Professional Documents

Culture Documents

Power Management System PMA 300: SIEMENS Marine Solutions Automation On Ships

Uploaded by

hamzehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Management System PMA 300: SIEMENS Marine Solutions Automation On Ships

Uploaded by

hamzehCopyright:

Available Formats

Power Management System - PMA 300 USER MANUAL

SIEMENS Marine Solutions

Automation on Ships

Power Management System

PMA 300

PART 3 – TECHNICAL DESCRIPTION

Project document no: PO03020-12-M001A Part 3 Technical description

B 18.08.2009 First Project specific data entered KTj

A 17.11.2008 Standard Document PMA300 V5.0 Aro Ty

Rev Date Description By Check Accept.

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 1 of 21

Power Management System - PMA 300 USER MANUAL

CONTENT Page

3 INTRODUCTION............................................................................................................................3

3.1 SYSTEM REQUIREMENTS.................................................................................................... 4

3.1.1 Classification requirements ............................................................................................. 4

3.1.2 System redundancy......................................................................................................... 4

3.1.3 Communication................................................................................................................ 5

3.2 Generator & SWITCHBOARD overview.................................................................................. 6

3.2.1 Generator main data........................................................................................................ 6

3.2.2 Switchboard Single line diagram ..................................................................................... 7

3.2.3 PMA 300 Touch panel MP377......................................................................................... 8

POWER MANAGEMENT .................................................................................................................... 9

3.2.4 Blackout start and minimum number of sets ................................................................... 9

3.2.5 Standby sequence ........................................................................................................... 9

3.2.6 Total load dependent start/stop ....................................................................................... 9

3.2.7 Individual load, frequency or voltage dependent start..................................................... 9

3.2.8 PMA 300 Load sharing supervision & control ............................................................... 10

3.3 Generator cubicle interface ................................................................................................... 11

3.3.1 Generator data:.............................................................................................................. 11

3.3.2 Generator breaker ......................................................................................................... 11

3.3.3 Diesel engine main data ................................................................................................ 11

3.3.4 Engine functions ............................................................................................................ 11

3.3.5 Engine alarm / system alarm (pre-warning/delayed shutdown) .................................... 11

3.3.6 Engine prelubrication pumps ......................................................................................... 12

3.3.7 Engine auxiliary system................................................................................................. 12

3.3.8 Interface to PMA 300 Generator I/O station .................................................................. 13

3.4 MAIN BUSBAR INTERFACE ................................................................................................ 15

3.4.1 Busbar data collection ................................................................................................... 15

3.4.2 Power available signal to bridge system (diesel electric propulsion) ............................ 15

3.4.3 Bus-tie trip...................................................................................................................... 15

3.4.4 Non essential consumer trip (Load shedding)............................................................... 15

3.4.5 HEAVY CONSUMERS .................................................................................................. 17

3.4.6 Interface to PMA 300 Busbar control I/O station ........................................................... 18

3.4.7 Interface to PMA 300 HC/NEC control I/O station......................................................... 19

3.5 ALARM LIMITS...................................................................................................................... 21

3.5.1 Class required alarms (alarm limit 2)............................................................................. 21

3.5.2 Additional generator alarms........................................................................................... 21

3.5.3 Loadsharing alarms ....................................................................................................... 21

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 2 of 21

Power Management System - PMA 300 USER MANUAL

3 Introduction

This document is the basis for project specific configuration of the PMA300 power management sys-

tem.

It is a part of the PMA 300 User Manual. Together with “Part 02 MAIN DATA & SYSTEM PHILOSPHY”

it is suitable for handing over to customers in the early stages of a project for information.

Valid revisions of the document can only when filled out by Siemens.

Check boxes in bold typing indicate the default setting. Only check boxes where your selection differs

from the default values is required to be filled in. Tables indicated with colour must be specified for the

project.

Generally it is possible to configure each generator set individually; some functions should however be

similar within the plant. Parameter settings for these functions are indicated with simple common

Yes/No check boxes.

