Professional Documents

Culture Documents

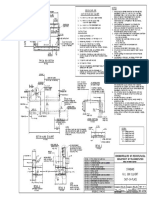

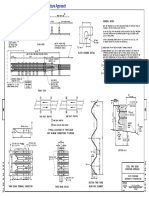

"4" Bar Detail "3" Bar Detail "2" Bar Detail "1" Bar Detail "5" Bar Detail

Uploaded by

Pooya NikOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"4" Bar Detail "3" Bar Detail "2" Bar Detail "1" Bar Detail "5" Bar Detail

Uploaded by

Pooya NikCopyright:

Available Formats

= = = = = = = = = = = = = = = NOTES

= = = SEE NOTE "6" = =

(TYP.) 1-ALL THICKNESS VALUES AND DIMENSIONS ARE

IN mm.

2-ALIGNMENT BARS TO BE SQUARE END CUT AND

CORNER GROUND TO CONTOUR OF CROTCH &

FLUSH MOUNTED IN LINE WITH THE INSIDE

DETAIL "B" WALL OF RUN PIPE.

(TYP.)

3-FILLET WELDS OF BARS MUST NOT EXTEND

INTO CROTCH OF TEE.

4-BAR MATERIAL IS HOT ROLLED MILD STEEL

PLATE UNLESS OTHERWISE SPECIFIED.

"5" BAR DETAIL "4" BAR DETAIL "3" BAR DETAIL "2" BAR DETAIL "1" BAR DETAIL 5-PER STANDARD PRACTICE WELDING IS

PERMITTED ON PLATE TYPE BARS IN ORDER TO

"A"

MAINTAIN THE SPECIFIED CLEARENCE OF TEE.

6-THIS DIMENSION SHALL BE SAME AS BAR PLATE

THICKNESS USED IN OUTLET. IT MAY VARY

DUE TO OUTLET HEIGHT AVAILABLE.

BRANCH PIPE SIZE

NPS 4" 6" 8" 10" 12" 14" 16" 18" 20" 22" 24" 26" 28" 30" 32" 34" 36" 42" 48" 7-SQUARE END CUT AND GROUND TO FIT OUTLET

CONTOUR ALONG ONE CORNER OF BAR.

NPS DN 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800 850 900 1050 1200

8-SQUARE END CUT AND ROUND ALL SHARP

4" 100

CORNERS TO 3mm. RADIUS.

6" 150 6

9-CLEARANCE 1.5+

- 1.5 FOR ALL PLATES.

8" 200 6

6

10-FOR REINFORCEMENT & PROTECTION OF

10" 250 6

SIDE VIWE SECTION

SCRAPER GUIDE BAR, EQUALLY SPACED GUIDE

12" 300 12 BAR SUPPORTS SHOULD BE USE AS

FOLLOWING:

14" 350 12

NOTE "7 & 9" BRANCH NO. OF GUIDE Ø DIA.

16" 400 12 DIAMETER BAR SUPPORT mm

RUN PIPE SIZE

18" 450 12 22"~30" 3 12

20" 500 12 TEE OUTLET BARS 32"~48" 4 20

INSIDE

22" 550 12 "C"

24" 600 12

26" 650 12 SEE NOTE "9"

2

VIEW "A"

28" 700 12

1

30" 750 0

NOTE "2"

REV. DESCRIPTION DATE

32" 800 20 20

20

34" 850 20 20

20

20

20 IRANIAN PETROLEUM STANDARDS

36" 900 20

NOTE "3"

20 NO REVISION PERMITTED UNLESS APPROVED BY STANDARD ORGANIZATION

42" 1050 RUN D

20

2D

25 INSIDE DIAMETER

48" 1200 25 SCRAPER GUIDE BARS FOR

1 2 3 4 5

PIPELINE TEES

BAR No. BARS SHOULD

NOT EXTEND

INTO FLOW AREA

DIMENSION TABLE

PLATE THICKNESS (D) OF BARS

DETAIL "B" VIEW "C" DATE DRAWING No. SHEET REV.

