Professional Documents

Culture Documents

132 KVA Grid Station and Their Components of Islamabad Electric Supply Company (IESCO)

Uploaded by

Muhammad AnasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

132 KVA Grid Station and Their Components of Islamabad Electric Supply Company (IESCO)

Uploaded by

Muhammad AnasCopyright:

Available Formats

Grid station report of internship at IESCO

132 KVA Grid Station and their components

of Islamabad Electric Supply

Company (IESCO)

Submitted By: Muhammad Zahid

Grid station components and their functioning

Grid station report of internship at IESCO

Contents

1. Grid Station or Sub Station ..............................................................................................................4

1.1. According to the service requirement: .......................................................................................5

1.2. According to the constructional features: ..................................................................................5

1.3. TRANSFORMER SUBSTATION.....................................................................................................5

1.3.1. STEP UP SUBSTATION ............................................................................................................5

1.3.2. PRIMARY GRID SUBSTATION...................................................................................................5

1.3.3. SECONDARY SUBSTATIONS.....................................................................................................5

1. 4. DISTRIBUTION SUBSTATION .....................................................................................................6

1.5. Advantage and Disadvantage of GS ...........................................................................................6

1.6. Gris station visit by us...................................................................................................................6

1.6.1. I.10 Grid Station ....................................................................................................................6

1.6.2. Satellite Grid Station ..............................................................................................................6

1.6.3. Cantt Grid Station..................................................................................................................6

1.6.4. Zero point Grid Station...........................................................................................................7

1.7. Single line Key Diagram.................................................................................................................7

2. SUBSTATION CHARACTERISTICS .......................................................................................................7

2.1. STEPS IN DESIGNING SUBSTATION.................................................................................................8

2.1.1. Earthing and Bonding.............................................................................................................8

2.1.1.1. Touch Voltage .................................................................................................................8

2.1.1.2. Step Voltage....................................................................................................................8

2.1.1.3. Mesh Voltage ..................................................................................................................8

2.2. Substation Earthing Calculation Methodology ............................................................................8

2.2.1. Earthing Materials..............................................................................................................8

2.2.1.4. Switchyard Fence Earthing...............................................................................................9

2.2.1.5. CONDUCTORS USED IN SUBSTATION DESIGN ....................................................................9

2.3. OVERHEAD LINE TERANSMINATIONS.............................................................................................9

2.3.1. SIZES OF CONDUCTOR FOR LINES OF VARIOUS VOLTAGES ......................................................... 10

2.3.1.1. 220 KV Lines ..................................................................................................................... 10

2.3.1.2. 132 KV Lines ..................................................................................................................... 10

2.4. TRANSFORMERS......................................................................................................................... 10

2.4.1. TYPES OF TRANSFORMERS .............................................................................................. 10

Grid station components and their functioning

Grid station report of internship at IESCO

2.4.1.1. Power Transformer ....................................................................................................... 10

2.4.1.2. Instrument Transformers ............................................................................................... 11

2.5. POWER LINE CARRIER COMMUNICATION (PLCC).......................................................................... 12

2.5.1. PRINCIPLE OF PLCC .............................................................................................................. 13

2.5.1.1. Wave Trap or Line Trap.................................................................................................. 13

2.5.1.2. Coupling Capacitor ........................................................................................................ 13

2.5.2. APPLICATION OF PLCC.......................................................................................................... 13

2.6. BUSBARS ................................................................................................................................... 14

2.6.1. BUS COUPLER ...................................................................................................................... 15

2.7. CIRCUIT BREAKERS ..................................................................................................................... 15

2.7.1. Low-voltage circuit breakers................................................................................................. 15

2.7.2. Magnetic circuit breakers ..................................................................................................... 15

2.7.3. Thermal magnetic circuit breakers ........................................................................................ 16

2.7.4. Common trip breakers ......................................................................................................... 16

2.7.5. Air circuit breakers............................................................................................................... 16

2.7.6. Vacuum circuit breakers....................................................................................................... 16

2.7.7. Oil circuit breakers............................................................................................................... 17

2.8. ISOLATERS ................................................................................................................................. 17

2.9. INSULATORS .............................................................................................................................. 18

2.9.1. Pin type insulator................................................................................................................. 18

2.9.2. Suspension insulator............................................................................................................ 18

2.9.3. Strain insulator.................................................................................................................... 19

2.9.4. Shackle insulator ................................................................................................................. 19

2.10. RELAYS .................................................................................................................................... 19

2.10.1. RELAY USED IN CONTROLLING PANEL OF SUBSTATION......................................................... 20

2.10.1.1. Differential Relay ......................................................................................................... 20

2.10.1.2. Over Current Relay ...................................................................................................... 20

2.10.1.3. Tripping Relay ............................................................................................................. 20

2.10.1.4. Auxiliary Relay ............................................................................................................. 20

2.11. CAPACITOR BANK ..................................................................................................................... 20

2.12. Battery Room and Control Room ........................................................................................... 21

3. PROTECTION OF SUBSTATION........................................................................................................ 22

Grid station components and their functioning

Grid station report of internship at IESCO

3.1. LIGHTNING ARRESTORS .......................................................................................................... 22

3.2. TRANSFORMER PROTECTION .................................................................................................. 22

3.2.1. Buchholz Relay................................................................................................................. 22

3.2.3. Conservator and Breather................................................................................................. 22

3.2.4. Marshalling box ............................................................................................................... 23

3.2.5. Transformer cooling ......................................................................................................... 23

4. CONCLUSION ................................................................................................................................ 24

References ....................................................................................................................................... 25

1. Grid Station or Sub Station

A substation is a part of an electrical generation, transmission and distribution system.

In Pakistan grid system must be in ring system mean transmission lines interconnected with

each other. Main purpose of GS is switching between connected lines and load centers.

Because at generation voltage is low it’s up to 11KVA so through transmission and distribution

to reduce line losses due to current, step up the 11KVA to 500,220,132,66,33 KVA for

transmission from power house to grid station. Grid station will 1 st step down to low voltage so

different components in grid station are used for different purpose like metering, measuring

and protection of equipments etc.

Grid station consists of transformer have 4 parts Line bay, Main bus bar, Transformer bay and

Power transformer. Line bay contains line insulator, breaker, line CT, isolator. After main bus

bar transformer bay located and contain isolator, CT, breakers and lighting arrester.

Single line diagram of each grid station identify the input (incoming) and output (outgoing) of

the grid, mean which is primary source and where we feed its output or consumers.

According to assign details of grids, Zero Point GS 132KVA/11KVA contains 2 source Sangjani GS

and Uni GS (Gas Insulated GS). Sangjani line have coming from Tarbela to Burhan GS to Sangjani

GS. Zero point has 2 direct lines while 2 indirect lines. Zero point have 3 circuit output line are I-

10, I-8 and Satellite town.

Most of grid stations are 132 KVA while some are 220 KVA and 500 KVA. Above 220 all

transmission line are handle by national transmission and dispatch center (NTDC).

Substations transform voltage from high to low, or the reverse, or perform any of several other

important functions. Between the generating station and consumer, electric power may flow

through several substations at different voltage levels. Substations may be owned and operated

Grid station components and their functioning

Grid station report of internship at IESCO

by an electrical utility, or may be owned by a large industrial or commercial customer. Generally

substations are unattended, relying on SCADA for remote supervision and control. A substation

may include transformers to change voltage levels between high transmission voltages and

lower distribution voltages, or at the interconnection of two different transmission voltages.

