Professional Documents

Culture Documents

AHU Datasheet Sample Detailed Page 1 of 6 1635440149

Uploaded by

alim khan0 ratings0% found this document useful (0 votes)

26 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 pageAHU Datasheet Sample Detailed Page 1 of 6 1635440149

Uploaded by

alim khanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

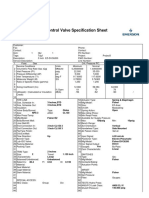

PROJECT DETAILS

CLIENT LOGO COMPANY LOGO

DATASHEET FOR AIR HANDLING UNIT

Doc. number: Contractor document N°: Not Applicable Page 1 / 6

Equipment location:

Tag No: Model:

System No: Serial No:

Sub-system No:

Supplier:

Manufacturer:

Reason for issue Rev. Stat. Date By: Checked by: Approved by:

ISSUED FOR REVIEW 0 IFR

1 Technical data 53 Ambient conditions (surrounding the AHU )

2 Air flow rate (at fan discharge): L/s. 54 Minimum temperature : °C

3 Total fan pressure: Pa 55 Relative humidity (associated to minimum temp.):

4 System effect pres. loss (inside casing): Pa 56 %

5 Available pressure for ducting: Pa 57 Maximum temperature : °C

6 Inspection side: 58 Relative humidity (associated to maximum temp.):

7 Left: Right: 59 %

8 Lifting pad eyes : Yes: No: 60 Conformance to EN 1886

9 Perforated internal skin: Yes: X 61 Unit is certified in accordance with above standard:

10 Non perforated internal skin: Yes: 62 Yes: No:

11 Earthing boss : Yes: No: 63 Certificate is issued from:

12 Performance as per EN 1886 standard: 64 VTA

13 Casing strength class: D2 65 Unit composition

14 Casing air leakage class: L2 66 Entering box: Yes: No:

15 Thermal bridge factor class: T2 67 Mixing box: Yes: No:

16 U value of casing panel: 68 Prefilter: Yes: No:

17 Unit mass: dry: kg 69 Filter: Yes: No:

18 operating: kg 70 Final filtration: Yes: No: x

19 ATEX Classification for AHU 71 Cooling coil number:

20 72 Heaing coil number:

21 Drains on left and right sides of unit: 73 Electrical heating coil number:

22 Yes: No: 74 Humidifier: Yes: No: x

23 75 Final filtering stage: Yes: No: x

24 IEC Ex Certifying Body (for ATEX certified fire dampers): 76 Dry Weight of AHU (kg):

25 77 Wet Weight of AHU (kg):

26 IEC Ex certificat reference (for ATEX certified fire dampers): 78 Operating Dynamic Weights i.e. in forces

27 79

Direction of flow

Fx:

28 When ATEX certified, unit must be inspected on site by 80 Fy:

L (left side)

29 MANUFACTURER , after assembly: 81 Fz:

30 Yes: No: 82 Dh

31 83 AHU

(right side)

32 Casing construction 84 Dw

33 Bolted: Cleated: Welded: VTA 85 Dl

34 Insulation density: kg/m3 86

35 Insulation thickness: mm 87 Lenght of air handling unit (Dl): VTA m

36 Panels thermal conductivity: W/m2.°C 88 Width of air handling unit (Dw): VTA m

37 Material thickness of external skin: mm 89 Height of air handling unit (Dh): VTA m

38 Material thickness of internal skin: mm 90 Maintenance

39 Casing material (external): 91 Inspection door with inside access

40 Casing material (internal): 92 Safety switch for Door

41 93 Entry Door

42 Ducting connections: (Raised flanged type) 94

43 Outdoor air ducting: Yes: No: 95 Mt Ml

44 Longest dimension: VTA mm 96

45 Shortest dimension: VTA mm 97

46 Recirculation air ducting: Yes: No: 98 Mi AHU Mo

(right side)

47 Longest dimension: VTA mm 99 Mi: VTA m

48 Shortest dimension: VTA mm 100 Mo: VTA m

49 Supply air ducting: Yes: No: 101 Mr Mr: VTA m

50 Longest dimension: VTA mm 102 Ml: VTA m

51 Shortest dimension: VTA mm 103 Mt: VTA m

52 *: These info shall be chkd. and updated during detailed engg. 104 Note:-Only access from Left/Right Side is available

