Professional Documents

Culture Documents

Commissioning Methodologies (CM) - MUS 11 PAC Unit Testing Method Statement

Uploaded by

Mazen Oud0 ratings0% found this document useful (0 votes)

10 views3 pagesOriginal Title

MUS-11_PAC_Unit_testing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

10 views3 pagesCommissioning Methodologies (CM) - MUS 11 PAC Unit Testing Method Statement

Uploaded by

Mazen OudCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

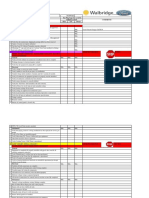

Commissioning Methodologies (CM) – MUS‐11

PAC Unit Testing Method Statement

Client: Project Name: Project No:

Area: Drawing No’s: Date: Sheet: 1 of 2

Check Signature: Check Approved By: Signature:

Conducted

By:

INTRODUCTION

The test procedure guideline has been prepared to explain the minimum standard for testing packaged air

conditioning units.

Procedure recommended general checks

1. Visibly check installation against approved shop drawings

2. Check that general construction and standard of finish is acceptable

3. Check levelling and alignment of packaged units on anti-vibration mounts is acceptable

4. Check that adequate access for maintenance is provided both at ceiling level and at each unit

5. Record nameplate information and compare against approved specification

6. Confirm all transit bolts, wedges, motor packing and vibration packing and the like are removed

7. Check that condenser water is available at each unit and is ready for use, has been pressured tested and

water balanced and have adequate measuring facilities for flow, pressure and temperature

8. Check all upstream and downstream duct work systems are complete and free of dust or hazards

9. Confirm air balance both upstream and downstream of the unit has been completed

10. Confirm no damage to the electric components

11. Confirm all electrical terminals are correctly tightened

12. Check power supply is isolated, has the correct power source, voltage circuit breaker sizing

13. Check all control items have been fitted to each unit and that they are sealed to avoid air leakage

14. Check condensate drain pans can fully drain

15. Confirm condensate drain trap is adequate for fan suction with fan operating with dirty filters

16. Check heat exchanger and refrigerant coils are not damaged

17. Check fans are free to rotate

18. Bump spin fans to confirm rotation and operation

Procedure recommended for testing operation

1. Confirm condenser water solenoid valves are working correctly by adjusting the set point and observe valve

operating, disconnect power and verify that valve can be manually overridden

2. With the condenser water passing through the unit record the condenser water flow rate, differential pressure

across the unit, entering water and leaving water temperature, air entering and leaving temperature from the

unit

3. With the unit operating at full capacity record the amps of the unit

4. Operational test in AUTO mode to verify that the unit operates without alarms present

5. Operational test in AUTO mode to verify that unit can satisfy temperature set points

6. Operational test to verify that the alarms operate for high temperature, blocked filter, unit fault as applicable

REFERENCE STANDARDS

CIBSE Commissioning Code W – Water Distribution Systems

NEBB Procedural Standards for Testing Adjusting and Balancing of Environmental Systems

Commissioning Methodologies (CM) – MUS‐11

PAC Unit Testing Method Statement

CHECKLIST

PAC Unit Reference

Drawing Number

VERIFICATION RESULT RESULT RESULT

ITEM METHOD

Check installation against approved shop drawings Site Inspection

1

Site Inspection

2 Check installation and finish is acceptable with coils undamaged

Site Inspection

3 Check unit level and alignment on vibration isolation is acceptable

Site Inspection

4 Check access for maintenance is acceptable

Site Inspection

5 Confirm all transit bolts, wedges etc. have been removed

Site Inspection

6 Check fans are free to rotate

Site Inspection

7 Check condenser water flows are available

Site Inspection

8 Check all duct work connected to units is complete and filters are

fitted

Site Inspection

9 Check all electrical connections and confirm acceptance

Bump spin fan and check correct rotation and VSD operation (as Site Inspection

10 applicable)