1

NOTES "2" & "8" NOTE "5" IPS-D-PI-149 1

0

You might also like

- Alignment bar installation detailsDocument1 pageAlignment bar installation detailsPooya NikNo ratings yet

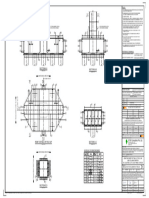

- Plan View Section A-A Scale: N.T.S.: NAUBU-1-8737-D-16605Document1 pagePlan View Section A-A Scale: N.T.S.: NAUBU-1-8737-D-16605GNo ratings yet

- Junction Box Installation in Traffic BarrierDocument1 pageJunction Box Installation in Traffic BarrierAdnan NajemNo ratings yet

- Grease Trap Manhole Frame InstallationDocument1 pageGrease Trap Manhole Frame Installationbladeliger22No ratings yet

- 1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)Document1 page1 Detail (Type 1 Capping Beam) Elevation of Expansion Joint Details (Typ.)rohanZorbaNo ratings yet

- SIP 패널 설계예제 (Washington DoT)Document19 pagesSIP 패널 설계예제 (Washington DoT)Yongsoo AhnNo ratings yet

- Glamping, Deluxe, Power, MRF, Guard ST-3Document1 pageGlamping, Deluxe, Power, MRF, Guard ST-3engr. abet hilarioNo ratings yet

- QP10-U-703 Rev0 Typical Line MarkerDocument1 pageQP10-U-703 Rev0 Typical Line MarkernawajhaNo ratings yet

- End of Bridge Approach Slab Guardrail Connection DetailsDocument1 pageEnd of Bridge Approach Slab Guardrail Connection DetailsAdnan NajemNo ratings yet

- R.C. Columns Schedule and Details: Schedule of Reinforced Concrete Columns Schedule of Reinforced Concrete BeamsDocument1 pageR.C. Columns Schedule and Details: Schedule of Reinforced Concrete Columns Schedule of Reinforced Concrete BeamsMario MuliNo ratings yet

- QP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementDocument1 pageQP10-Q-610 Rev0 Typical Yard Shaft - General ArrangementnawajhaNo ratings yet

- House PlanDocument1 pageHouse PlanEury AlzagaNo ratings yet

- Inlet Structures I-3, EX-3, MH-1Document6 pagesInlet Structures I-3, EX-3, MH-1Ethan AlpheusNo ratings yet

- Septic Tank DetailsDocument1 pageSeptic Tank DetailsRohn J JacksonNo ratings yet

- Bridge Engineeing Drawings 10.2 - A6 - 3Document1 pageBridge Engineeing Drawings 10.2 - A6 - 3Adnan NajemNo ratings yet

- Column Location Layout: - Cadd Designer'SDocument1 pageColumn Location Layout: - Cadd Designer'SDileep K MahadevaiahNo ratings yet

- Typical U.S. Harbour Tug: James P. WoodsDocument2 pagesTypical U.S. Harbour Tug: James P. WoodsPeterNo ratings yet

- Bridge Engineering Drawings 10.2 - A3 - 3Document1 pageBridge Engineering Drawings 10.2 - A3 - 3Adnan NajemNo ratings yet

- Bed Up Bar For WatertankDocument1 pageBed Up Bar For WatertankE.PrasathNo ratings yet

- ECE01Document1 pageECE01johnkarl.bentingNo ratings yet

- 01 Car Expo 7 Oct 022 Final 27Document1 page01 Car Expo 7 Oct 022 Final 27adnan-651358No ratings yet

- DWG. No. 117Document1 pageDWG. No. 117Mubashar Islam JadoonNo ratings yet

- Ad 036763 001Document1 pageAd 036763 001hai sunNo ratings yet

- A B C 2650 2200 4850 9700 A1: Revision No. byDocument1 pageA B C 2650 2200 4850 9700 A1: Revision No. byPaschal MazikuNo ratings yet

- Bridge Girder Reinforcement DetailsDocument1 pageBridge Girder Reinforcement DetailsJesús Rodríguez RodríguezNo ratings yet

- Bridge Engineeing Drawings 10.2 - A4 - 3Document1 pageBridge Engineeing Drawings 10.2 - A4 - 3Adnan NajemNo ratings yet

- 7 Section XXDocument1 page7 Section XXmdNo ratings yet

- 450mm retaining wall cross section detailsDocument1 page450mm retaining wall cross section detailsArchana PansareNo ratings yet

- Existing Building: To Existing Waterline To Existing Drainage LineDocument1 pageExisting Building: To Existing Waterline To Existing Drainage Linejoseph arao-araoNo ratings yet

- Junction Box Installation in Traffic BarrierDocument1 pageJunction Box Installation in Traffic BarrierAdnan NajemNo ratings yet

