Professional Documents

Culture Documents

WIN PROGRESS CO.,Ltd. (Pharkant Branch) D7D Engine Head Assemble Check Sheet

WIN PROGRESS CO.,Ltd. (Pharkant Branch) D7D Engine Head Assemble Check Sheet

Uploaded by

Ko ZayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WIN PROGRESS CO.,Ltd. (Pharkant Branch) D7D Engine Head Assemble Check Sheet

WIN PROGRESS CO.,Ltd. (Pharkant Branch) D7D Engine Head Assemble Check Sheet

Uploaded by

Ko ZayCopyright:

Available Formats

WIN PROGRESS CO.,Ltd.

(Pharkant Branch)

D7D Engine Head Assemble Check Sheet

Customer Report No.

Machine Model Service date

Machine Sr;No Component Sr; No.

Working Hour Cause of Problem

Reason Of Overhaul Yes No Remark

Flushing?

Recondition?

Preparation

(i) Prepare the tools as follow

•General Tools

W

Wrench-13mm,14mm,17mm,19mm,Rubber

h 13 14 17 19 R bb H Hammer,screw driver(minus).

di ( i )

•Special Tools

Valve spring compressor(LT-05),9998262,LT-63,LT-64,9998678,

Dial indicator with magnetic stand

No Description Status Figure

1 Clean the head with cleaning solvent and compress with air.

2 Press the valve seat with LT‐63(inlet),LT‐64(exhaust).

3 Press

P th

the valve

l guide

id with

ith special

i l ttooll no‐9998262.

9998262

4 Grinding the valve with grinding paste.

5 Mesure the valve depth with special tool no. 9998678 &

dial gauge.

Measure the depth of the valves in the cylinder head

(the distance between the valve head centre and

the cylinder head sealing surface).

W

Wear limit:

li it

Inlet 1.5 mm (0.055 in)

Exhaust 1.5 mm (0.055 in)

No 1 2 3 4 5 6

Inlet

Exhaust

6 Measure the valve clearance in the valve guides with the

dial

di l gauge and d magnetic

ti stand.

t d

The seals must not be installed.

Wear limits:

Inlet 0.1 mm

Exhaust 0.13 mm

No 1 2 3 4 5 6

Inlet

E h

Exhaust

7 Install the Valve guide seal.

8 Install the Inlet and Exhaust Valves.

9 Measure the valve spring lengths (unloaded).

Standard lengths: 64.7 mm (2.55 in)

10 Install the Valve Spring,washer and Valve Collect with

special tool no‐LT‐05.

11 Impact theh Valvel spring

i b by rubber

bb h hammer.

12 Install the Exhaust Stud bolts.

13 Install the Exhaust Manifold with exhaust gasket,

spacer and nut.

14 Install the lifting eyes (1), the temperature sensor (3)

and plugs (2)and nipples (4).

Service person Sign_ _ _ _ _ _ _ _ Supervisor Sign_ _ _ _ _ _ _ _

Service person Name_ _ _ _ _ _ _ _ Supervisor Name_ _ _ _ _ _ _ _

You might also like

- Denso PDFDocument36 pagesDenso PDFGiovaniBalzani95% (22)

- Libro of GeologyDocument188 pagesLibro of GeologyEvelyn Ebenezer100% (1)

- Troubleshooting & Repairing Consumer Electronics Without a SchematicFrom EverandTroubleshooting & Repairing Consumer Electronics Without a SchematicNo ratings yet

- Eaton 70145-Rdy-02Document20 pagesEaton 70145-Rdy-02Nate SpaydNo ratings yet

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Fluid Mechanics and Darcy's LawDocument51 pagesFluid Mechanics and Darcy's LawUche Ukpai100% (5)

- 290BPSWING Gearbox AssDocument2 pages290BPSWING Gearbox AssKo ZayNo ratings yet

- Desarme Parking Brake Wa600-6Document2 pagesDesarme Parking Brake Wa600-6Oliver ArcosNo ratings yet

- Orbitrol Repairing1Document30 pagesOrbitrol Repairing1Islam ShoukryNo ratings yet

- Sanden SD6V12 Service Manual. Date of Issue May Prepared by Sanden International (Europe) Ltd. For Opel.Document25 pagesSanden SD6V12 Service Manual. Date of Issue May Prepared by Sanden International (Europe) Ltd. For Opel.Luigi TencoNo ratings yet

- Series of Pressure Relief Device For Transformers User's ManualDocument6 pagesSeries of Pressure Relief Device For Transformers User's ManualwondNo ratings yet

- Ajuste de Tren de EngranesDocument9 pagesAjuste de Tren de Engranessinger50100% (1)