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 3 of 21

Power Management System - PMA 300 USER MANUAL

3.1 SYSTEM REQUIREMENTS

3.1.1 Classification requirements

Classification Soci- DNV

ety:

Class Notation:

Vessel classification

ID

No Dynamic Positioning (DP) DP class II DP class III Redundant propulsion (RP)

Other requirements specific;

3.1.2 System redundancy

Single CPU controller Double CPU controller Triple CPU controller

One MP377 Touch panel Two MP377 Touch panel’s Three MP377 Touch panel’s

Other requirements specific;

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 4 of 21

Power Management System - PMA 300 USER MANUAL

3.1.3 Communication

Profibus DP interface to IAS/ remote alarm and control system Yes No

If Yes:

RHMI document sent to customer and IAS vendor Version & Date

(if not Siemens):

PO03020-12-

PMA 300 V5.0 Remote Human Machine Interface Description H001_A_RHMI_PMA300_V5.00

18.08.2009

IAS vendor: Siemens, Kongsberg etc.

Block local alarms on the touch screen panel when remote control is selected Yes No

from the IAS.

Profinet interface to Siemens Teleservice Yes No

Other requirements specific;

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 5 of 21

Power Management System - PMA 300 USER MANUAL

3.2 Generator & SWITCHBOARD overview

3.2.1 Generator main data

Gen. Type (1) Nominal Active Nominal Ap- Nominal Cur- Nominal Volt- Nominal

no. Power [KW] parent Power rent [A] age [V] Frequency

[kVAr] [Hz]

G1 DG 1278 1420 1188 690 50

G2 DG 1278 1420 1188 690 50

G3 DG 1278 1420 1188 690 50

(1) DG: Diesel Generator, SG: Shaft Generator

Remarks:

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 6 of 21

Power Management System - PMA 300 USER MANUAL

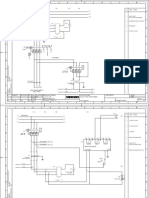

3.2.2 Switchboard Single line diagram

Drawing number: PO03020-01-H001-1A

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 7 of 21

Power Management System - PMA 300 USER MANUAL

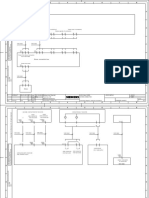

3.2.3 PMA 300 Touch panel MP377

Specific location of panel

MP377 Panel no. 1 690V swbd. cubicle no. 4 (+GA04)

MP377 Panel no. 2

(optional)

Sketch of panel picture:

Remarks:

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 8 of 21

Power Management System - PMA 300 USER MANUAL

POWER MANAGEMENT

3.2.4 Blackout start and minimum number of sets

Minimum number of DG sets to run Default: 1 Change to:

Number of sets to start after blackout Default: 1 Change to:

3.2.5 Standby sequence

Enable auto rearrange after new start order selection. Yes No

(If 'Yes' the start stop controller rearranges the running sets when a new

start order is entered. The controller only starts the first set in the order

which is not running. There is no forcing of correct start order.)

3.2.6 Total load dependent start/stop

Default Default New New

limit delay limit [%] delay

[s]

Total power start threshold. (power dependent automatic

start) 85% 5s

(This is the total bus-bar power limit which the load has to be

above before a standby start is activated. The load must be

above the limit the entire delay time, if not the delay will be

retriggered.)

Total current start threshold 100%

(As for power start)

Total power stop block limit (power dependent automatic

stop) 70% 120s

(This limit is the total bus-bar power limit which the load has

to be below before the power stop delay is activated. The

automatic stop is active if the total load on the remaining

generator sets are below this limit.)

Total current stop block limit 70%

(As for power stop)

Enforce set stop order Yes No

(In systems with different sized generators the stop order can be disregarded

and stop the smallest generator if the largest could not be stopped, selection

'Enforce set stop order' = No).

3.2.7 Individual load, frequency or voltage dependent start

Normal standby start (without alarm) on individual generator power, current, volt- Yes No

age or frequency.

