Professional Documents

Culture Documents

Doc1226 Hipot Testing

Uploaded by

César Díaz Liberona0 ratings0% found this document useful (0 votes)

12 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views2 pagesDoc1226 Hipot Testing

Uploaded by

César Díaz LiberonaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Hipot Testing of

Magnetic Components

High potential testing of insulation integrity

This application note discusses the purpose of hipot (high

potential) testing and how the hipot test relates to inductor

and transformer safety.

Warning Hipot testing involves hazardous voltages

and may present a safety hazard. Always

carefully follow all manufacturer’s instructions

for hipot test equipment.

What is working voltage?

Working voltage, as defined by UL 60950-1, is: Highest

voltage to which insulation or the component under con-

sideration is, or can be, subjected when the equipment is

operating under conditions of normal use. computing. Because magnetic components can be used

in multiple applications involving different hazard levels,

Why is the hipot test performed? the hipot test voltage for any specific application must be

The hipot test is a Dielectric Withstand Voltage (DWV) carefully determined by referring to the pertinent standards

test used to verify the capability of insulation to withstand for the equipment type.

a specified voltage without electrical breakdown. The Hipot voltages are chosen in order to test insulation to en-

objective is to ensure the insulation can withstand more sure there will be no electrical breakdown from the expected

than the expected working voltage by a sufficient margin. working voltage and voltage transients. A general rule of

A hipot test can be performed on any two materials that thumb for establishing the hipot test voltage is two times the

are separated by insulation, including those separated working voltage + 1000 V. For a working voltage of 220 V,

by an air gap. the rule of thumb test voltage is (2 × 220 + 1000) = 1440 V.

Therefore, 1500 V is a common hipot test voltage.

How is the test performed?

Hipot test voltage may be specified as either ac or dc.

Hipot testing is performed by applying a voltage between Since hipot stress is generally considered to be greatest

any two points intended to be electrically isolated, and at the peak voltage of an ac waveform, ac and dc hipot

measuring the resulting leakage current. The hipot voltage test voltages are typically equated by Vdc = Vac (PEAK) =

may be applied between electrical circuits and chassis Vac (rms) × 2.

ground, for example, or between primary and second-

ary circuits isolated by a transformer. The test waveform, Test voltage duration is usually 60 seconds, however UL

whether dc or an ac sine wave is also typically specified. and other safety standards typically allow a duration of one

or two seconds for the purpose of production line testing,

What constitutes a failure? provided that the voltage is increased by 20% or so from

Hipot test failure is when the leakage current exceeds the one minute test.

a specified limit or rapidly increases in an uncontrolled

What hipot tests apply to Coilcraft inductors,

manner, or if arcing is observed. Typical leakage current

limits range from 0.5 to 20 mA.

coupled inductors, and transformers?

Hipot testing is typically not specified for single coil in-

What are typical hipot requirements for ductors since they do not function to provide electrical

magnetic components? isolation. There are many considerations in determining

Hipot test voltages are defined by the point of application, the safe working voltage across an inductor, as described

grade of insulation, anticipated environmental conditions in the Coilcraft application note Working Voltage Ratings

and the safety agency standards that apply to that applica- Applied to Inductors.

tion. For example, UL/IEC 60950 standard typically applies For coupled inductors and transformers, hipot testing is

to magnetic components used in telecommunications and used to verify proper electrical isolation. The application

Document 1226-1 Revised 10/02/17

working voltage determines the hipot test voltage, which those points affect hipot test results. Dielectric variation

then is specified on the data sheet for each product. For is rarely cited as a cause of a failure. The safety factor in-

core and bobbin style transformers, the schematic and volved in the hipot test is typically large enough to cover any

hipot specification define the test voltage and test points. variation in the dielectric characteristics of the insulating

Most Coilcraft standard products use Functional insulation materials. If there is a large variation in spacing between

unless otherwise specified. For Functional insulation, the conductors, such as wires or terminations, and this is the

hipot test is typically 1500 Vrms for one minute duration weakest point providing the lowest dielectric constant in

for primary winding to secondary winding isolation. The the current path, the variation in hipot test results could be

test is performed with a 50 Hz or 60 Hz sine wave under wide. Proper sampling techniques and statistical analysis

controlled humidity conditions. should be followed to define any variation in the test results.