Site Inspection

11 Check all control devices are fitted and are air tight

Site Inspection

12 Check condensate trays are fully drained and that trap is sized to

suit operating pressure of the fan with dirty filters

Site Inspection

13 Verify fan and motor speeds and unit amps at full design loading

Site Inspection

14 Check operation of pressure switches, temperature sensors for

accuracy, solenoid valves for operation, fan/unit fault/trips, dirty

filter alarm

Site Inspection

15 Operational test in AUTO mode to verify units run without alarms

Site Measurement

16 Run system in AUTO mode and verify EWT, LWT, EAT (°CDB and

°CWB), LAT (°CDB, °CWB)

Site measurement

17 Verify unit achieves room set point temperature

Site Inspection

18 Check fire trip operation

Commissioning Methodologies (CM) – MUS‐11

PAC Unit Testing Method Statement

Certified By Sub Contractor (initial):

Date:

Confirmed By (Head Contractor / Client) (initial):

Date:

You might also like

- Commissioning Methodologies (CM) – MUS-06Document3 pagesCommissioning Methodologies (CM) – MUS-06JM ArcillaNo ratings yet

- MUS-5 Cooling Tower TestingDocument3 pagesMUS-5 Cooling Tower TestingHaider FaresNo ratings yet

- Testing & Commissioning of Chilled Water Pressurization UnitsDocument3 pagesTesting & Commissioning of Chilled Water Pressurization Unitsvin ssNo ratings yet

- Method Statement For Precommissioning & Commissioning of Close Control Units CCU'sDocument3 pagesMethod Statement For Precommissioning & Commissioning of Close Control Units CCU'svin ssNo ratings yet

- Commissioning Methodologies (CM) - MUS-07 Water Balancing Method StatementDocument2 pagesCommissioning Methodologies (CM) - MUS-07 Water Balancing Method StatementFahad MuhammadNo ratings yet

- Air Handling Units COB AHU-10ADocument3 pagesAir Handling Units COB AHU-10AHernan RomeroNo ratings yet

- Checklist For Installation of Chemical Fire Suppression SystemDocument1 pageChecklist For Installation of Chemical Fire Suppression Systembeho2000100% (1)

- S.No Characteristics: Checklist Commissioning For Foam TankDocument4 pagesS.No Characteristics: Checklist Commissioning For Foam TanknathisonsNo ratings yet

- Testing, Adjusting, and Balancing (TABDocument5 pagesTesting, Adjusting, and Balancing (TABtristan guarinoNo ratings yet

- Pre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5Document5 pagesPre-Commissioning Checklist For New Assets Water Sites: Page 1 of 5u nizami0% (1)

- Commissioning Check Sheet For Air Distribution SystemDocument1 pageCommissioning Check Sheet For Air Distribution SystemvoNo ratings yet

- Testing & Commissioning of Split Air Conditioning AC UnitsDocument3 pagesTesting & Commissioning of Split Air Conditioning AC Unitsvin ssNo ratings yet

- Checklist For Testing Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing Commissioning of Sprinkler SystemMuhammad Fathullah bin SuhailiNo ratings yet

- Method Statement For Testing & Commissioning of Smoke Extract FansDocument3 pagesMethod Statement For Testing & Commissioning of Smoke Extract Fansvin ssNo ratings yet

- AHU Operation Qualification TestingDocument21 pagesAHU Operation Qualification TestingMohammadNo ratings yet

- Checklist For Testing & Commissioning of Sprinkler SystemDocument2 pagesChecklist For Testing & Commissioning of Sprinkler Systembeho2000100% (6)

- Method Statement For Testing & Commissioning of Fresh Air Handling Units FAHUs With Heat Recovery Wheel SystemDocument4 pagesMethod Statement For Testing & Commissioning of Fresh Air Handling Units FAHUs With Heat Recovery Wheel Systemvin ssNo ratings yet

- Method Statement For Precommissioning & Commissioning of Extract FansDocument3 pagesMethod Statement For Precommissioning & Commissioning of Extract Fansvin ssNo ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument2 pagesTesting & Commissioning of Fan Coil Units FCU'sDong VanraNo ratings yet