- Pedestrian Bridge Design SpecificationsDocument13 pagesPedestrian Bridge Design SpecificationsyasirjurabaNo ratings yet

- A008 Stan Roof FRDocument1 pageA008 Stan Roof FRkecalli.restauranteNo ratings yet

- Screenshot 2023-12-07 at 12.32.50 PMDocument1 pageScreenshot 2023-12-07 at 12.32.50 PMrashidkamal456No ratings yet

- WDD First Floor Plaster-Layout1Document1 pageWDD First Floor Plaster-Layout1Aaron lisboaNo ratings yet

- WDD First Floor Plaster-ELEVATIONS-Layout1Document1 pageWDD First Floor Plaster-ELEVATIONS-Layout1Aaron lisboaNo ratings yet

- Design reinforcement for cast-in-place box culvertDocument13 pagesDesign reinforcement for cast-in-place box culvertPRAKASHNo ratings yet

- Besada BT05 Sheet3 SectionandplotdetailsDocument1 pageBesada BT05 Sheet3 SectionandplotdetailsBesada BryanNo ratings yet

- Tender Drawing For StructuralDocument12 pagesTender Drawing For StructuralSaif MohammadNo ratings yet

- List of Miscellenious DrawingDocument1 pageList of Miscellenious DrawingRamBhuvan SonkarNo ratings yet

- Transportation Idaho Department: NotesDocument1 pageTransportation Idaho Department: NotesBikash SigdelNo ratings yet

- Thrie Beam DesignDocument10 pagesThrie Beam DesignParikshit GaurNo ratings yet

- Wall Footing Details: Typical Connection Detail of Masonry WallDocument1 pageWall Footing Details: Typical Connection Detail of Masonry WallCarlo M. FloresNo ratings yet

- Slab and beam reinforcement scheduleDocument1 pageSlab and beam reinforcement scheduleZandie GarciaNo ratings yet

- Roof bracing dimensionsDocument1 pageRoof bracing dimensionsmirfanjpcgmailcomNo ratings yet

- Mega-Stup-St-Ns-Apm-Pk1-Fdn-04 R0Document1 pageMega-Stup-St-Ns-Apm-Pk1-Fdn-04 R0swapan.boseNo ratings yet

- 2 Row HPC For BC SoilDocument1 page2 Row HPC For BC SoilShivam SharmaNo ratings yet

- PVCPipe Bow PlansDocument1 pagePVCPipe Bow Planscharles blairNo ratings yet

- UBMPVCPipeBowPlans PDFDocument1 pageUBMPVCPipeBowPlans PDFtaufiqNo ratings yet

- DD 950016 001Document1 pageDD 950016 001samiabdulwahabNo ratings yet

- Section A-A: NotesDocument1 pageSection A-A: NotesYazan MohammadNo ratings yet

- TempleDocument1 pageTempleAMAZE INTERIORNo ratings yet

- SD-208 - Rev 2Document1 pageSD-208 - Rev 2sathishNo ratings yet

- HPC 1x1000 EncasingDocument1 pageHPC 1x1000 EncasingShivam SharmaNo ratings yet

- FUEL TANK 500 LITER-ModelDocument1 pageFUEL TANK 500 LITER-ModelzeshanjamilNo ratings yet

- CM Pit Details 6X8Document4 pagesCM Pit Details 6X8Felipe Godinez GarciaNo ratings yet

- FOOTING IBS & RC WALL - New PRGS 11 Apr 2019-ModelDocument1 pageFOOTING IBS & RC WALL - New PRGS 11 Apr 2019-Modelazhar ahmadNo ratings yet

- Three-tier fountain structural detailsDocument1 pageThree-tier fountain structural detailsPrashant100% (1)

- Bridge Engineeing Drawings 10.2 - A1 - 3Document1 pageBridge Engineeing Drawings 10.2 - A1 - 3Adnan NajemNo ratings yet

- Legend: Cbsc8 Earth Pit: Pig Signaller PTDocument1 pageLegend: Cbsc8 Earth Pit: Pig Signaller PTFinanceAdmin FKSIENo ratings yet

- OIL & GAS Maintenance Guide - VALVEDocument24 pagesOIL & GAS Maintenance Guide - VALVENouredine Looki100% (1)

- PSC Two Span Bridge Design TutorialDocument37 pagesPSC Two Span Bridge Design TutorialSony JsdNo ratings yet

