted devices

(meters, push buttons, switches, indicator lamps,

etc.) are functional.

3 Check for correct all disconnected and grounding

switches

4 Check if there is any leakage of the cooling

medium (SF6) gas

5 Check for correct spring status indication (spring

charged/discharged).

6 Check for the capacitive voltage value. It only blink not display voltage

value

7 Check the correctness of CT and PT ratio CT ration indication is not

indicated on the RMU. working.

9 Other Remarks:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Monthly dry type transformer inspection of OSS

Daily transformer inspection checklist

CS Number:- AIP Location:- OSS Week:- Type:- Dry type transformer

W TEMP0C= Date:-1-08-2023 Enclosed( ) Open ( )

A=40.5,B=52.8,C=47.9

Humidity%= Feeder No:- OBFR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Ye No Remark (If not what measures

s taken or should be taken

1 Check for cracks and dirt deposit on the

bushings.

2 Verify that the transformer cooling systems

(fans) are functioning properly.

3 Check for any signs of overheating, such as a

burning smell or hot spots, and investigate any

issues promptly.

4 Check the transformer's control system and Transformer protection and

monitoring equipment, to ensure it is monitoring relay is not working.

functioning properly.

5 Perform a visual inspection of the transformer's

exterior for any signs of leaks or other

abnormalities.

6 Verify that the transformer is operating within Based on transformer

its rated temperature range and address any temperature control it works

issues promptly. properly.

7 Verify that air vents and filters are clean and

unobstructed.

8 Inspect the transformer's enclosure for any signs

of damage, such as cracks or corrosion.

9 Other Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by___________________

DAILY TRANSFORMER INSPECTION OF POWER HOUSE

Daily transformer inspection checklist

CS Number:- AIP Location:- Power Week:- Type:- Dry type transformer

W,TEMP0C= house Date:-1-8-2023 Enclosed( ) Open ( )

A=37.4 B=36.2

C=35.3

Humidity%= Feeder No:- PDR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions It is dry type

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges. It is dry type

4 Visual inspection of oil leakages It is dry type

5 Check proper rotating direction of oil pumps. (If It is dry type

exist)

6 Check flow indicators of oil pumps. (If exist) It is dry type

7 Inspect cooling fans and radiators for cleanliness

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Daily transformer inspection for waste water treatment plant

Daily transformer inspection checklist

CS Number:- AIP Location:- waste Week:- Type:- Oil immersed

TEMP0C= WT 55 Water Date:-1-8-2023 Enclosed( ) Open ( )

OT=55 treatment(ZLD)

Humidity%= Feeder No:- Inspected by:- Dead inspection is required

Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges.

4 Visual inspection of oil leakages

5 Check proper rotating direction of oil pumps. (If There is no oil pump motor

exist)

6 Check flow indicators of oil pumps. (If exist) There is no oil pump motor

7 Inspect cooling fans and radiators for cleanliness

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Monthly RMU inspection for Power house

Daily transformer inspection checklist

CS Number:- AIP Location:- power Week:- Type AC gas insulated switch gear

TEMP0C= house Date:-2-8-2023 Enclosed( ) Open ( )

Humidity%= Feeder No:-PDR 01 Inspected by:- Dead inspection is required

& 02 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Check bus and support enclosure for defects such

as cracked welds, chipped porcelain, cracked

insulation, etc., and free of dust accumulation.

2 Verify that all front panel mounted devices

(meters, push buttons, switches, indicator lamps,

etc.) are functional.

3 Check for correct all disconnected and grounding

switches

4 Check if there is any leakage of the cooling

medium (SF6) gas

5 Check for correct spring status indication (spring

charged/discharged).

6 Check for the capacitive voltage value. It shows that power incoming

signal but not show its value.

7 Check the correctness of CT and PT ratio CT ratio indicator is not showing

indicated on the RMU. any value.

