Professional Documents

Culture Documents

Problems With Commutation in Real Machines Lesson 2: What Is This Lesson About?

Problems With Commutation in Real Machines Lesson 2: What Is This Lesson About?

Uploaded by

Russel BubanCopyright:

Available Formats

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Motor, Electric Traction and Electrical Control Trainer YL-195Document41 pagesMotor, Electric Traction and Electrical Control Trainer YL-195jhgffdfdffNo ratings yet

- Module 10 - Paralleling of DC GeneratorsDocument24 pagesModule 10 - Paralleling of DC GeneratorsNoel Bacton100% (1)

- Trabajo de Investigacion Maquinas CC.-1Document8 pagesTrabajo de Investigacion Maquinas CC.-1ßräyän Nðnð FichüNo ratings yet

- Lessons in Electric Circuits Volume II Chapter 1 Basic Ac TheoryDocument25 pagesLessons in Electric Circuits Volume II Chapter 1 Basic Ac TheoryDeepakDeepNo ratings yet

- Topik 1 - DC Generator BiDocument14 pagesTopik 1 - DC Generator BiMuhd MijieNo ratings yet

- ch20 DCMotorApplicationsDocument39 pagesch20 DCMotorApplicationsmehralsmenschNo ratings yet

- Electrical MachinesDocument24 pagesElectrical MachinesimranakhtarNo ratings yet

- Commutation and Armature Construction Lesson 1: What Is This Lesson About?Document9 pagesCommutation and Armature Construction Lesson 1: What Is This Lesson About?Russel BubanNo ratings yet

- Electric Vehicle - Design and Implementation Strategies For The Power TrainDocument7 pagesElectric Vehicle - Design and Implementation Strategies For The Power TrainkamaleshsNo ratings yet

- Laboratory Experiment 1 TA-AY MEE31Document5 pagesLaboratory Experiment 1 TA-AY MEE31JayNo ratings yet

- EASA Mod 3 BK 4 Ac & DC Mech PDFDocument76 pagesEASA Mod 3 BK 4 Ac & DC Mech PDFNavaraj BaniyaNo ratings yet

- Summary of DC GeneratorDocument10 pagesSummary of DC GeneratorChristopher YsitNo ratings yet

- Electrical System Technology: DC MachinesDocument95 pagesElectrical System Technology: DC MachinesunknownNo ratings yet

- What Is Alternating Current (AC) ?: Search This SiteDocument5 pagesWhat Is Alternating Current (AC) ?: Search This SiteQuang BuiNo ratings yet

- Lessons in Electric CircuitsDocument575 pagesLessons in Electric CircuitsBing WangNo ratings yet

- DC Machine L02Document12 pagesDC Machine L02luckyNo ratings yet

- Svs Group of Institutions: Electrical & Electronics Engneering On Line Coaching ClassesDocument19 pagesSvs Group of Institutions: Electrical & Electronics Engneering On Line Coaching ClassesPdisk MoviesNo ratings yet

- Chapter 1 Basic Ac Theory What Is Alternating Current (AC) ?Document19 pagesChapter 1 Basic Ac Theory What Is Alternating Current (AC) ?Jack MartinsonNo ratings yet

- Series and Shunt DC Motors: Villanueva, Boj NDocument2 pagesSeries and Shunt DC Motors: Villanueva, Boj Nboj VillanuevaNo ratings yet

- Armature (Electrical Engineering) - Wikipedia, The Free EncyclopediaDocument3 pagesArmature (Electrical Engineering) - Wikipedia, The Free EncyclopediaChytra DivakarNo ratings yet

- 21 EE44 - Module 1Document28 pages21 EE44 - Module 1AshwiniNo ratings yet

- D.C. Machine - Study NotesDocument32 pagesD.C. Machine - Study NotesGentle ManNo ratings yet

- Lab 3abDocument16 pagesLab 3abLiaqat AliNo ratings yet

- Alternating and Direct CurrentDocument11 pagesAlternating and Direct CurrentlovleshrubyNo ratings yet

- C 2003 James L. Kirtley JRDocument18 pagesC 2003 James L. Kirtley JRMadina KalmuhambetovaNo ratings yet

- Implementation of Boost Converter Applied For DC Motor DriveDocument51 pagesImplementation of Boost Converter Applied For DC Motor DriveLeri FirdianNo ratings yet

- 2.1 Video ReflectionDocument2 pages2.1 Video ReflectionChriscarl De LimaNo ratings yet

- 10 1002@etep 4450100505 PDFDocument8 pages10 1002@etep 4450100505 PDFrsantanaNo ratings yet

- 1what Is Alternating Current (AC)Document24 pages1what Is Alternating Current (AC)Kassem KallasNo ratings yet

- Ac-Dc 00Document7 pagesAc-Dc 00Jessie OlantigueNo ratings yet

- Lec 1 Introduction 19 Series EEE 2205Document22 pagesLec 1 Introduction 19 Series EEE 2205Nasif TahmidNo ratings yet

- Transition Between Metadyne and Amplidyne ModesDocument5 pagesTransition Between Metadyne and Amplidyne ModeshezugNo ratings yet

- Lec 2 - Fundamentals DC Machine - EEE 2205Document59 pagesLec 2 - Fundamentals DC Machine - EEE 2205Nasif TahmidNo ratings yet

- EI6402 - Electrical Machines Department of EIE&ICE 2016-2017Document91 pagesEI6402 - Electrical Machines Department of EIE&ICE 2016-2017Dhivya SNo ratings yet

