Professional Documents

Culture Documents

Fresher Mechanical Design Engineer Interview Q and A

Fresher Mechanical Design Engineer Interview Q and A

Uploaded by

Naveen HlCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fresher Mechanical Design Engineer Interview Q and A

Fresher Mechanical Design Engineer Interview Q and A

Uploaded by

Naveen HlCopyright:

Available Formats

What are engineering tolerance?

are allowable variation from given dimensions. In other words, it is the total

amount by which a given dimension may vary without affecting product

function.

Tolerance (for hole) = Hole (MMC) – Hole

(LMC)

Why are Tolerance Required?

The production of closely mating parts, without tolerances is economically

unfeasible. This will increase the rejection rate and manufacturing cost.

Therefore, tolerances are used with part dimensions to facilitate

manufacturer and reduce cost.

What is tolerance Stackup Analysis?

Tolerance Stackup analysis is a design tool used to analyse and

optimize product assembly. It calculates the cumulative effects of

part tolerances in an assembly.

What are the types of tolerance?

• Unilateral Tolerance

• Bilateral Tolerance

What do you understand by fit?

The term fit refers to the permissible clearances between mating

parts. The clearance between mating parts determines the type of

Fit.

What are the different types of fits?

• Clearance Fit

• Interference Fit

• Transition Fit

What do you understand by Engineering Drawing?

Engineering drawing is a technical document used to transfer technical

information and define requirements. In other words, it’s a graphical

language that communicates ideas and information from one mind to

another.

What is Section, Projection, Isometric & Detailed View?

• Projection View : Projection view represents a 3

dimensional objects in 2 dimensions while looking from

one side.

• Section View: It is used to show the interior construction of a part

in engineering drawing.

• Isometric View: Isometric projection represents a 3D object into

2D in an engineering drawings. In this three coordinate axes

appear equally foreshortened and the angle between any two

axes is 120 degrees.

• Detailed View: It represents the larger view of any section of

engineering drawing.

What is the symbol of 1st and 3rd angle projection?

Angle Projection Symbol

Angle Projection Symbol

Which projections are preferred for engineering drawings?

Following two types of projections are used :

• First Angle Projection

• Third Angle projection

What is the difference Between First and third angle Projection?

The 1st angle projection part lies in the first quadrant. Therefore the object

lies in between plane and observer.

Whereas in third angle projection, the projection plane lies in between

observer and object.

Why 2nd and 4th angle projections are not used?

Because of overlapping of front and top views 2nd and 4th angle

projections are not used.

What is the least count and how is it calculated?

It is the smallest value measured with the measuring instrument. For

example, the least count for a normal scale is 1 mm whereas for vernier

scale it is 0.01 mm.

Least Count= Value of one main scale Division – Total Number of Vernier

scale division

What is the least count for Vernier Scale, Micrometer and normal scale?

• Vernier Caliper Least Count = 0.01 mm (Digital) , 0.02 mm (manual)

• Micrometer Least Count = 0.01 mm

• Normal scale Least Count = 1 mm

What is the factor of safety and how it is calculated?

FOS describes the load carrying capacity of a system beyond the expected

or actual loads. In other words, FOS represents : how much stronger the

system is compared to intended load.

FOS is calculated considering design load maximum value. Value of FOS is

always greater than one.

What are types of screws?

Here are the various types of screw available in

the market: According to the type of Screw

Head

• Countersunk Screw

• Raised or oval head screw

• Pan Head Screw

• Flat Head Screw

• Flange Head Screw

According to Screw Drive Type

• Slotted

• Phillip

• Pozi Drive

• Torx Head

• Hex Socket

• Triangular head

• Security Head Socket

According to Screw Thread Type

• Machine Screw

• Thread Forming

• Thread Cutting Screw

What is a Stress-Strain Curve?

Stress Strain curve represents the behavior of material when an external

force is applied to it. This diagram is used by product design engineers

during material selection and structure design calculations.

Draw Stress and Strain Curve for Ductile and Brittle Material?

What is a datum plane?

A datum is a theoretical exact plane, axis or point location that GD&T or

dimensional tolerances are referenced to.

What is GD&T (Geometric Dimension & Tolerance) ?

GD&T is a system for defining engineering tolerances. It helps in conveying

product assembly requirements to manufacturers.