If Yes, fill in one or more new start limits;

Default limit Default delay New limit (in % if different

sized generators)

Generator power start threshold [%] 99999 % (as for total

Generator start threshold [A] 99999 A power/ current

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 9 of 21

Power Management System - PMA 300 USER MANUAL

Generator voltage start threshold [V] -99999 V start thresh. )

Generator frequency start threshold -99999 Hz

[Hz]

3.2.8 PMA 300 Load sharing supervision & control

Limit for PMA 300 to automatically switch to droop Default limit Default New New

mode and execute load sharing. delay limit [%] delay

[s]

Active power/current loadsharing deviation 15% 3s

Allow load sharing in droop mode to be chosen Yes No

(normal loadsharing is isochron controlled from the engine speed controller &

loadsharing unit)

Allow Asymmetric Load sharing to be chosen Yes No

(normal loadsharing is isochron controlled from the engine speed controller &

loadsharing unit)

Enable auto droop in special conditions (e.g parallel with shaft generator) Yes No

If yes, specify:

If frequency-variation is high, PMS will switch from Isochron to droop

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 10 of 21

Power Management System - PMA 300 USER MANUAL

3.3 Generator cubicle interface

3.3.1 Generator data:

Generator type & desig- Voltage regula- Excitation meas- Generator protec-

nation tor type uring scale tion unit

G1 Hyundai (HHI/HFJ7 566-4) Current Siprotec 7UM62

G2 Hyundai (HHI/HFJ7 566-4) Current Siprotec 7UM62

G3 Hyundai (HHI/HFJ7 566-4) Current Siprotec 7UM62

3.3.2 Generator breaker

Allow to open generator breaker manually in SAM (Last set) and create blackout Yes No

Remarks:

3.3.3 Diesel engine main data

Engine Engine type/maker Load Sharing Load Sharing unit Engine is Nominal

no. (for information only) Unit type black-out start Power [kW]

capable (required if

shaft gen.)

G1 Yes No Yes No

G2 Yes No Yes No

G3 Yes No Yes No

3.3.4 Engine functions

Number of start attempts Default: 1 Change to:

If more than 1 start attempt;

Pause between start attempts Default: 5sec Change to:

sec.

Cool down run time Default: 180sec Change to:

sec.

3.3.5 Engine alarm / system alarm (pre-warning/delayed shutdown)

En- Delayed Input Remarks

gine from IAS

no.

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 11 of 21

Power Management System - PMA 300 USER MANUAL

G1 Yes No

G2 Yes No

G3 Yes No

Latched delayed shutdown. Yes No

(Not generator protection delayed shutdown conditions. When the option is not set

the motor controller is free to return to running and connected state if the delayed

shutdown condition disappears.)

Generator breaker trip when delayed shutdown. Yes No

(Trip the breaker instead of offload and disconnect. Generator protection alarm

(under voltage/frequency 2) will always trip the breaker without offloading, after

the 'delayed shutdown time window')

Delayed shutdown stop after new set start Yes No

(Stops the set if delayed shutdown is active, and if a new set is connected to the

bus. High power stop block will inhibit this function )

If No, specify;

Delayed shutdown time window Default: 180sec Change to:

(Time delay for running with delayed shutdown alarm sec.

before completing a changeover or shutdown.)

Remarks:

3.3.6 Engine prelubrication pumps

Control from the PMA300 system Yes No

(available as standard but not recommended to use)

If Yes, specify;

Prelubrication before engine start _________sec ( 0 if not required )

Prelubrication ON time__________sec

OFF time__________sec ( 0 if continuous prelubrica-

tion )

Pump running feedback signal available Yes No

(Continuous pre-lubrication will require the feedback signal to be connected)

3.3.7 Engine auxiliary system

Control from the PMA300 system Yes No

(available as standard but not recommended to use)

(Start/stop of one aux. system required to run together with the generator set.