- Fuctioning of The Collector & Effect of The Magnetomotive Force in The ArmatureDocument4 pagesFuctioning of The Collector & Effect of The Magnetomotive Force in The ArmatureDavid Acevedo CardonaNo ratings yet

- MIT6 685F13 Chapter1 PDFDocument18 pagesMIT6 685F13 Chapter1 PDFJack SoNo ratings yet

- Armature Reaction in Direct Current Machines: Pereira, Colombia Julianesteban - Garcia@utp - Edu.coDocument3 pagesArmature Reaction in Direct Current Machines: Pereira, Colombia Julianesteban - Garcia@utp - Edu.coJulian GarciaNo ratings yet

- 45 16255 EE321 2015 1 1 1 Week 9 10Document22 pages45 16255 EE321 2015 1 1 1 Week 9 10Zakaria MaazazNo ratings yet

- DC Machines PresentationDocument66 pagesDC Machines PresentationMarcos AquinoNo ratings yet

- Reading.6 - Introduction To Electric MachinesDocument8 pagesReading.6 - Introduction To Electric MachinesCát TườngNo ratings yet

- Photovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleDocument7 pagesPhotovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleMani KandanNo ratings yet

- MOTORsDocument1 pageMOTORsjoseperalta.13ppNo ratings yet

- Armature Reaction. Neutral-Plane Shift. NingDocument3 pagesArmature Reaction. Neutral-Plane Shift. NingomairNo ratings yet

- Analysis and Applications of Electric Machines in DCDocument6 pagesAnalysis and Applications of Electric Machines in DCanon_504291142No ratings yet

- ECE Electrical Engineering 2 Marks PDFDocument22 pagesECE Electrical Engineering 2 Marks PDFsivagamiNo ratings yet

- Direct Vs Alternating Current: BelowDocument5 pagesDirect Vs Alternating Current: Belowtgs100No ratings yet

- Demagnetizing and Cross-Magnetizing Conductors: Calculation of Demagnetizing Ampere-Turns Per Pole (Atd/Pole)Document2 pagesDemagnetizing and Cross-Magnetizing Conductors: Calculation of Demagnetizing Ampere-Turns Per Pole (Atd/Pole)Engr M.Arshad KhalidNo ratings yet

- Electrical Machines I: Week 3-4: Direct Current GeneratorDocument18 pagesElectrical Machines I: Week 3-4: Direct Current Generatorkaloy33No ratings yet

- Unit-2 (DC Motors)Document50 pagesUnit-2 (DC Motors)Devi Sri PrasadNo ratings yet

- Motor Protection, Control & MaintenanceDocument337 pagesMotor Protection, Control & Maintenancepattan madhuNo ratings yet

- Analysis of The Residual Flux Influence On InrushDocument4 pagesAnalysis of The Residual Flux Influence On InrushMoba AddictNo ratings yet

- 5 DC Equipment and GeneratorsDocument20 pages5 DC Equipment and Generatorsronniee287No ratings yet

- EEE-2302 Sessional Sheet - UpdatedDocument13 pagesEEE-2302 Sessional Sheet - UpdatedAsia AlamNo ratings yet

- Makalah BHS Inggris InsanulDocument12 pagesMakalah BHS Inggris InsanulInsanul AdliNo ratings yet

- DC MachinesDocument9 pagesDC MachinesSIVARASU RATHINAVELUNo ratings yet

- Analysis and Design of Isolated SEPIC Converter With Greinacher Voltage Multiplier CellDocument8 pagesAnalysis and Design of Isolated SEPIC Converter With Greinacher Voltage Multiplier CellBernardo AndresNo ratings yet

- DC GeneratorsDocument52 pagesDC GeneratorsDevi Sri PrasadNo ratings yet

- Unit 3Document74 pagesUnit 3Arjun PratabNo ratings yet

- 05 - Planos Ge 320ac (Tamaño Carta)Document28 pages05 - Planos Ge 320ac (Tamaño Carta)MARIO DEL PINO MUÑOZNo ratings yet

- Codesolar Sma Sunny Island 4548 6048us Dus113711Document2 pagesCodesolar Sma Sunny Island 4548 6048us Dus113711HeysenCesarPayahuancaChavezNo ratings yet

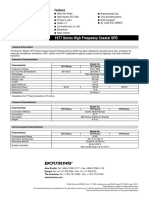

- 1977 Series High Frequency Coaxial SPD: FeaturesDocument2 pages1977 Series High Frequency Coaxial SPD: FeaturesAshish KumarNo ratings yet

- Semiconductor DiodeDocument74 pagesSemiconductor DiodeOnie EstrellaNo ratings yet

- Polylux WebkatalogDocument96 pagesPolylux WebkatalogNesil Abiera50% (2)

- 2G Solis InverterDocument15 pages2G Solis InverterMarian MogildeaNo ratings yet

- Catalogue Indoor MV Instrument Transformers (Version 3.1) 2008Document19 pagesCatalogue Indoor MV Instrument Transformers (Version 3.1) 2008Georgios PourtsidisNo ratings yet

- Membrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Document7 pagesMembrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Mila CalderónNo ratings yet

- DatasheetDocument23 pagesDatasheetAfif ArdiyansahNo ratings yet

- كرولا Manual - Inspection - Air conditioning system - Heater & air conditionerDocument5 pagesكرولا Manual - Inspection - Air conditioning system - Heater & air conditionerBashir MtwaklNo ratings yet

