Professional Documents

Culture Documents

Certificado Guayas Escala Reales MT Ice Victory

Certificado Guayas Escala Reales MT Ice Victory

Uploaded by

carlomonsalve1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Certificado Guayas Escala Reales MT Ice Victory

Certificado Guayas Escala Reales MT Ice Victory

Uploaded by

carlomonsalve1Copyright:

Available Formats

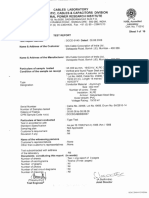

CERTIFICATE OF TEST

OF WIRE ROPE

trTLAN|rIC CORDAGE

STEELSTRAN INDUSTRIES

ATLANTIC CORDAGE

A. L. DON_AISCO_ATI,AS RIGGING

AVENEL, N,J O7O01-OO3OIGGING

'IeI:80O-458-5722

Faxt732-574-9191

2887 94

1/Atl DIATX19GAC

Ree1 Nunü)er: 12598

Nunüre r of Cuts and Lenqth Per Cub '7x 656 Feet

Method of Test RR-W_410F

Date of Test 6/13/rr

Mlnimum Breaking Load 7,000 LBS

L.'l- rr¡ I Rré^Li ññ T.^á.1 7 ,296 LBS

NOTE: ACCEPTANCE STRENGTH IS NOMINAL BREAKING LOAD LESS l2-ll2Vo PER FED. SPEC. RR-W-410F

:

TEE DATA SHOWN MREIN IS IN SIJBSTANTIAL AGREEMENT

WTTIr TIrE RpQIIIREMENTS OF THE FOLLO\VII.JG

National Cargo Bureau, Inc. Form No.5

WARNING: Any wa[anties, expressed or implied, conceming the use of this product apply or y to the nominal slrength of new, unused wire rope. All

equrpment uslng this product must be prope¡ly used and maintained. Wire rope must be properly stored, handled, us€d and maintained. Most impo¡tandy,

wire rope must be regularly inspected during use. Damage, abuse o¡ imp¡oper maintenance can cau$e rope failure. Consuh dle AISI Wire Rope Users

Manual, ASME or ANSI Standards, or Atlantic Cordage before usage Wire rope removal crirc¡ia are based on the use ofsteel sheaves. Ifsynthetic sheaves

¿re used, consult the sheave equipment manufacturer

T .'érl- i f\¡ | he above

R.ecrd@ Pen rÉtuhen on tq,o6 a,r r R.ene,.rui Pa(Tsroe 23 o6'7otL

CERTIFICATE OF TEST

OF WIRE ROPE

ATI"ANTIC. CORI'AGI

STEELSTRAN INDUSTRIES

ATLANT I C CORDAGE

A. L. DON_AISCO_ATLAS RIGGING

AVENEL, NJ O7OO1_OO3OIGGING

TeIt80O-458-5722

Faxt732-574-9I9L

2887 94

7/ 4', DIATX19GAC

Reel Nurnber: f 2599

Nunber of cuts and Lenqth Per cut 3x b5b ¡ eet

Method of Test RR - W- 410F

Date of Test 6/L3/tr

Minimum Breaking Load 7 , OOO LBS

Actual Breakíng Load 7,296 LBS

NOTE: ACCEPTANCE STRI,NGTII IS NOMINAL BREAKING LOAD LESS l2-l/29o PER FED. SPEC. RR-W-410F

;,

THE DATA SHOWN MREIN IS IN SIJBSTANTIAL AGREEMENT

wTTrr Tm RPO_UIREI{ENTS OF TIIE FOLLOWING

National Cargo Bu¡eau, Inc Form No.5

WARNING: Any wa¡raDties, exprcssed or implied, concerning the use of this product apply o¡rly to the nominal strength of new, unused wire rope. All

equipment using this p¡oduct must be properly used and maintained. Wi¡e rope must be p¡operly siored, handled, used and maintained. Most importantly,

wirc rope must be regularly inspected during use. Damage, abuse o¡ improper marntenance can cause rope failu¡e. Consult üe AISI Wire Rope Users

Manual, ASME o¡ ANSI St¿ndards, or Atlanric Cordage before usage Wire rope removal crite a arc based on the use of steel sheaves. If syñlhetic sheaves

are used, consult the sheave equipment manufacture¡,

T .rerf i fv f haf l- hÉ' ,ahove

You might also like

- Everyday Materials QuizDocument1 pageEveryday Materials Quizh4fzzNo ratings yet

- Dokumen - Tips Spherical Tanks Erection ProcedureDocument9 pagesDokumen - Tips Spherical Tanks Erection ProcedureAhmad Tedjo RukmonoNo ratings yet