A winding to core (or sometimes case) hipot voltage may

Is a hipot test destructive to the tested part?

also be specified, and is typically lower voltage, such as

500 Vrms. Potentially yes. Hipot testing can stress and damage the

insulation if the voltage and/or duration are excessive for

Hipot test voltages for Coilcraft transformers are typically the specific design. Damage to insulation can be difficult

below 5 kVrms and 6 kVdc. to detect, so production hipot testing is a trade-off in test

voltage versus possible damage to the component.

How do safety standards relate to hipot

testing? One method of determining a safe production test voltage

Coilcraft products are not usually certified as standalone is to test a sufficient random sample to failure by dielectric

items by UL, CSA, TUV, CE or other agencies. Safety breakdown testing. The test voltage is increased until the

standard listings generally apply to complete electronic dielectric fails, based on a leakage limit or arcing. The hipot

assemblies such as power supplies, computers, modems, test would then be performed at some lower voltage with

televisions, etc., so the hipot test for magnetics is dictated a sufficient safety factor.

both by the safety standards and the intended application Care should be taken to avoid applying hipot voltage in

conditions. excess of the product rating to avoid causing damage to

Many Coilcraft parts are designed to meet specific insulation. Care must also be taken to avoid repeated test-

UL / CSA / IEC or other standards and this information is ing. For repeat testing, lower voltage should be considered

noted on the particular Coilcraft data sheet. to avoid insulation damage.

How do the test conditions affect the References:

Working Voltage Ratings Applied to Inductors, Coilcraft Document

outcome of the test? 712, Rev. 07/25/08

Frequency, humidity, waveform, ramp time, and duration Coilcraft web page: Assistance with Safety Agency Approvals

of the voltage all may affect the outcome of a hipot test. Wikipedia Article: Dielectric withstand test

The test should be performed in a humidity-controlled UL 60950-1, March 27, 2007, ISBN 0-7629-1238-3 “Information

environment. Technology Equipment – Safety – Part 1: General Requirements”

Para 1.2.9.6

How does product variation affect the test

results?

The distance between points of contact as well as the

dielectric properties of the insulating materials between

Document 1226-2 Revised 10/02/17

You might also like

- Hipot Testing of Magnetic ComponentsDocument2 pagesHipot Testing of Magnetic ComponentsSahreen AbbiiNo ratings yet

- 1 E Doc1236 Hipot TestingDocument2 pages1 E Doc1236 Hipot TestingSahreen AbbiiNo ratings yet

- Understanding The How and Why of Electrical Product Safety TestingDocument8 pagesUnderstanding The How and Why of Electrical Product Safety TestingLanstein Joe E PNo ratings yet

- HIPOT Testing (Dielectric Strength Test)Document5 pagesHIPOT Testing (Dielectric Strength Test)Wathik AbmNo ratings yet

- HIPOT, Lorenz, EtcDocument52 pagesHIPOT, Lorenz, EtcEmanuCrsua100% (1)

- Hipot testing ensures electrical safetyDocument5 pagesHipot testing ensures electrical safetySumit SawaiNo ratings yet

- Importance of HIPOT Testing: Dielectric Withstand TestDocument6 pagesImportance of HIPOT Testing: Dielectric Withstand TestelsayedNo ratings yet

- HIPOTDocument5 pagesHIPOTHARIHARANNo ratings yet

- Hipot TestDocument5 pagesHipot Testmurugakings2008No ratings yet

- Functions and Features of Advanced Hipot Testers: June 18, 2018 by Lee TeschlerDocument4 pagesFunctions and Features of Advanced Hipot Testers: June 18, 2018 by Lee TeschlerVishal ShahNo ratings yet

- Hipot TestDocument5 pagesHipot TestSanjeet Saud100% (2)

- HIPOT TestingDocument4 pagesHIPOT Testingparuchurivenkat5272100% (1)

- What Is HIPOT Testing (Dielectric Strength Test) ?Document52 pagesWhat Is HIPOT Testing (Dielectric Strength Test) ?raza239100% (3)

- Hipot Testing in Industry: Standards and Good Practices: M. Marchevsky, LBNLDocument17 pagesHipot Testing in Industry: Standards and Good Practices: M. Marchevsky, LBNLnachiNo ratings yet