- Components CatalogueDocument44 pagesComponents CatalogueJarrett Mathews100% (1)

- A Low-Quiescent Current Full On-Chip 1.2 V CMOS Low Drop-Out RegulatorDocument2 pagesA Low-Quiescent Current Full On-Chip 1.2 V CMOS Low Drop-Out RegulatorNam Luu Nguyen NhatNo ratings yet

- Series M50 Diode: - High Surge Current Rectifier Circuits - Up To 1600 Volt Blocking StandardDocument2 pagesSeries M50 Diode: - High Surge Current Rectifier Circuits - Up To 1600 Volt Blocking Standardfaraz24No ratings yet

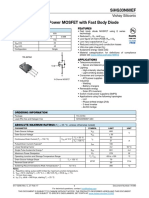

- Sihg33N60Ef: Vishay SiliconixDocument10 pagesSihg33N60Ef: Vishay SiliconixdkelicNo ratings yet

- Inspection Form Multi-Step Capacitor Bank, 600V: Insulation Resistance (M ) 1000V Phase To GND Test SummaryDocument5 pagesInspection Form Multi-Step Capacitor Bank, 600V: Insulation Resistance (M ) 1000V Phase To GND Test SummaryJonathan SantiagoNo ratings yet

- Zinc Oxide Varistor 07DDocument5 pagesZinc Oxide Varistor 07DAnonymous Wzuop6L9SNo ratings yet

- Bushing Ge PDFDocument17 pagesBushing Ge PDFEMD NSPCLNo ratings yet

- 4 Three Phase Induction Motors 1Document37 pages4 Three Phase Induction Motors 1Terry rickyNo ratings yet

- AE-2K - Address Units, (Old Types With Bases)Document2 pagesAE-2K - Address Units, (Old Types With Bases)cembozNo ratings yet

- NTPL-xxx-01-xxx - Excitation - Misc Calculations - Rev 01Document1 pageNTPL-xxx-01-xxx - Excitation - Misc Calculations - Rev 01Jayarajan Jayarajan C NNo ratings yet

- 08140h PDFDocument12 pages08140h PDFAmine EmineNo ratings yet

- Codigos ESC PDFDocument212 pagesCodigos ESC PDFRuthAnayaNo ratings yet

- High-Voltage High-Frequency Transformer Design For A 7.2kV To 120V/240V 20kVA Solid State TransformerDocument6 pagesHigh-Voltage High-Frequency Transformer Design For A 7.2kV To 120V/240V 20kVA Solid State TransformerAnonymous gr5v18ItJ5No ratings yet

- FM200 - Fire Extinguishing Control PanelDocument13 pagesFM200 - Fire Extinguishing Control Panelnastyn-1100% (1)

- Emcp II +P Emergency Stop - Google SearchDocument3 pagesEmcp II +P Emergency Stop - Google SearchahmedcoNo ratings yet

- High Voltage Test EquipmentDocument6 pagesHigh Voltage Test EquipmentPaulo CardosoNo ratings yet

- 01 Schneider-Acti9 PDFDocument3 pages01 Schneider-Acti9 PDFNguyen AnhNo ratings yet

- HoneywellDocument5 pagesHoneywellQuocBaoNo ratings yet

- Ebook Electrical Machine Design PDF Full Chapter PDFDocument49 pagesEbook Electrical Machine Design PDF Full Chapter PDFevelyn.beeman923100% (35)

Problems With Commutation in Real Machines Lesson 2: What Is This Lesson About?

Problems With Commutation in Real Machines Lesson 2: What Is This Lesson About?

Uploaded by

Russel BubanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Problems With Commutation in Real Machines Lesson 2: What Is This Lesson About?

Problems With Commutation in Real Machines Lesson 2: What Is This Lesson About?

Uploaded by

Russel BubanCopyright:

Available Formats

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

2

Lesson 2

PROBLEMS WITH COMMUTATION IN REAL MACHINES

What is this Lesson about?

In this lesson we will discuss the differences between the operation of real DC machine and

theoretical DC machine, what causes these differences and how to address them.

What Will You Learn? What Do You Already Know?

At the end of the lesson, you should be (PRE-TEST)

able to do the following:

✓ discuss what is armature reaction, and

its effects;

✓ discuss what is inductive kick, and its

effects; and

✓ differentiate different solution to these

effects.

To achieve the said outcomes, this

lesson is divided into the following sub-topics:

● Introduction

● Armature Reaction

● L di/dt voltages

● Solution to problems in Real DC

machines

o Brush shifting

o Commutating poles or interpoles

o Compensating windings

What You Should Already Know?

Before taking this lesson, you are expected

to be knowledgeable in the following topics:

✓ Faraday’s Law

✓ Fundamentals of Electromagnetism

✓ Magnetic Fields and circuits

✓ Commutation and Armature Construction

DEMATERA & GEALONE | Bicol University | 1

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

Let us READ! To better understand this concept,

consider the terms (Magnetic Neutral Axis)

INTRODUCTION

MNA and (Geometrical Neutral Axis) GNA. We

know that in a ‘running” DC machine, there are

The commutation process as described

two fluxes (magnetic field) that is present: the

in theory (watch the discussion here) is not as

'armature flux' and 'main field flux'. The main

simple in real life. The difference primarily exists

field flux is produced by the main poles, and the

because of the magnetism and electromagnetic

induction. armature flux is the flux that causes armature

The effects can be categorized into two: reaction as described in preceding paragraph.

