Professional Documents

Culture Documents

D12D Eng Ass and Disass (Piston)

Uploaded by

Ko ZayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D12D Eng Ass and Disass (Piston)

Uploaded by

Ko ZayCopyright:

Available Formats

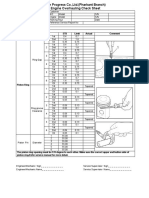

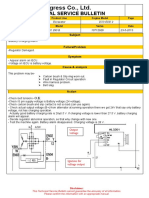

Win Progress Co.,Ltd.

(Pharkant Branch)

Engine Overhauling Check Sheet

Customer

D12D Piston

M/C Model S/N

check Sheet Engine Model S/N

Disassembly Working Hour Date

Assembly Reference Service Report No

Unit=mm

Piston Crown Condition

Piston Scuff Condition

Item Check Point STD Limit Actual Comment

1st 0.4 0.65

1 2nd 1.1 1.3

Oil 0.35 0.65

1st 0.4 0.65

2 2nd 1.1 1.3

Oil 0.35 0.65

1st 0.4 0.65

3 2nd 1.1 1.3

Oil 0.35 0.65

Ring Gap

1st 0.4 0.65

4 2nd 1.1 1.3

Oil 0.35 0.65

1st 0.4 0.65

5 2nd 1.1 1.3

Oil 0.35 0.65

1st 0.4 0.65

6 2nd 1.1 1.3

Oil 0.35 0.65

Piston Ring

1st Tapered

1 2nd 0.09 0.13

Oil 0.05 0.1

1st Tapered

2 2nd 0.09 0.13

Oil 0.05 0.1

1st Tapered

3 2nd 0.09 0.13

Ring groove Oil 0.05 0.1

Clearance 1st Tapered

4 2nd 0.09 0.13

Oil 0.05 0.1

1st Tapered

5 2nd 0.09 0.13

Oil 0.05 0.1

1st Tapered

6 2nd 0.09 0.13

Oil 0.05 0.1

1 55.00

2 55.00

3 55.00

Piston Pin Diameter

4 55.00

5 55.00

6 55.00

The piston ring opening must be 120 degree to each other. Make sure the correct upper and button side of

piston ring.Refer service manual for more detail.

Engineer/Mechanic Sign_ _ _ _ _ _ _ _ _ _ _ _ Service Supervisior Sign_ _ _ _ _ _ _ _ _ _ _ _

Engineer/Mechanic Name_ _ _ _ _ _ _ _ _ _ _ _ Service Supervisior Name_ _ _ _ _ _ _ _ _ _ _ _

You might also like

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityFrom EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityRating: 3 out of 5 stars3/5 (4)

- D12C EngAss, Diss (Piston)Document1 pageD12C EngAss, Diss (Piston)Ko ZayNo ratings yet

- D7EEng Ass, Diss, RecDocument32 pagesD7EEng Ass, Diss, RecAimHighNo ratings yet

- Binod Krishna: Development of Novel Lubricant For Minimisation of Rolling Friction of Cold Rolling MillsDocument23 pagesBinod Krishna: Development of Novel Lubricant For Minimisation of Rolling Friction of Cold Rolling MillsPrasun KunduNo ratings yet

- Especificações Técnicas - Motores JimbeiDocument4 pagesEspecificações Técnicas - Motores JimbeiWiterMarcosNo ratings yet

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDocument8 pagesMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaNo ratings yet

- Lub Oil Report IDocument15 pagesLub Oil Report Ishipdesigner088No ratings yet

- CPCL Turbine ReportDocument25 pagesCPCL Turbine ReportRajesh GoladaNo ratings yet

- GARDNER DENVER LABOUR CALCULATION For WARRANTY 051124Document3 pagesGARDNER DENVER LABOUR CALCULATION For WARRANTY 051124andy habibiNo ratings yet