Substations are classified by two broad categories:-

1.1. According to the service requirement:

Transformer substation

Switch substation

Power factor correction substation

Frequency change substation

Converting substation

Industrial substation

1.2. According to the constructional features:

Indoor substation

Outdoor substation

Underground substation

Pole mounted substation

1.3. TRANSFORMER SUBSTATION

They are known as transformer substations as because transformer is the main component employed to

change voltage level, depending upon the purposed served transformer substations may be classified

into:

1.3.1. STEP UP SUBSTATION

The generation voltage is steeped up to high voltage to affect economy in transmission of electric

power. These are generally located in the power houses and are of outdoor type.

1.3.2. PRIMARY GRID SUBSTATION

Here, electric power is received by primary substation which reduces the voltage level to 132KV, 66KV,

33KV and 11KV for secondary transmission. The primary grid substation is generally of outdoor type.

1.3.3. SECONDARY SUBSTATIONS

At a secondary substation, the voltage is further steeped down to 11KV . The 11KV lines runs along the

important road of the city. The secondary substations are also of outdoor type.

Grid station components and their functioning

Grid station report of internship at IESCO

1. 4. DISTRIBUTION SUBSTATION

These substations are located near the consumer’s localities and step down to 440V 3-phase, 4-wire for

supplying to the consumers. The voltage between any two phases is 400V & betwee n any phase and

neutral it is 220V.

1.5. Advantage and Disadvantage of GS

Electrical powers are available for customer at lower cost.

Energy flow is continuous and available for emergency use.

Better regulation of voltage wit control frequency and power factor.

It helps to maintain the record of generation, load to manage load shading etc.

Reduce fault timing with safety of humans and transmission networks.

While some disadvantage also cater in this situation,

Cost of system operation and its maintenance must be increase and complex.

It affect the environment and unsafe during war.

Difficult to add or remove the power lines mean difficult to expand the network.

It will be highly costly due to heavy equipment installation and their maintenance.

Additional load cost on consumer due to theft short circuit etc.

Due to maintenance, faults and lighting affect the continuity of supply.

1.6. Gris station visit by us

I.10 grid station 132/11 KVA

Satellite town grid station 132/11 KVA

Cantt grid station 132/11KVA

Zero point grid station 132/11KVA

1.6.1. I.10 Grid Station

I.10 GS have initial capacity of 20/26 MVA in 10 feeders cover area of Islamabad and

Rawalpindi. GS in IESCO exists in ring system mean it can give and take supply, so it contain 2

source of supply one from T/line 132kv GSS Zero point (ISD-2) and second from 132kv GSS H-11

(ISH-2). So I-10 GSS feed from 132kv GSS Zero point and H-11.

1.6.2. Satellite Grid Station

It is also in ring system it have 2 source one from I-8 GSS and other one from MES GSS. It means

GSS take supply from anyone and provide other one.

1.6.3. Cantt Grid Station

Similarly GSS contain 2 source, it feed from 132kv GSS of AGL GSS (Attcok generation limited)

and Chaklala GSS.

Grid station components and their functioning

Grid station report of internship at IESCO

1.6.4. Zero point Grid Station

Zero point GSS contain 2 source 220kva GS Sangjani (AIS) and other 220kva Uni GS (GIS). One

source Sangjani 220kva step down 132kva in zero point and Sangjani feed from Burhan GS

which feed from Tarbela power house. While it has 3 outgoing circuit I-10, I-8 (IJP) via and

Satellite town.

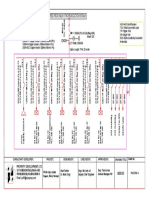

1.7. Single line Key Diagram

Single line key diagram of CANTT grid station, In which we see it have 2 source of main bus bar

One is Islamabad and other one is chaklala cantt And in ring system it can take supply from one

Source to and provide supply other source in case Of emergency. At start we have line bay

which Feed into main bus bar and after it connect with Transformer bay and a power

transformer and Current transformer and isolator before incoming panel in control room. It

also indicate a capacitor bank for power factor increase. While at the end we have incoming

and outgoing feeder for distribution of power supply to the consumers for domestic and

commercial use. Similarly other grid stations have same type of diagram but every grid station

have different power source and outgoing panel. According to the capacity of grid station the

protection and other grid equipment install with respect to them.

2. SUBSTATION CHARACTERISTICS

Each circuit is protected by its own circuit breaker and hence plant outage does not

necessarily result in loss of supply.

A fault on the feeder or transformer circuit breaker causes loss of the transformer and

feeder circuit, one of which may be restored after isolating the faulty circuit breaker.

A fault on the bus section circuit breaker causes complete shutdown of the substation.

All circuits may be restored after isolating the faulty circuit breaker.

Maintenance of a feeder or transformer circuit breaker involves loss of the circuit.

Grid station components and their functioning

Grid station report of internship at IESCO

Introduction of bypass isolators between bus bar and circuit isolator allows circuit breaker

maintenance facilities without loss of that circuit.

2.1. STEPS IN DESIGNING SUBSTATION

The First Step in designing a Substation is to design an Earthing and Bonding System.

2.1.1. Earthing and Bonding

The function of an earthing and bonding system is to provide an earthing system connection to

which transformer neutrals or earthing impedances may be connected in order to pass the

maximum fault current. The earthing system also ensures that no thermal or mechanical

damage occurs on the equipment within the substation, thereby resulting in safety to operation

and maintenance personnel. The earthing system also guarantees equipotent bonding such

that there are no dangerous potential gradients developed in the substation.

In designing the substation, three voltages have to be considered these are:

2.1.1.1. Touch Voltage

This is the difference in potential between the surface potential and the potential at earthed equipment

whilst a man is standing and touching the earthed structure.

2.1.1.2. Step Voltage

This is the potential difference developed when a man bridges a distance of 1m with his feet while not

touching any other earthed equipment.

2.1.1.3. Mesh Voltage

This is the maximum touch voltage that is developed in the mesh of the earthing grid.

2.2. Substation Earthing Calculation Methodology

Calculations for earth impedance touch and step potentials are based on site measurements of

ground resistivity and system fault levels. A grid layout with particular conductors is then

analyzed to determine the effective substation earthing resistance, from which the earthing

voltage is calculated. In practice, it is normal to take the highest fault level for substation earth

grid calculation purposes. Additionally, it is necessary to ensure a sufficient margin such that

expansion of the system is catered for. To determine the earth resistivity, probe tests are

carried out on the site. These tests are best performed in dry weather such that conservative

resistivity readings are obtained.

2.2.1. Earthing Materials

2.2.1.1. Conductors

Bare copper conductor is usually used for the substation earthing grid. The copper bars

themselves usually have a cross-sectional area of 95 square millimeters, and they are laid at a

Grid station components and their functioning

Grid station report of internship at IESCO

shallow depth of 0.25-0.5m, in 3-7m squares. In addition to the buried potential earth grid, a

separate above ground earthing ring is usually provided, to which all metallic substation plant is

bonded.

2.2.1.2. Connections

Connections to the grid and other earthing joints should not be soldered because the heat

generate during fault conditions could cause a soldered joint to fail. Joints are usually bolted.