- Flange Material TCDocument1 pageFlange Material TCSACHIN PATELNo ratings yet

- H Sơ NLDT Shell 818Document3 pagesH Sơ NLDT Shell 818tranthinguyet9279No ratings yet

- F, CCT: Oe EeaDocument2 pagesF, CCT: Oe Eeaabdulla kasimNo ratings yet

- Frictional Hold of Various Sheave Configurations On Synthetic RopesDocument154 pagesFrictional Hold of Various Sheave Configurations On Synthetic RopesWojciechNo ratings yet

- RM-1N2N3NHGDG SN39507Document8 pagesRM-1N2N3NHGDG SN39507jair barruetaNo ratings yet

- WellDocument1 pageWellBhargav LahonNo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- Ats1 0001 PDFDocument20 pagesAts1 0001 PDFBalvindra Singh JodhaNo ratings yet

- Service Record January PDFDocument4 pagesService Record January PDFYusuf AkhtarNo ratings yet

- Other DocumentsDocument16 pagesOther DocumentsSekharam KoppineediNo ratings yet

- Subsea Concrete CylindersDocument89 pagesSubsea Concrete CylindersSteven SebastianNo ratings yet

- STAMFORD, HCM534F - Technical Data Sheet (Power Generators)Document11 pagesSTAMFORD, HCM534F - Technical Data Sheet (Power Generators)eduardo ayalaNo ratings yet

- 3X300 A2xcefyDocument20 pages3X300 A2xcefybdmNo ratings yet

- ADA079618Document45 pagesADA079618rmilhomemNo ratings yet

- 63 KVA Dausa TransformerDocument15 pages63 KVA Dausa TransformernishantsinNo ratings yet

- Ap1152 RPTRDocument5 pagesAp1152 RPTRKRISHNAN ELANGOVANNo ratings yet

- Tinker Rasor - CP ProductsDocument22 pagesTinker Rasor - CP ProductsrachedNo ratings yet

- WPS PQR CompressedDocument5 pagesWPS PQR CompressedBalaje MantravadiNo ratings yet

- 2B40208-2 Capacity TestDocument8 pages2B40208-2 Capacity Testameya gawadeNo ratings yet

- Las Doc X 70 Hyundai MetDocument24 pagesLas Doc X 70 Hyundai MetdvsdNo ratings yet

- Drop TestDocument4 pagesDrop TestDæmon PhobosNo ratings yet

- Fire Detection and Alarm SystemsDocument25 pagesFire Detection and Alarm SystemsBenigno Baranda100% (1)

- GEC GL107 Manual CatId11329Document107 pagesGEC GL107 Manual CatId11329ashton.emslieNo ratings yet

- Aquavane BrochureDocument5 pagesAquavane Brochurenovarhai100% (1)

- Sertifikat SlingDocument1 pageSertifikat SlingHendra SaputraNo ratings yet

- Manual ALTEC D2050BR NS 0701-Y0725 Reducido PDFDocument113 pagesManual ALTEC D2050BR NS 0701-Y0725 Reducido PDFcperalta_4100% (2)

- Axial Flow Check ValveDocument2 pagesAxial Flow Check ValveProject MarsysNo ratings yet

- A Test Method For Measuring Corona Inception VoltageDocument39 pagesA Test Method For Measuring Corona Inception VoltageRamzanNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SawThe Welding Inspections CommunityNo ratings yet

- Lds-Jsa-001 - Jsa ForkliftDocument62 pagesLds-Jsa-001 - Jsa ForkliftRonniNo ratings yet

- IND Drawworks DLS 163Document11 pagesIND Drawworks DLS 163Jose Luis MazzoniNo ratings yet

- MTC's ARAMCODocument17 pagesMTC's ARAMCOMotahar NajiNo ratings yet

- E-Jis - HTDocument6 pagesE-Jis - HTmuhammad85No ratings yet

- Documents I TL Lines I Practice I - : 1961 SKM FWDocument7 pagesDocuments I TL Lines I Practice I - : 1961 SKM FWManoj AhirwarNo ratings yet

- Sec. 8 Item 7.00.1 WO15466-02.r0Document5 pagesSec. 8 Item 7.00.1 WO15466-02.r0aymangamalsmeNo ratings yet

- NDE Procedure: Leak Test and Test No. /Z 07-FiDocument4 pagesNDE Procedure: Leak Test and Test No. /Z 07-FiVũ Lê NguyênNo ratings yet

- Installation Materials - Valve SpecificationsDocument2 pagesInstallation Materials - Valve SpecificationsKasarachi AmadiNo ratings yet