- Stoppage Analysis Report Cement Mill 2022-23Document32 pagesStoppage Analysis Report Cement Mill 2022-23Valipireddy NagarjunNo ratings yet

- On The Job Training Laboratory: Presented By: Ngurah Putu Tirta Prascita Mill Cadet Batch XDocument35 pagesOn The Job Training Laboratory: Presented By: Ngurah Putu Tirta Prascita Mill Cadet Batch XWilly AbertasiusNo ratings yet

- Product Knowledge 2 Engine 4BE1: Isuzu Training Center - 1Document19 pagesProduct Knowledge 2 Engine 4BE1: Isuzu Training Center - 1mulyono smkn2sbyNo ratings yet

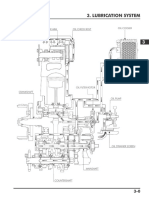

- A86&a88-Chapter 4 (Lubrication System)Document5 pagesA86&a88-Chapter 4 (Lubrication System)Stojanov MarjanNo ratings yet

- Refinery OptimizationDocument7 pagesRefinery OptimizationgenergiaNo ratings yet

- Kymco Vitality Cilindro Pistón PDFDocument19 pagesKymco Vitality Cilindro Pistón PDFFlanagan MatusNo ratings yet

- KXR50 Cap 08 (Cilindro Pistone)Document18 pagesKXR50 Cap 08 (Cilindro Pistone)tutifruti649No ratings yet

- Manual Lubricador AlemiteDocument6 pagesManual Lubricador Alemiteandreshuertascalderon02No ratings yet

- Trailblazer: Vehicle Dismantling ManualDocument22 pagesTrailblazer: Vehicle Dismantling ManualBrandon MawhorterNo ratings yet

- 07-08-2018 Rekap Trial GorengDocument9 pages07-08-2018 Rekap Trial GorengMargareth RiriedNo ratings yet

- 04 - Lubrication SystemDocument10 pages04 - Lubrication SystemMarcos Mo CatalanNo ratings yet

- Exp BootDocument3 pagesExp BootEdgar Enrique Garcia FloresNo ratings yet

- 303-01b Engine TD4Document166 pages303-01b Engine TD4Juraci Diniz100% (1)

- Final Inspection - Tata Ace DiscDocument3 pagesFinal Inspection - Tata Ace DiscazadNo ratings yet

- Oil ContaminationDocument7 pagesOil ContaminationChandra AeniyahNo ratings yet

- Ratio Analysis of FMCGDocument12 pagesRatio Analysis of FMCGDevansh DubeyNo ratings yet

- Norma para Los Aceites de Oliva Y Aceites de Orujo de Oliva CODEX STAN 33-1981Document8 pagesNorma para Los Aceites de Oliva Y Aceites de Orujo de Oliva CODEX STAN 33-1981MayraTgNo ratings yet

- Im MT 013Document7 pagesIm MT 013Emy SumartiniNo ratings yet

- Grade/Tonne ClassificationDocument14 pagesGrade/Tonne ClassificationkokekanonNo ratings yet

- Palm Oil MillDocument52 pagesPalm Oil MillengrsurifNo ratings yet

- Fabrikasi Perakitan Jumlah Mesin 01 02 03 1-1 1-2 1-3 1-4 1-5 Teoritis AktualDocument1 pageFabrikasi Perakitan Jumlah Mesin 01 02 03 1-1 1-2 1-3 1-4 1-5 Teoritis AktualDeri AriyantoNo ratings yet

- 114-3 Unit Assembling Check Sheet KOMATSU ENGINE 114-3-87874Document12 pages114-3 Unit Assembling Check Sheet KOMATSU ENGINE 114-3-87874เชิดศักดิ์ สอาดศรีNo ratings yet

- Well Fluid Type: Mole PercentDocument26 pagesWell Fluid Type: Mole PercentWael BadriNo ratings yet

- Nya Cement Company Limited: Daily Production ReportDocument1 pageNya Cement Company Limited: Daily Production ReportIrshad HussainNo ratings yet