- Commissioning Methodologies (CM) - MUBS-12 Modulating Valve + Actuator Testing Method StatementDocument3 pagesCommissioning Methodologies (CM) - MUBS-12 Modulating Valve + Actuator Testing Method StatementNikhil AggarwalNo ratings yet

- Method Statement of Sprinkler System Without LogoDocument9 pagesMethod Statement of Sprinkler System Without LogokiranramNo ratings yet

- Work Method StatementDocument6 pagesWork Method StatementbnmqweNo ratings yet

- Pre Commiss. Check List Chilled Water PumpsDocument3 pagesPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- CO2 Sensor Testing Method StatementDocument3 pagesCO2 Sensor Testing Method StatementReginaNo ratings yet

- MS-FIRE-001 - Automatic Sprinkler Circuit TestingDocument8 pagesMS-FIRE-001 - Automatic Sprinkler Circuit TestingKo KoNo ratings yet

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- Testing-Commissioning-Checklist-for-Fuel-PumpDocument1 pageTesting-Commissioning-Checklist-for-Fuel-PumpMoh'd SameerNo ratings yet

- 557113822Document7 pages557113822Billy BrownNo ratings yet

- Method Statement T&C FIRE PROTECTION SYSTEMDocument10 pagesMethod Statement T&C FIRE PROTECTION SYSTEMcic engineeringNo ratings yet

- Testing & Commissioning Procedure For Staircase Pressurisation SystemDocument3 pagesTesting & Commissioning Procedure For Staircase Pressurisation Systemvin ssNo ratings yet

- Commissioning High Voltage Switchgear & TransformersDocument13 pagesCommissioning High Voltage Switchgear & TransformersJesus RodriguezNo ratings yet

- 111563693-IQ-OQ-PQ-for-FBDDocument31 pages111563693-IQ-OQ-PQ-for-FBDNur Nabi RashedNo ratings yet

- FBD Tray Dryer Validation MalibaDocument46 pagesFBD Tray Dryer Validation MalibaApoloTrevinoNo ratings yet

- Hydrostatic Testing Specification for PipelinesDocument12 pagesHydrostatic Testing Specification for PipelinesMoaatazz NouisriNo ratings yet

- AC Installation - Testing Form Template - CRAC - UnitDocument4 pagesAC Installation - Testing Form Template - CRAC - UnitVincent LeeNo ratings yet

- Checklist For Above Ground Water Piping InstallationDocument1 pageChecklist For Above Ground Water Piping InstallationBelal Alrwadieh50% (2)

- Mechanical Systems Starting and TestingDocument4 pagesMechanical Systems Starting and Testingabdullah sahibNo ratings yet

- SOP WI Pneumatic On-Off Valves - Calibrating Stroke CheckDocument1 pageSOP WI Pneumatic On-Off Valves - Calibrating Stroke CheckJarrodNo ratings yet

- The Central Business District: New Administrative CapitalDocument18 pagesThe Central Business District: New Administrative CapitalAbanoub HakeemNo ratings yet

- TE CONNECTIVITY MANUFACTURING PHILIPPINES INC. TESTING AND COMMISSIONING REPORTDocument36 pagesTE CONNECTIVITY MANUFACTURING PHILIPPINES INC. TESTING AND COMMISSIONING REPORTNorman CanlasNo ratings yet

- Testing & Commissioning of Fan Coil Units FCU'sDocument3 pagesTesting & Commissioning of Fan Coil Units FCU'svin ssNo ratings yet

- Air Compressor Pre-Startup Inspection ChecklistDocument1 pageAir Compressor Pre-Startup Inspection Checklistgede aris prayoga mahardika50% (2)

- 1 Power Plant Commissioning PreparationsDocument18 pages1 Power Plant Commissioning PreparationsArjun SaojiNo ratings yet

- WI-EI-064 Rotating Machinery MonitoringDocument2 pagesWI-EI-064 Rotating Machinery MonitoringMohd A IshakNo ratings yet

- TAB of HVAC Water Systems at Saddara ComplexDocument22 pagesTAB of HVAC Water Systems at Saddara ComplexRaziKhan50% (2)