- TheHipotTest-5.16 2Document27 pagesTheHipotTest-5.16 2justin cardinalNo ratings yet

- Unit 5Document3 pagesUnit 5Ahmed Essam Abd RabouNo ratings yet

- HIPOT Test Checks Electrical InsulationDocument4 pagesHIPOT Test Checks Electrical InsulationAriel DimacaliNo ratings yet

- FIELD TESTING CABLE SYSTEMSDocument7 pagesFIELD TESTING CABLE SYSTEMS2003vinay100% (1)

- A Review of Common Electrical Safety Test Requirements: by Dwayne M. Davis, Associated ResearchDocument4 pagesA Review of Common Electrical Safety Test Requirements: by Dwayne M. Davis, Associated ResearchzedricNo ratings yet

- Insulation Resistance Test - Factors Affecting Test ResultsDocument2 pagesInsulation Resistance Test - Factors Affecting Test Resultstenk_manNo ratings yet

- High-voltage dielectric strength test for electrical equipmentDocument4 pagesHigh-voltage dielectric strength test for electrical equipmentDev Swain100% (1)

- High Voltage TestingDocument3 pagesHigh Voltage TestingpriyadarshniNo ratings yet

- CHAPTER 10 - High Voltage TestingDocument29 pagesCHAPTER 10 - High Voltage TestingDeepan0507No ratings yet

- Field Testing and Diagnostic Methods for Power CablesDocument22 pagesField Testing and Diagnostic Methods for Power CablesanuragpugaliaNo ratings yet

- What Is HIPOT Testing Dielectric Strength TestDocument4 pagesWhat Is HIPOT Testing Dielectric Strength TesthafizgNo ratings yet

- Insulation Resistance Test GuideDocument4 pagesInsulation Resistance Test GuideDelmar FerrerNo ratings yet

- High Voltage Testing of Electrical ApparatusDocument29 pagesHigh Voltage Testing of Electrical ApparatusNRCM EEENo ratings yet

- HIGH VOLTAGE TESTING OF ELECTRICAL APPARATUSDocument29 pagesHIGH VOLTAGE TESTING OF ELECTRICAL APPARATUSNRCM EEENo ratings yet

- l3 304-04 Handout Testing 2018Document3 pagesl3 304-04 Handout Testing 2018Iffi KingggNo ratings yet

- 9.inspection and Testing Lecture NotesEDocument13 pages9.inspection and Testing Lecture NotesEmola znbuNo ratings yet

- Measurement of FLUKE Insulation Resistance MeggerDocument22 pagesMeasurement of FLUKE Insulation Resistance MeggerEmmanuel S SombilonNo ratings yet

- Device TESTDocument4 pagesDevice TESTNAYEEMNo ratings yet

- Measuring Insulation Resistance Withstand of CablesDocument10 pagesMeasuring Insulation Resistance Withstand of Cablesrishika chhibberNo ratings yet

- Guidelines For High Potential (Hi-Pot) DC Testing of Medium Voltage Cables - EEPDocument11 pagesGuidelines For High Potential (Hi-Pot) DC Testing of Medium Voltage Cables - EEPSheraz Khan100% (2)

- Electrical Engineering Department Electrical Installations and Drawings (ENEE323) Lecture Notes Instruments, Inspection, and Testing A) InstrumentsDocument13 pagesElectrical Engineering Department Electrical Installations and Drawings (ENEE323) Lecture Notes Instruments, Inspection, and Testing A) InstrumentsHamza KefayahNo ratings yet

- Doc712 Inductor Voltage RatingsDocument2 pagesDoc712 Inductor Voltage Ratingskprasad_mlNo ratings yet

- High Voltage Testing: Application NoteDocument11 pagesHigh Voltage Testing: Application Notedienlangchu100% (1)

- DC HiPot Testing Guidelines For MV Cables - General CableDocument2 pagesDC HiPot Testing Guidelines For MV Cables - General CableMBulga100% (2)

- AN-Safety-Tutorial On Safety Testing-042014Document9 pagesAN-Safety-Tutorial On Safety Testing-042014NameNo ratings yet