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 12 of 21

Power Management System - PMA 300 USER MANUAL

Running feedback signal is required)

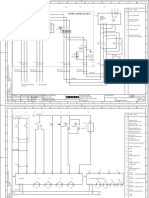

3.3.8 Interface to PMA 300 Generator I/O station

Listed is signals available on a standard Generator ET200S I/O station

Diesel Diesel Alarm Remarks

Signal Description To be used Signal SWBD Other

starter regulator system

Diesel Engine, Remote Yes No DI x (x)

Diesel Engine, Running Yes No DI x

Diesel Engine, Shutdown Yes No DI x (x)

Diesel Engine, Alarm Yes No DI (x) x

Diesel Engine, Prelubri- Yes No DI x

cation Running

Diesel Engine, Auxiliary Yes No DI x

Equipment Running

Diesel Engine, Ready to Yes No DI x

Start

Diesel Engine, Fixed Yes No DI x

speed

Generator, Remote con- Yes No DI x

trol

Generator, Breaker Yes No DI x

Closed

Generator, Breaker Open Yes No DI x

Generator, Deexitation Yes No DI x

Trip

Bus-bar, Control Fuse Yes No DI x

Fault

Bus-bar, Blackout Yes No DI x

Generator, Running with- Yes No DI x

out Differential Protection

Diesel Engine, Clutch Yes No DI x

engaged

Generator, Overcurrent Yes No DI x

trip

Generator, Short circuit Yes No DI x

trip

Generator excitation cur- Yes No AI x

rent

Diesel engine total load Yes No AI x

(kW)

Diesel Engine, Start Yes No Relay x

out

Diesel Engine, Stop Yes No Relay x

out

Generator Circuit Breaker Yes No Relay x

Close out

Generator Circuit Breaker Yes No Relay x

Open out

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 13 of 21

Power Management System - PMA 300 USER MANUAL

Diesel Diesel Alarm Remarks

Signal Description To be used Signal SWBD Other

starter regulator system

Generator, Asymmetric Yes No Relay x

Load On out

Generator, Off Yes No Relay x

load/Disconnect out

Diesel Engine, Diesel Yes No Relay x

Black Out Start out

Diesel Engine, Interlock Yes No Relay x

Start out

Generator, Yes No Relay (x) x

Synch./Loadshare out

Generator, Increase Load Yes No Relay x

out

Generator, Decrease Yes No Relay x

Load out

Diesel Engine, Start Pre- Yes No Relay x

lubrication out

Diesel Engine, Start Aux- Yes No Relay x

iliaries out

Diesel Engine, Droop Yes No Relay x

mode out

Remarks:

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 14 of 21

Power Management System - PMA 300 USER MANUAL

3.4 MAIN BUSBAR INTERFACE

3.4.1 Busbar data collection

Voltage & Frequency measuring data collection

Data collector Type, scale etc

Measuring converter via Profibus DP

Measuring converter via Analogue 4-20mA signals SIMEAS P50: 0-800V/4-20mA, 45-65Hz/4-20mA

BusTie breaker protection device via Profibus DP

Other

3.4.2 Power available signal to bridge system (diesel electric propulsion)

Analogue output 4-20mA Not required

Scale if Analogue output: 0-5000kW / 4-20mA

3.4.3 Bus-tie trip

Disable manual bus-tie operation (open command) if this will create blackout on Yes No

one bus-bar

Enable bus-tie trip on high frequency (engine overspeed situation) Yes No

(only if generators connected on both bus-bars)

If Yes, fill in;

Default Default New limit New de-

limit delay [Hz] lay [s]

Bus-tie breaker trip 55Hz 500ms

3.4.4 Non essential consumer trip (Load shedding)

Use NEC trip functionality on Busbar power limit (see table under) Yes No

Enable load shedding on low bus voltage/frequency (alarm limit 2, see section 8) Yes No

Trip limits and time delays

Bus-bar total Delay Con- Bus-bar total Delay Con- Bus-bar total Delay Con-

power limit sumers 1 power limit sumers 2 power limit sumers 3

consumers 1 consumers 2 consumers

[%] (Most Es- [%] [%] (Least Es-

sential) sential)

