Professional Documents

Culture Documents

10 PDFsam TN62Part1

Uploaded by

mrmerajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10 PDFsam TN62Part1

Uploaded by

mrmerajCopyright:

Available Formats

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.

Figure 7.2(d) – View of the torque wrench on the True Checker

True Checker device is used to

outline the torque setting for a torque

wrench. Many wenches are set via

pressure and the true checker

determines the torque in the torque

wrench for a specific pressure. True

Checker can also be used to ensure

the torque in the torque wrench

correctly calibrated.

8 Installation of the bolts, nuts and washers

The nut must be able to run freely up and down the bolt. The correct way to clear a blockage is to run

the nut up and down the thread until the nut is free running. If the nut still will not run freely on the bolt

the contractor shall discard the nut and the bolt. This procedure must occur before taking bolts and

nuts to site.

The contractor shall draw together the two surfaces which require joining so they are in full contact.

This may involve the use of tacking bolts. Once the parts are in full contact, the contractor shall

replace any tacking bolts with high strength bolts one at a time.

The following requirements are to be satisfied:

• Driving of high strength bolts into the holes is unacceptable. In order to fit the bolts without

force, the contractor may ream or drift the holes.

• Washers are required under both the head of the bolt and the nut.

• Lubricate the bolt thread with “Stearin Wax” or “Relton Stick Wax” prior to installing the nut on

the bolt.

• There shall be a minimum of one full thread projecting above the top of the nut after assembly.

• If one full thread is not visible, then a longer bolt shall be used. If selecting a longer bolt, the

maximum amount of projection of the bolt end passed the nut shall be 15 mm. Packing with up

to three washers not exceeding 12 mm thickness is acceptable on the joint side not being

turned.

• Note: The reason a bolt cannot have to too much thread projection is due to the bolt not

having sufficient thread and when tightened the nut can run out of thread and will not be

tensioned correctly.

• Once all the bolts are assembled, the bolts shall be tensioned so they are snug tight and the

connecting surfaces are drawn together.

Technical Note, Transport and Main Roads, November 2015 8

You might also like

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingFrom EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingRating: 4.5 out of 5 stars4.5/5 (9)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- List of SEng With Name, Designation & Contact DetailsDocument6 pagesList of SEng With Name, Designation & Contact DetailsS. M. Habibul AhsanNo ratings yet

- Procedure For Wrench Calibration and Snug TighteningDocument5 pagesProcedure For Wrench Calibration and Snug TighteningWNo ratings yet

- Senr3130 19 00 - Manuals Service Modules - SpecificationsDocument24 pagesSenr3130 19 00 - Manuals Service Modules - Specificationsmostafa aliNo ratings yet

- Senr3130 14 00 AllDocument20 pagesSenr3130 14 00 AllAhmed MoustafaNo ratings yet

- A New Approach To The Tightness Checking of Bolts PDFDocument3 pagesA New Approach To The Tightness Checking of Bolts PDFKOMATSU SHOVELNo ratings yet

- Stairs, Ladders, and Open-Edge Guards For Use With Material Handling StructuresDocument20 pagesStairs, Ladders, and Open-Edge Guards For Use With Material Handling Structuresmrmeraj100% (1)

- Installation and Maintenance of Threaded Fasteners Nuts and BoltsDocument73 pagesInstallation and Maintenance of Threaded Fasteners Nuts and BoltsPrashant Kumar mishraNo ratings yet

- Cat General Torque Specifications PDFDocument48 pagesCat General Torque Specifications PDFAlaudin Awang Xwijaya0% (1)

- Headstock Part 1Document10 pagesHeadstock Part 1api-327987286No ratings yet

- How To Determine Cable Size With Exampe-1Document8 pagesHow To Determine Cable Size With Exampe-1Charles Ekpima100% (1)

- Bolted Joints Are One of The Most Common Elements in Construction and Machine DesignDocument8 pagesBolted Joints Are One of The Most Common Elements in Construction and Machine Designkhalid7015No ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- Model M ManualsDocument6 pagesModel M ManualsdiegoNo ratings yet