- Graco Fire Ball 300Document20 pagesGraco Fire Ball 300Rudi Abu ZahraNo ratings yet

- 1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Document11 pages1/11 Engine Model: 4He1-X: Ass'y No.: 107492-1112Marco100% (3)

- Carrete Serie 750Document16 pagesCarrete Serie 750JulioNo ratings yet

- Track Gearbox, Assembly: Service InformationDocument10 pagesTrack Gearbox, Assembly: Service InformationaungaungoomanualNo ratings yet

- 63:1 Ratio King: T PumpDocument24 pages63:1 Ratio King: T PumpF.Javier LobeiraNo ratings yet

- Ed5 - E Floor Sand RammerDocument56 pagesEd5 - E Floor Sand RammerJeffrey ArandiaNo ratings yet

- Unit Injector - Install: Installation ProcedureDocument6 pagesUnit Injector - Install: Installation ProceduredayanaNo ratings yet

- 102 ME Exhaust V, OverhaulDocument5 pages102 ME Exhaust V, Overhaulrajesh.purkar9378No ratings yet

- John Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)Document16 pagesJohn Deere PowerTech 2.9L Diesel Engine Diagnostic Service Repair Technical Manual (CTM125)laopaodunNo ratings yet

- MR Valve Guide, SealDocument15 pagesMR Valve Guide, SealbejoythomasNo ratings yet

- Yamada Diaphragm Pump 80 Series ManualDocument18 pagesYamada Diaphragm Pump 80 Series Manualarun kumarNo ratings yet

- ZF 2Document49 pagesZF 2Silvio Roman100% (2)

- SY-5 Manual enDocument7 pagesSY-5 Manual entienNo ratings yet

- Creality CR-10 ManualDocument18 pagesCreality CR-10 ManualhijodeibnNo ratings yet

- Dive Rite Reg - ManualDocument97 pagesDive Rite Reg - ManualRichard BrownNo ratings yet

- John Deere 80C Excavator Service Repair Technical Manual (TM1939)Document18 pagesJohn Deere 80C Excavator Service Repair Technical Manual (TM1939)laopaodunNo ratings yet

- Fire Ball Pump ManualDocument10 pagesFire Ball Pump Manualgulam husseinNo ratings yet

- SOP TemplateDocument2 pagesSOP TemplateAnkur Dhir100% (1)

- DG1000 OpsDocument24 pagesDG1000 OpsYury GonzalesNo ratings yet

- En 1 5 235 PRA 822000 M EXDocument16 pagesEn 1 5 235 PRA 822000 M EXAlessandro Pereira CunhaNo ratings yet

- CR-10 Series User ManualDocument16 pagesCR-10 Series User ManualFrein Fernando VeraNo ratings yet

- Final DriveDocument10 pagesFinal DriveaungaungoomanualNo ratings yet

- Check-Mate 200 Pumps: Instructions - Parts ListDocument32 pagesCheck-Mate 200 Pumps: Instructions - Parts Listvals valsNo ratings yet

- Alarm Check Valve - MECHDocument5 pagesAlarm Check Valve - MECHGabriel TapiaNo ratings yet

- Graco 239887 Grease Pump BreakdownDocument20 pagesGraco 239887 Grease Pump BreakdownBrandon Smithers100% (2)

- The Essential Guide To Spring Technology: WWW - Springs.co - UkDocument32 pagesThe Essential Guide To Spring Technology: WWW - Springs.co - UkFurqan ShabbirNo ratings yet

- Sis 2.0 3Document1 pageSis 2.0 3kqgy9s6sgvNo ratings yet

- Job Plan 102, 103, 104Document2 pagesJob Plan 102, 103, 104Damn ScaredNo ratings yet

- Valve Clearance Adjustment: Service InformationDocument20 pagesValve Clearance Adjustment: Service InformationNay GyanNo ratings yet

- CNC Worksheet - djj40142 Mechanical Workshop Practice 4Document7 pagesCNC Worksheet - djj40142 Mechanical Workshop Practice 4DKM3C-F1056-PRAVINESHNo ratings yet

- CNC Worksheet - DJJ40142 Mechanical Workshop Practice 4Document7 pagesCNC Worksheet - DJJ40142 Mechanical Workshop Practice 4DKM3C-F1056-PRAVINESHNo ratings yet

- DPODocument2 pagesDPOKhristina Stefanova100% (1)

- ls400 TrannyDocument3 pagesls400 TrannyDohc MasterNo ratings yet

- Engine Timing ValvesDocument44 pagesEngine Timing ValvesSlobodanNo ratings yet

- Calibracion de Valvulas John Deere 6090Document3 pagesCalibracion de Valvulas John Deere 6090青春只是一张黑白画。100% (1)