Default: 115% Default: 0s Default: 110% Default: 5s Default: 105% Default:10s

Port bus-bar

(LS11)

Stbd bus-

bar (LS21)

Trip circuits (Required for main switchboard design and PMS test purposes)

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 15 of 21

Power Management System - PMA 300 USER MANUAL

Switchboard Description Consumer 1 Consumer 2 Consumer 3 Consumer 1 Consumer 2 Consumer

circuits no. Port [x] Port [x] Port [x] Stbd [x] Stbd [x] 3 Stbd [x]

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 16 of 21

Power Management System - PMA 300 USER MANUAL

3.4.5 HEAVY CONSUMERS

Use the Heavy Consumer functionality Yes No

If Yes, specify;

Heavy Description Required Required Required Reserved Reserved Range of

con- (text to be shown on power for current for number of power number of kW feed-

sumer the touch screen start [kW] start [A] sets for when run- sets when back signal

no. panel) start ning [kW] running 4-20mA

No.1

port

bus-bar

(HC11)

No.2

port

bus-bar

(HC12)

No.3

port

bus-bar

(HC13))

No.4

port

bus-bar

(HC14)

No.1

stbd

bus-bar

(HC21)

No.2

stbd

bus-bar

(HC22)

No.3

stbd

bus-bar

(HC23)

No.4

stbd

bus-bar

(HC24)

NOTE!

Fill in only desired requirements for the heavy consumer functionality (not all!).

Any combination of required power for start, required current for start, required number of sets for

start, reserved power when running and reserved number of sets when running is available.

The PMA300 is prepared for handling a load signal (4-20mA) from selected heavy consumers. This al-

lows for dynamic load reservation when the consumer is running.

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 17 of 21

Power Management System - PMA 300 USER MANUAL

3.4.6 Interface to PMA 300 Busbar control I/O station

Listed is signals available on a standard Busbar control ET200S I/O station

Diesel Diesel re- Alarm sys- Remarks

Signal Description To be used Signal SWBD Other

starter gulator tem

01-BTR-AS Yes No DI x

Bus-tie breaker right -BT12,

Auto Selected

01-BTR-CBC Yes No DI x

Bus-tie breaker right - BT12,

Breaker Closed

01-BTR-CBO Yes No DI x

Bus-tie breaker right - BT12,

Breaker Open

I 110.3 Spare Yes No DI

BTL-AS Yes No DI x

Bus-tie breaker left- BT11,

Auto Selected

BTL-CBC Yes No DI x

Bus-tie breaker left – BT11,

Breaker Closed

BTL-CBO Yes No DI x

Bus-tie breaker left – BT11,

Breaker Open

I 111.3 Spare Yes No DI

01-02-BTR-CBC Yes No DI x

Bus-tie breaker right – BT21,

Breaker Closed

01-02-BTR-CBO Yes No DI x

Bus-tie breaker right – BT21,

Breaker Open

01-02-BTL-CBC Yes No DI x

Bus-tie breaker left – BT42,

Breaker Closed

01-02-BTL-CBO Yes No DI x

Bus-tie breaker left – BT42,

Breaker Open

01-BTR-CL Yes No Relay x

Bus-tie breaker – BT12, out

Close

01-BTR-TP Yes No Relay x

Bus-tie breaker – BT12, out

Open

01-BTL-CL Yes No Relay x

Bus-tie breaker – BT11, out

Close

01-BTL-TP Yes No Relay x

Bus-tie breaker – BT11, out

Open

01-BB-LV Yes No Relay x

Bus-bar Low Voltage out

01-BB-HV Yes No Relay x

Bus-bar High Voltage out

01-BB-LF Yes No Relay x

Bus-bar Low Frequency out

01-BB-HF Yes No Relay x

Bus-bar High Frequency out

01-PMA-GF Yes No Relay x

PMA, General Fault out

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 18 of 21

Power Management System - PMA 300 USER MANUAL

Diesel Diesel re- Alarm sys- Remarks

Signal Description To be used Signal SWBD Other

starter gulator tem

01-MP-GF Yes No Relay x

Control panel Fault out

01-BB-AVP Yes No AO x

Available Power

PQW 258 Yes No AO x

Spare

01-BB-BV Yes No AI x

Busbar voltage

01-BB-BF Yes No AI x

Busbar frequency

Remarks:

3.4.7 Interface to PMA 300 HC/NEC control I/O station

Listed is signals available on a standard HC/NEC ET200S I/O station

Diesel Diesel re- Alarm sys- Remarks

Signal Description To be used Signal SWBD Other

starter gulator tem

11-HC-RQ Yes No DI x

HC11, Request

12-HC-RQ Yes No DI x

HC12, Request

13-HC-RQ Yes No DI x

HC13, Request

14-HC-RQ Yes No DI x

HC14, Request

11-HC-RG Yes No DI x

HC11, Running

12-HC-RG Yes No DI x

HC12, Running

13-HC-RG Yes No DI x

HC13, Running

14-HC-RG Yes No DI x

HC14, Running

11-HC-ST Yes No Relay x

HC11, Start Enabled out

12-HC-ST Yes No Relay X

HC12, Start Enabled out

13-HC-ST Yes No Relay X

HC13, Start Enabled out

14-HC-ST Yes No Relay x

HC14, Start Enabled out

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 19 of 21

Power Management System - PMA 300 USER MANUAL

Diesel Diesel re- Alarm sys- Remarks

Signal Description To be used Signal SWBD Other

starter gulator tem

11-HC-ACTP Yes No AI x

HC11, Active power

12-HC-ACTP Yes No AI x

HC12, Active power

13-HC-ACTP Yes No AI x

HC13, Active power

14-HC-ACTP Yes No AI x

HC14, Active power

01-NEL-TP1 Yes No Relay x

Trip non ess. Load 1. out

01-NEL-TP2 Yes No Relay x

Trip non ess. Load 1. out

01-NEL-TP3 Yes No Relay x

Trip non ess. Load 1. out

01-NEL-TP4 Yes No Relay x

Trip non ess. Load 1. out

Remarks:

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 20 of 21

Power Management System - PMA 300 USER MANUAL

3.5 ALARM LIMITS

3.5.1 Class required alarms (alarm limit 2)

Default li- Default New New de-

mit delay limit: lay [s]

Voltage phase asymmetry 15V 10s V

Voltage alarm 1 +/- 20V V

(Advised limit: 2,5% of system voltage (690V: +/- 17V) 10s

Voltage alarm 2 +/- 25V V

(Generator set standby start and relay output to alarm system)

Advised limit: 3,5% of system voltage (690V: +/- 25V)

Frequency alarm 1 +/- 1.0Hz Hz

10s

Frequency alarm 2 +/- 2.0Hz Hz

(Generator set standby start and relay output to alarm system)

Advised maximum limits: 60Hz: +/- 3Hz, 50Hz: +/- 2,5Hz

3.5.2 Additional generator alarms

Default Default New limit New de-

limit delay [%] lay [s]

Current alarm 1 110%

(% of generator nominal current)

10s

Current alarm 2 115%

(% of generator nominal current)

Generator high power alarm (kW) 105% 5s

3.5.3 Loadsharing alarms

Default Default New limit New de-

limit delay [%] lay [s]

Active power/current loadsharing deviation 10% 3s

Reactive power loadsharing deviation 10% 5s

Doc.no:PO03020-12-M001A Part 3 Technical description Date:18.08.2009

Copyright © Siemens AS. All Rights reserved. Page 21 of 21

You might also like

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Power Management System PMA 300: Remote Human Machine Interface Protocol DescriptionDocument23 pagesPower Management System PMA 300: Remote Human Machine Interface Protocol Descriptionhamzeh0% (1)

- Profile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997From EverandProfile of the Worldwide Semiconductor Industry - Market Prospects to 1997: Market Prospects to 1997No ratings yet