- Running A Bridge Plug and Cement Retainers 4531366 01Document32 pagesRunning A Bridge Plug and Cement Retainers 4531366 01Mohamed HashemNo ratings yet

- DataBase 2020 StucoDocument20 pagesDataBase 2020 StucoPranjal TiwariNo ratings yet

- Siemens Arcadis Varic ReplacementDocument96 pagesSiemens Arcadis Varic ReplacementLeonardo ChirinosNo ratings yet

- Distribution System PlanningDocument91 pagesDistribution System PlanningOMAR METRINo ratings yet

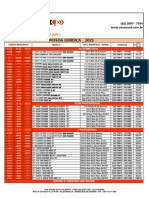

- Tabla Tension Correas GatesDocument4 pagesTabla Tension Correas Gatesvibrador0% (1)

- Torque Wrench Standard Practices - Full Version.Document7 pagesTorque Wrench Standard Practices - Full Version.Siva SubramaniNo ratings yet

- Micrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsFrom EverandMicrometers - Slide Gauges and Calipers - Principles, Construction, Operation and Use of Appliances for Fine Mechanical MeasurementsNo ratings yet

- New Microsoft Office Word DocumentDocument3 pagesNew Microsoft Office Word DocumentKarthik VadlamudiNo ratings yet

- Grin Evi ChsDocument5 pagesGrin Evi Chssagar1503No ratings yet

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Document12 pagesAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNo ratings yet

- Alignment: Torque vs. TensionDocument6 pagesAlignment: Torque vs. Tensionfrancesca_bonfanti_1No ratings yet

- TENTEC Operator ManualDocument15 pagesTENTEC Operator ManualDeividas BNo ratings yet

- CAT Torque Specifications General InformationDocument2 pagesCAT Torque Specifications General InformationSergeyNo ratings yet

- Skidmore Instructions Model MS ManualsDocument15 pagesSkidmore Instructions Model MS ManualsbwbrockNo ratings yet

- Fiesta 14 16v Fxja Engine Timing Belt GuideDocument1 pageFiesta 14 16v Fxja Engine Timing Belt GuideIdam Syahputra SamosirNo ratings yet

- General InformationDocument7 pagesGeneral InformationRobert SantiagoNo ratings yet

- Synchronous Drive InstallationDocument4 pagesSynchronous Drive InstallationryanmackintoshNo ratings yet

- IS233Document2 pagesIS233Carlos Lara CastroNo ratings yet

- Presentation On Torqueing Tension IngDocument13 pagesPresentation On Torqueing Tension IngudayalNo ratings yet

- Er 063 2Document4 pagesEr 063 2ariel.garayNo ratings yet

- Procedures For Rotational Capacity Testing For High Strength BoltsDocument12 pagesProcedures For Rotational Capacity Testing For High Strength BoltsAGnes Stephani MuntheNo ratings yet

- Installation Instructions For Stop CollarsDocument4 pagesInstallation Instructions For Stop CollarsWise SoNo ratings yet

- Assembly and Tensioning of High Strength Bolts andDocument14 pagesAssembly and Tensioning of High Strength Bolts andKirtichandraKomarrajuNo ratings yet

- Torque WrenchDocument12 pagesTorque WrenchJonathan TedriaNo ratings yet

- Northwest: Maintenance Manual DC9Document10 pagesNorthwest: Maintenance Manual DC9Erik Joan Quiroga RamirezNo ratings yet

- LS1 PTV Measuring Procedure DRAFT 20-Apr-13Document5 pagesLS1 PTV Measuring Procedure DRAFT 20-Apr-13RezinTexasNo ratings yet

- Model MS ManualsDocument15 pagesModel MS ManualsbarrettshawnNo ratings yet

- CRV Valve AdjustmentDocument7 pagesCRV Valve AdjustmentJamieNo ratings yet

- Magpower Clutch Model CDocument4 pagesMagpower Clutch Model CJuan CaceresNo ratings yet