9 Other Remarks:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Monthly dry type transformer inspection of power house

Daily transformer inspection checklist

CS Number:- AIP Location:- OSS Week:- Type:- Dry type transformer

0

W TEMP C= Date:-2-08-2023 Enclosed( ) Open ( )

A=34.8,B=32.1,C=33.1

Humidity%= Feeder No:- PDR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Ye No Remark (If not what measures

s taken or should be taken

1 Check for cracks and dirt deposit on the

bushings.

2 Verify that the transformer cooling systems

(fans) are functioning properly.

3 Check for any signs of overheating, such as a

burning smell or hot spots, and investigate any

issues promptly.

4 Check the transformer's control system and Transformer protection and

monitoring equipment, to ensure it is monitoring device is not

functioning properly. working.

5 Perform a visual inspection of the transformer's

exterior for any signs of leaks or other

abnormalities.

6 Verify that the transformer is operating within Based on transformer

its rated temperature range and address any temperature cooling system it

issues promptly. works properly. Fan starting

working fan star value

temperature equal to

transformer winding

temperature.

7 Verify that air vents and filters are clean and

unobstructed.

8 Inspect the transformer's enclosure for any signs

of damage, such as cracks or corrosion.

9 Other Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by____________________

Daily transformer inspection of OSS

Daily transformer inspection checklist

CS Number:- AIP Location:- OSS Week:- Type:- Dry type transformer

W TEMP0C= Date:-2-08-2023 Enclosed( ) Open ( )

A=48,B=58.3,C=53

Humidity%= Feeder No:- OBFR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions It is dry type

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges. It is dry type

4 Visual inspection of oil leakages It is dry type

5 Check proper rotating direction of oil pumps. (If It is dry type

exist)

6 Check flow indicators of oil pumps. (If exist) It is dry type

7 Inspect cooling fans and radiators for cleanliness Only axial fans are existed.

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Daily transformer inspection for waste water treatment plant

Daily transformer inspection checklist

CS Number:- AIP Location:- waste Week:- Type:- Oil immersed

TEMP0C= WT 55 Water Date:-2-8-2023 Enclosed( ) Open ( )

OT=55 treatment(ZLD)

Humidity%= Feeder No:- Inspected by:- Dead inspection is required

Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges.

4 Visual inspection of oil leakages

5 Check proper rotating direction of oil pumps. (If There is no oil pump motor

exist)

6 Check flow indicators of oil pumps. (If exist) There is no oil pump motor

7 Inspect cooling fans and radiators for cleanliness

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

Monthly RMU inspection for Waste water treatment

Daily transformer inspection checklist

CS Number:- AIP Location:- ZLD Week:- Type AC gas insulated switch gear

TEMP0C= Date:-3-8-2023 Enclosed( ) Open ( )

Humidity%= Feeder No:- Inspected by:- Dead inspection is required

Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Check bus and support enclosure for defects such

as cracked welds, chipped porcelain, cracked

insulation, etc., and free of dust accumulation.

2 Verify that all front panel mounted devices

(meters, push buttons, switches, indicator lamps,

etc.) are functional.

3 Check for correct all disconnected and grounding

switches

4 Check if there is any leakage of the cooling

medium (SF6) gas

5 Check for correct spring status indication (spring

charged/discharged).

6 Check for the capacitive voltage value. It shows that power incoming

signal but not show its value.

7 Check the correctness of CT and PT ratio

indicated on the RMU.

9 Other Remarks:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by____________________

Monthly Oil type transformer inspection of Waste water treatment

Transformer (Oil type) Monthly inspection checklist

CS Number:- AIP Location:- ZLD Week:- Type:- Dry type transformer

W TEMP0C= Date:-3-08-2023 Enclosed( ) Open ( )

WT=55,OTI=55

Humidity%= Feeder No:- PDR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Check for cracks and dirt deposit on the bushings.

2 Check for any signs of physical damage, such as

cracks, dents, or discoloration, and address any

issues promptly.