- Work Instruction #S1 - Offline Slickline Packer Pressure Test - BRG-A5 - DRAFTDocument10 pagesWork Instruction #S1 - Offline Slickline Packer Pressure Test - BRG-A5 - DRAFTAnto NirmalNo ratings yet

- #4 Cep Motor-ADocument4 pages#4 Cep Motor-APabitraMandalNo ratings yet

- Vheadquarters,: Methods of Predicting Blast Loads Inside and Blast Fields Outside Suppressive StructuresDocument28 pagesVheadquarters,: Methods of Predicting Blast Loads Inside and Blast Fields Outside Suppressive StructuresinglevoNo ratings yet

- Equipment ListDocument11 pagesEquipment ListTunaNo ratings yet

- Commander Aircraft 112 Service LettersDocument135 pagesCommander Aircraft 112 Service Lettersrop703406No ratings yet

- RRP User Manual Multi LanguageDocument72 pagesRRP User Manual Multi LanguageHyeena AtNo ratings yet

- 3x400 A2XCEFYDocument16 pages3x400 A2XCEFYbdmNo ratings yet

- " RTR:+-#L': CarryingDocument41 pages" RTR:+-#L': CarryingAaron WilsonNo ratings yet

- ASTM F1387 Approval Letter PDFDocument4 pagesASTM F1387 Approval Letter PDFRafael AndradeNo ratings yet

- Dtic Ada043399Document250 pagesDtic Ada043399aero sapaceNo ratings yet

- 20BEE074 MD Rashid Transformer and Induction Machine Lab Rotor-2 Experiment-1Document7 pages20BEE074 MD Rashid Transformer and Induction Machine Lab Rotor-2 Experiment-1Thor OdinsonNo ratings yet

- Spec A - 1475.23.02.0625Document1 pageSpec A - 1475.23.02.0625fneelavNo ratings yet

- Rotor-Bearing Dynamics Technology Design Guide Par PDFDocument370 pagesRotor-Bearing Dynamics Technology Design Guide Par PDFSeethaNo ratings yet

- 11 4Ar5Ctle - Ii Rofatg: Bharat Heavy Electricals LimitedDocument93 pages11 4Ar5Ctle - Ii Rofatg: Bharat Heavy Electricals LimitedSugadev SinghNo ratings yet

- Spaulding Lighting Ventura Spec Sheet 8-84Document2 pagesSpaulding Lighting Ventura Spec Sheet 8-84Alan MastersNo ratings yet

- Laboratory W Nawm: Servicts 'Document3 pagesLaboratory W Nawm: Servicts 'Perminder SinghNo ratings yet

- Scan 12 Jul 2020Document2 pagesScan 12 Jul 2020dhriti kapoorNo ratings yet

- Ho (V) - 4-1 Side ThrustersDocument125 pagesHo (V) - 4-1 Side ThrustershamzehNo ratings yet

- 01.20.0652 Scan Certificate Bg. Indotrans 3006 20102020Document3 pages01.20.0652 Scan Certificate Bg. Indotrans 3006 20102020johnyNo ratings yet

- WPS 002 ASME Section IXDocument4 pagesWPS 002 ASME Section IXIvan KawempyNo ratings yet

- Cr?Ulbex: It IsDocument63 pagesCr?Ulbex: It IsfedNo ratings yet

- Automation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingFrom EverandAutomation and Robotisation in Welding and Allied Processes: Proceedings of the International Conference Held at Strasbourg, France, 2-3 September 1985, under the Auspices of the International Institute of WeldingP D BoydNo ratings yet

- Modulo 4 CM 19 09 2020Document25 pagesModulo 4 CM 19 09 2020carlomonsalve1No ratings yet

- Module 4 - Concrete Structures 11 10 2021 ENTREGADODocument13 pagesModule 4 - Concrete Structures 11 10 2021 ENTREGADOcarlomonsalve1No ratings yet

- Course Name: CE 3130: Steel Structures DesignDocument25 pagesCourse Name: CE 3130: Steel Structures Designcarlomonsalve1No ratings yet

- MODULO 3 Carlo MonsalveDocument14 pagesMODULO 3 Carlo Monsalvecarlomonsalve1No ratings yet

- MODULO 5 Compression MembersDocument23 pagesMODULO 5 Compression Memberscarlomonsalve1No ratings yet

- MODULO 10 Beam-ColumnsDocument16 pagesMODULO 10 Beam-Columnscarlomonsalve1No ratings yet

- Modulo 12 Beams-Design Beam-ColumnDocument10 pagesModulo 12 Beams-Design Beam-Columncarlomonsalve1No ratings yet

- Cap 8 Bending Strength of Compact and Noncompact ShapesDocument13 pagesCap 8 Bending Strength of Compact and Noncompact Shapescarlomonsalve1No ratings yet