You might also like

- RE10, RG8, RF8 SeriesDocument330 pagesRE10, RG8, RF8 Seriesanggie93% (57)

- Vogele - Parts and More Catalogue 2017Document118 pagesVogele - Parts and More Catalogue 2017CATALOGOS 83M100% (11)

- Manufacturing Technology: Unit - IDocument18 pagesManufacturing Technology: Unit - Iapi-271354682100% (1)

- Mechanical Design Engineer Interview QuestionsDocument13 pagesMechanical Design Engineer Interview QuestionspravagaNo ratings yet

- Basic Manufacturing ProcessesDocument71 pagesBasic Manufacturing Processessuneel kumar rathoreNo ratings yet

- InterviewDocument3 pagesInterviewNaniNo ratings yet

- Important Topics For GATE 2017Document6 pagesImportant Topics For GATE 2017Suraj SerigarNo ratings yet

- Chemical MachiningDocument23 pagesChemical MachiningAbhishek Chadaga100% (6)

- Mechanical Interview Questions and Answers PDFDocument4 pagesMechanical Interview Questions and Answers PDFHardikDevdaNo ratings yet

- 101 Mechanical Engineering Interview QuestionsDocument16 pages101 Mechanical Engineering Interview Questionsamr yosry100% (2)

- Ashok LeylandDocument23 pagesAshok LeylandBhuvanesh Ponnan100% (1)

- Limits Fits Engineering TolerancesDocument29 pagesLimits Fits Engineering TolerancesEmmanuel Nicholas100% (2)

- Mechanical Engineering Interview Questions and AnswersDocument17 pagesMechanical Engineering Interview Questions and AnswersprasathbalaNo ratings yet

- 600+ TOP MECHANICAL ENGINEERING Interview Questions & AnswersDocument37 pages600+ TOP MECHANICAL ENGINEERING Interview Questions & AnswersNikhil Prasanna100% (1)

- Psu Interview Guidance PDFDocument2 pagesPsu Interview Guidance PDFkailash100% (1)

- 300+ Top Engineering Drawing Lab Viva Questions and AnswersDocument4 pages300+ Top Engineering Drawing Lab Viva Questions and AnswersIrfan AwanNo ratings yet

- Barc Interview QuestionDocument4 pagesBarc Interview QuestionkishanNo ratings yet

- Design Engineer New ResumeDocument2 pagesDesign Engineer New ResumeAmit KumarNo ratings yet

- Mechanical Engineering Job Interview Questions and AnswersDocument24 pagesMechanical Engineering Job Interview Questions and AnswersAbdul SalamNo ratings yet

- Single Point Cutting ToolDocument16 pagesSingle Point Cutting ToolSoumik DasNo ratings yet

- 100 TECHNICAL MECHANICAL ENGINEERING Interview Questions Answers PDF MECHANICAL ENGINEERING Interview Questions Answers PDFDocument17 pages100 TECHNICAL MECHANICAL ENGINEERING Interview Questions Answers PDF MECHANICAL ENGINEERING Interview Questions Answers PDFsampat kumarNo ratings yet

- Interview Preparation For Ese PDFDocument6 pagesInterview Preparation For Ese PDFkailashNo ratings yet

- Crisil Interview QuestionsDocument7 pagesCrisil Interview QuestionsNagarajanRKNo ratings yet

- Interview QuestionsDocument151 pagesInterview QuestionsFownoonNo ratings yet

- 600+ TOP MECHANICAL ENGINEERING Interview Questions & AnswersDocument29 pages600+ TOP MECHANICAL ENGINEERING Interview Questions & AnswersMayank PachauriNo ratings yet

- MT 2 MCQDocument9 pagesMT 2 MCQRanjith GopalakrishnanNo ratings yet

- Pieas Mech 2019 TestDocument4 pagesPieas Mech 2019 TestAli MurtazaNo ratings yet

- Engineering GraphicsDocument2 pagesEngineering GraphicsVikram RaoNo ratings yet

- Mechanical Engineering Interview Questions and AnswersDocument10 pagesMechanical Engineering Interview Questions and AnswerstopotopNo ratings yet

- Mechanical InterviewDocument2 pagesMechanical InterviewRaj VermaNo ratings yet

- RRB Mechanical Engineer Model Question Paper With Answer Key 14Document43 pagesRRB Mechanical Engineer Model Question Paper With Answer Key 14Y Babu0% (1)