- Rwo Gear MotorDocument4 pagesRwo Gear MotorTejas MehtaNo ratings yet

- Lubricating Oil Pressure Low: Cause CorrectionDocument3 pagesLubricating Oil Pressure Low: Cause CorrectionYasser JaviNo ratings yet

- Oily WatersDocument8 pagesOily WatersRAGHU MALLEGOWDANo ratings yet

- Lubricants For Wingd Engines v6Document31 pagesLubricants For Wingd Engines v6nikospg9427No ratings yet

- 03 Lubrication System AbwtDocument12 pages03 Lubrication System Abwtcarlos melendez morenoNo ratings yet

- Trazo Cancha 120822Document1 pageTrazo Cancha 120822Tomas CarrilloNo ratings yet

- PosterDocument1 pagePosterΟδυσσεας ΚοψιδαςNo ratings yet

- Girth Gear Axial Reading After Full WeldingDocument1 pageGirth Gear Axial Reading After Full WeldingAbobakr GaberNo ratings yet

- Grease Selection StepsDocument12 pagesGrease Selection StepsSusibrat SarmaNo ratings yet

- Characterstics of GreaseDocument6 pagesCharacterstics of Greaseelias chernetNo ratings yet

- Omm Ex1200-6 PDFDocument22 pagesOmm Ex1200-6 PDFdayatNo ratings yet

- Tabel 1. Analisis Komposisi Kimia Pipa Terhadap Kerentanan Rentak1901 - PT. Pertamina Hulu MahakamDocument1 pageTabel 1. Analisis Komposisi Kimia Pipa Terhadap Kerentanan Rentak1901 - PT. Pertamina Hulu MahakamArifo Gunawan CahyanegoroNo ratings yet

- Lyon2007 Friction Wear BoreDocument17 pagesLyon2007 Friction Wear BoreCLAUDIO RODRIGUES DA SILVA JUNIORNo ratings yet

- Grade Tonne Report22Document42 pagesGrade Tonne Report22kokekanonNo ratings yet

- Precios ProductosDocument12 pagesPrecios Productosvales.procosa2809No ratings yet

- AFA II III OilDocument74 pagesAFA II III OilAbdallah Mansour100% (1)

- ScP045 Scales ToolboxDocument2 pagesScP045 Scales ToolboxORBeducationNo ratings yet

- BW125 - 150 Cap 07 (Cilindro Pistone)Document9 pagesBW125 - 150 Cap 07 (Cilindro Pistone)Franckie HyacintheNo ratings yet

- Arbol de Falla Baja Presion de Aceite K50y38Document3 pagesArbol de Falla Baja Presion de Aceite K50y38kamana7No ratings yet

- BW125 - 150 Cap 04 (Lubrificazione)Document7 pagesBW125 - 150 Cap 04 (Lubrificazione)Franckie HyacintheNo ratings yet

- Water Resistance Grease For Steel MillsDocument4 pagesWater Resistance Grease For Steel Millsmohamed bakryNo ratings yet

- 22 Manual TransmissionDocument20 pages22 Manual TransmissionstuparNo ratings yet

- Mitsubishi Manual TransmissionDocument20 pagesMitsubishi Manual TransmissionEwa SurewaNo ratings yet

- Chart TitleDocument3 pagesChart TitleSolange RiveraNo ratings yet

- Model 6yl-120 Screw Oil PressDocument5 pagesModel 6yl-120 Screw Oil PressRoula EbrahimNo ratings yet

- Olive Oil FacDocument8 pagesOlive Oil Faccoleen T.No ratings yet

- Performance Test For Zx670-3: Unit Actual Value Standard Value RemarkDocument2 pagesPerformance Test For Zx670-3: Unit Actual Value Standard Value RemarkKo ZayNo ratings yet

