Professional Documents

Culture Documents

Filler Wire Selection - 1

Filler Wire Selection - 1

Uploaded by

Tulasidas SugguOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filler Wire Selection - 1

Filler Wire Selection - 1

Uploaded by

Tulasidas SugguCopyright:

Available Formats

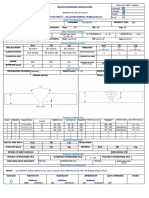

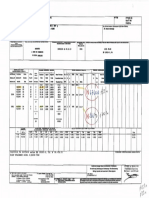

WELDING CONSUMABLE CHART

Welding Process Preheat Temp. Interpass Temp. Post

Material

GTAW SMAW FCAW SAW (°C) (°C) Heating

SA 106 Gr.B EA2 + 10 °C for

250°C for

CARBON STEEL

SA 210 Gr.A1 UV420TTR FLUX T < 25

4 Hrs. (Min.)

SA 516 Gr. 60 or

& 100 °C for

ER70S-2 E7018 E71T-1 250°C ,400'C for STBW 350°C for

SA 516 Gr. 70 25 <T < 150

2 Hrs. (Min.)

EL8 +

SA 105 / IS 2062 LINCOLN 780 FLUX 150 °C for if T > 50 mm.

(FOR PEMA) T > 150

SA 234 WPB/WPC

SA 213 T11/T12 120 °C for

S 335 P11/P12 T < 13

350°C for

EB2 +

SA 182 F11/F12 ER80S-B2 E8018-B2 E81T1-B2 350°C 2 Hrs. (Min.)

UV420TTR FLUX

150 °C for if T > 35 mm.

SA 234 WP11/12

T > 13

SA 387 Gr.11/12

SA 213 T21/T22 150 °C for

T < 13

ALLOY STEEL

S 335 P21/P22

350°C for

EB3 +

SA 182 F21/F22 ER90S-B3 E9018-B3 E91T1-B3C 350°C 2 Hrs. (Min.)

UV420TTR FLUX

200 °C for if T > 25 mm.

SA 234 WP21/22

T > 13

SA 387 Gr.22

SA 335 P9 350°C for

2 Hrs. (Min.)

SA 213 T9 for GTAW upto

ER80S-B8 E8018-B8 E81T1-B8C ---------

SA 234 WP9 12 mm thk.

200 °C 350°C

SA 182 F9 350°C for

SA 335 P91 4 Hrs. (Min.)

ER90S-B9 E9015-B9 E91T1-B9C --------- for GTAW+SMAW,

SA 213 T91 FCAW

SS 304 ER308 E308-16 E308T1-1 ---------

SS 304L ER308L E308L-16 E308LT1-1 ---------

SS 304H ER308H E308H-16 E308HT1-1 ---------

STAINLESS

SS 310 / SS 310H ER310 E310-16 E310T1-1 ---------

STEEL

SS 316 ER316 E316-16 E316T-1 --------- 10°C 150°C N.A.

SS 316L ER316L E316L-16 E316LT-1 ---------

SS 316H ER316H E316H-16 E316T-1 ---------

SS 321 / SS 321H ER321 E347-16 E347T0-3 ---------

SS 347 / SS 347H ER347 E347-16 E347T0-3 ---------

Gr.11 to C.S. ER80S-B2 E8018-B2 E81T1-B2 EB2 + UV420TTR FLUX SAME as GR.11

Gr.22 to C.S. ER90S-B3 E9018-B3 E91T1-B3 EB3 +

SAME as GR.22

Gr.11 to Gr.22 ER90S-B3 E9018-B3 E91T1-B3 UV420TTR FLUX

Gr.22 to Gr.91/Gr.9 ER90S-B3 E9018-B3 E91T1-B3 --------- SAME as GR.91

CS to SS 304 ER309 E309-16 E309T1-1 ---------

CS to SS 316 / SS 316H ER309Mo E309Mo-16 E309MoT1-1 ---------

PREHEATING IS REQUIRED FOR C.S. SIDE

CS to SS 304L ER309L E309L-16 E309LT1-1 --------- N.A.

NOT FOR SS SIDE

CS to SS 304H ER309 E309H-16 E309T1-1 ---------

CS to SS 316L ER309LMo E309LMo-16 E309LMoT1-1 ---------

AS to SS 304/310/316/321/347 ER309Mo E309Mo-16 E309MoT1-1 --------- PREHEATING IS REQUIRED FOR A.S. SIDE

N.A.