- Comment Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument41 pagesComment Insulation Resistance (IR) Values - Electrical Notes & ArticlesMunazar HussainNo ratings yet

- HV Testing and Insulation Coordination GuideDocument4 pagesHV Testing and Insulation Coordination GuideIndongo EliaserNo ratings yet

- Digital Testing of HV Circuit BreakerDocument21 pagesDigital Testing of HV Circuit Breakervamshi4all100% (10)

- TransformerDocument9 pagesTransformerVikas GuptaNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument29 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesSunny SinghNo ratings yet

- What Is HIPOT TestingDocument4 pagesWhat Is HIPOT TestingYasir JamilNo ratings yet

- Hi POT Test BasicsDocument6 pagesHi POT Test BasicsdeepakNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument13 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesSharath Teja ReddyNo ratings yet

- Off-Line Insulation Testing and Diagnosis of HV MachinesDocument4 pagesOff-Line Insulation Testing and Diagnosis of HV MachinesnaveenNo ratings yet

- Short-Circuit Current Making and Breaking TestsDocument16 pagesShort-Circuit Current Making and Breaking TestsFelipe Mafioletti Schuartz100% (1)

- Diagnostic Tests and Condition Monitoring of Electrical MachinesDocument3 pagesDiagnostic Tests and Condition Monitoring of Electrical Machineslbk50No ratings yet

- High Voltage Testing & Insulation CoordinationDocument60 pagesHigh Voltage Testing & Insulation CoordinationAnish John Paul MNo ratings yet

- High Voltage TestingDocument60 pagesHigh Voltage TestingAnish John Paul M100% (1)

- Measurement of Insulation Resistance Withstand of Cables: Experiment 6Document15 pagesMeasurement of Insulation Resistance Withstand of Cables: Experiment 6shalini nimsNo ratings yet

- The Truth About Arc DetectionDocument3 pagesThe Truth About Arc DetectionRobert GalarzaNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument31 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesKush SharmaNo ratings yet

- Insulation Resistance (IR) Values - Electrical Notes & ArticlesDocument28 pagesInsulation Resistance (IR) Values - Electrical Notes & ArticlesjengandxbNo ratings yet

- Motor and Generator High Voltage AC Testing ExplainedDocument6 pagesMotor and Generator High Voltage AC Testing ExplainedCristian NicolaeNo ratings yet

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Insulation Co-ordination in High-voltage Electric Power SystemsFrom EverandInsulation Co-ordination in High-voltage Electric Power SystemsRating: 4.5 out of 5 stars4.5/5 (5)

- Shukla 2015Document15 pagesShukla 2015César Díaz LiberonaNo ratings yet

- CA MV Fuses (EN) E 2401PL1613 PDFDocument68 pagesCA MV Fuses (EN) E 2401PL1613 PDFCésar Díaz LiberonaNo ratings yet

- IEEEMag 24 1 2008 HVDCdesignpart2Document12 pagesIEEEMag 24 1 2008 HVDCdesignpart2César Díaz LiberonaNo ratings yet

- Solar PV Power Plant Underground Cable Sizing Case StudyDocument7 pagesSolar PV Power Plant Underground Cable Sizing Case StudyNavneet SinghNo ratings yet

- XLPE Cable Systems Users Guide-ABBDocument32 pagesXLPE Cable Systems Users Guide-ABBsujithmohandasNo ratings yet

- Review of Capacitor Bank Control Practices 0321Document13 pagesReview of Capacitor Bank Control Practices 0321Ian CabuyaoNo ratings yet

- Aislador PoliméricoDocument40 pagesAislador PoliméricoCésar Díaz LiberonaNo ratings yet

- Ieee Recommended Practice For Partial Discharge Measurement in LDocument47 pagesIeee Recommended Practice For Partial Discharge Measurement in LCésar Díaz LiberonaNo ratings yet

- Technical Catalogue for ConductorsDocument150 pagesTechnical Catalogue for ConductorsGanesh Veeran100% (1)

- Measuring and Quantifying Acoustic Noise from Power TransformersDocument20 pagesMeasuring and Quantifying Acoustic Noise from Power TransformersCésar Díaz LiberonaNo ratings yet

- Nema WC 70 Icea S 95 658Document9 pagesNema WC 70 Icea S 95 658rlaureano0% (1)