- ReturnDocument27 pagesReturnKo ZayNo ratings yet

- Zaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDDocument13 pagesZaxis-5G Maintenance Guide: Hitachi Construction Machinery Asia & Pacific Pte LTDKo ZayNo ratings yet

- Upperstructure: Section 2Document193 pagesUpperstructure: Section 2Ko ZayNo ratings yet

- Specifications Zaxis650LcDocument10 pagesSpecifications Zaxis650LcKo ZayNo ratings yet

- Common Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDDocument11 pagesCommon Rail Diagnostics: Hitachi Construction Machinery Asia & Pacific Pte. LTDKo ZayNo ratings yet

- Hydraulic SymbolsDocument15 pagesHydraulic SymbolsKo ZayNo ratings yet

- Boom Raise Function SlowDocument1 pageBoom Raise Function SlowKo ZayNo ratings yet

- SpecificationsDocument9 pagesSpecificationsKo ZayNo ratings yet

- Boom Can't DownDocument1 pageBoom Can't DownKo ZayNo ratings yet

- Boom Cylinder Creeping &driftDocument2 pagesBoom Cylinder Creeping &driftKo ZayNo ratings yet

- SpecificationsDocument5 pagesSpecificationsKo ZayNo ratings yet

- Isuzu Parts Catalog 4HK1Document62 pagesIsuzu Parts Catalog 4HK1Ko ZayNo ratings yet

- SpecificationsDocument4 pagesSpecificationsKo ZayNo ratings yet

- Hitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Document71 pagesHitachizaxiszx75us 3excavatorservicerepairmanual 171124075345Ko Zay100% (1)

- Boom Cylinder Can't LiftDocument2 pagesBoom Cylinder Can't LiftKo ZayNo ratings yet

- SB020Document2 pagesSB020Ko ZayNo ratings yet

- 290BPSWING Gear Box DisassDocument2 pages290BPSWING Gear Box DisassKo ZayNo ratings yet

- Training Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Document18 pagesTraining Manual Electrical: Cable Systems - Cable Termination Revised March 2006 Page 1 of 18Ko ZayNo ratings yet

- 290BPSWING Gearbox AssDocument2 pages290BPSWING Gearbox AssKo ZayNo ratings yet

- Damage Crank Shaft BearingDocument2 pagesDamage Crank Shaft BearingKo ZayNo ratings yet

- Engine Oil Pressure Alarm 128 Pid 100 FMI 1Document2 pagesEngine Oil Pressure Alarm 128 Pid 100 FMI 1Ko ZayNo ratings yet

- Electrical Assessment QuestionsDocument24 pagesElectrical Assessment QuestionsKo ZayNo ratings yet

- Weichai Engine PrintDocument52 pagesWeichai Engine PrintKo ZayNo ratings yet

- 6.section C - ElectricsDocument225 pages6.section C - ElectricsKo Zay100% (4)

- Win Progress Co., LTD.: Technical Service BulletinDocument3 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- FS Curtis FAC 28B 28BC Instruction Manual KubotaDocument69 pagesFS Curtis FAC 28B 28BC Instruction Manual KubotaKo ZayNo ratings yet

- Win Progress Co., LTD.: Technical Service BulletinDocument2 pagesWin Progress Co., LTD.: Technical Service BulletinKo ZayNo ratings yet

- Electronic Circuit For A Delphi Direct Fuel Injection System - Initial Approach - Malc's Blog PDFDocument9 pagesElectronic Circuit For A Delphi Direct Fuel Injection System - Initial Approach - Malc's Blog PDFMichael DavenportNo ratings yet

- Jac HFC4GB1Document70 pagesJac HFC4GB1Jeifred Espitia AraujoNo ratings yet

- Government Polytechnic, Nagpur: Course CurriculumDocument8 pagesGovernment Polytechnic, Nagpur: Course CurriculumAyush LolusareNo ratings yet

- YANMAR Part Catalog - 8 LAA-UTE - UmakaladaDocument145 pagesYANMAR Part Catalog - 8 LAA-UTE - Umakaladariwian100% (3)