AS to SS 304L/316L ER309LMo E309LMo-16 E309LMoT1-1 --------- NOT FOR SS SIDE

Gr.9 & Gr.91 to SS ERNiCr-3 ENiCrFe-3/ENiCrFe-2 --------- --------- SAME as GR.91

NOTES (1) FOR SMAW PROCESS, WEAVING SHALL BE 3 TIMES CORE DIA. (MAX.)

(2) FOR GTAW PROCESS, SHIELDING GAS - ARGON (FLOW RATE 5 TO 12 LPM)

(3) FOR GTAW PROCESS, BAKING GAS (IF APPLICABLE) - ARGON (FLOW RATE 8 TO 12 LPM)

(4) FOR FCAW PROCESS, SHIELDING GAS - CO2 (FLOW RATE 10 TO 20 LPM)

(5) USE DCEP POLARITY FOR SMAW, FCAW, SAW PROCESS

(6) USE DCEN POLARITY FOR GTAW PROCESS

(7) USE UPHILL PROGRESSION FOR VERTICAL WELDING

(8) THESE ARE GENERAL REQUIREMENTS

(9) PLEASE REFER THE APPLICABLE WPS FOR SPECIFIC REQUIREMENTS

CS - CARBON STEEL, AS - ALLOY STEEL OTHER THAN Gr.9 & Gr.91, SS - STAINLESS STEEL, N.A. - NOT APPLICABLE

You might also like

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- Weld Repair Rev. 1Document3 pagesWeld Repair Rev. 1vinas kusdinarNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- Welding Insection ReportDocument4 pagesWelding Insection ReportRanjeet MouryaNo ratings yet

- WPS ISO 15614-1 WeldNote MetricDocument1 pageWPS ISO 15614-1 WeldNote MetricVirgil SorcaruNo ratings yet

- ALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and InspectionDocument31 pagesALN FP ESA MEC SPC 0001 - 92B2.1 General Welding, Fabrication and Inspectionahmed.njahNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Zox ListDocument2 pagesZox ListAdrijana MiladinovicNo ratings yet

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- DPR FormatDocument79 pagesDPR FormatMITHUNNo ratings yet

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- Preparation and Control of WeldingDocument3 pagesPreparation and Control of Weldingbalakumar rajaramNo ratings yet

- Material Traceability ProcedureDocument12 pagesMaterial Traceability Procedureqamar qateebNo ratings yet

- Wps FormatDocument12 pagesWps FormatGohilakrishnan ThiagarajanNo ratings yet

- Hard Facing Overlay PDF FreeDocument2 pagesHard Facing Overlay PDF Freemayav1No ratings yet

- Weld History Sheet-4Document4 pagesWeld History Sheet-4MITHUN100% (1)

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Visual Inspection FormatDocument2 pagesVisual Inspection Formattuan mai vanNo ratings yet

- Guidance To Prepare Wps PQR For WeldingDocument1 pageGuidance To Prepare Wps PQR For WeldingHamid MansouriNo ratings yet

- Wqt-Visual-Mag - BS 2Document24 pagesWqt-Visual-Mag - BS 2KyNo ratings yet

- Welding Repair ProcedureDocument4 pagesWelding Repair ProcedureRiky SumantriNo ratings yet

- Welding Coordinator WeldMap Weld Data Sheet PDFDocument1 pageWelding Coordinator WeldMap Weld Data Sheet PDFAzhar AhmadNo ratings yet

- Demystifying vSAN Management For The Traditional Storage AdministratorDocument63 pagesDemystifying vSAN Management For The Traditional Storage Administratormuhammad ihsanNo ratings yet

- P-WPS 135 - MAG (GR 316)Document9 pagesP-WPS 135 - MAG (GR 316)Tarun PatelNo ratings yet

- Welding Procedure Qualification Record: Shipyard LogoDocument4 pagesWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- Siemens Mobilett Plus HP Prospekt enDocument2 pagesSiemens Mobilett Plus HP Prospekt enNathaniel Imade100% (1)

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Piping Course 1Document97 pagesPiping Course 1AfetNo ratings yet

- Welding Parameters Control PipelineDocument1 pageWelding Parameters Control PipelinemusheerNo ratings yet

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- Harmonized Standards Under PED - Pressure Equipment - European Standards - Enterprise and IndustryDocument12 pagesHarmonized Standards Under PED - Pressure Equipment - European Standards - Enterprise and IndustryKetan Choukekar0% (1)