1. Armature reaction In a DC Generator, voltage (emf) is

2. L dildt voltages induced by the conductors cutting the magnetic

flux. There is an axis (or a plane) along which

We will consider each effect, their armature conductors move parallel to the flux

characteristics and effects in the operation DC lines and, hence, they do not cut the flux lines

machines. while on that plane

MNA may be defined as the axis along

ARMATURE REACTION which no emf is generated in the armature

If the field poles of a dc machine are conductors as they move parallel to the flux

energized, that is magnetic field windings are lines. Brushes are always placed along the MNA

connected to a power supply (in case of because reversal of current in the armature

electromagnets) and the rotor of the machine is conductors takes place along this axis.

driven by an external source of mechanical GNA (Geometrical Neutral Axis) may be

torque, then a (AC) voltage will be induced in defined as the axis which is perpendicular to the

the conductors of the rotor. This voltage will be stator field axis.

rectified into a DC output by the machine's

commutator.

Note that there is no current is flowing

in the armature since at no-load; the machine is

considered open-circuited. Once the load is

connected to the terminals of the machine, a

current will flow in its armature windings. This

current flow will produce a magnetic field

(because of electromagnetic induction) of its

own, which will affect the original magnetic

Figure 2-1: MNA & GNA

field. This distortion of the flux in a machine as GNA & MNA [Diagram]. (n.d.). Retrieved from

https://www.electricaledition.com/2016/01/armature-reaction-in-

the load is increased is called armature reaction. dc-machines.html

It causes two serious problems in real dc

machines.

DEMATERA & GEALONE | Bicol University | 2

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

Neutral-Plane Shift

One of the effects of the armature

reaction is called the “neutral-plane shift”, or

simply the misalignment of MNA from GNA.

Ideally, the brush should be in MNA, which is

physically also the GNA. But when neutral-plane

shift occurs, the brushes are no longer in MNA,

this causes serious problem, such as sparking

that can damage both the brush and the Figure 2-2: Armature Flux

Armature Flux [Diagram]. (n.d.). Retrieved from

commutator segment. In extreme cases, https://www.electricaledition.com/2016/01/armature-reaction-in-

dc-machines.html

flashover may also occur that can melt the

commutator itself. Flashover occurs when the

voltage of adjacent commutator segments gets

large enough to sustain an arc in the ionized air

above them.

Flux Weakening

The second major effect of armature

reaction is the flux weakening, this is because

the armature flux is opposite in direction to the

main flux. This weakening of flux is dangerous

both for generators and motors. In generators,

the output voltage of the generator decreases.

For motors, this factor causes serious problems. Figure 2-3: Neutral Plane Shift

With the decrement of a flux, rotation speed of Neutral Plane Shift [Diagram]. (n.d.). Retrieved from

https://www.electricaledition.com/2016/01/armature-reaction-in-

motor also decreases. Speed increment also dc-machines.html

enhances the load connected with the motor

that causes a lessening of flux. It is likely in some

shunt dc motors to approach a running state

because of flux weakening, where the speed of

the motor increasing till the machine is

detached with input supply or until it damages

itself.

Let us WATCH!

Click the video icon to watch the video: Figure 2-4: Flux Weakening Diagram

Armature reaction | Animation |DC Machines Flux Weakening Diagram [Diagram]. (n.d.). Retrieved from

https://www.youtube.com/watch?v=RmVd5xbspE4 https://hackaday.io/project/164932-axiom-100kw-motor-

controller/log/162931-field-weakening-support

DEMATERA & GEALONE | Bicol University | 3

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

L di/dt VOLTAGES

The second major problem is the L di/dt

voltage that occurs in commutator segments

being shorted out by the brushes, also called

inductive kick. This figure represents a series of

commutator segments and the conductors

connected between them. Assuming that the

current in the brush is 400 A, the current in each

path is 200 A. Notice that when a commutator

segment is shorted out, the current flow

through that commutator segment must

reverse. How fast must this reversal occur?

Assuming that the machine is turning at 800

r/min and that there are 50 commutator

segments (a reasonable number for a typical

motor), each commutator segment moves

under a brush and clears it again in t = 0.00 15

s. Therefore, the rate of change in current with

respect to time in the shorted loop must

average:

di/dt = (400 A / 0.0015 s)

= 266,667 A/s.

With even a tiny inductance in the loop,

a very significant inductive voltage kick v = L

di/dt will be induced in the shorted commutator

segment. This high voltage naturally causes

sparking at the brushes of the machine,

resulting in the same arcing problems that the

neutral-plane shift causes. Figure 2-5: (a) the reversal of current flow in a coil undergoing

commutation. Note that the current in the coil between segments a

and b must reverse direction while the brush shorts together the two

Let us WATCH! commutator segments. (b) The current reversal in the coil undergoing

commutation as a function of time for both ideal commutation and real

commutation with the coil inductance considered.

Click the video icon to watch the video: Source: Chapman, S. J. (2012). Electric machinery fundamentals. McGraw-Hill

Commutation and the Ldi/dt problem Medical Publishing

https://www.youtube.com/watch?v=p1ZRqJS9y-c

DEMATERA & GEALONE | Bicol University | 4

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

Solutions to the Problems with Commutation its normal load and the mode of operation. Due

Three approaches have been to these limitations, this method is generally not

developed to (partially or completely) correct preferred.

the problems of armature reaction and L di/dt

voltages; the following are:

1. Brush shifting

2. Commutating poles or interpoles

3. Compensating windings

Each of these techniques is explained

below, together with its advantages and

disadvantages.