- 1.4 Hdi Tdci 1.4Document6 pages1.4 Hdi Tdci 1.4Victor AyalaNo ratings yet

- Catalogo WisecoDocument35 pagesCatalogo WisecobrunnomaiaNo ratings yet

- Marine Propulsion Engine: Fast VesselDocument4 pagesMarine Propulsion Engine: Fast VesselSiding BarroNo ratings yet

- IC Engine - Chapter 5, 6 & 7 Handout - 2022Document21 pagesIC Engine - Chapter 5, 6 & 7 Handout - 2022nunuNo ratings yet

- Alh Turbo RemovalDocument14 pagesAlh Turbo RemovalbamseflorinNo ratings yet

- KCG-2001I Service ManualDocument5 pagesKCG-2001I Service ManualPatrick BouffardNo ratings yet

- Ace CranesDocument29 pagesAce CranesAnkit SalujaNo ratings yet

- Perkins T6.354 WorkshopDocument130 pagesPerkins T6.354 WorkshopAlexis Socarrós100% (1)

- Yanmar Mechnical PumpDocument16 pagesYanmar Mechnical Pump송성훈100% (9)

- WM Porsche 944 Vol 1a Engine 16vDocument150 pagesWM Porsche 944 Vol 1a Engine 16v9TECHNIKNo ratings yet

- Stanadyne de Pump Timing InstructionsDocument1 pageStanadyne de Pump Timing InstructionsPiotr Kowal100% (5)

- 3-Engine Hydrodynamic Intake, Exhaus Lecture-3Document41 pages3-Engine Hydrodynamic Intake, Exhaus Lecture-3Roberto de VirgilioNo ratings yet

- 6LY2A-UTP / STP Series: Marine Diesel EnginesDocument2 pages6LY2A-UTP / STP Series: Marine Diesel EnginesHuỳnh Quý ThiênNo ratings yet

- Cylinder Liner 2NDDocument5 pagesCylinder Liner 2NDThuria TunNo ratings yet

- DAIHATSU SERVICE INFORMATION (Read-Only) PDFDocument96 pagesDAIHATSU SERVICE INFORMATION (Read-Only) PDFSajeev NerurkarNo ratings yet

- Compressor: HATLAPA Water-Cooled Piston Compressor W30, W40Document2 pagesCompressor: HATLAPA Water-Cooled Piston Compressor W30, W40Vanas ShahNo ratings yet

- Error Sumitomo - 6Document4 pagesError Sumitomo - 6dodi chandraNo ratings yet

- Parts Catalog: 0CR10-M74901ENDocument65 pagesParts Catalog: 0CR10-M74901ENÎle MarineNo ratings yet

- PionjarDocument40 pagesPionjarWender Silva0% (1)

- Weichai WP7 SCR PDFDocument145 pagesWeichai WP7 SCR PDFANH LÊNo ratings yet

- Tundra Partes 2Document3 pagesTundra Partes 2alexander pintoNo ratings yet

- Manage The Operation of Propulsion Plant From UKP AllDocument73 pagesManage The Operation of Propulsion Plant From UKP AllAndhikaNo ratings yet

- PULSAR NS 160 Fi 2021Document92 pagesPULSAR NS 160 Fi 2021Juan Manuel Ortega0% (1)

- Engine Coding: 1988 Mazda 626 1988 Mazda 626Document26 pagesEngine Coding: 1988 Mazda 626 1988 Mazda 626lopezdestructionNo ratings yet

- 41 Fuel and Lubrication SystemsDocument52 pages41 Fuel and Lubrication Systemsnvene9696100% (4)

- GT / GB Series: Price List / Mitsubishi Gasoline Engine, Four-StrokeDocument1 pageGT / GB Series: Price List / Mitsubishi Gasoline Engine, Four-StrokeCuneyt TekinNo ratings yet