You might also like

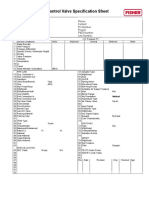

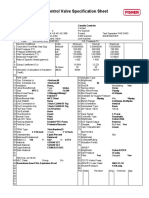

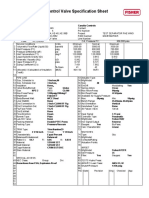

- Control Valve Specification SheetDocument8 pagesControl Valve Specification SheetEmilio GordilloNo ratings yet

- Aspf Blue Book - Fire Resisting DuctworkDocument99 pagesAspf Blue Book - Fire Resisting Ductworkm2cru70No ratings yet

- Introduction of Aluminum FormworkDocument19 pagesIntroduction of Aluminum FormworkJanice YuanNo ratings yet

- Training Manual: EASA Part-66 38 Level 3Document24 pagesTraining Manual: EASA Part-66 38 Level 3Luis Enrique La Font FrancoNo ratings yet

- BPCL Technical-DataSheet-a8a979Document13 pagesBPCL Technical-DataSheet-a8a979cnrk777inNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetGlorie Mae BurerosNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetAnthony InostrozaNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetJuan Krloz CastañedaNo ratings yet

- LaboratorioDocument2 pagesLaboratorioCesar Gabriel Zapata CasariegoNo ratings yet

- Olukunle Afeni - Datasheet Refrigerative ChillerDocument2 pagesOlukunle Afeni - Datasheet Refrigerative ChillerBolakale UthmanNo ratings yet

- Instructions For The Use of Allied Valve Control Valve Spec SheetDocument4 pagesInstructions For The Use of Allied Valve Control Valve Spec Sheetmainur mechanical engineerNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetDiego Alberto Pavisich ThomNo ratings yet

- Control Valve Specification Sheet: Fisher 2 Inches, Fisher 2 Inches, None,, Globe NPS 1/2 CL150 Fisher/24000SBDocument2 pagesControl Valve Specification Sheet: Fisher 2 Inches, Fisher 2 Inches, None,, Globe NPS 1/2 CL150 Fisher/24000SBJavier LopezNo ratings yet

- FCV 103Document1 pageFCV 103Juan Krloz CastañedaNo ratings yet

- Project NoDocument1 pageProject Nokoraina2015No ratings yet

- Control Valve Specification Sheet - PCV 3inch 600# R 1Document1 pageControl Valve Specification Sheet - PCV 3inch 600# R 1FIRMANSYAHNo ratings yet

- Opal Wwts - Tender Doc - Part 3 1411817364 14Document1 pageOpal Wwts - Tender Doc - Part 3 1411817364 14SHIVAJINo ratings yet

- TDS L290 202004Document1 pageTDS L290 202004carlosinfhNo ratings yet

- TCV 101Document1 pageTCV 101Juan Krloz CastañedaNo ratings yet

- Control Valve Specification SheetDocument1 pageControl Valve Specification SheetJuan Krloz CastañedaNo ratings yet

- LCV 105Document1 pageLCV 105Juan Krloz CastañedaNo ratings yet

- Control Valve Specification Sheet - LCV 2inch 600# R 1Document1 pageControl Valve Specification Sheet - LCV 2inch 600# R 1FIRMANSYAHNo ratings yet

- PressureReliefValves SpecsDocument11 pagesPressureReliefValves SpecsnmosilvaNo ratings yet

- WILAmed INTENSA Adult, Pediatric, Infant With EtCO2Document4 pagesWILAmed INTENSA Adult, Pediatric, Infant With EtCO2Iman Chimonx NurjamanNo ratings yet

- Offer: Project: Executed By: Contact: Pump Unit:: Operating Data Motor SpecificationDocument3 pagesOffer: Project: Executed By: Contact: Pump Unit:: Operating Data Motor Specificationkoraina2015No ratings yet

- Technical Data Sheets - Centrifugal Pumps ANSIDocument6 pagesTechnical Data Sheets - Centrifugal Pumps ANSIAdit NugrahaNo ratings yet

- PVVDocument10 pagesPVVJorge Arturo Rodríguez HerreraNo ratings yet

- 100 PSV 001 AZ Safety Pressure Valve (Design)Document2 pages100 PSV 001 AZ Safety Pressure Valve (Design)magdy salehNo ratings yet