- Modulo 11 Beams-Columns Members in Braced FramesDocument9 pagesModulo 11 Beams-Columns Members in Braced Framescarlomonsalve1No ratings yet

- CAP 9 Shear Strength - Block Shear - Deflections - DesignDocument11 pagesCAP 9 Shear Strength - Block Shear - Deflections - Designcarlomonsalve1No ratings yet

- Facade System Installation ManualDocument29 pagesFacade System Installation ManualAcesNo ratings yet

- Moodle Exercise 1, AGKDocument5 pagesMoodle Exercise 1, AGKNikola TorbicaNo ratings yet

- HAWC12D User ManualDocument19 pagesHAWC12D User ManualUEENo ratings yet

- Gypsum Board Part III PDFDocument77 pagesGypsum Board Part III PDFimran100% (1)

- Grain Diameter (MM) Strength (Mpa) : 0.015 170 Mpa 0.025 158 Mpa 0.035 151 Mpa 0.050 145 MpaDocument1 pageGrain Diameter (MM) Strength (Mpa) : 0.015 170 Mpa 0.025 158 Mpa 0.035 151 Mpa 0.050 145 MpaTEBATSONo ratings yet

- Name of The Work: Construction of Mahila Mandali Building at Pati (V) of Patancheru (M) of Sangareddy DistrictDocument9 pagesName of The Work: Construction of Mahila Mandali Building at Pati (V) of Patancheru (M) of Sangareddy DistrictAbu MariamNo ratings yet

- Btech Me 5 Sem Advanced Welding Kme055 2021Document2 pagesBtech Me 5 Sem Advanced Welding Kme055 2021Wizard ToxicNo ratings yet

- Corrosion Control For Buried Water MainsDocument43 pagesCorrosion Control For Buried Water Mainsdelta_scopeNo ratings yet

- Fitting Note TambahanDocument9 pagesFitting Note TambahanAbdur RashidNo ratings yet

- BS en 13500-2003Document22 pagesBS en 13500-2003محمد قديشي50% (2)

- Mechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsDocument9 pagesMechanical Ventilation Systems Are Frequently Applied To Commercial BuildingsIbn Shaffee IVNo ratings yet

- High Velocity Hyfro FormingDocument32 pagesHigh Velocity Hyfro FormingKaustubh JoshiNo ratings yet

- Katalog 3Document8 pagesKatalog 3Kenny YjwNo ratings yet

- Sintex 33: Trajno Plastična Zaptivna MasaDocument2 pagesSintex 33: Trajno Plastična Zaptivna Masapavle jovicNo ratings yet

- TSP Work - Estimate - Template 330Document6 pagesTSP Work - Estimate - Template 330shivapannaleNo ratings yet

- Quality Control FormulaDocument8 pagesQuality Control FormulafoxmancementNo ratings yet

- TC Total Corrosion Management SystemsDocument7 pagesTC Total Corrosion Management SystemsJill Jim LivestockNo ratings yet

- BASF MasterRoc® HCA 10 Tds PDFDocument2 pagesBASF MasterRoc® HCA 10 Tds PDFdana setiawanNo ratings yet

- LC PurlinDocument9 pagesLC PurlinRachelle QuilalaNo ratings yet

- Chloride Attack On Stainless SteelDocument10 pagesChloride Attack On Stainless SteelgovimanoNo ratings yet

- CWT - Roof Flat Slab & BaseDocument31 pagesCWT - Roof Flat Slab & BaseNaziemi AhmadNo ratings yet

- Whitecroft 2013Document16 pagesWhitecroft 2013Ninyo LaurenceNo ratings yet

- Effect of Cold Work and Aging On Mechanical Properties of A Copper Bearing HSLA-100 SteelDocument7 pagesEffect of Cold Work and Aging On Mechanical Properties of A Copper Bearing HSLA-100 Steelvladimirsoler01No ratings yet

- Design Build Qa QC PlanDocument23 pagesDesign Build Qa QC Planomar_adel463950% (2)

- Chethan S PDocument38 pagesChethan S PspthebuilderNo ratings yet

- 5 Denture Base Materials and Processsing TechsDocument78 pages5 Denture Base Materials and Processsing TechsDRNIRBANMITRANo ratings yet

- Acsr 700-86 - Martin (B232)Document3 pagesAcsr 700-86 - Martin (B232)Dang DoNo ratings yet

- Worked Example 01 Semi ContinuousDocument17 pagesWorked Example 01 Semi Continuousnurul adilahNo ratings yet

- Benni MINI Service Manul - (Part 3)Document165 pagesBenni MINI Service Manul - (Part 3)barriaeduNo ratings yet