BRUSH SHIFTING

A natural solution to the problem

appears to shift the brushes along the direction Figure 2-6: Sample DC Generator Construction

DC Generator [Diagram]. (September 13, 2017). Retrieved from

of rotation in generator action and against the https://2.bp.blogspot.com/wJSRlrhlhZo/WblbI7htQeI/AAAAAAAAA

rI/n8XYHuYf19cUGMSjG5UOFVmuHP9FMxtQCEwYBhgL/s640/CON

direction of rotation in motor action; this would STRUCTION%2BOF%2BGENERATOR.png

result into a reduction in air gap flux. This will

reduce the induced voltage in generator and

would increase the speed in motor. The

demagnetizing mmf (magneto motive force)

thus produced is given by:

𝑍𝐼𝛽

𝐴𝑇𝑑 =

180𝑃

where: Z = total number of conductors

I = armature current

P = number of poles

Β = angular shift of carbon brushes (in Figure 2-7: The concept of brush shifting

Brush Shifting [Diagram]. (n.d.). Retrieved from

electrical degrees) https://www.google.com/url?sa=i&url=https%3A%2F%2Fwww.sem

anticscholar.org%2Fpaper%2FVariable-characteristics-DC-motor-

by-changing-brush-Takura-Akatsu

Brush shift has serious limitations, so the

brushes must be shifted to a new position every

time the load changes or the direction of Let us WATCH!

rotation changes or the mode of operation

changes. In view of this, brush shift is limited Click the video icon to watch the video:

only to very small machines. Here also, the Brush Shifting

https://www.youtube.com/watch?v=W5peV5LaK7w

brushes are fixed at a position corresponding to

DEMATERA & GEALONE | Bicol University | 5

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

COMMUTATING POLES OR INTERPOLES The use of commutating poles or

interpoles is very common, because they

The basic idea behind this new

correct the sparking problems of dc machines

approach is that if the voltage in the wires

at a low cost. They are almost always found in

undergoing commutation can be made zero,

any dc machine of 1 hp or larger.

then there will be no sparking at the brushes. To

accomplish this, small poles, called

commutating poles or interpoles, are placed

midway between the main poles.

Inter poles are long but narrow poles

placed in the inter polar axis. They have the

polarity of succeeding pole (coming next in

sequence of rotation) in generator action and

proceeding (which has passed behind in

rotation sequence) pole in motor action. The

inter pole is designed to neutralize the armature

reaction mmf in the inter polar axis. Since inter

poles are connected in series with armature, the Figure 2-8: Sample Diagrams of Interpoles

Interpoles [Diagram]. (n.d.). Retrieved from

change in direction of current in armature https://joliettech.com/information/easa-electrical-engineering-

changes direction of inter pole. handbook/field-polarities-of-dc-machines-easa-electrical-

engineering-handbook/

This is because the direction of

armature reaction mmf is in the inter polar axis.

It also provides commutation voltage for the

coil undergoing commutation such that the

commutation voltage completely neutralizes

the reactance voltage (L × di/dt). Thus, no

sparking takes place.

Inter polar windings are always kept in

series with armature, so inter polar winding

carries the armature current; therefore, works

satisfactorily irrespective of load, the direction Figure 2-9: Sample Diagrams of Interpoles

of rotation or the mode of operation. Inter poles Interpoles [Diagram]. (n.d.). Retrieved from

https://www.google.com/url?sa=i&url=http%3A%2F%2Fwww.vias.o

are made narrower to ensure that they rg%2Fkimberlyee%2Fee_12_22.html&psig=AOvVaw0OVY6gaIvfO8r

652hFRSDh&ust=1593185472865000&source=images&cd=vfe&ve

influence only the coil undergoing d=0CAIQjRxqFwoTCLC7wc2kneoCFQAAAAAdAAAAABAb

commutation and its effect does not spread to

the other coils. The base of the inter poles is Let us WATCH!

made wider to avoid saturation and to improve

Click the video icon to watch the video:

response.

Interpoles for DC machines

https://www.youtube.com/watch?v=AGoJGWhFzY4

DEMATERA & GEALONE | Bicol University | 6

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

It is important to realize, though, that windings do not cancel L di/dt effects. The

they do nothing for the flux distribution under interpoles do not have to be as strong, though,

the pole faces, so the flux-weakening problem since they are canceling only L di/dt voltages in

is still present. Most medium-size, general- the windings, and not the voltages due to

purpose motors correct for sparking problems neutral-plane shifting. Because of the expense

with interpoles and just live with the flux of having both compensating windings and

weakening effects. interpoles on such a machine, these windings

are used only where the extremely severe

COMPENSATING WINDING nature of a motor's duty demands them.

For very heavy, severe duty cycle

motors, the flux-weakening problem can be

very serious. To completely cancel armature

reaction and thus eliminate both neutral-plane

shift and flux weakening, a different technique

was developed. This third technique involves

placing compensating windings in slots carved

in the faces of the poles parallel to the rotor

conductors, to cancel the distorting effect of

armature reaction. These windings are

connected in series with the rotor windings, so Figure 2-10: Compensating Winding

Interpoles [Diagram]. (n.d.). Retrieved from

that whenever the load changes in the rotor, the https://web.uettaxila.edu.pk/CMS/SP2013/ectEMbs/notes%5Carmat

ure%20reaction%20&%20commutation.pdf

current in the compensating windings changes,

too.