2.2.1.3. Earthing Rods

The earthing grid must be supplemented by earthing rods to assist in the dissipation of earth fault s

current and further reduce the overall substation earthing resistance. These rods are usually made of

solid copper, or copper clad steel.

2.2.1.4. Switchyard Fence Earthing

The switchyard fence earthing practices are possible and are used by different utilities. These

are:

Extend the substation earth grid 0.5m-1.5m beyond the fence perimeter. The fence is

then bonded to the grid at regular intervals.

Place the fence beyond the perimeter of the switchyard earthing grid and bond the

fence to its own earthing rod system. This earthing rod system is not coupled to the

main substation earthing grid.

2.2.1.5. CONDUCTORS USED IN SUBSTATION DESIGN

An ideal conductor should fulfill the following requirements:

Should be capable of carrying the specified load currents and short time currents.

Should be able to withstand forces on it due to its situation. These forces comprise self-

weight, and weight of other conductors and equipment, short circuit forces and

atmospheric forces such as wind and ice loading.

Should be corona free at rated voltage.

Should have the minimum number of joints.

Should need the minimum number of supporting insulators.

Should be economical.

The most suitable material for the conductor system is copper or aluminums. Steel may be used

but has limitations of poor conductivity and high susceptibility to corrosion.

In an effort to make the conductor ideal, three different types have been utilized, and these

include: Flat surfaced Conductors, Stranded Conductors, and Tubular Conductors .

2.3. OVERHEAD LINE TERANSMINATIONS

Two methods are used to terminate overhead lines at a substation.

Grid station components and their functioning

Grid station report of internship at IESCO

Tensioning conductors to substation structures or buildings

Tensioning conductors to ground winches.

The choice is influenced by the height of towers and the proximity to the substation. The

following clearances should be observed:

2.3.1. SIZES OF CONDUCTOR FOR LINES OF VARIOUS VOLTAGES

The following sizes have now been standardized by CEA for transmission lines of different

voltages:-

2.3.1.1. 220 KV Lines

'Zebra' ACSR having 7-strand of steel of dia 3.18 mm and 54-Strands of Aluminum of dia 3.18 mm.

2.3.1.2. 132 KV Lines

'Panther' ACSR having 7-strands of steel of dia 3.00 mm and 30-Strands of Aluminum of dia 3.00 mm.

2.4. TRANSFORMERS

Transformer is a static machine, which transforms the potential of alternating current at same

frequency. It means the transformer transforms the low voltage into high voltage & high

voltage to low voltage at same frequency. It works on the principle of static induction principle.

When the energy is transformed into a higher voltage, the transformer is called step up

transformer but in case of other is known as step down transformer.

2.4.1. TYPES OF TRANSFORMERS

2.4.1.1. Power Transformer

It is used for the transmission purpose at heavy load,

high voltage greater than 33 KV & 100% efficiency.

It also having a big in size as compare to distribution

transformer, it used in generating station and Transmission substation at high insulation l evel.

They can be of two types: Single Phase Transformers and Multi Phase Transformers.

Grid station components and their functioning

Grid station report of internship at IESCO

2.4.1.2. Instrument Transformers

These transformers are used for the measurement purposes at that points where standard voltmeters

and ammeters cannot be used. They are of two types:-

2.4.1.2.1. CURRENT TRANSFORMER

A current transformer (CT) is used for

measurement of alternating electric currents.

When current in a circuit is too high to apply

directly to measuring instruments, a current

transformer produces a reduced current

accurately proportional to the current in

the circuit, which can be conveniently connected to measuring and recording instruments. A

current transformer isolates the measuring instruments from what may be very high voltage in

the monitored circuit.

2.4.1.2.2. POTENTIAL OR VOLTAGE TRANSFORMER

Voltage transformers (VT) (also called potential transformers (PT))

are a parallel connected type of instrument transformer, used

for metering and protection in high-voltage circuits or phasor

Grid station components and their functioning

Grid station report of internship at IESCO

phase shift isolation. They are designed to present negligible load to the supply being

measured and to have an accurate voltage ratio to enable accurate metering. A potential

transformer may have several secondary windings on the same core as a primary windi ng, for

use in different metering or protection circuits.

2.4.1.2.3. Auto Transformers

An autotransformer is an electrical transformer with only

one winding. The "auto" prefix refers to the single coil

acting on itself and not to any kind of automatic mechanism. In an autotransformer, portions of

the same winding act as both the primary and secondary sides of the transformer. The winding

has at least three taps where electrical connections are made. Autotransformers have the

advantages of often being smaller, lighter, and cheaper than typical dual-winding transformers,

but the disadvantage of not providing electrical isolation.

2.4.1.2.3. On the basis of working

On the above basis, transformers are of two types: Step up Transformer and Step down Transformer.

2.4.1.2.4. Distribution Transformers

A distribution transformer is a transformer that

provides the final voltage transmission in the

electrical power distribution system, stepping

down voltage to the level used by customers.

2.5. POWER LINE CARRIER COMMUNICATION (PLCC)

Reliable & fast communication is necessary for safe efficient &economic power supply. To

reduce the power failure in extent & time, to maintain the interconnected grid system in

optimum working condition; to coordinate the operation of various generating unit

communication network is indispensable for state electricity board.

In state electricity boards, the generating & distribution stations are generally located at a far

distance from cities where P & T communication provided through long overhead lines in

neither reliable nor quick.

Power-line communication (PLC) carries data on a conductor that is also used simultaneously

for AC electric power transmission or electric power distribution to consumers.

By using the existing AC power lines as a medium to transfer the information, it becomes easy

to connect the houses with a high speed network access point without installing new wirings.

This technology has been in wide use since 1950 and was mainly used by the grid stations to

transmit information at high speed.

Grid station components and their functioning

Grid station report of internship at IESCO

2.5.1. PRINCIPLE OF PLCC

Power-line communications systems operate by adding a modulated carrier signal to the wiring

system. All type of information is modulated on carried wave at frequency 50Hz to 500 KHz. The

modulated HF carrier fed into the power line conductor at the sending end and filtered out

again at the respective stations. Long earlier system double side band amplitude modulation

was more common but the present amplitude modulated system.

Since high voltage power lines are designed to carry large quantities of energy on the high

voltage and the communication system at low voltage, they cannot be directly connected to

high voltage lines. Suitably designed coupling equipments have therefore to be employed which

will permit the injection of high frequency carrier signal without undue loss and with absolute

protection of communication equipments or operating personal from high voltage hazard.

Therefore, the coupling equipment essentially comprises the following:

2.5.1.1. Wave Trap or Line Trap

Wave trap is connected in series with power line between the point of connection of coupling capacitor

and S/S. Wave trap offers negligible impedance to HF carrier. Wave trap stands electromechanically and

thermally for short circuit current in the event of fault on the line. On the basis of blocking frequency

bank, the wave trap can be following type:

All wave

Single Frequency

Double Frequency’

Broad Band

2.5.1.2. Coupling Capacitor

The modulated carrier is let into power line through coupling capacitor specially designed to with stand

line voltage under all-weather condition. The upper end of the coupling capacitor is connected directly

to the line and the lower end is connected to the ground through a carrier frequency chock coil or drain

coil. Thus coupling capacitor forms the link between the PLCC equipment and power line. The coupling

capacitor used in UPSEB is 2200pf capacitance.