- At TC3CN006 18 T1 Ja101Document3 pagesAt TC3CN006 18 T1 Ja101Dhaneswar SwainNo ratings yet

- Lug Nut Torque: Requirements & MaintenanceDocument5 pagesLug Nut Torque: Requirements & MaintenanceSupriyanto AntokNo ratings yet

- Calibrated Wrench DownloadDocument7 pagesCalibrated Wrench DownloadAnonyNo ratings yet

- Instructions ReportDocument2 pagesInstructions Reportapi-610017694No ratings yet

- 2001 Chevrolet Cavalier L4-2.2L: Timing Chain: Service and RepairDocument4 pages2001 Chevrolet Cavalier L4-2.2L: Timing Chain: Service and RepairAbel QuintanaNo ratings yet

- Mantenimiento de Caja Chery QQ PDFDocument14 pagesMantenimiento de Caja Chery QQ PDFJose FerrerNo ratings yet

- Bolted Joint - Wikipedia v123Document8 pagesBolted Joint - Wikipedia v123Juan F CrsNo ratings yet

- CRAFT Installation-Guide For Split Bearings PDFDocument7 pagesCRAFT Installation-Guide For Split Bearings PDFAdrian CantaragiuNo ratings yet

- Chery SQR372 0.8LDocument8 pagesChery SQR372 0.8Lferran_alfonsoNo ratings yet

- Methods of Tightening Threaded FastenersDocument4 pagesMethods of Tightening Threaded FastenersABDONo ratings yet

- Tools Install PDFDocument20 pagesTools Install PDFmfj79607555No ratings yet

- Question & AnswerDocument12 pagesQuestion & AnswerbalamuruganNo ratings yet

- 106.5 - BeltsDocument10 pages106.5 - BeltsHassan GDOURANo ratings yet

- Page87 172Document86 pagesPage87 172Flavia PereiraNo ratings yet

- deltaSeriesTensioner OperationManualDocument26 pagesdeltaSeriesTensioner OperationManualAlan100% (1)

- Timing BeltDocument28 pagesTiming BeltRaj Bikram MaharjanNo ratings yet

- A325-Twist of BoltDocument6 pagesA325-Twist of BoltPham NhatNo ratings yet

- 4M41Document10 pages4M41Guadalupe GuerreroNo ratings yet

- eTORK Digital Wrench InstructionsDocument8 pageseTORK Digital Wrench InstructionsJHON FREDY PEREZ ZAMUDIONo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- TGN-RT-03 - Bolting Procedure For Steel Structures Rev 1Document3 pagesTGN-RT-03 - Bolting Procedure For Steel Structures Rev 1mostafamaroc0% (1)

- How It Works - PDF RotaBoltDocument5 pagesHow It Works - PDF RotaBoltaop10468No ratings yet

- 16 CompoComposite Structures of Steel and ConcreDocument7 pages16 CompoComposite Structures of Steel and ConcremrmerajNo ratings yet

- R. Stroetmann, T. Kästner: A New Design Model For Welded JointsDocument1 pageR. Stroetmann, T. Kästner: A New Design Model For Welded JointsmrmerajNo ratings yet

- Welded DesignDocument1 pageWelded DesignmrmerajNo ratings yet

- 9 Check of Torque and Re-Calibration: Number of Available Places Accept or Reject CommentDocument1 page9 Check of Torque and Re-Calibration: Number of Available Places Accept or Reject CommentmrmerajNo ratings yet

- 3 Str223 STRDocument1 page3 Str223 STRmrmerajNo ratings yet

- 1 Str223 STRDocument1 page1 Str223 STRmrmerajNo ratings yet

- 4.2 8.8/TF and 8.8/TB (Or 8.8/T When Referring To Both Types)Document1 page4.2 8.8/TF and 8.8/TB (Or 8.8/T When Referring To Both Types)mrmerajNo ratings yet

- Design Bearing Strength (LRFD J3.10) : WhereDocument1 pageDesign Bearing Strength (LRFD J3.10) : WheremrmerajNo ratings yet