With complete compensation the main Let us WATCH!

field is restored. This also reduces armature

circuit’s inductor and improves system Click the video icon to watch the video:

Compensating Winding in DC machines

response. Compensating winding functions https://www.youtube.com/watch?v=w-G3WONoEVw

satisfactorily irrespective of the load, direction

of rotation and mode of operation. Obviously,

it is help in commutation as the interpolar

Additional Resource:

winding gets relieved from its duty to

compensate for the armature mmf under the

Click the video icon to watch the video:

pole arc.

DC MOTORS AND GENERATORS

The major disadvantage of https://www.youtube.com/watch?v=OpL0joqJmqY

compensating windings is that they are

expensive since they must be machined into the

faces of the poles. Any motor that uses them

must also have interpoles, since compensating

DEMATERA & GEALONE | Bicol University | 7

ELECTRICAL MACHINE 1 Lesson 2: Problems with Commutation in Real Machines

ASSESSMENT ASSESSMENT TASK

Choose a mode of presentation (video,

POST-TEST power point, etc.); identify three major solutions

to different commutation problems; prepare a

Take time to take the Post-Test for this report/discussion about each solution; and

lesson to check your learning. Please refer to the submit it in the given link.

lesson if you score less than 80%. The Post-Test can

be accessed in the course site.

REFERENCES

Chapman, S. J. (2012). Electric machinery

fundamentals. McGraw-Hill Medical Publishing.

ACTIVITY 2-1 Gross, C. A. (2006). Electric machines. CRC Press.

Instruction: In a letter-sized paper, answer the Fitzgerald, A., Fitzgerald, A. E., Kingsley, C., &

following questions. Upload your answer in .pdf Umans, S. (2003). Electric machinery. McGraw-Hill

format to this link. Professional.

1. What are the challenges/problems of

commutation? Support your answer with

diagrams, and at least 3-cases of commutation

problems that occurred in real life.

2. Explain the concept of Brush shifting and why it

is still used in small machines.

DEMATERA & GEALONE | Bicol University | 8

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Motor, Electric Traction and Electrical Control Trainer YL-195Document41 pagesMotor, Electric Traction and Electrical Control Trainer YL-195jhgffdfdffNo ratings yet

- Module 10 - Paralleling of DC GeneratorsDocument24 pagesModule 10 - Paralleling of DC GeneratorsNoel Bacton100% (1)

- Trabajo de Investigacion Maquinas CC.-1Document8 pagesTrabajo de Investigacion Maquinas CC.-1ßräyän Nðnð FichüNo ratings yet

- Lessons in Electric Circuits Volume II Chapter 1 Basic Ac TheoryDocument25 pagesLessons in Electric Circuits Volume II Chapter 1 Basic Ac TheoryDeepakDeepNo ratings yet

- Topik 1 - DC Generator BiDocument14 pagesTopik 1 - DC Generator BiMuhd MijieNo ratings yet

- ch20 DCMotorApplicationsDocument39 pagesch20 DCMotorApplicationsmehralsmenschNo ratings yet

- Electrical MachinesDocument24 pagesElectrical MachinesimranakhtarNo ratings yet

- Commutation and Armature Construction Lesson 1: What Is This Lesson About?Document9 pagesCommutation and Armature Construction Lesson 1: What Is This Lesson About?Russel BubanNo ratings yet

- Electric Vehicle - Design and Implementation Strategies For The Power TrainDocument7 pagesElectric Vehicle - Design and Implementation Strategies For The Power TrainkamaleshsNo ratings yet

- Laboratory Experiment 1 TA-AY MEE31Document5 pagesLaboratory Experiment 1 TA-AY MEE31JayNo ratings yet

- EASA Mod 3 BK 4 Ac & DC Mech PDFDocument76 pagesEASA Mod 3 BK 4 Ac & DC Mech PDFNavaraj BaniyaNo ratings yet

- Summary of DC GeneratorDocument10 pagesSummary of DC GeneratorChristopher YsitNo ratings yet

- Electrical System Technology: DC MachinesDocument95 pagesElectrical System Technology: DC MachinesunknownNo ratings yet

- What Is Alternating Current (AC) ?: Search This SiteDocument5 pagesWhat Is Alternating Current (AC) ?: Search This SiteQuang BuiNo ratings yet

- Lessons in Electric CircuitsDocument575 pagesLessons in Electric CircuitsBing WangNo ratings yet

- DC Machine L02Document12 pagesDC Machine L02luckyNo ratings yet

- Svs Group of Institutions: Electrical & Electronics Engneering On Line Coaching ClassesDocument19 pagesSvs Group of Institutions: Electrical & Electronics Engneering On Line Coaching ClassesPdisk MoviesNo ratings yet

- Chapter 1 Basic Ac Theory What Is Alternating Current (AC) ?Document19 pagesChapter 1 Basic Ac Theory What Is Alternating Current (AC) ?Jack MartinsonNo ratings yet

- Series and Shunt DC Motors: Villanueva, Boj NDocument2 pagesSeries and Shunt DC Motors: Villanueva, Boj Nboj VillanuevaNo ratings yet