- Welding Specification ChartDocument189 pagesWelding Specification ChartVivek SatapathyNo ratings yet

- MPQT Alishar SPM 3 31.08.2013 To 02.09.2013Document68 pagesMPQT Alishar SPM 3 31.08.2013 To 02.09.2013mdsajidalamNo ratings yet

- Wps Register Last Updated May 12Document1 pageWps Register Last Updated May 12Abdullah Al JubayerNo ratings yet

- QW-403 6Document1 pageQW-403 6Solikhul HarisNo ratings yet

- Company Profile - Rizhao Steel YingkouDocument41 pagesCompany Profile - Rizhao Steel Yingkourashid isaarNo ratings yet

- Vishal Mart Week 1 ProjectDocument23 pagesVishal Mart Week 1 Projectsyed ahmedNo ratings yet

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- Welder CertificateDocument6 pagesWelder CertificateA. ΒρατσισταNo ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNo ratings yet

- Prequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Document2 pagesPrequalified Welding Procedure Spesification (WPSS) : (Semiautomatics, Mechanized, Etc)Nuril VS theWorldNo ratings yet

- Welding Procedure SpecificationDocument2 pagesWelding Procedure SpecificationHasan Ahmed100% (1)

- En 12451 1999Document24 pagesEn 12451 1999victoraghiNo ratings yet

- Weld Repair Rate - MFJO542Document2 pagesWeld Repair Rate - MFJO542Salahuddin Farooqui100% (1)

- Inspection of Heat ExcahngeDocument32 pagesInspection of Heat ExcahngeAfetNo ratings yet

- Arcomed Volumed UVP-7000 - Maintenance ManualDocument44 pagesArcomed Volumed UVP-7000 - Maintenance Manualmorton1472No ratings yet

- Flame StraighteningDocument3 pagesFlame StraighteningAvishek Gupta100% (1)

- Welder Monitoring SheetDocument1 pageWelder Monitoring SheetQC apollohx100% (1)

- 10.LPI. Report FormatDocument1 page10.LPI. Report FormatEr Sumant Kumar SinghNo ratings yet

- Welding Procedure Specification (WPS) : Joint Design Welding SequencesDocument1 pageWelding Procedure Specification (WPS) : Joint Design Welding SequencesFerhat KahveciNo ratings yet

- 2010 SIMR ApplicationDocument5 pages2010 SIMR Applicationrdor5No ratings yet

- MTC 4500528257 Iii - 210209Document3 pagesMTC 4500528257 Iii - 210209Saul Omar Fernandez RojasNo ratings yet

- Body Flanges On Shells: (Name and Address of Manufacturer)Document3 pagesBody Flanges On Shells: (Name and Address of Manufacturer)David SantosNo ratings yet

- EN 15614-1 Welding Procedure Qualification Record List: F - 7.5.1 - TI - (R00) - 02Document6 pagesEN 15614-1 Welding Procedure Qualification Record List: F - 7.5.1 - TI - (R00) - 02BasarNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- A Comparison of ISO 15614 Part 1 and ASME IXDocument2 pagesA Comparison of ISO 15614 Part 1 and ASME IXtuanNo ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Test Certificate: Zhejiang Huaxia Flow Technology Co.,LtdDocument1 pageTest Certificate: Zhejiang Huaxia Flow Technology Co.,LtdjohnjaricocNo ratings yet

- TDC - CS PipeDocument1 pageTDC - CS PipetrushalpanchalNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- Welding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Document1 pageWelding Procedure Specification: WPS For Overlay and Repair OF Martenzetic SS (GTAW +SMAW)Lipika GayenNo ratings yet

- ASTM A453 Grade 660 Stud - Bolt.nut - WasherDocument1 pageASTM A453 Grade 660 Stud - Bolt.nut - WasherTdk DallasNo ratings yet

- Material Certificate Plate 16mmDocument1 pageMaterial Certificate Plate 16mmAdeoyeNo ratings yet

- Poster Consumable - Data 7Document4 pagesPoster Consumable - Data 7Harminder KumarNo ratings yet

- Poster-Consumable Data-1Document4 pagesPoster-Consumable Data-1Lipika GayenNo ratings yet

- SITE WPS-IndexDocument7 pagesSITE WPS-Indexgowtham_venkat_4No ratings yet

- Data Sheet: Standard and Test Method Unit PropertiesDocument2 pagesData Sheet: Standard and Test Method Unit PropertiesAfetNo ratings yet