- Industrial Training Presentation-1 On Rajkot, Gujarat: ProtecDocument31 pagesIndustrial Training Presentation-1 On Rajkot, Gujarat: ProtecJAY KACHANo ratings yet

- Win Progress.,Co - LTD (Pharkant Branch) : D6E/D7E Engine Head Receiving/Delivery Inspection FormDocument1 pageWin Progress.,Co - LTD (Pharkant Branch) : D6E/D7E Engine Head Receiving/Delivery Inspection FormKo ZayNo ratings yet

- Process Blowers: NX S SeriesDocument4 pagesProcess Blowers: NX S SeriesЮрій ГоловащукNo ratings yet

- Multi-Port Flow Selector Valve: KitsnetDocument14 pagesMulti-Port Flow Selector Valve: KitsnetNigin ParambathNo ratings yet

- Sis 2.0 2Document3 pagesSis 2.0 2Rui ArezesNo ratings yet

- Engine Rebuild Inspection Sheet: Job No: Eng. Model: Customer: ESN: CPL: Pump Code: Start Date: Finish DateDocument14 pagesEngine Rebuild Inspection Sheet: Job No: Eng. Model: Customer: ESN: CPL: Pump Code: Start Date: Finish DateRijal Furqaan MardhatillahNo ratings yet

- Cil Rexroth Banco de La RepublicaDocument14 pagesCil Rexroth Banco de La RepublicaGustavo CardenasNo ratings yet

- Herramientas para Reparacion de Motor Cummins C Gas PlusDocument19 pagesHerramientas para Reparacion de Motor Cummins C Gas PlusJusto Paniagua ChampaNo ratings yet

- Install Piston and ConrodDocument8 pagesInstall Piston and ConrodLUIZ GUSTAVONo ratings yet

- Product Information: Air Impact WrenchDocument56 pagesProduct Information: Air Impact WrenchApoorva Vikram SinghNo ratings yet

- Installation Procedure For Vertical Glandless Process PumpDocument22 pagesInstallation Procedure For Vertical Glandless Process PumpYoutube For EducationNo ratings yet

- 1DZ EngineDocument181 pages1DZ EngineGonçalo SousaNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- An Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberFrom EverandAn Introduction to Timber Engineering: Pergamon Series of Monographs on Furniture and TimberRating: 5 out of 5 stars5/5 (1)

- Specifications Zaxis650LcDocument10 pagesSpecifications Zaxis650LcKo ZayNo ratings yet

- Hydraulic SymbolsDocument15 pagesHydraulic SymbolsKo ZayNo ratings yet

- ReturnDocument27 pagesReturnKo ZayNo ratings yet

- Common Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDDocument11 pagesCommon Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDKo ZayNo ratings yet

- Zaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDDocument13 pagesZaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDKo ZayNo ratings yet

- Performance Test For Zx670-3: Unit Actual Value Standard Value RemarkDocument2 pagesPerformance Test For Zx670-3: Unit Actual Value Standard Value RemarkKo ZayNo ratings yet

- SpecificationsDocument5 pagesSpecificationsKo ZayNo ratings yet

- SpecificationsDocument4 pagesSpecificationsKo ZayNo ratings yet

- SpecificationsDocument9 pagesSpecificationsKo ZayNo ratings yet

- Isuzu Parts Catalog 4HK1Document62 pagesIsuzu Parts Catalog 4HK1Ko Zay100% (1)

- Boom Raise Function SlowDocument1 pageBoom Raise Function SlowKo ZayNo ratings yet

- Upperstructure: Section 2Document193 pagesUpperstructure: Section 2Ko ZayNo ratings yet

- Hitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Document71 pagesHitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Ko Zay100% (1)

- Boom Can't DownDocument1 pageBoom Can't DownKo ZayNo ratings yet

- D12C EngAss, Diss (Piston)Document1 pageD12C EngAss, Diss (Piston)Ko ZayNo ratings yet

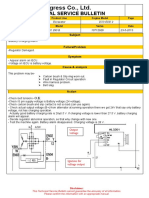

- Win Progress Co., LTD.: Technical Service BulletinDocument3 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- D12D Eng Ass and Disass (Piston)Document1 pageD12D Eng Ass and Disass (Piston)Ko ZayNo ratings yet

- Boom Cylinder Can't LiftDocument2 pagesBoom Cylinder Can't LiftKo ZayNo ratings yet

- Boom Cylinder Creeping &driftDocument2 pagesBoom Cylinder Creeping &driftKo ZayNo ratings yet

- 290BPSWING Gear Box DisassDocument2 pages290BPSWING Gear Box DisassKo ZayNo ratings yet