3

4

5

6

7

8

9 Other Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by____________________

DAILY TRANSFORMER INSPECTION OF POWER HOUSE

Daily transformer inspection checklist

CS Number:- AIP Location:- Power Week:- Type:- Dry type transformer

W,TEMP0C= house Date:-04-8-2023 Enclosed( ) Open ( )

A=33.6 B=31.6

C=32.8

Humidity%= Feeder No:- PDR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions It is dry type

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges. It is dry type

4 Visual inspection of oil leakages It is dry type

5 Check proper rotating direction of oil pumps. (If It is dry type

exist)

6 Check flow indicators of oil pumps. (If exist) It is dry type

7 Inspect cooling fans and radiators for cleanliness

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

DAILY TRANSFORMER INSPECTION OF OSS

Daily transformer inspection checklist

CS Number:- AIP Location:- OSS Week:- Type:- Dry type transformer

W TEMP0C= Date:-4-08-2023 Enclosed( ) Open ( )

A=46.3,B=61.8,

C=53.3

Humidity%= Feeder No:- OBFR- Inspected by:- Dead inspection is required

AH04 Yes ( ) No ( )

No Inspection Yes No Remark (If not what measures

taken or should be taken

1 Visual inspection of valve positions It is dry type

2 Visual inspection of temperature indicators

3 Visual inspection of level gauges. It is dry type

4 Visual inspection of oil leakages It is dry type

5 Check proper rotating direction of oil pumps. (If It is dry type

exist)

6 Check flow indicators of oil pumps. (If exist) It is dry type

7 Inspect cooling fans and radiators for cleanliness Only axial fans are existed.

and fans for proper rotation.

8 Inspect visually identified vibrations on the

transformer.

9 Remark:-

Inspected by__________________ Check and approved _________________

Signature by__________________ Signature by_____________________

You might also like

- Inspection Report Week 1 AprilDocument5 pagesInspection Report Week 1 Aprilyibelta abebeNo ratings yet

- AIP July Inspection ReportDocument1 pageAIP July Inspection Reportyibelta abebeNo ratings yet

- AIP-Preventive Maintenance Week 4 - Inspecton Report April 13-2023Document39 pagesAIP-Preventive Maintenance Week 4 - Inspecton Report April 13-2023yibelta abebeNo ratings yet

- AIP Preventive Mainteanace Week 3 March 31-2023 Inspection ReportDocument24 pagesAIP Preventive Mainteanace Week 3 March 31-2023 Inspection Reportyibelta abebeNo ratings yet

- Standard Operating Procedure: Operation and Preventive Maintenance of TransformersDocument5 pagesStandard Operating Procedure: Operation and Preventive Maintenance of TransformersMaryanthony NamyaloNo ratings yet

- HT-LN Process Audit SEP 2020Document2 pagesHT-LN Process Audit SEP 2020Ram KumarNo ratings yet

- DEC Transformer Monthly Inspection ChecklistDocument14 pagesDEC Transformer Monthly Inspection ChecklistlegasuNo ratings yet

- Generator PM ChecklistDocument2 pagesGenerator PM ChecklistYan's Senora Bescoro100% (3)

- Maintenance Schedule For SubstationDocument21 pagesMaintenance Schedule For SubstationSajid Shaikh100% (1)

- Halliburton: MO# OK F Fail (Create RPM Order) N/A Not ApplicableDocument4 pagesHalliburton: MO# OK F Fail (Create RPM Order) N/A Not ApplicableKhalfan Al HabsiNo ratings yet

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDocument3 pages6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARNo ratings yet

- PM Schedule Plan For All MachinesDocument32 pagesPM Schedule Plan For All MachineskumaresanNo ratings yet

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESDocument3 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESkaleem ullah janNo ratings yet

- Mud Pump - High Pressure Lines PDFDocument7 pagesMud Pump - High Pressure Lines PDFKaleem UllahNo ratings yet

- Maintenance Procedures of Electrical EquipmentDocument4 pagesMaintenance Procedures of Electrical EquipmentEdwin Cob GuriNo ratings yet

- Lead Stringer Monthly Check ListDocument2 pagesLead Stringer Monthly Check ListkotimarriagephotosNo ratings yet

- HT CARB Process Audit SEP 2020Document2 pagesHT CARB Process Audit SEP 2020Ram KumarNo ratings yet