- DTS TrafoDocument2 pagesDTS TrafoNicodemus Ervino MandalaNo ratings yet

- ADE6698 PT Motor Tech DataDocument8 pagesADE6698 PT Motor Tech DataberkahharianNo ratings yet

- Control Valve Datasheet & BOQ PDFDocument4 pagesControl Valve Datasheet & BOQ PDFFireNo ratings yet

- Data Sheet For Fire Alam & Gas Detection SystemDocument2 pagesData Sheet For Fire Alam & Gas Detection SystemShabahat Husain100% (1)

- Refereigeration Package (Convert To Chiller)Document7 pagesRefereigeration Package (Convert To Chiller)ramkumarNo ratings yet

- ARNU30GTBB4Document2 pagesARNU30GTBB4Cristian monsalve mendozaNo ratings yet

- ARUV578BTE5Document2 pagesARUV578BTE5jaimegutierrezlinganNo ratings yet

- Datasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionDocument5 pagesDatasheet Vacuum Gauge: Project Project Number Purchase Order RequisitionManodipPatilNo ratings yet

- Control Valves Specification Sheet: PT. PI EnergiDocument1 pageControl Valves Specification Sheet: PT. PI EnergiAnoNo ratings yet

- Check Sheet Rotamass TIDocument2 pagesCheck Sheet Rotamass TIdiego 10 xD OMG 2 CANAL oviedoNo ratings yet

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyenNo ratings yet

- Itherm Compactline Tm311: No AplicaDocument1 pageItherm Compactline Tm311: No AplicaFausto IguagoNo ratings yet

- GeneralDocument6 pagesGeneralmilton1987No ratings yet

- ASME Pump TemplateDocument6 pagesASME Pump TemplateyuleNo ratings yet

- Submittal FCQ24MVJU - RZQ24MVJU 07-06 - DaikinDocument1 pageSubmittal FCQ24MVJU - RZQ24MVJU 07-06 - Daikinedward sabedraNo ratings yet

- Packaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorDocument6 pagesPackaged Positive Displacement Rotary Screw Plant and Instrument Air CompressorNuzul FurqonyNo ratings yet

- Control Valve Specification SheetDocument2 pagesControl Valve Specification SheetPablo Daniel Rodriguez HernandezNo ratings yet

- Opal Wwts - Tender Doc - Part 3 1411817364 15Document1 pageOpal Wwts - Tender Doc - Part 3 1411817364 15SHIVAJINo ratings yet

- 05 PCV 07 252a, BDocument2 pages05 PCV 07 252a, BSTG INSTRUMENTNo ratings yet

- SPC/PNSDP-LPG/1/2012: of 3 Barg Req. When 50% Closed at 6,270 L/min FlowDocument1 pageSPC/PNSDP-LPG/1/2012: of 3 Barg Req. When 50% Closed at 6,270 L/min Flowkoraina2015No ratings yet

- Datasheet - Compressor - StarterDocument4 pagesDatasheet - Compressor - StarterAudhinna ZuffyNo ratings yet

- Valve Samson Model 3241 Serial 470 132 B347W701 ENDocument1 pageValve Samson Model 3241 Serial 470 132 B347W701 ENClaudio StadelmannNo ratings yet

- Harmony Control Relays - REG48PUN1JHUDocument4 pagesHarmony Control Relays - REG48PUN1JHUJose Miguel GonzalesNo ratings yet

- Compliance SheetDocument21 pagesCompliance Sheetjassim mohammedNo ratings yet

- 00257650-1000-45ED-0034 - Rev PB - WHB and Steam DrumDocument9 pages00257650-1000-45ED-0034 - Rev PB - WHB and Steam DrumSubrata DasNo ratings yet

- 05 PCV 07 296a, BDocument2 pages05 PCV 07 296a, BSTG INSTRUMENTNo ratings yet

- ARNU24GTBB4Document2 pagesARNU24GTBB4Cristian monsalve mendozaNo ratings yet

- Tya2431zes PDFDocument2 pagesTya2431zes PDFAndersson ArenasNo ratings yet

- Pumps Final TeDocument48 pagesPumps Final Tegharsallah mounaNo ratings yet

- AWR5524EXCDocument2 pagesAWR5524EXCpant.vk8514No ratings yet

- Heatcon CatalogueDocument129 pagesHeatcon CatalogueElkar CaceresNo ratings yet

- The PIC Microcontroller: Your Personal Introductory CourseFrom EverandThe PIC Microcontroller: Your Personal Introductory CourseRating: 1 out of 5 stars1/5 (2)