- Power Transformer Application For Wind Plant Substations: IEEE PES Wind Plant Collector System Design Working GroupDocument6 pagesPower Transformer Application For Wind Plant Substations: IEEE PES Wind Plant Collector System Design Working GroupCésar Díaz LiberonaNo ratings yet

- Power Quality Analysis of Distributed Wind Generation SystemsDocument6 pagesPower Quality Analysis of Distributed Wind Generation SystemsCésar Díaz LiberonaNo ratings yet

- A Comprehensive Review On Distributed Power GenerationDocument5 pagesA Comprehensive Review On Distributed Power GenerationCésar Díaz LiberonaNo ratings yet

- Ampacity Calculations For Cables in Shallow TroughsDocument9 pagesAmpacity Calculations For Cables in Shallow TroughsVăn Chung NguyễnNo ratings yet

- Insulators 101 Panel Final ADocument84 pagesInsulators 101 Panel Final ABlakeNo ratings yet

- Grounding: IEEE Guide For Safety in AC SubstationDocument226 pagesGrounding: IEEE Guide For Safety in AC SubstationCésar Díaz LiberonaNo ratings yet

- All Aluminium Conductor - AAC (KCMIL Series) : DescriptionDocument2 pagesAll Aluminium Conductor - AAC (KCMIL Series) : DescriptionCésar Díaz LiberonaNo ratings yet

- GAS-INSULATED SWITCHGEARELK-14 & THE MODULAR SYSTEM FOR GIS 245kV PDFDocument24 pagesGAS-INSULATED SWITCHGEARELK-14 & THE MODULAR SYSTEM FOR GIS 245kV PDFBudi SantonyNo ratings yet

- Conditions of Discharge-Free Operation of XLPE InsDocument12 pagesConditions of Discharge-Free Operation of XLPE InsCésar Díaz LiberonaNo ratings yet

- Medium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFDocument79 pagesMedium Voltage Surge Arresters Catalog HG 31.1 2017 Low Resolution PDFAnkur_soniNo ratings yet

- Gas Insulated Substation GIS: Committee Committee A. DevelopmentDocument3 pagesGas Insulated Substation GIS: Committee Committee A. DevelopmentInmusta GisinNo ratings yet

- APL2015 Paper InsulationCoordinationv1.1Document7 pagesAPL2015 Paper InsulationCoordinationv1.1César Díaz LiberonaNo ratings yet

- STNW3034 Standard For Insulation CoordinationDocument26 pagesSTNW3034 Standard For Insulation CoordinationCésar Díaz LiberonaNo ratings yet

- Calculating Lightning Failure Rates for SubstationsDocument4 pagesCalculating Lightning Failure Rates for SubstationsCésar Díaz LiberonaNo ratings yet

- GIS Primary Components: Peter Glaubitz, Carolin Siebert, and Klaus ZuberDocument21 pagesGIS Primary Components: Peter Glaubitz, Carolin Siebert, and Klaus ZuberCésar Díaz LiberonaNo ratings yet

- STNW3034 Standard For Insulation CoordinationDocument26 pagesSTNW3034 Standard For Insulation CoordinationCésar Díaz LiberonaNo ratings yet

- APL2015 Paper InsulationCoordinationv1.1Document7 pagesAPL2015 Paper InsulationCoordinationv1.1César Díaz LiberonaNo ratings yet

- Diomedes: Inno Vation T Ha T Lif Tsy OuDocument2 pagesDiomedes: Inno Vation T Ha T Lif Tsy Outhanggimme.phanNo ratings yet

- Orchard Introduction To Simulink With Engineering Applications 2nd Edition MarDocument716 pagesOrchard Introduction To Simulink With Engineering Applications 2nd Edition MarmarnoonpvNo ratings yet

- MPU & MCU 8 X Lessons NotesDocument233 pagesMPU & MCU 8 X Lessons NotesserjaniNo ratings yet

- Max21100 ImuDocument32 pagesMax21100 ImuErwin ArdiasNo ratings yet

- Modul Praktikum Elda Satu Semester 5 FinalDocument29 pagesModul Praktikum Elda Satu Semester 5 FinalZdSentono ChannelNo ratings yet