- Bypass Terminal Reheat Units TestingDocument1 pageBypass Terminal Reheat Units TestingDong VanraNo ratings yet

- Warman-Flow System Maintenance ChecklistDocument2 pagesWarman-Flow System Maintenance ChecklistWilliam EvansNo ratings yet

- Method of Statement For Precommissioning & Commissioning of ChillersDocument4 pagesMethod of Statement For Precommissioning & Commissioning of Chillersvin ssNo ratings yet

- Quy Trinh T&C BMS Cho MVAC - Tham KhaoDocument79 pagesQuy Trinh T&C BMS Cho MVAC - Tham Khaovin ssNo ratings yet

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemDocument20 pagesStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (3)

- SECTION 15954 Hvac Systems Testing, Adjusting, and BalancingDocument6 pagesSECTION 15954 Hvac Systems Testing, Adjusting, and Balancinghitokiri_knives100% (1)

- CW Distribution System Commissioning ChecklistDocument1 pageCW Distribution System Commissioning ChecklistvoNo ratings yet

- Method of Statemnet For Testing Commissioning of Chilled Water PumpsDocument3 pagesMethod of Statemnet For Testing Commissioning of Chilled Water PumpsHasan V SNo ratings yet

- Validation & Qualification of Dry Powder Mixers, Fluid Bed Dryer, Tray DryerDocument32 pagesValidation & Qualification of Dry Powder Mixers, Fluid Bed Dryer, Tray DryerPatricia Joyce Malabanan SunglaoNo ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- Commissioning Checklist For Sewerage Pumping StationsDocument3 pagesCommissioning Checklist For Sewerage Pumping Stationssajidziyan67% (3)

- Intermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESDocument3 pagesIntermediate Well Control Equipment Inspection Criteria: Equipment Group: SIDE OUTLET VALVESkaleem ullah janNo ratings yet

- Valve MaintenanceDocument20 pagesValve MaintenanceSaka MpfmNo ratings yet

- Manual de DRESSER Meter B3Document32 pagesManual de DRESSER Meter B3Maxx MamaniNo ratings yet

- Calculation NotesDocument536 pagesCalculation NotesMazen OudNo ratings yet

- Catalogue: Power SolutionsDocument42 pagesCatalogue: Power SolutionsMazen OudNo ratings yet

- Knauf Alutop Access PanelsDocument20 pagesKnauf Alutop Access PanelsMazen OudNo ratings yet

- Residency ProgramDocument59 pagesResidency ProgramMazen OudNo ratings yet

- Liquid Applied, One Component Polyurethane Waterproofing MembraneDocument2 pagesLiquid Applied, One Component Polyurethane Waterproofing MembraneMazen OudNo ratings yet

- Nice - Folder - Bar - System - en Mbar HighlightedDocument16 pagesNice - Folder - Bar - System - en Mbar HighlightedSamastha Nair SamajamNo ratings yet

- Supplier Item Description With Brand & Model Remarks Item No. Unit (Pce/m) Qty Requested Qty ApprovedDocument1 pageSupplier Item Description With Brand & Model Remarks Item No. Unit (Pce/m) Qty Requested Qty ApprovedMazen OudNo ratings yet

- Manpower Request Form TemplateDocument1 pageManpower Request Form TemplateMazen OudNo ratings yet

- Manpower Distribution Form TemplateDocument1 pageManpower Distribution Form TemplateMazen OudNo ratings yet

- Divisions-Account AllocationDocument3 pagesDivisions-Account AllocationMazen OudNo ratings yet

- Prob Thermo chp2Document7 pagesProb Thermo chp2Muhammad FaizanNo ratings yet

- Design To Capacity Vip Workshop ReportDocument86 pagesDesign To Capacity Vip Workshop ReportEmad El Gebesy100% (2)

- GEIT-65027US Remote Visual InspectionDocument16 pagesGEIT-65027US Remote Visual InspectionvrapciudorianNo ratings yet

- Product Catalogue1Document80 pagesProduct Catalogue1Maria StoicaNo ratings yet

- Pip Vesst002-2018Document14 pagesPip Vesst002-2018d-fbuser-93320248No ratings yet