- Basics of Mechanical EngineeringDocument8 pagesBasics of Mechanical EngineeringPallavi DetneNo ratings yet

- Interview QuestionsDocument10 pagesInterview QuestionsrahultrinaNo ratings yet

- Threaded & Riveted JointsDocument43 pagesThreaded & Riveted JointsMadhurima BhandariNo ratings yet

- Dang Tutorial 1 2 Solution (Metal Cutting) - 04112014174823135Document10 pagesDang Tutorial 1 2 Solution (Metal Cutting) - 04112014174823135Bi ChenNo ratings yet

- Mechanical Engineering Interview Questions I-200Document26 pagesMechanical Engineering Interview Questions I-200Durga PrasadNo ratings yet

- Mechanical Interview QuestionsDocument3 pagesMechanical Interview Questionsz_sheerazNo ratings yet

- MMS Unit IVDocument4 pagesMMS Unit IVAdula RajasekharNo ratings yet

- 1503 Sample Interview Questions Mechanical EngineeringDocument2 pages1503 Sample Interview Questions Mechanical EngineeringBaskar ANgadeNo ratings yet

- Development by TriangulationDocument22 pagesDevelopment by Triangulationsarahussain12367% (3)

- Design of ShaftDocument32 pagesDesign of ShaftaliNo ratings yet

- 300+ TOP INDUSTRIAL Engineering Interview Questions and Answers PDFDocument15 pages300+ TOP INDUSTRIAL Engineering Interview Questions and Answers PDFNikhil PrasannaNo ratings yet

- 25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedDocument7 pages25 Mechanical Engineering Interview Questions and Answers - Freshers, ExperiencedAnonymous RVO3O6zm0No ratings yet

- Codes and Standards: ASME B31 Piping CodesDocument44 pagesCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahNo ratings yet

- Seminar On Non-Destructive Testing: Submitted To: Submitted byDocument25 pagesSeminar On Non-Destructive Testing: Submitted To: Submitted byMahesh TamboliNo ratings yet

- Finite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenDocument16 pagesFinite Element Analysis of Large Diameter Concrete Spherical Shell Domes - Hani Aziz AmeenHani Aziz AmeenNo ratings yet

- Module 1 - Fits, LimitsDocument18 pagesModule 1 - Fits, LimitsShanhoodNo ratings yet

- HPCL Syllabus For Officer TraineeDocument1 pageHPCL Syllabus For Officer TraineeGirija VaniNo ratings yet

- Friction Stir WeldingDocument20 pagesFriction Stir WeldingjoshibecNo ratings yet

- Manufacturing ProcessDocument23 pagesManufacturing ProcessSombwit KabasiNo ratings yet

- Tolerances FitsDocument25 pagesTolerances FitsAnonymous E2oSW7No ratings yet

- Mechanical Engineering Interview Question by Pradip SalunkheDocument18 pagesMechanical Engineering Interview Question by Pradip SalunkhePradip SalunkheNo ratings yet

- MCQs Chip FormationDocument9 pagesMCQs Chip FormationMohsin QaziNo ratings yet

- Important Topics For GATEDocument6 pagesImportant Topics For GATEuddeshya patel100% (1)

- Computer Applications in DesignDocument7 pagesComputer Applications in Designmskumar_5540% (1)

- Limits and TolerancesDocument15 pagesLimits and TolerancesVipin SurendranathNo ratings yet

- Interview Questions For Fresher Mechanical Design Engineer - 1552753384Document7 pagesInterview Questions For Fresher Mechanical Design Engineer - 1552753384Radhika SuhasNo ratings yet

- Mechanical Design Interview Questions and AnswersDocument16 pagesMechanical Design Interview Questions and Answersarshad khanNo ratings yet

- Drawing SymbolsDocument56 pagesDrawing Symbolsmohan reddyNo ratings yet

- Measurement - Using Basic Precision Dimensional InstrumentsDocument49 pagesMeasurement - Using Basic Precision Dimensional InstrumentskrishnaNo ratings yet

- ACCRETECH Guide Measuring Forms ENDocument20 pagesACCRETECH Guide Measuring Forms ENpatrikcncNo ratings yet

- AD-75V / AD-758V Parts Manual: Phase 7 / Dual Timer / OPL With Fire Suppression System OptionsDocument52 pagesAD-75V / AD-758V Parts Manual: Phase 7 / Dual Timer / OPL With Fire Suppression System OptionsCarlos Castillo UrrunagaNo ratings yet