- Single Sections in BendingDocument1 pageSingle Sections in BendingmrmerajNo ratings yet

- LF Loudspeakers TF1525: General SpecificationsDocument1 pageLF Loudspeakers TF1525: General SpecificationsJoel Hipolito ReyesNo ratings yet

- 7PG18 TR A Catalogue SheetDocument12 pages7PG18 TR A Catalogue SheetAmaresh NayakNo ratings yet

- BJT - Examples & SolutionsDocument15 pagesBJT - Examples & SolutionsRobiul Haque BhuyanNo ratings yet

- Take Away 2Document25 pagesTake Away 2Mohamed Omar IbrahimNo ratings yet

- DUET Career and Research Club: Senior Advisory CouncilDocument7 pagesDUET Career and Research Club: Senior Advisory CouncilRiyad AhmedNo ratings yet

- Multi Engine Lesson PlansDocument11 pagesMulti Engine Lesson PlanscharlieyankeenzNo ratings yet

- IFC User Manual V.G Oct2021Document33 pagesIFC User Manual V.G Oct2021jonny manzanoNo ratings yet

- Square D 8501 Type K Relays - 8501KPD12V51Document2 pagesSquare D 8501 Type K Relays - 8501KPD12V51RomankoNo ratings yet

- Test 1 Eee121 Jun2020Document4 pagesTest 1 Eee121 Jun2020Nabil ZamriNo ratings yet

- Datasheet ST VND7N V04Document21 pagesDatasheet ST VND7N V04Alexandre KaczanukNo ratings yet

- SST ManDocument30 pagesSST ManquangNo ratings yet

- Labour ContractDocument2 pagesLabour ContractMuthukumarNo ratings yet

- SGL8022W SiGmaMicroDocument9 pagesSGL8022W SiGmaMicroGILMAR DA SILVA NETONo ratings yet

- Restore-A-Phase: H.J. Arnett Industries Tualatin, OR 97062Document14 pagesRestore-A-Phase: H.J. Arnett Industries Tualatin, OR 97062mojsic6313No ratings yet

- Lenovo V110 Hardware Maintenance Manual: V110-14IAP/V110-14AST V110-15ISK/V110-15IAP/V110-15ASTDocument87 pagesLenovo V110 Hardware Maintenance Manual: V110-14IAP/V110-14AST V110-15ISK/V110-15IAP/V110-15ASTMauludi MukhlisNo ratings yet

- Model Curriculum: Field Engineer - RACWDocument20 pagesModel Curriculum: Field Engineer - RACWpatel gauravNo ratings yet

- Tabela Alto Falante 2021Document2 pagesTabela Alto Falante 2021danraceroficialNo ratings yet

- Service Manual: CX-JDS55Document64 pagesService Manual: CX-JDS55Jose Enrique Aguirre GuerreroNo ratings yet

- UT - EXWI-NDT-21103 - Rev.00 - AWS D1.1Document14 pagesUT - EXWI-NDT-21103 - Rev.00 - AWS D1.1Cherdchai nuntariNo ratings yet

- Located In: Arcgis/Bin/Styles/Utilities - Style Version: Arcgis 9.0 1Document21 pagesLocated In: Arcgis/Bin/Styles/Utilities - Style Version: Arcgis 9.0 1Ephrem GizachewNo ratings yet

- Using Differential IOLVDSSub LVDSini CE40 DevicesDocument20 pagesUsing Differential IOLVDSSub LVDSini CE40 DevicesBrian CannardNo ratings yet

- Engel 2015Document14 pagesEngel 2015Muhammad NazeerNo ratings yet

- DIP Type Diodes: Schottky Barrier Diodes MBR20100FDocument2 pagesDIP Type Diodes: Schottky Barrier Diodes MBR20100FTri RandiNo ratings yet

- What Is Counter?: Flip-FlopDocument8 pagesWhat Is Counter?: Flip-FlopArunNo ratings yet

- Coe 271-8-OpampDocument57 pagesCoe 271-8-OpampJohn Idun EssumanNo ratings yet