- Sealed Quench FurnaceDocument20 pagesSealed Quench FurnaceSathiyaPrakashNo ratings yet

- DryingDocument51 pagesDryingShubham BhandariNo ratings yet

- Purgadores MecânicosDocument22 pagesPurgadores MecânicosEmmerickNo ratings yet

- Heat Transfer White PaperDocument14 pagesHeat Transfer White PaperflitzzzNo ratings yet

- Instruction Manual: Controlled Evaporator and Mixer (CEM)Document22 pagesInstruction Manual: Controlled Evaporator and Mixer (CEM)mahradNo ratings yet

- Helisorber Final Report B1aDocument36 pagesHelisorber Final Report B1amsaadullahNo ratings yet

- LGR 7000XLi Owners Manual - 2015Document63 pagesLGR 7000XLi Owners Manual - 2015hqwaterNo ratings yet

- (Reinhard Radermacher, Yunho Hwang) Vapor CompressDocument315 pages(Reinhard Radermacher, Yunho Hwang) Vapor CompressAhmed nawfalNo ratings yet

- Chapter 1Document19 pagesChapter 1Mintesnot TadeleNo ratings yet

- S E9 12ckp5 PDFDocument94 pagesS E9 12ckp5 PDFJohn Ray Esmama CalasicasNo ratings yet

- Instruction Book FXe1-5 enDocument32 pagesInstruction Book FXe1-5 envisaguyNo ratings yet

- MJADOM FIBER OPTIC LIMITED / ADD: No. 8 Daqi Avenue, Guancheng Town, Ningbo City, Zhejiang Province, ChinaDocument3 pagesMJADOM FIBER OPTIC LIMITED / ADD: No. 8 Daqi Avenue, Guancheng Town, Ningbo City, Zhejiang Province, ChinaDanny AvilésNo ratings yet

- Plate and Frame Heat Exchanger Design Cheatsheet: Conditions Needed For HX SelectionDocument1 pagePlate and Frame Heat Exchanger Design Cheatsheet: Conditions Needed For HX SelectionIynulF.OmarNo ratings yet

- Plant Commissioning Start Up ProcedureDocument100 pagesPlant Commissioning Start Up Proceduremsaad292% (124)

- Instrumentation and Control of Heat ExchangerDocument29 pagesInstrumentation and Control of Heat Exchangerpra578No ratings yet

- Clean Coal Reference Plants: Pulverized Coal Boiler With Flue Gas DesulfurizationDocument129 pagesClean Coal Reference Plants: Pulverized Coal Boiler With Flue Gas Desulfurizationraharjoitb100% (1)

- Trane Giải Nhiệt Gió CG-PRC048B-GB - 0121 - smDocument52 pagesTrane Giải Nhiệt Gió CG-PRC048B-GB - 0121 - smPhạm ĐứcNo ratings yet

- Evoflat HandbookDocument72 pagesEvoflat HandbookanescuveronicaNo ratings yet

- 4 - HX PresentationDRAFT 3Document14 pages4 - HX PresentationDRAFT 3Islam SolimanNo ratings yet

- Lurgi Deodorizing PDFDocument6 pagesLurgi Deodorizing PDFAnonymous 6Nt20xKNo ratings yet

- Bombas de Glicol KimrayDocument14 pagesBombas de Glicol KimrayLuis Carlos Saavedra100% (1)

- 09-00 - Shell and Tube Heat Exchangers For Routine ServiceDocument17 pages09-00 - Shell and Tube Heat Exchangers For Routine ServiceFolayemiNo ratings yet

- Parker Sporlan Refrigeration & Air Conditioning Catalogue 2015Document320 pagesParker Sporlan Refrigeration & Air Conditioning Catalogue 2015Hnin PwintNo ratings yet

- 1.0 Chiller UnitDocument12 pages1.0 Chiller UnitfebousNo ratings yet

- Alpha CondensingDocument16 pagesAlpha Condensingdanielteo2008No ratings yet