- HWDocument20 pagesHWAnonymous zpitrB80oNo ratings yet

- Power Transformer Pre Commisioning ChecklistDocument26 pagesPower Transformer Pre Commisioning ChecklistRajesh TK100% (2)

- Autoclave PPMDocument5 pagesAutoclave PPMZaheer Ahmad100% (1)

- 8-Maintenance and InspectionDocument10 pages8-Maintenance and InspectionmominzadahNo ratings yet

- stc12017q0002 - Post Provided Generator Checklist PDFDocument13 pagesstc12017q0002 - Post Provided Generator Checklist PDFAnand KrishnanNo ratings yet

- QMLSF-4!7!2020-016 螺杆空压机开关机点检表 Daily Check List for Screw Air Compressor SwitchingDocument1 pageQMLSF-4!7!2020-016 螺杆空压机开关机点检表 Daily Check List for Screw Air Compressor SwitchingJeevan RajNo ratings yet

- Maintenance of TransformerDocument4 pagesMaintenance of Transformerdownload4sumitNo ratings yet

- CL GL Hal Ni 205Document4 pagesCL GL Hal Ni 205LismiantoNo ratings yet

- 3e PSCDocument3 pages3e PSCsagar masandNo ratings yet

- Standby GeneratorDocument11 pagesStandby Generatortecmak AngolaNo ratings yet

- Void SubstationDocument46 pagesVoid SubstationPrabhat HambireNo ratings yet

- Equipment Group:: Intermediate Inspection Criteria, Well Control EquipmentDocument2 pagesEquipment Group:: Intermediate Inspection Criteria, Well Control Equipmentkaleem ullah janNo ratings yet

- National Transmission and Despatch Company Mechanicalchecks, Visualinspections and ElectricaltestsDocument22 pagesNational Transmission and Despatch Company Mechanicalchecks, Visualinspections and Electricaltestsmirmunum100% (1)

- ACMV Maintenance Check ListDocument7 pagesACMV Maintenance Check ListHtet Linn Aung100% (2)

- Form Inspeksi Concrete PumpDocument1 pageForm Inspeksi Concrete PumpSeptian Syahputra100% (1)

- Transformer Daily Checklist Month:: Description of The Equipment Location CapacityDocument10 pagesTransformer Daily Checklist Month:: Description of The Equipment Location Capacityabdulkadir aliNo ratings yet

- PMT Format NewDocument38 pagesPMT Format NewNeeraj SinghNo ratings yet

- Checklist of DU250 & DU400Document9 pagesChecklist of DU250 & DU400MadanBhadoriyaNo ratings yet

- Nglo Astern Roup: Checklist For Steering Gear Testing & ChecksDocument1 pageNglo Astern Roup: Checklist For Steering Gear Testing & ChecksSourabh Harel100% (1)

- Emergency Generator MaintenanceDocument8 pagesEmergency Generator MaintenanceGerardo Rubio100% (1)

- Maintenance Manual - TD-TSP-0004-2A PDFDocument19 pagesMaintenance Manual - TD-TSP-0004-2A PDFSidhartha MallickNo ratings yet

- Precommissioning Test FormatDocument72 pagesPrecommissioning Test Formatashutosh2009100% (3)

- Weekly Fire Pump Inspection ChecklistDocument2 pagesWeekly Fire Pump Inspection Checklistkhalid_ghafoor6226100% (6)

- JXFM325 132e 05SDocument4 pagesJXFM325 132e 05SgiahaoNo ratings yet

- Несення Вахти в МКОDocument1 pageНесення Вахти в МКОВалерий РыбалкаNo ratings yet

- MJR For 30M Maintenance Check of Check ValvesDocument9 pagesMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- High Pressure Lines PDFDocument3 pagesHigh Pressure Lines PDFKaleem UllahNo ratings yet

- Instruction Value: Generator SkidDocument4 pagesInstruction Value: Generator Skiddima65No ratings yet

- HVAC Maintenance Checklist Template Iauditor Sample ReportDocument11 pagesHVAC Maintenance Checklist Template Iauditor Sample Reportravi badariyaNo ratings yet