- Engine Oil Pressure Alarm 128 Pid 100 FMI 1Document2 pagesEngine Oil Pressure Alarm 128 Pid 100 FMI 1Ko ZayNo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- SB020Document2 pagesSB020Ko ZayNo ratings yet

- Training Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Document18 pagesTraining Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Ko ZayNo ratings yet

- FS Curtis FAC 28B 28BC Instruction Manual KubotaDocument69 pagesFS Curtis FAC 28B 28BC Instruction Manual KubotaKo ZayNo ratings yet

- Damage Crank Shaft BearingDocument2 pagesDamage Crank Shaft BearingKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Electrical Assessment QuestionsDocument24 pagesElectrical Assessment QuestionsKo ZayNo ratings yet

- 6.section C - ElectricsDocument225 pages6.section C - ElectricsKo Zay100% (4)

- Investigation ReportDocument9 pagesInvestigation ReportAditya PrajasNo ratings yet

- IEC CatalogueDocument38 pagesIEC Cataloguejohn_serafica7104100% (1)

- Synchronization of Grid Tied Inverter Using DQ-PLL: Ms. Prajakta R. Narkhede, Dr.P.J.ShahDocument7 pagesSynchronization of Grid Tied Inverter Using DQ-PLL: Ms. Prajakta R. Narkhede, Dr.P.J.ShahPrajakta dahakeNo ratings yet

- AOSCA80000Document60 pagesAOSCA80000Rafael Echano AcederaNo ratings yet

- KonversiDocument3 pagesKonversiFitriNo ratings yet

- Eskom PresentationDocument26 pagesEskom PresentationMatthewLeCordeur100% (1)

- BFD SOP 1A Operation of Elevator Key SwitchDocument11 pagesBFD SOP 1A Operation of Elevator Key SwitchPEDRO CAPARACHIN PALPANo ratings yet

- Pete 321 SyllabusDocument2 pagesPete 321 SyllabusGhafour Ď BourasNo ratings yet

- Hag enDocument7 pagesHag enAnh Viet VuNo ratings yet

- KAvika Visit 5Document4 pagesKAvika Visit 5Damodharan ChandranNo ratings yet

- (L8) - (JLD 2.0) - Current Electricity - 27th JuneDocument43 pages(L8) - (JLD 2.0) - Current Electricity - 27th JuneAtishay VermaNo ratings yet

- Tool Catalog Ei18e 11020Document370 pagesTool Catalog Ei18e 11020phankhoa83100% (1)

- The Intricate MechanismDocument2 pagesThe Intricate MechanismRetsuko NiseNo ratings yet

- Aplicaciones Del MC10116Document4 pagesAplicaciones Del MC10116julio gamboaNo ratings yet

- Chemical Effect of Electric Current-5 (2021-22)Document24 pagesChemical Effect of Electric Current-5 (2021-22)Avyam SharmaNo ratings yet

- Science of The SagesDocument176 pagesScience of The SagesSandorhazi Robertino MihaiNo ratings yet

- Mig 4004i PulseDocument4 pagesMig 4004i PulseOkan KöksalNo ratings yet

- Intelilite Mrs 11/Mrs 16: Manual and Remote ControllerDocument2 pagesIntelilite Mrs 11/Mrs 16: Manual and Remote ControllerRonaldCarrasquelNo ratings yet

- Assignment CMT668Document18 pagesAssignment CMT668Khairun NiesaNo ratings yet

- Energy and Work 6Document21 pagesEnergy and Work 6Yash SharmaNo ratings yet

- OH44E-svg44e Data SheetDocument3 pagesOH44E-svg44e Data SheetharshaNo ratings yet

- Face & Bypass DamperDocument7 pagesFace & Bypass DamperMaysaraNo ratings yet

- National Institute of Technology Agartala: Major Project Report TitleDocument7 pagesNational Institute of Technology Agartala: Major Project Report TitleSaransh PandeyNo ratings yet

- Synergy Question 2019Document5 pagesSynergy Question 2019Glysarien GlysarienNo ratings yet

- Electrical Engineering Actual BoardDocument13 pagesElectrical Engineering Actual BoardRaslany Mambuay100% (1)

- Tech Tip #19: How Do You Keep Steam Coils From Freezing?Document7 pagesTech Tip #19: How Do You Keep Steam Coils From Freezing?adil_farooq_6No ratings yet

- UPS5000-E Series (30k-120kVA) - FM DatasheetDocument2 pagesUPS5000-E Series (30k-120kVA) - FM Datasheetsanizam79No ratings yet

- Magnetic Materials IDocument24 pagesMagnetic Materials IrajeswariNo ratings yet