The coupling capacitor are designed for outdoor use and hence to withstand normal atmospheric

phenomenon such as temperature & humidity changes, rain, snow, anticipated wind load, nominal wire

tension etc. at full rated voltage. In some case capacitive voltage transformers (CVT) used as a source of

line voltage for metering and protection as also used coupling capacitor for PLCC.

2.5.2. APPLICATION OF PLCC

PLCC technology can be deployed into different types of applications in order to provide

economic networking solutions. Hence merging with other technologies it proves useful in

Grid station components and their functioning

Grid station report of internship at IESCO

different areas. These are few key areas where PLC communications are utilized:

Transmission & Distribution Network: PLCC was first adopted in the electrical

transmission

and distribution system to transmit information at a fast rate.

Home control and Automation: PLCC technology is used in home control and

automation. This technology can reduce the resources as well as efforts for activities like

power management, energy conservation, etc.

Entertainment: PLCC is used to distribute the multimedia content throughout the home.

Telecommunication: Data transmission for different types of communications like

telephonic communication, audio, video communication can be made with the use of

PLCC technology.

Security Systems: In monitoring houses or businesses through surveillance cameras,

PLCC technology is far useful.

Automatic Meter Reading – Automatic Meter reading applications use the PLCC

technology to send the data from home meters to Host Central Station.

2.6. BUSBARS

When numbers of generators or feeders operating at the same voltage have to be directly

connected electrically, bus bar is used as the common electrical component. Bus bars are made

up of copper rods operate at constant voltage. The following are the important bus bars

arrangements used at substations:

Single bus bar system

Single bus bar system with section allocation.

Duplicate bus bar system

In large stations it is important that break downs

and maintenance should interfere as little as

possible with continuity of supply to achieve

this, duplicate bus bar system is used. Such a

system consists of two bus bars, a main bus bar

and a spare bus bar with the help of bus

coupler, which consist of the circuit breaker and

isolator. In substations, it is often desired to

disconnect a part of the system for general maintenance Bus Bars

and repairs. An isolating switch or isolator accomplishes this.

Isolator operates under no load condition. It does not have any specified current breaking

capacity or current making capacity. In some cases isolators are used to breaking charging

Grid station components and their functioning

Grid station report of internship at IESCO

currents or transmission lines.

While opening a circuit, the circuit breaker is

opened first then isolator while closing a circuit

the isolator is closed first, then circuit breakers.

Isolators are necessary on supply side of circuit

breakers, in order to ensure isolation of the circuit breaker from live parts for the purpose of

maintenance.

A transfer isolator is used to transfer main supply from main bus to transfer bus by using bus

coupler (combination of a circuit breaker with two isolators), if repairing or maintenance of any

section is required.

2.6.1. BUS COUPLER

The bus coupler consists of circuit breaker and isolator.

Each generator and feeder may be connected to either

main bus bar or spar bus bar with the help of bus coupler.

Repairing, maintenance and testing of feeder circuit or other section can be done by putting them on

spar bus bar, thus keeping the main bus bar undisturbed.

2.7. CIRCUIT BREAKERS

A circuit breaker is an automatically operated electrical switch designed to protect an electrical

circuit from damage caused by overload or short circuit. Its basic function is to detect a fault condition

and interrupt current flow. Unlike a fuse, which operates once and then must be replaced, a circuit

breaker can be reset (either manually or automatically) to resume normal operation. Circuit breakers

are made in varying sizes, from small devices that protect an individual household appliance up to

large switchgear designed to protect high voltage circuits feeding an entire city. There are different

types of circuit breakers which are:-

2.7.1. Low-voltage circuit breakers

Low-voltage (less than 1,000 V AC) types are common in domestic,

commercial and industrial application, and include Miniature

Circuit Breaker (MCB) and Molded Case Circuit Breaker (MCCB).

2.7.2. Magnetic circuit breakers

Magnetic circuit breakers use a solenoid (electromagnet)

Grid station components and their functioning

Grid station report of internship at IESCO

whose pulling force increases with the current. Certain designs

utilize electromagnetic forces in addition to those of the solenoid.

2.7.3. Thermal magnetic circuit breakers

Thermal magnetic circuit breakers, which are the type found

in most distribution boards, incorporate both techniques with

the electromagnet responding instantaneously to large surges in current (short circuits) and the

bimetallic strip responding to less extreme but longer-term over-current conditions. The thermal portion

of the circuit breaker provides an "inverse time" response feature, which trips the circuit breaker sooner

for larger over currents.

2.7.4. Common trip breakers

Three-pole common trip breaker for supplying a three-phase device. This breaker has a 2A rating. When

supplying a branch circuit with more than one live conductor, each live conductor must be protected by

a breaker pole. To ensure that all live

conductors are interrupted when any pole trips, a "common trip"

breaker must be used. These may either contain two or three

tripping mechanisms within one case, or for small breakers,

may externally tie the poles together via their operating handles.

2.7.5. Air circuit breakers

Rated current up to 6,300 A and higher for generator circuit breakers.

Trip characteristics are often fully adjustable including configurable

trip thresholds and delays. Usually electronically controlled, though

some models are microprocessor controlled via an integral electronic

trip unit. Often used for main power distribution in large industrial

plant, where the breakers are arranged in draw-out enclosures for

ease of maintenance.

2.7.6. Vacuum circuit breakers

With rated current up to 6,300 A, and higher for generator circuit breakers.

These breakers interrupt the current by creating and extinguishing the

Grid station components and their functioning

Grid station report of internship at IESCO

arc in a vacuum container.

2.7.7. Oil circuit breakers

A high-voltage circuit breaker in which the arc is drawn in oil

to dissipate the heat and extinguish the arc; the intense heat

of the arc decomposes the oil, generating a gas whose high

pressure produces a flow of fresh fluid through the arc that furnishes

the necessary insulation to prevent a re strike of the arc.The arc is

then extinguished, both because of its elongation upon

parting of contacts and because of intensive cooling by the gases and oil vapor. They are further of two

types: Bulk Oil Circuit Breaker (BOCB) and Minimum Oil Circuit Breaker (MOCB).

2.7.8. Sulfur hexafluoride (Sf6) high-voltage circuit breakers

A sulfur hexafluoride circuit breaker uses contacts

surrounded by sulfur hexafluoride gas to quench the

arc. They are most often used for transmission-level

voltages and may be incorporated into compact

gas-insulated switchgear.

2.8. ISOLATERS

In electrical engineering, a disconnector, disconnect switch or isolator switch is used to ensure

that an electrical circuit is completely de-energized for service or maintenance. Such switches

are often found in electrical distribution and industrial applications, where machinery must

have its source of driving power removed for adjustment or repair. High-voltage isolation

switches are used in electrical substations to allow isolation of apparatus such as circuit

breakers, transformers, and transmission lines, for maintenance. The disconnector is usually

not intended for normal control of the circuit, but only for safety isolation. Disconnector can be

operated either manually or automatically (motorized disconnector).

Unlike load break switches and circuit breakers,

disconnectors lack a mechanism for suppression

of electric arc, which occurs when conductors

Grid station components and their functioning

Grid station report of internship at IESCO

carrying high currents are electrically interrupted. Thus, they are off-load devices, intended to

be opened only after current has been interrupted by some other control device. Safety

regulations of the utility must prevent any attempt to open the disconnector while it supplies a

circuit. Standards in some countries for safety may require either local motor isolators or

lockable overloads (which can be padlocked).