- Armature (Electrical Engineering) - Wikipedia, The Free EncyclopediaDocument3 pagesArmature (Electrical Engineering) - Wikipedia, The Free EncyclopediaChytra DivakarNo ratings yet

- 21 EE44 - Module 1Document28 pages21 EE44 - Module 1AshwiniNo ratings yet

- D.C. Machine - Study NotesDocument32 pagesD.C. Machine - Study NotesGentle ManNo ratings yet

- Lab 3abDocument16 pagesLab 3abLiaqat AliNo ratings yet

- Alternating and Direct CurrentDocument11 pagesAlternating and Direct CurrentlovleshrubyNo ratings yet

- C 2003 James L. Kirtley JRDocument18 pagesC 2003 James L. Kirtley JRMadina KalmuhambetovaNo ratings yet

- Implementation of Boost Converter Applied For DC Motor DriveDocument51 pagesImplementation of Boost Converter Applied For DC Motor DriveLeri FirdianNo ratings yet

- 2.1 Video ReflectionDocument2 pages2.1 Video ReflectionChriscarl De LimaNo ratings yet

- 10 1002@etep 4450100505 PDFDocument8 pages10 1002@etep 4450100505 PDFrsantanaNo ratings yet

- 1what Is Alternating Current (AC)Document24 pages1what Is Alternating Current (AC)Kassem KallasNo ratings yet

- Ac-Dc 00Document7 pagesAc-Dc 00Jessie OlantigueNo ratings yet

- Lec 1 Introduction 19 Series EEE 2205Document22 pagesLec 1 Introduction 19 Series EEE 2205Nasif TahmidNo ratings yet

- Transition Between Metadyne and Amplidyne ModesDocument5 pagesTransition Between Metadyne and Amplidyne ModeshezugNo ratings yet

- Lec 2 - Fundamentals DC Machine - EEE 2205Document59 pagesLec 2 - Fundamentals DC Machine - EEE 2205Nasif TahmidNo ratings yet

- EI6402 - Electrical Machines Department of EIE&ICE 2016-2017Document91 pagesEI6402 - Electrical Machines Department of EIE&ICE 2016-2017Dhivya SNo ratings yet

- Fuctioning of The Collector & Effect of The Magnetomotive Force in The ArmatureDocument4 pagesFuctioning of The Collector & Effect of The Magnetomotive Force in The ArmatureDavid Acevedo CardonaNo ratings yet

- MIT6 685F13 Chapter1 PDFDocument18 pagesMIT6 685F13 Chapter1 PDFJack SoNo ratings yet

- Armature Reaction in Direct Current Machines: Pereira, Colombia Julianesteban - Garcia@utp - Edu.coDocument3 pagesArmature Reaction in Direct Current Machines: Pereira, Colombia Julianesteban - Garcia@utp - Edu.coJulian GarciaNo ratings yet

- 45 16255 EE321 2015 1 1 1 Week 9 10Document22 pages45 16255 EE321 2015 1 1 1 Week 9 10Zakaria MaazazNo ratings yet

- DC Machines PresentationDocument66 pagesDC Machines PresentationMarcos AquinoNo ratings yet

- Reading.6 - Introduction To Electric MachinesDocument8 pagesReading.6 - Introduction To Electric MachinesCát TườngNo ratings yet

- Photovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleDocument7 pagesPhotovoltaic Based Brushless DC Motor Closed Loop Drive For Electric VehicleMani KandanNo ratings yet

- MOTORsDocument1 pageMOTORsjoseperalta.13ppNo ratings yet

- Armature Reaction. Neutral-Plane Shift. NingDocument3 pagesArmature Reaction. Neutral-Plane Shift. NingomairNo ratings yet

- Analysis and Applications of Electric Machines in DCDocument6 pagesAnalysis and Applications of Electric Machines in DCanon_504291142No ratings yet

- ECE Electrical Engineering 2 Marks PDFDocument22 pagesECE Electrical Engineering 2 Marks PDFsivagamiNo ratings yet

- Direct Vs Alternating Current: BelowDocument5 pagesDirect Vs Alternating Current: Belowtgs100No ratings yet

- Demagnetizing and Cross-Magnetizing Conductors: Calculation of Demagnetizing Ampere-Turns Per Pole (Atd/Pole)Document2 pagesDemagnetizing and Cross-Magnetizing Conductors: Calculation of Demagnetizing Ampere-Turns Per Pole (Atd/Pole)Engr M.Arshad KhalidNo ratings yet

- Electrical Machines I: Week 3-4: Direct Current GeneratorDocument18 pagesElectrical Machines I: Week 3-4: Direct Current Generatorkaloy33No ratings yet

- Unit-2 (DC Motors)Document50 pagesUnit-2 (DC Motors)Devi Sri PrasadNo ratings yet

- Motor Protection, Control & MaintenanceDocument337 pagesMotor Protection, Control & Maintenancepattan madhuNo ratings yet

- Analysis of The Residual Flux Influence On InrushDocument4 pagesAnalysis of The Residual Flux Influence On InrushMoba AddictNo ratings yet

- 5 DC Equipment and GeneratorsDocument20 pages5 DC Equipment and Generatorsronniee287No ratings yet

- EEE-2302 Sessional Sheet - UpdatedDocument13 pagesEEE-2302 Sessional Sheet - UpdatedAsia AlamNo ratings yet

- Makalah BHS Inggris InsanulDocument12 pagesMakalah BHS Inggris InsanulInsanul AdliNo ratings yet