- Where We Go Wrong in Pump Design: Dick Hawrelak Presented To ES317Y in 1999 at UWODocument20 pagesWhere We Go Wrong in Pump Design: Dick Hawrelak Presented To ES317Y in 1999 at UWOAfetNo ratings yet

- 2016 CPE3002 L5 Separators Compressors 12 October (1) (Autosaved)Document60 pages2016 CPE3002 L5 Separators Compressors 12 October (1) (Autosaved)AfetNo ratings yet

- Iso 8503 4Document11 pagesIso 8503 4AfetNo ratings yet

- Training Guidelines in Non-Destructive Testing Techniques: Leak Testing at Level 2Document186 pagesTraining Guidelines in Non-Destructive Testing Techniques: Leak Testing at Level 2AfetNo ratings yet

- Hempel's Curing Agent MSDSDocument10 pagesHempel's Curing Agent MSDSAfet50% (2)

- Material Testing MethodsDocument21 pagesMaterial Testing MethodsAfetNo ratings yet

- Awwa C209-06Document30 pagesAwwa C209-06AfetNo ratings yet

- Filme, CartiDocument12 pagesFilme, CartiDiana RădulescuNo ratings yet

- Milling Process Slides PDFDocument22 pagesMilling Process Slides PDFNishchay pratapNo ratings yet

- Hoopz AimbotDocument11 pagesHoopz AimbotAarav AnandNo ratings yet

- Perusahaan Di Daerah Pondok IndahDocument7 pagesPerusahaan Di Daerah Pondok IndahNIKOLAUS MITENNo ratings yet

- Caltex Aquatex 3180-0805Document3 pagesCaltex Aquatex 3180-0805faisiiNo ratings yet

- Claremont COURIER 1-12-18Document32 pagesClaremont COURIER 1-12-18Peter WeinbergerNo ratings yet

- Donnie DarkoDocument8 pagesDonnie DarkoTopängä MändingoNo ratings yet

- Management A Focus On Leaders 2nd Edition Mckee Test BankDocument25 pagesManagement A Focus On Leaders 2nd Edition Mckee Test Bankwalterhubert6rl7mj100% (26)

- Yealink SIP Phones Release Notes of Version80Document34 pagesYealink SIP Phones Release Notes of Version80Muhammad SiddiuqiNo ratings yet

- Earthquake Analysis Based On Eurocode 8 Static Lateral Force MethodDocument4 pagesEarthquake Analysis Based On Eurocode 8 Static Lateral Force MethodAnonymous O404LiV4CNo ratings yet

- Cambridge IGCSE: MATHEMATICS 0580/04Document64 pagesCambridge IGCSE: MATHEMATICS 0580/04lhaNo ratings yet

- Fundamentals of Accountancy, Business, and Management 2 Activity 2Document1 pageFundamentals of Accountancy, Business, and Management 2 Activity 2Joseph CincoNo ratings yet

- Colorful Number Wall Mathematics PosterDocument4 pagesColorful Number Wall Mathematics PosterNURUL SYAHIRAH BINTI MOHD ZOLKIPLI KPM-GuruNo ratings yet

- 6se7087 6BH70 PDFDocument74 pages6se7087 6BH70 PDFAmir SayahanNo ratings yet

- Lemak Dan MinyakDocument93 pagesLemak Dan MinyakBunga AnggrainiNo ratings yet

- Woodwork: PAPER 2 Practical TestDocument6 pagesWoodwork: PAPER 2 Practical Testmstudy123456No ratings yet

- Snag List For 142041Document4 pagesSnag List For 142041kassa hilemnehNo ratings yet

- 1 PBDocument19 pages1 PB200111100281No ratings yet

- PsychopathxXx Alpha Sigma Omicron 2 SlavedDocument225 pagesPsychopathxXx Alpha Sigma Omicron 2 Slavedwafah pangcogaNo ratings yet

- Robots Fail Too - A Case StudyDocument3 pagesRobots Fail Too - A Case StudyShaharyar Khan100% (4)

- Pytmmca Ficcl85158973215 LDNDocument2 pagesPytmmca Ficcl85158973215 LDNjaya krishnaNo ratings yet

- Loop O9300-25Document93 pagesLoop O9300-25Bogdan CacuciNo ratings yet

- LG FFH386Document14 pagesLG FFH386Abraham BautistaNo ratings yet

- Combina Sanyo Service ManualDocument41 pagesCombina Sanyo Service ManualflorinNo ratings yet