- Bacton Case StudyDocument6 pagesBacton Case StudyNoel BactonNo ratings yet

- Stone ArchitectureDocument257 pagesStone ArchitectureakNo ratings yet

- Zenbes Catalogue (2018)Document6 pagesZenbes Catalogue (2018)Haris FarhanNo ratings yet

- Scope of Works - Dam FenceDocument13 pagesScope of Works - Dam FenceNaji AhmedNo ratings yet

- Description of PremisesDocument2 pagesDescription of PremisesRio KelsonNo ratings yet

- Tank-A Tank-B Tank-C: Bus BayDocument4 pagesTank-A Tank-B Tank-C: Bus BayMohit AgarwalNo ratings yet

- Questions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGDocument8 pagesQuestions & Answers: Webinar: Leveraging Caesar Ii and Featools Featuring PRGMina MagdyNo ratings yet

- Calculation Rail Beam (Hoist Capacity 3 Ton)Document4 pagesCalculation Rail Beam (Hoist Capacity 3 Ton)Edo Faizal2No ratings yet

- Registration CRDocument5 pagesRegistration CRnandha gopalNo ratings yet

- What Is An Overflow Relief Gully and Why Is It Important?Document2 pagesWhat Is An Overflow Relief Gully and Why Is It Important?kjdaraNo ratings yet

- Dale Sinclair (Author) - Guide To Using The RIBA Plan of Work 2013-RIBA Publishing (2019) PDFDocument121 pagesDale Sinclair (Author) - Guide To Using The RIBA Plan of Work 2013-RIBA Publishing (2019) PDFPalaNo ratings yet

- Case Study 2Document24 pagesCase Study 2VeereshNo ratings yet

- SPAN Part H - Particular Construction...Document8 pagesSPAN Part H - Particular Construction...ang.xicongNo ratings yet

- TCC15 Resistance of Retaining Members XLDocument8 pagesTCC15 Resistance of Retaining Members XLalexanderNo ratings yet

- Deep Drawing: Benefits and Industrial ApplicationsDocument3 pagesDeep Drawing: Benefits and Industrial ApplicationsChandru NatarajanNo ratings yet

- CB Disc Spring CatalogueDocument28 pagesCB Disc Spring Cataloguekjagu87No ratings yet

- Types of Stairs PDFDocument12 pagesTypes of Stairs PDFAkshay Kumar100% (1)

- Crane Buffer ForcesDocument243 pagesCrane Buffer ForcesFourHorsemenNo ratings yet

- Technical Topics: Allowable Depth-to-Width Ratios For Glulam BeamsDocument2 pagesTechnical Topics: Allowable Depth-to-Width Ratios For Glulam BeamsciviliiiNo ratings yet

- Waterproofing ApplicationsDocument16 pagesWaterproofing ApplicationsTansel YılmazNo ratings yet

- Design Steps of One Way Slab RCCDocument7 pagesDesign Steps of One Way Slab RCCKosygin LeishangthemNo ratings yet

- Bored Pile Construction - ChrisDocument38 pagesBored Pile Construction - ChrisTerry Choi100% (2)

- Construction Industry Intrnal AuditDocument129 pagesConstruction Industry Intrnal AuditAlexandros Mavratsas100% (2)

- Water Hammer in Gravity LinesDocument12 pagesWater Hammer in Gravity LinesMuhammad Ehtsham0% (1)

- Table 13 Permitted Variations From A Flat Surface For Carbon Steel PlatesDocument1 pageTable 13 Permitted Variations From A Flat Surface For Carbon Steel PlatesamevaluacionesNo ratings yet

- Dorot S300 - English PDFDocument48 pagesDorot S300 - English PDFarmando0212-1No ratings yet

- Adecco Salary Guide: SingaporeDocument21 pagesAdecco Salary Guide: SingaporeLina GanNo ratings yet