- DC MachinesDocument9 pagesDC MachinesSIVARASU RATHINAVELUNo ratings yet

- Analysis and Design of Isolated SEPIC Converter With Greinacher Voltage Multiplier CellDocument8 pagesAnalysis and Design of Isolated SEPIC Converter With Greinacher Voltage Multiplier CellBernardo AndresNo ratings yet

- DC GeneratorsDocument52 pagesDC GeneratorsDevi Sri PrasadNo ratings yet

- Unit 3Document74 pagesUnit 3Arjun PratabNo ratings yet

- 05 - Planos Ge 320ac (Tamaño Carta)Document28 pages05 - Planos Ge 320ac (Tamaño Carta)MARIO DEL PINO MUÑOZNo ratings yet

- Codesolar Sma Sunny Island 4548 6048us Dus113711Document2 pagesCodesolar Sma Sunny Island 4548 6048us Dus113711HeysenCesarPayahuancaChavezNo ratings yet

- 1977 Series High Frequency Coaxial SPD: FeaturesDocument2 pages1977 Series High Frequency Coaxial SPD: FeaturesAshish KumarNo ratings yet

- Semiconductor DiodeDocument74 pagesSemiconductor DiodeOnie EstrellaNo ratings yet

- Polylux WebkatalogDocument96 pagesPolylux WebkatalogNesil Abiera50% (2)

- 2G Solis InverterDocument15 pages2G Solis InverterMarian MogildeaNo ratings yet

- Catalogue Indoor MV Instrument Transformers (Version 3.1) 2008Document19 pagesCatalogue Indoor MV Instrument Transformers (Version 3.1) 2008Georgios PourtsidisNo ratings yet

- Membrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Document7 pagesMembrane/Bag Rupture Relay MBR CA-035 11/12/2008 Rev. 4Mila CalderónNo ratings yet

- DatasheetDocument23 pagesDatasheetAfif ArdiyansahNo ratings yet

- كرولا Manual - Inspection - Air conditioning system - Heater & air conditionerDocument5 pagesكرولا Manual - Inspection - Air conditioning system - Heater & air conditionerBashir MtwaklNo ratings yet

- Components CatalogueDocument44 pagesComponents CatalogueJarrett Mathews100% (1)

- A Low-Quiescent Current Full On-Chip 1.2 V CMOS Low Drop-Out RegulatorDocument2 pagesA Low-Quiescent Current Full On-Chip 1.2 V CMOS Low Drop-Out RegulatorNam Luu Nguyen NhatNo ratings yet

- Series M50 Diode: - High Surge Current Rectifier Circuits - Up To 1600 Volt Blocking StandardDocument2 pagesSeries M50 Diode: - High Surge Current Rectifier Circuits - Up To 1600 Volt Blocking Standardfaraz24No ratings yet

- Sihg33N60Ef: Vishay SiliconixDocument10 pagesSihg33N60Ef: Vishay SiliconixdkelicNo ratings yet

- Inspection Form Multi-Step Capacitor Bank, 600V: Insulation Resistance (M ) 1000V Phase To GND Test SummaryDocument5 pagesInspection Form Multi-Step Capacitor Bank, 600V: Insulation Resistance (M ) 1000V Phase To GND Test SummaryJonathan SantiagoNo ratings yet

- Zinc Oxide Varistor 07DDocument5 pagesZinc Oxide Varistor 07DAnonymous Wzuop6L9SNo ratings yet

- Bushing Ge PDFDocument17 pagesBushing Ge PDFEMD NSPCLNo ratings yet

- 4 Three Phase Induction Motors 1Document37 pages4 Three Phase Induction Motors 1Terry rickyNo ratings yet

- AE-2K - Address Units, (Old Types With Bases)Document2 pagesAE-2K - Address Units, (Old Types With Bases)cembozNo ratings yet

- NTPL-xxx-01-xxx - Excitation - Misc Calculations - Rev 01Document1 pageNTPL-xxx-01-xxx - Excitation - Misc Calculations - Rev 01Jayarajan Jayarajan C NNo ratings yet

- 08140h PDFDocument12 pages08140h PDFAmine EmineNo ratings yet

- Codigos ESC PDFDocument212 pagesCodigos ESC PDFRuthAnayaNo ratings yet

- High-Voltage High-Frequency Transformer Design For A 7.2kV To 120V/240V 20kVA Solid State TransformerDocument6 pagesHigh-Voltage High-Frequency Transformer Design For A 7.2kV To 120V/240V 20kVA Solid State TransformerAnonymous gr5v18ItJ5No ratings yet

- FM200 - Fire Extinguishing Control PanelDocument13 pagesFM200 - Fire Extinguishing Control Panelnastyn-1100% (1)

- Emcp II +P Emergency Stop - Google SearchDocument3 pagesEmcp II +P Emergency Stop - Google SearchahmedcoNo ratings yet

- High Voltage Test EquipmentDocument6 pagesHigh Voltage Test EquipmentPaulo CardosoNo ratings yet

- 01 Schneider-Acti9 PDFDocument3 pages01 Schneider-Acti9 PDFNguyen AnhNo ratings yet

- HoneywellDocument5 pagesHoneywellQuocBaoNo ratings yet

- Ebook Electrical Machine Design PDF Full Chapter PDFDocument49 pagesEbook Electrical Machine Design PDF Full Chapter PDFevelyn.beeman923100% (35)