- OverheatingDocument31 pagesOverheatingCosmicdancer RudraNo ratings yet

- Commissioning Methodologies (CM) - MUS 11 PAC Unit Testing Method StatementDocument3 pagesCommissioning Methodologies (CM) - MUS 11 PAC Unit Testing Method StatementMazen OudNo ratings yet

- Autonomous Maintenance Standards & ChecklistDocument4 pagesAutonomous Maintenance Standards & ChecklistPanch BNo ratings yet

- Revise Periodic PMS ChecklistDocument21 pagesRevise Periodic PMS Checklistjherson gravides100% (3)

- SLPG Gtg-2yDocument5 pagesSLPG Gtg-2yAshraf MohammedNo ratings yet

- Land Rover Fault CodesDocument4 pagesLand Rover Fault Codesajac29630100% (2)

- Form Inspeksi CompressorDocument1 pageForm Inspeksi CompressorekoimampNo ratings yet

- Manual de DRESSER Meter B3Document32 pagesManual de DRESSER Meter B3Maxx MamaniNo ratings yet

- AC Installation - Testing Form Template - Chiller UnitDocument6 pagesAC Installation - Testing Form Template - Chiller UnitVincent LeeNo ratings yet

- PPM Task Sheet - MPGSDocument4 pagesPPM Task Sheet - MPGSJacobNo ratings yet

- Checklist For Shunt Reactor Rev01Document4 pagesChecklist For Shunt Reactor Rev01Santhosh Kumar VinayagamNo ratings yet

- RMS - Boiler Maintenance & Periodic Testing ChecklistDocument5 pagesRMS - Boiler Maintenance & Periodic Testing ChecklistERplant RefinersNo ratings yet

- Gauging Manual Rev 1.6Document22 pagesGauging Manual Rev 1.6ابوالحروف العربي ابوالحروفNo ratings yet

- Generaror Inspection ChecklistDocument1 pageGeneraror Inspection Checklistyibelta abebeNo ratings yet

- Week 4 Inspection ReportDocument19 pagesWeek 4 Inspection Reportyibelta abebeNo ratings yet

- April 2-2023Document4 pagesApril 2-2023yibelta abebeNo ratings yet

- AIP - Shed-Week - Two - Jan-2024 Inspection ReportDocument14 pagesAIP - Shed-Week - Two - Jan-2024 Inspection Reportyibelta abebeNo ratings yet

- AIP - Shed-Week - Two - Jan-2024 Inspection ReportDocument14 pagesAIP - Shed-Week - Two - Jan-2024 Inspection Reportyibelta abebeNo ratings yet

- AIP-Shed-week One-Inspection ReportDocument15 pagesAIP-Shed-week One-Inspection Reportyibelta abebeNo ratings yet

- Chapter Four Earthing Systems and Lightning ProtectionDocument7 pagesChapter Four Earthing Systems and Lightning Protectionyibelta abebeNo ratings yet

- Wiring Material and AccessoryDocument13 pagesWiring Material and AccessoryKinfe Dufera GonfaNo ratings yet

- Chapter 1 Electrical SafetyDocument5 pagesChapter 1 Electrical Safetyyibelta abebeNo ratings yet

- Chapter 5bestDocument10 pagesChapter 5bestyibelta abebeNo ratings yet

- Protection Principles and ComponentsDocument57 pagesProtection Principles and Componentsyibelta abebeNo ratings yet

- Circuit Breaker RatingsDocument75 pagesCircuit Breaker Ratingsyibelta abebeNo ratings yet

- 2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredDocument7 pages2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredAbhijeet KulkarniNo ratings yet

- Chapter-3 Electrical Protection System PDFDocument101 pagesChapter-3 Electrical Protection System PDFBalachandra MallyaNo ratings yet

- Power Contactor 1250 A - HubbellDocument4 pagesPower Contactor 1250 A - Hubbellmanuel99a2kNo ratings yet

- How To Build A 8x8x8 Led Cube (English Version)Document21 pagesHow To Build A 8x8x8 Led Cube (English Version)Rajesh DasNo ratings yet