Disconnectors have provisions for a padlock so that inadvertent operation is not possible

(lockout-tag out). In high-voltage or complex systems, these padlocks may be part of a trapped-

key interlock system to ensure proper sequence of operation. In some designs, the isolator

switch has the additional ability to earth the isolated circuit thereby providing additional safety.

Such an arrangement would apply to circuits which inter-connect power distribution systems

where both ends of the circuit need to be isolated.

2.9. INSULATORS

An electrical insulator is a material whose internal electric charges do not flow freely, and

therefore make it very hard to conduct an electric current under the influence of an electric

field. The insulator serves two purposes. They support the conductors (bus bar) and confine the

current to the conductors. The most common used material for the manufacture of insulator is

porcelain. There are several types of insulators (e.g. pin type, suspension type, post insulator

etc.) and their use in substation will depend upon the service requirement.

Different types of insulator are:-

2.9.1. Pin type insulator

As the name suggests, the pin type insulator is mounted on a pin

on the cross-arm on the pole. There is a groove on the upper end

of the insulator. The conductor passes through this groove and is

tied to the insulator with annealed wire of the same material as

the conductor. Pin type insulators are used for transmission and distribution of electric power at

voltages up to 33 kV. Beyond operating voltage of 33 kV, the pin type insulators become too bulky and

hence uneconomical.

2.9.2. Suspension insulator

For voltages greater than 33 kV, it is a usual practice to use

suspension type insulators shown in Figure. Consist of a

number of porcelain discs connected in series by metal links

Grid station components and their functioning

Grid station report of internship at IESCO

in the form of a string. The conductor is suspended at the bottom end of this string while the other end

of the string is secured to the cross-arm of the tower. The number of disc units used depends on the

voltage.

2.9.3. Strain insulator

A dead end or anchor pole or tower is used where a straight section

of line ends, or angles off in another direction. These poles must

withstand the lateral (horizontal) tension of the long straight section of wire. In order to support this

lateral load, strain insulators are used. For low voltage lines (less than 11 kV), shackle insulators are used

as strain insulators. However, for high voltage transmission lines, strings of cap-and-pin (disc) insulators

are used, attached to the cross arm in a horizontal direction. When the tension load in lines is

exceedingly high, such as at long river spans, two or more strings are used in parallel.

2.9.4. Shackle insulator

In early days, the shackle insulators were used as strain insulators.

But now a day, they are frequently used for low voltage distribution lines.

Such insulators can be used either in a horizontal position or in a vertical position.

They can be directly fixed to the pole with a bolt or to the cross arm.

2.10. RELAYS

In a power system it is inevitable that immediately or later some failure does occur somewhere

in the system. When a failure occurs on any part of the system, it must be quickly detected and

disconnected from the system. Rapid disconnection of faulted apparatus limits the amount of

damage to it and prevents the effects of fault from spreading into the system. For high voltage

circuits relays are employed to serve the desired function of automatic protective gear. The

relays detect the fault and supply the information to the circuit breaker.

The electrical quantities which may change under fault condition are voltage, frequency,

current, phase angle. When a short circuit occurs at any point on the transmission line the

current flowing in the line increases to the enormous value. This result in a heavy current flow

through the relay coil, causing the relay to operate by closing its contacts. This in turn closes the

trip circuit of the breaker making the circuit breaker open and isolating the faulty section from

the rest of the system. In this way, the relay ensures the safety of the circuit equipment from

the damage and normal working of the healthy portion of the system.

Relay works on two main operating principles:-

Electromagnetic Attraction

Grid station components and their functioning

Grid station report of internship at IESCO

Electromagnetic Induction

2.10.1. RELAY USED IN CONTROLLING PANEL OF SUBSTATION

2.10.1.1. Differential Relay

A differential relay is one that operates when vector difference

of the two or more electrical quantities exceeds a predetermined value.

If this differential quantity is equal or greater than the pickup value,

the relay will operate and open the circuit breaker to isolate the faulty section.

2.10.1.2. Over Current Relay

This type of relay works when current in the circuit exceeds the

predetermined value. The actuating source is the current in the

circuit supplied to the relay from a current transformer.

These relay are used on A.C. circuit only and can operate for fault flow in the either direction. This relay

operates when phase to phase fault occurs.

2.10.1.3. Tripping Relay

This type of relay is in the conjunction with main relay. When main

relay sense any fault in the system, it immediately operates the trip

relay to disconnect the faulty section from the section.

2.10.1.4. Auxiliary Relay

An auxiliary relay is used to indicate the fault

by glowing bulb or showing various flags.

2.11. CAPACITOR BANK

The load on the power system is varying being high during morning and evening which

increases the magnetization current. This result in the decreased power factor. The low power

factor is mainly due to the fact most of the power loads are inductive and therefore take

lagging currents. The low power factor is highly undesirable as it causes increases in current,

resulting in additional losses. So in order to ensure most favorable conditions for a supply

system from engineering and economic stand point it is important to have power factor as

close to unity as possible.

Grid station components and their functioning

Grid station report of internship at IESCO

In order to improve the power factor come device taking

leading power should be connected in parallel with

the load. One of such device can be capacitor bank.

The capacitors draw a leading current and partly

or completely neutralize the lagging reactive component of load current.

Main functions of Capacitor Bank are:-

Supply Reactive Power

Improve Terminal Voltage

Improve Power Factor

2.12. Battery Room and Control Room

At last but not least every grid station contains a

battery room for DC power supply, because every

protection component in grid station operated at DC.

If this equipment doesn’t work properly the whole

system must be shut down or serious damage must

occur. Transformer is most costly components install

in grid station and all other equipment must be install

for protection of man power and equipments especially

transformer. So it is alos know or call “Heart of Grid station”.

For switching and metering purpose a control room must exists in grid station to maintained

record and balance for load shading and load shifting purpose. Because in every grid station a

smart meter install with every feeder to note down the record of power consumption and

generation. Also indicate fault and provide this measured data to higher authority and regional

control center (RCC) for load shading management. Most of grid station control room have

smart meter with sim install in it to provide the total record to RCC, SO and XEN for their

calculation. This project is funded by USAID to enhance the power sector generation and

reduce their losses because it’s provide the whole record of received units from generation

source and sold units to consumers and calculate and minimize the losses and improve

distribution powers.

Grid station components and their functioning

Grid station report of internship at IESCO

3. PROTECTION OF SUBSTATION

Following components are used for the protection purpose on grid station.

3.1. LIGHTNING ARRESTORS

A lightning arrestor is a device used in power systems and telecommunications systems to

protect the insulation and conductors of the system from the damaging effects of lightning. The

typ.ical lightning arrester has a high-voltage terminal and a ground terminal. When a lightning

surge (or switching surge, which is very similar) travels along the power line to the arrester, the

current from the surge is diverted through the arrestor, in most cases to earth.

3.2. TRANSFORMER PROTECTION

Transformers are totally enclosed static devices and generally oil immersed. Therefore chances

of fault occurring on them are very easy rare, however the consequences of even a rare fault

may be very serious unless the transformer is quickly disconnected from the system. This

provides adequate automatic protection for transformers against possible faul ts. Various

protection methods used for transformers are:-

3.2.1. Buchholz Relay

Buchholz relay is a safety device mounted on some

oil-filled power transformers and reactors, equipped

with an external overhead oil reservoir called a

conservator. The Buchholz Relay is used as a

protective device sensitive to the effects of

dielectric failure inside the equipment.