- Geotechnical Earthquake EngineeringDocument3 pagesGeotechnical Earthquake EngineeringSwapan PaulNo ratings yet

- Module 2 - Diesel FinalDocument24 pagesModule 2 - Diesel FinalCharmaine Mae RetizaNo ratings yet

- SP 2345000Document1 pageSP 2345000Yirleen Quiroz MielesNo ratings yet

- 11-An - Industrial Dehumidifier SizingDocument4 pages11-An - Industrial Dehumidifier Sizingthilangac100% (1)

- Ferritic Malleable Iron Castings: Standard Specification ForDocument5 pagesFerritic Malleable Iron Castings: Standard Specification ForVIKAS DAHIYANo ratings yet

- Induction Heating Validation of Dieless SPIF of AHSSDocument10 pagesInduction Heating Validation of Dieless SPIF of AHSSrene.mayerNo ratings yet

- EDD - Electronic - Diagnostic - DeviceDocument6 pagesEDD - Electronic - Diagnostic - DeviceM. Shaat100% (1)

- A GA-230077 1 OF 1: Bore & Keyway Details Id Fan Hub Bore & Keyway Details Motor (VFD) HubDocument1 pageA GA-230077 1 OF 1: Bore & Keyway Details Id Fan Hub Bore & Keyway Details Motor (VFD) Hubwaj1No ratings yet

- Curriculum Vitae: ObjectiveDocument5 pagesCurriculum Vitae: ObjectiveMD ASIF ALINo ratings yet

- Bro - Cryogenic Pumps Edition - 2024 V6 - Single PagesDocument50 pagesBro - Cryogenic Pumps Edition - 2024 V6 - Single PagesDũng LêNo ratings yet

- 1TL0022英文(11.29) BEIDE MOTORDocument26 pages1TL0022英文(11.29) BEIDE MOTORRoberto Casper100% (1)

- Analysis of Cylindrical Water TanksDocument8 pagesAnalysis of Cylindrical Water TanksNabeel KhanNo ratings yet

- Astm A394 PDFDocument6 pagesAstm A394 PDFedue slip100% (1)

- Npcil Question Paper Kakrapar PDFDocument14 pagesNpcil Question Paper Kakrapar PDFRandax Bhosdax0% (1)

- Physgen Cu2Document27 pagesPhysgen Cu2emji miraNo ratings yet

- Esdep Lecture Note (Wg15a)Document18 pagesEsdep Lecture Note (Wg15a)GhoozyNo ratings yet

- JCB 3CX15Document28 pagesJCB 3CX15Leobardo DiazNo ratings yet

- PAI Mack & Volvo Applications 2018: Catalog Data Sheet MP7 / MP8 SeriesDocument3 pagesPAI Mack & Volvo Applications 2018: Catalog Data Sheet MP7 / MP8 SeriesAlexis SanchezNo ratings yet

- DAIKINDocument20 pagesDAIKINallym81No ratings yet

- INSPECTION REPORT EQUIPMENT Vacum, W Truck 1 Rev.3Document4 pagesINSPECTION REPORT EQUIPMENT Vacum, W Truck 1 Rev.3tirtamas berkah makmur100% (1)

- Glossary of ForgingDocument46 pagesGlossary of ForgingBHAVESH JOSHINo ratings yet

- National Certificate in Automotive MachanicsDocument63 pagesNational Certificate in Automotive MachanicsMuwonge StephanoNo ratings yet

- ® Maintenance: Ctros TelligentDocument5 pages® Maintenance: Ctros TelligentBishoo ShenoudaNo ratings yet

- Catalogo Motor DFAC 2.5 TDocument78 pagesCatalogo Motor DFAC 2.5 Tjimmorse100% (1)

- 2017-Kawasaki-Kx450f-7 Owners ManualDocument206 pages2017-Kawasaki-Kx450f-7 Owners ManualBong BongNo ratings yet

- Kg-Mech - Mep (Training Details)Document25 pagesKg-Mech - Mep (Training Details)Adil49No ratings yet

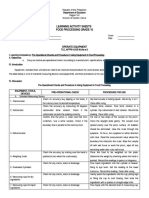

- Learning Activity Sheets Food Processing Grade 10: Operate EquipmentDocument4 pagesLearning Activity Sheets Food Processing Grade 10: Operate EquipmentPrilaNo ratings yet