- D3 K XL Cat - Sis Electrico PDFDocument6 pagesD3 K XL Cat - Sis Electrico PDFFranco Korn100% (7)

- Y212 EN2 06+IndAutoSelection2016Document420 pagesY212 EN2 06+IndAutoSelection2016Luis RolaNo ratings yet

- C03 - HVSG 11Document20 pagesC03 - HVSG 11princensikan23No ratings yet

- 4 JB 1Document60 pages4 JB 1Rex Palmitos100% (1)

- Te43 CabinetDocument68 pagesTe43 CabinetAravind BalajiNo ratings yet

- Making A Pendant For Mach With PoKeysRev3Document11 pagesMaking A Pendant For Mach With PoKeysRev3Jack SparowNo ratings yet

- Remote Control ManualDocument3 pagesRemote Control ManualcssohNo ratings yet

- Operating Manual: Touchmatrix Indicator Dx350 / Dx355Document67 pagesOperating Manual: Touchmatrix Indicator Dx350 / Dx355Jonathas SilvaNo ratings yet

- Manual Bomba WalchemDocument32 pagesManual Bomba WalchemCésar Rosillo MateosNo ratings yet

- ABB Disconnectors OWD OWIII - EN - 16-04 PDFDocument36 pagesABB Disconnectors OWD OWIII - EN - 16-04 PDFAndrew SisonNo ratings yet

- 3) 4H.1790.06.0.00 Etp Installation Instruction DocumentDocument13 pages3) 4H.1790.06.0.00 Etp Installation Instruction DocumentAlfiya AnamNo ratings yet

- Growatt MAX 50-80KTL3 LV MV User ManualDocument35 pagesGrowatt MAX 50-80KTL3 LV MV User ManualEder JofreNo ratings yet

- Notes On Tripping RelaysDocument7 pagesNotes On Tripping RelaysSenthil KumarNo ratings yet

- Ose 5-91 2066-9001-200-Im PDFDocument210 pagesOse 5-91 2066-9001-200-Im PDFironite100% (1)

- SM6-36 Catalog AMTED396006V1EN PDFDocument64 pagesSM6-36 Catalog AMTED396006V1EN PDFJuan E Torres MNo ratings yet

- Woodward Peak 150 - 85549 PDFDocument4 pagesWoodward Peak 150 - 85549 PDFJose Luis Castro AguilarNo ratings yet

- Military HandbookDocument80 pagesMilitary HandbookLuthfyatma HardyNo ratings yet

- MC Balance 2002 Manual English V3.0Document27 pagesMC Balance 2002 Manual English V3.0Dandy ChavezNo ratings yet

- Crane Failure Investigation Report Rowan Gorilla - PCM 350SS CraneDocument3 pagesCrane Failure Investigation Report Rowan Gorilla - PCM 350SS CranesyedainahmadNo ratings yet

- Easy 512 DC RDocument13 pagesEasy 512 DC RHaris MašićNo ratings yet

- Alba D-52L User ManualDocument24 pagesAlba D-52L User ManualdrmassterNo ratings yet

- InternshipDocument25 pagesInternshipLohitNo ratings yet

- Digital Multimeter User Manual: B35 (T) (+) D35 (T) B41T (+)Document55 pagesDigital Multimeter User Manual: B35 (T) (+) D35 (T) B41T (+)peladillanetNo ratings yet

- Electronic Circuit Design and Component Selection PDFDocument46 pagesElectronic Circuit Design and Component Selection PDFAnand ShekhawatNo ratings yet

- ES16RS Operation ManualDocument53 pagesES16RS Operation ManualM DJNo ratings yet

- Installation and Operating Manual Model 440/450 Electronic SwitchDocument17 pagesInstallation and Operating Manual Model 440/450 Electronic SwitchignacioramirezNo ratings yet

- C5G Tech Specs enDocument65 pagesC5G Tech Specs enСања БанковићNo ratings yet

- Operation Manual of Air Permeability TesterDocument23 pagesOperation Manual of Air Permeability TesterCẩm Chướng Huỳnh NgọcNo ratings yet