- Performance Evaluation of Intersatellite Free Space Optical Communication System With Varied Parameters and Transceiver DiversityDocument6 pagesPerformance Evaluation of Intersatellite Free Space Optical Communication System With Varied Parameters and Transceiver Diversitypyro_pradeepNo ratings yet

- BPI MT6595 project overviewDocument35 pagesBPI MT6595 project overviewAlexei BazNo ratings yet

- Traveling Waves For Fault Location and Protection: Venkat MynamDocument56 pagesTraveling Waves For Fault Location and Protection: Venkat Mynambetter pasaribuNo ratings yet

- Madan H R: Phone - +91 81090 34545 / +91 90607 34545 E-MailDocument7 pagesMadan H R: Phone - +91 81090 34545 / +91 90607 34545 E-MailMadan R HonnalagereNo ratings yet

- GE Lighting Manuals PDFDocument18 pagesGE Lighting Manuals PDFMohammed Jahir HusainNo ratings yet

- Quiz 4 - Attempt Review1Document10 pagesQuiz 4 - Attempt Review1Ishfaq AhmadNo ratings yet

- Siemens G50 Service ManualDocument234 pagesSiemens G50 Service Manualmasroork_289% (9)

- Case Allocation PGP Term IV 2016-17Document8 pagesCase Allocation PGP Term IV 2016-17Praveen JujjuvarapuNo ratings yet

- BTI-7000 System OverviewDocument1 pageBTI-7000 System OverviewSal InguaggiatoNo ratings yet

- Steca Solsum F Specification enDocument1 pageSteca Solsum F Specification enÉlio SilvaNo ratings yet

- AC Circuis: Dr. Ashwini Kumar Nayak Asst. Professor School of Electrical Sciences NistDocument28 pagesAC Circuis: Dr. Ashwini Kumar Nayak Asst. Professor School of Electrical Sciences NistssNo ratings yet

- WH2310 User ManualDocument41 pagesWH2310 User Manualrullycosta85No ratings yet

- Simoco TSF2000Document2 pagesSimoco TSF2000Paolo UssiNo ratings yet

- M1205A-069 Enhanced Parts Replacement Tables 1Document17 pagesM1205A-069 Enhanced Parts Replacement Tables 1EDGAR CRUZ VINUEZANo ratings yet

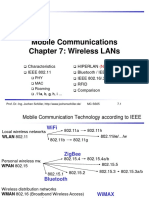

- C07 Wireless LANsDocument134 pagesC07 Wireless LANsalokNo ratings yet

- Review of Battery Management Systems for EV Lithium-Ion BatteriesDocument43 pagesReview of Battery Management Systems for EV Lithium-Ion BatteriesAditya PatilNo ratings yet

- Fse 727 (INGLESE)Document16 pagesFse 727 (INGLESE)LuisTolosa80% (5)

- Siprotec 4, Siprotec Easy, SIPROTEC 600 Series, Communication, AccessoriesDocument14 pagesSiprotec 4, Siprotec Easy, SIPROTEC 600 Series, Communication, AccessorieskumarNo ratings yet

- GerbView Reference ManualDocument23 pagesGerbView Reference ManualAlexandrNo ratings yet

- Islanding Scheme and Auto Load Shedding To Protect Power SystemDocument5 pagesIslanding Scheme and Auto Load Shedding To Protect Power SystemKingsuk SahaNo ratings yet

- ATOICV1 1 3 Bent Rule and Energetic of Hybridization PDFDocument21 pagesATOICV1 1 3 Bent Rule and Energetic of Hybridization PDFAmala Rose BabychanNo ratings yet

- EVOLVE ATS Panel Installation ManualDocument28 pagesEVOLVE ATS Panel Installation ManualAndre EinsteinNo ratings yet

- Natural Gas 130KW GeneratorDocument6 pagesNatural Gas 130KW Generatorrechtman1289No ratings yet

- Fig. 1 Circuit Diagram: The Figures Described in The Table Obtained at Heli Test TruckDocument1 pageFig. 1 Circuit Diagram: The Figures Described in The Table Obtained at Heli Test TruckAdam SchwemleinNo ratings yet

- Ballast Water Treatment System FRD Check MethodDocument2 pagesBallast Water Treatment System FRD Check Methodvasilis9No ratings yet