Depending on the model, the relay has multiple

methods to detect a failing transformer. On a slow accumulation of gas, due perhaps to slight

overload, gas produced by decomposition of insulating oil accumulates in the top of the relay

and forces the oil level down. A float switch in the relay is used to initiate an alarm signal.

Depending on design, a second float may also serve to detect slow oil leaks.If an arc forms, gas

accumulation is rapid, and oil flows rapidly into the conservator. This flow of oil operates a

switch attached to a vane located in the path of the moving oil. This switch normally will

operate a circuit breaker to isolate the apparatus before the fault causes additional damage.

3.2.3. Conservator and Breather

When the oil expands or contacts by the change in the temperature, the oil level goes either up

or down in main tank. A conservator is used to maintain the oil level up to predetermined value

Grid station components and their functioning

Grid station report of internship at IESCO

in the transformer main tank by placing it above

the level of the top of the tank. Breather is

connected to conservator tank for the purpose

of extracting moisture as it spoils the insulating

properties of the oil. During the contraction and

expansion of oil air is drawn in or out through

breather silica gel crystals impregnated with cobalt

chloride. Silica gel is checked regularly and dried

and replaced when necessary.

3.2.4. Marshalling box

It has two meter which indicate the temperature of

the oil and winding of main tank. If temperature of

oil or winding exceeds than specified value, relay

operates to sound an alarm. If there is further

increase in temperature then relay completes the

trip circuit to open the circuit breaker controlling the transformer.

3.2.5. Transformer cooling

When the transformer is in operation heat is generated due to iron losses the removal of heat is

called cooling.

There are several types of cooling methods, they are as follows:

3.2.5.1. Air natural cooling

In a dry type of self-cooled transformers, the natural circulation of surrounding air is used for its cooling.

This type of cooling is satisfactory for low voltage small transformers.

3..2.5.2. Air blast cooling

It is similar to that of dry type self-cooled transformers with to addition that continuous blast of filtered

cool air is forced through the core and winding for better cooling. A fan produces the blast.

3.2.5.3. Oil natural cooling

Medium and large rating transformers have their winding and core immersed in oil, which act both as a

cooling medium and an insulating medium. The heat produce in the cores and winding is passed to the

oil becomes lighter and rises to the top and place is taken by cool oil from the bottom of the cooling

tank.

3.2.5.4. Oil blast cooling

In this type of cooling, forced air is directed over cooling elements of transformers immersed in oil.

3.2.5.5. Forced oil and forced air flow (OFB) cooling

Oil is circulated from the top of the transformers tank to a cooling tank to a cooling plant. Oil is then

returned to the bottom of the tank.

Grid station components and their functioning

Grid station report of internship at IESCO

3.2.5.6. Forced oil and water (OWF) cooling

In this type of cooling oil flow with water cooling of the oil in external water heat exchanger takes place.

The water is circulated in cooling tubes in the heat exchanger.

4. CONCLUSION

Now from this report one can conclude that electricity plays an important role in our life. At the

end of the training, I came to know about the various parts of substations and how they are

operated. Also I learnt about how transmission is done in various parts of Pakistan especially in

Islamabad.

As evident from the report, a substation plays a very important role in the transmission system.

That’s why various protective measures are taken to protect the substations from various faults

and its smooth functioning. Power Transmission Corporation of IESCO takes such steps so that

a uniform and stable supply of electricity can reach in every part of this state.

Awareness of the causes and their effects through management of grid station itself would

reduce the system irregularities to some extent. All these difficulties ultimately lead to a low

voltage profile in the system.

The poor voltage profile causes loss of equipments and energy. Thus, maintenance of the

voltage profile to keep the consumer voltage at the declared level allowing the deviation wi thin

the permissible limits would keep the losses at control. The consumer voltage may be kept at

the desired level by controlling one or more of the following variable on which it is dependent.

Adequate Size of Conductors is required for Distribution lines and installation of Distribution

transformers nearer to load centers. High Power Factor of Primary and secondary distribution

system are started in different area of country. Feeder phase current and load balancing while

load factor should be increased to control low power and energy losses by transformer Sizing

(based on load) and Selection (core material). Switching off transformers in period of low

demands and maximum demand indication (MDI) time. Due to more consumption we should

need more power generation to full fill our demand. So by using different economical and

reliable method to generate power for different type of customer like power generation

through:

Hydel Generation

Thermal Generation

Nuclear Power Generation

Wind Energy

Coal Reserves

Biomass Energy and Solar energy

Grid station components and their functioning

Grid station report of internship at IESCO

References

1. www.slidshare.com

2. www.google.com/wikipedia/energy/gridstation

3. www.enerysources.com

4. www.iesco.com

5. www.ntdc.com

6. www.usaid.com

Grid station components and their functioning

You might also like

- DatasheetDocument36 pagesDatasheetAndres GuerreroNo ratings yet

- J.C. Compter, Electrical Drives For Precision Engineering Designs, 2007 1Document91 pagesJ.C. Compter, Electrical Drives For Precision Engineering Designs, 2007 1geenjunkmailNo ratings yet

- Spider - Tle7238Gs: 8 Channel High-Side and Low-Side Relay Switch With Limp Home ModeDocument37 pagesSpider - Tle7238Gs: 8 Channel High-Side and Low-Side Relay Switch With Limp Home ModeHelal ShamesNo ratings yet

- Infineon-BTS5576-Datasheet Draiber Modulo Chevrolet Cruz LuzDocument42 pagesInfineon-BTS5576-Datasheet Draiber Modulo Chevrolet Cruz LuzErick CorzoNo ratings yet

- Spoc - BTS5482SFDocument57 pagesSpoc - BTS5482SFBaCresNo ratings yet

- Infineon Bts5200 4eka Ds v01 00 enDocument49 pagesInfineon Bts5200 4eka Ds v01 00 engNo ratings yet

- 460 Elec BK 1Document63 pages460 Elec BK 1Ramiro Joel Quiñonez RamosNo ratings yet

- Liebert Gxt3 208V, 5000-10,000VA, 6000RTL630: User ManualDocument52 pagesLiebert Gxt3 208V, 5000-10,000VA, 6000RTL630: User ManualMasterC3012No ratings yet

- Mastertig Acdc 2000Document31 pagesMastertig Acdc 2000Maikel WilkeNo ratings yet

- O&M UPS LiebertDocument48 pagesO&M UPS LiebertSergio Ivan Merchan MejiaNo ratings yet

- Standard - LV - Motors - Manual - ML - 01 - 2009 Rev DDocument160 pagesStandard - LV - Motors - Manual - ML - 01 - 2009 Rev DraluntitledNo ratings yet

- Standard - LV - Motors - Manual - EN - 01 - 2009 Rev D PDFDocument26 pagesStandard - LV - Motors - Manual - EN - 01 - 2009 Rev D PDFasifdcetNo ratings yet

- YASKAWA AC Drive-A1000: 6-Phase/12-Pulse Input Installation GuideDocument70 pagesYASKAWA AC Drive-A1000: 6-Phase/12-Pulse Input Installation GuideJosé María Rodríguez RiveraNo ratings yet