- DSR Book Vol 2 2016 (English Version) Final (Full Permission)Document258 pagesDSR Book Vol 2 2016 (English Version) Final (Full Permission)Shyam Kumar88% (16)

- PCCP Method StatementDocument4 pagesPCCP Method StatementWendell ParasNo ratings yet

- Fundamentals of Engineering Tribology With Applications / Harish Hirani. - Delhi, Cop. 2016Document5 pagesFundamentals of Engineering Tribology With Applications / Harish Hirani. - Delhi, Cop. 2016Dr Junaid Hassan MasoodiNo ratings yet

- Roofseal P & GDocument2 pagesRoofseal P & GStruct EngineeringNo ratings yet

- Tensile Test of Steelwork BS & enDocument11 pagesTensile Test of Steelwork BS & enTony Lai100% (1)

- Lecture # 3 - Building Permits, Codes, and Construction StandardsDocument24 pagesLecture # 3 - Building Permits, Codes, and Construction StandardsMohsin JavedNo ratings yet

- Final Report - 06.12.2018Document57 pagesFinal Report - 06.12.2018swapneelkalraNo ratings yet

- Limit State of Collapse-TorsionDocument34 pagesLimit State of Collapse-Torsionmdaashu100% (1)

- BFC 31802 Chapter 1 PDFDocument38 pagesBFC 31802 Chapter 1 PDFqqwertyuioppNo ratings yet

- B. Importance of Preheat, Interpass, DHT, Isr, PWHTDocument19 pagesB. Importance of Preheat, Interpass, DHT, Isr, PWHTJay ShahNo ratings yet

- Design BuildDocument5 pagesDesign BuildNitish JhaNo ratings yet

- ASTM D 3163 - 01 Determining Strength of Adhesively Bonded Rigid PlasticDocument3 pagesASTM D 3163 - 01 Determining Strength of Adhesively Bonded Rigid Plasticalin2005No ratings yet

- GBI CertificationDocument32 pagesGBI Certificationvyly1723100% (1)

- Ramp Layout and DesignDocument1 pageRamp Layout and DesignHassanIsmailJenehaNo ratings yet

- Flammable Liquid Storage Inspection (Monthly)Document8 pagesFlammable Liquid Storage Inspection (Monthly)Md: Rasel MahmudNo ratings yet

- Mechanical Engineer-Syed Zain AliDocument5 pagesMechanical Engineer-Syed Zain AliSyedZainAliNo ratings yet

- Cellular Glass DatasheetDocument2 pagesCellular Glass DatasheetmishraenggNo ratings yet

- DokaScaff Modular Scaffold SystemDocument80 pagesDokaScaff Modular Scaffold SystemFOZCAN100% (1)

- PNLD II Brochure - UsDocument2 pagesPNLD II Brochure - UsEnrique MejiaNo ratings yet

- Postmodernism Architecture: Postmodern Architecture Is A Style or MovementDocument10 pagesPostmodernism Architecture: Postmodern Architecture Is A Style or MovementAlcris CarinoNo ratings yet

- Ind PamDocument47 pagesInd PamAbhishek PandaNo ratings yet

- TDS-GEOPROTEC-GS3000S-22-01 Rev.01Document1 pageTDS-GEOPROTEC-GS3000S-22-01 Rev.01AMINNo ratings yet

- MP Hydraulic Lift Equipment 1 " 1 ": Bvin / Bvin A3Document43 pagesMP Hydraulic Lift Equipment 1 " 1 ": Bvin / Bvin A3Coil98No ratings yet

- ISO Standard Solenoid Valve SeriesDocument38 pagesISO Standard Solenoid Valve SeriesJose Julio Gomez LopezNo ratings yet

- Utilization of Plastic Bottle Waste in Sand Bricks: January 2015Document11 pagesUtilization of Plastic Bottle Waste in Sand Bricks: January 2015Sashi ThapaNo ratings yet

- NCHRP RPT 568 - Riprap Design Criteria, Recommended Specifications and Quality ControlDocument226 pagesNCHRP RPT 568 - Riprap Design Criteria, Recommended Specifications and Quality Controlaescarameia100% (1)

- Cargo - Solved Past Papers - Theory - Phase IDocument297 pagesCargo - Solved Past Papers - Theory - Phase IGurjit Singh100% (10)

- Connections ManualDocument90 pagesConnections ManualNiko Ništić100% (1)