- Liebert Gxt3 RT 5a10kva User ManualDocument44 pagesLiebert Gxt3 RT 5a10kva User ManualEdgar Alayo RojasNo ratings yet

- S MVS Prim Pu - 00Document49 pagesS MVS Prim Pu - 00afsar.erNo ratings yet

- BTS50015-1TAA: Automotive PowerDocument44 pagesBTS50015-1TAA: Automotive Powerdavid silveiraNo ratings yet

- Handleiding Flexball 3500 Tot 4500 SeriesDocument73 pagesHandleiding Flexball 3500 Tot 4500 SerieshamzehNo ratings yet

- Datasheet TLE8264EDocument99 pagesDatasheet TLE8264Ecj002No ratings yet

- Infineon Bts5180 2eka Ds v01 00 enDocument54 pagesInfineon Bts5180 2eka Ds v01 00 enPaulo PereiraNo ratings yet

- Power Electronics 2019Document367 pagesPower Electronics 2019WessamNo ratings yet

- S MVS Rmu33 - 00Document32 pagesS MVS Rmu33 - 00afsar.erNo ratings yet

- DSAISS00018439Document43 pagesDSAISS00018439SantiagoNo ratings yet

- Liebert Gxt3 230V, 5000-10,000VA: User ManualDocument44 pagesLiebert Gxt3 230V, 5000-10,000VA: User ManualCHIQUE GUSTAVONo ratings yet

- S MVS Prim BRB - 00Document55 pagesS MVS Prim BRB - 00afsar.erNo ratings yet

- i2000SR IM: Service Manual For The i2000SR Interface ModuleDocument212 pagesi2000SR IM: Service Manual For The i2000SR Interface ModuleALEJANDRONo ratings yet

- i2000SR IM: Service Manual For The i2000SR Interface ModuleDocument212 pagesi2000SR IM: Service Manual For The i2000SR Interface Modulewant807No ratings yet

- ABB Abbacus KompenzacijaDocument35 pagesABB Abbacus KompenzacijaDejanKuzmanovic100% (1)

- 718 599Document131 pages718 599Anonymous DjTnqWXU100% (1)

- Liebert APM: User Manual-15-90kVA, 120, 208, 480 and 600V, 50/60HzDocument144 pagesLiebert APM: User Manual-15-90kVA, 120, 208, 480 and 600V, 50/60Hzhector CarreraNo ratings yet

- AMRMeterDocument23 pagesAMRMeterKhaled SalemNo ratings yet

- CMC 353Document100 pagesCMC 353gede_trinataNo ratings yet

- CMC 256plus User Manual PDFDocument154 pagesCMC 256plus User Manual PDFbisas_rishiNo ratings yet

- BTT6200 4EMA InfineonDocument48 pagesBTT6200 4EMA InfineonAlbaro LedesmaNo ratings yet

- SL-25230 Rev5 NXa30-200kVA UserManualDocument132 pagesSL-25230 Rev5 NXa30-200kVA UserManualstasNo ratings yet

- Kohler RXT Transfer Switch InstallDocument60 pagesKohler RXT Transfer Switch Installginger1951100% (2)

- 150 At002 - en PDocument102 pages150 At002 - en PAlvaro GastañaduiNo ratings yet

- Power Electronics Design: A Practitioner's GuideFrom EverandPower Electronics Design: A Practitioner's GuideRating: 4.5 out of 5 stars4.5/5 (3)

- ML255 Electromagnetic Flow Meter Converter: Installation, Operation and Maintenance ManualDocument50 pagesML255 Electromagnetic Flow Meter Converter: Installation, Operation and Maintenance ManualJavierLugoNo ratings yet

- c4.4 & c6.6 (Electronic Application & Installation Guide)Document112 pagesc4.4 & c6.6 (Electronic Application & Installation Guide)Pedro Cerna Diaz88% (50)

- Esab Caddy Mig C200i Service ManualDocument50 pagesEsab Caddy Mig C200i Service ManualJohn Metaxas100% (2)

- Paneles Ax SeriesDocument80 pagesPaneles Ax Seriesisabel monroe.No ratings yet

- AN2586 Application Note: STM32F10xxx Hardware Development: Getting StartedDocument28 pagesAN2586 Application Note: STM32F10xxx Hardware Development: Getting StartedRouaissi RidhaNo ratings yet

- Liebert NX UPS: User Manual-10-30kVA, 208V, 60HzDocument112 pagesLiebert NX UPS: User Manual-10-30kVA, 208V, 60HzJavierM.GonzalezNo ratings yet

- Installation and Operating Instruction: Remote Control Station WCM-FS 2.0 and Solar Controller WCM-SOL 1.0 HomeDocument80 pagesInstallation and Operating Instruction: Remote Control Station WCM-FS 2.0 and Solar Controller WCM-SOL 1.0 HomeAnd B100% (2)

- Liebert Exm 20 200kva User Manual - 00 PDFDocument82 pagesLiebert Exm 20 200kva User Manual - 00 PDFKuldeep KoulNo ratings yet

- Liebert NX 10 30kva Installation ManualDocument80 pagesLiebert NX 10 30kva Installation ManualRodrigo MoratoNo ratings yet

- GXT2-6000RT230 & GXT2-4500RT230: Ower VailabilityDocument40 pagesGXT2-6000RT230 & GXT2-4500RT230: Ower Vailabilityabel ciezaNo ratings yet

- MFS 9130 Hardware DescriptionDocument112 pagesMFS 9130 Hardware DescriptionYasser AlqadhiNo ratings yet

- Sia Manu Siac Ing R013 PDFDocument135 pagesSia Manu Siac Ing R013 PDFJoe McGunnigleNo ratings yet

- SmartSolar MPPT RS-enDocument51 pagesSmartSolar MPPT RS-enwongdongNo ratings yet

- DC Machines 2020 NewDocument81 pagesDC Machines 2020 NewYaw Amankrah Sam-OkyereNo ratings yet

- UntitledDocument121 pagesUntitledAconatic tvhomeNo ratings yet

- Emerson UPSDocument88 pagesEmerson UPSserkalemtNo ratings yet

- Variable Speed Pumping: A Guide to Successful ApplicationsFrom EverandVariable Speed Pumping: A Guide to Successful ApplicationsRating: 3 out of 5 stars3/5 (2)

- Powerboater's Guide to Electrical Systems, Second EditionFrom EverandPowerboater's Guide to Electrical Systems, Second EditionRating: 5 out of 5 stars5/5 (1)

- Passive RF and Microwave Integrated CircuitsFrom EverandPassive RF and Microwave Integrated CircuitsRating: 5 out of 5 stars5/5 (1)

- International Islamic University Islamabad Department of Electrical Engineering Terminal Examination FALL 2020Document1 pageInternational Islamic University Islamabad Department of Electrical Engineering Terminal Examination FALL 2020Muhammad AnasNo ratings yet

- Islamabad Elctric Supply Company 132 KV Grid Station I-10/3 IslamabadDocument1 pageIslamabad Elctric Supply Company 132 KV Grid Station I-10/3 IslamabadMuhammad AnasNo ratings yet

- LAB 1-PE-LabDocument10 pagesLAB 1-PE-LabLovely JuttNo ratings yet

- LAB 1-PE-LabDocument10 pagesLAB 1-PE-LabLovely JuttNo ratings yet

- LAB 1-PE-LabDocument10 pagesLAB 1-PE-LabLovely JuttNo ratings yet

- Internship Report of 132 KV Grid StationDocument23 pagesInternship Report of 132 KV Grid Stationranawaqas11990% (20)

- Lab 9Document6 pagesLab 9Muhammad AnasNo ratings yet

- Ali Awais - 321 - DSD Lab - Final TermDocument8 pagesAli Awais - 321 - DSD Lab - Final TermMuhammad AnasNo ratings yet

- A Guide To Technical Report WritingDocument12 pagesA Guide To Technical Report WritingPrateek Sanghi100% (1)

- International Islamic University, Islamabad: Power Distribution and UtilizationDocument3 pagesInternational Islamic University, Islamabad: Power Distribution and UtilizationMuhammad AnasNo ratings yet

- Lab 4 - Single Side Fed Radial AC DistributorDocument5 pagesLab 4 - Single Side Fed Radial AC DistributorMuhammad AnasNo ratings yet

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document4 pagesInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNo ratings yet

- Technical Report v5Document33 pagesTechnical Report v5MariNo ratings yet

- Lab 5 - Ring AC DistributorDocument6 pagesLab 5 - Ring AC DistributorMuhammad AnasNo ratings yet

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document9 pagesInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNo ratings yet

- DSP Lab 1 TaskDocument18 pagesDSP Lab 1 TaskMuhammad AnasNo ratings yet

- PDU Lab Outlines - Spring 2021Document1 pagePDU Lab Outlines - Spring 2021Muhammad AnasNo ratings yet

- Lab Worksheet P:1 Code: Write Code For Deconvolution Process To Find An Unknown Input SignalDocument3 pagesLab Worksheet P:1 Code: Write Code For Deconvolution Process To Find An Unknown Input SignalMuhammad AnasNo ratings yet

- Lab Tasks Answer No. 01) :-: Code in Command WindowDocument5 pagesLab Tasks Answer No. 01) :-: Code in Command WindowMuhammad AnasNo ratings yet

- Lab Tasks Question No. 01) :-: Digital Signal Processing LabDocument3 pagesLab Tasks Question No. 01) :-: Digital Signal Processing LabMuhammad AnasNo ratings yet

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document10 pagesInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNo ratings yet

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document7 pagesInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNo ratings yet

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document10 pagesInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNo ratings yet

- Lab Tasks Answer No. 01) :-: Code in Command WindowDocument7 pagesLab Tasks Answer No. 01) :-: Code in Command WindowMuhammad AnasNo ratings yet

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document4 pagesInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNo ratings yet

- International Islamic University Islamabad: Workshop Practice Lab (EE102L)Document4 pagesInternational Islamic University Islamabad: Workshop Practice Lab (EE102L)Muhammad AnasNo ratings yet

- DSD Lab 14 HandoutDocument9 pagesDSD Lab 14 HandoutMuhammad AnasNo ratings yet

- DSD Lab 9 HandoutDocument5 pagesDSD Lab 9 HandoutMuhammad AnasNo ratings yet

- DSD Lab 13 HandoutDocument9 pagesDSD Lab 13 HandoutMuhammad AnasNo ratings yet

- Protection Scheme 13.8kV SwitchgearDocument69 pagesProtection Scheme 13.8kV Switchgeardaniel.cabasa2577100% (1)

- Blowout Preventer PDFDocument2 pagesBlowout Preventer PDFdazaev1100% (1)

- 04 Protective Device CoordinationDocument61 pages04 Protective Device CoordinationSupriyanto SuhonoNo ratings yet

- Network Design Manual v7.7Document194 pagesNetwork Design Manual v7.7somchak2000100% (3)

- Us6411 (10kva, 110VDC, 400vac - 3PH)Document5 pagesUs6411 (10kva, 110VDC, 400vac - 3PH)sayaliNo ratings yet

- اصطلاحات دکل حفاري PDFDocument23 pagesاصطلاحات دکل حفاري PDFmhaioocNo ratings yet

- For Print 2Document1 pageFor Print 2Sharif 087No ratings yet

- Siemens Protection CoordinationDocument9 pagesSiemens Protection CoordinationVic_ReaderNo ratings yet

- Application Notes: Application Notes P14X/En Ap/B54 Micom P141, P142, P143Document178 pagesApplication Notes: Application Notes P14X/En Ap/B54 Micom P141, P142, P143Dũng Đinh TiếnNo ratings yet

- Application Details Product Details: Prestige Royal Woods, HyderabadDocument14 pagesApplication Details Product Details: Prestige Royal Woods, HyderabadsanjayNo ratings yet

- Test Report: Measurement of Turns RatioDocument2 pagesTest Report: Measurement of Turns RatioJRC TestingNo ratings yet

- 132-33 KV BoqDocument2 pages132-33 KV Boqbanu50% (2)

- Breaker Failure ProtectionDocument28 pagesBreaker Failure Protectiontanmaybeckham07100% (1)

- Nec Chapter 6Document5 pagesNec Chapter 6Marie Grace DollentasNo ratings yet

- SUBSTATIONDocument23 pagesSUBSTATIONpunit ranjanNo ratings yet

- ABB Presentation On Transformer ProtectionDocument51 pagesABB Presentation On Transformer ProtectionKrishnakant Jashnani100% (1)

- C37.99™-2012, IEEE Guide For The Protection of Shunt Capacitor BankDocument14 pagesC37.99™-2012, IEEE Guide For The Protection of Shunt Capacitor BankRajnarayan Karmaker100% (1)

- Relay SettingsDocument174 pagesRelay SettingsTrần Văn Phúc100% (1)

- What Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPDocument4 pagesWhat Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPSeindahNyaNo ratings yet

- 1 2 Short Circuit Current Calculation at Various Point of Electrical Circuits (Isc)Document18 pages1 2 Short Circuit Current Calculation at Various Point of Electrical Circuits (Isc)Mark Tristan VallesterosNo ratings yet

- 1103 & 1104 GE0 ENGINE Wiring SchematicDocument7 pages1103 & 1104 GE0 ENGINE Wiring Schematicmahmoud ElmasryNo ratings yet

- Dir OC + EF Protn - APPSDocument72 pagesDir OC + EF Protn - APPSNeelakandan MasilamaniNo ratings yet

- Summary of SubstationDocument11 pagesSummary of SubstationOrenAzizNo ratings yet

- Thyristor and Diode Modules2013Document19 pagesThyristor and Diode Modules2013jagadeesh.bammidiNo ratings yet

- AXON 002 Pressure Products BOP Control SystemsDocument18 pagesAXON 002 Pressure Products BOP Control SystemsJuan Pablo Villazon Richter100% (1)

- Siemens XDocument13 pagesSiemens XXozanNo ratings yet

- XEL Siemens Price ListDocument5 pagesXEL Siemens Price Listমোঃ মোমিনুল ইসলাম শোভনNo ratings yet

- ATX SMPS - Power SupplyDocument71 pagesATX SMPS - Power Supplysupriya_banglaNo ratings yet

- Siemens MammomatDocument20 pagesSiemens MammomatАндрейNo ratings yet

- 2013HORSAvistaDistributionOverview PDFDocument83 pages2013HORSAvistaDistributionOverview PDFTosikur RahmanNo ratings yet