- Instruction Simeas P in Simatic Mu 280202Document13 pagesInstruction Simeas P in Simatic Mu 280202Jorge CopajaNo ratings yet

- Utran: Radio Subsystem Remote Modem Access FD012222A - UMR3.5Document19 pagesUtran: Radio Subsystem Remote Modem Access FD012222A - UMR3.5Anonymous g8YR8b9No ratings yet

- MEGA-GUARD Bridge Manoeuvring System ParametersDocument25 pagesMEGA-GUARD Bridge Manoeuvring System ParametersaloordominicNo ratings yet

- FS-8700-64 ATMI ACM: Driver ManualDocument22 pagesFS-8700-64 ATMI ACM: Driver ManualEric DunnNo ratings yet

- Electric Interface Specification 47711360 - ENDocument78 pagesElectric Interface Specification 47711360 - ENKASSIMNo ratings yet

- B787 a G71!00!00 10B 520A a Engine (Bootstrap Method) – RemovalDocument61 pagesB787 a G71!00!00 10B 520A a Engine (Bootstrap Method) – Removaldonghuizhen2004No ratings yet

- C3T40 Eng PDFDocument624 pagesC3T40 Eng PDFIsaac Taxa VillegasNo ratings yet

- Hardware Reference Manual: Turbo PMAC2 Realtime Express ControllerDocument53 pagesHardware Reference Manual: Turbo PMAC2 Realtime Express Controllerel daniNo ratings yet

- Operartor Manual Pcc2100Document98 pagesOperartor Manual Pcc2100علي محمد المزيقر100% (3)

- AEB15.74 Oct13 PDFDocument97 pagesAEB15.74 Oct13 PDFPhạm NhấtNo ratings yet

- Utran: Radio Subsystem SMS Cell Broadcast FD012219A - UMR5.0Document24 pagesUtran: Radio Subsystem SMS Cell Broadcast FD012219A - UMR5.0Anonymous g8YR8b9No ratings yet

- FTGS Requirements On TrackworkDocument31 pagesFTGS Requirements On TrackworkSatish KumarNo ratings yet

- BRUSH Technical SectionDocument57 pagesBRUSH Technical Section3319826No ratings yet

- Aeb15.22 OEM ProgramingDocument83 pagesAeb15.22 OEM ProgramingJose SantosNo ratings yet

- Manual Parameter 828DDocument898 pagesManual Parameter 828DSam eagle goodNo ratings yet

- Operation: Connection Management Omn-CmDocument49 pagesOperation: Connection Management Omn-CmMokbelNo ratings yet

- Vol1Document538 pagesVol1mariamadreNo ratings yet

- UD01138d BCU ABFIFF01 V002Document27 pagesUD01138d BCU ABFIFF01 V002Catalin PelinNo ratings yet

- SIM7000 Series - Low Power Mode - Application Note - V1.01Document18 pagesSIM7000 Series - Low Power Mode - Application Note - V1.01felipe.mottaNo ratings yet

- C3I10T10 - Analog CommDocument220 pagesC3I10T10 - Analog CommVickocorp SlpNo ratings yet

- Line Loss CompensationDocument2 pagesLine Loss Compensationwagner_guimarães_1No ratings yet

- SDI213S02++NOJA-523-09 OSM User ManualDocument121 pagesSDI213S02++NOJA-523-09 OSM User ManualNazmul HasanNo ratings yet

- FA0996 - (2021.08.02) Mini Pack (1) (1)Document33 pagesFA0996 - (2021.08.02) Mini Pack (1) (1)OratexaNo ratings yet

- AMT-3800 HGA Installation Manual PDFDocument69 pagesAMT-3800 HGA Installation Manual PDFroshan mungur100% (1)

- User's Manual: Brake Chopper Unit (Bcu) ApplicationDocument28 pagesUser's Manual: Brake Chopper Unit (Bcu) ApplicationCatalin PelinNo ratings yet

- PO03020-12-P003B Part 5 Operating InstructionsDocument31 pagesPO03020-12-P003B Part 5 Operating InstructionshamzehNo ratings yet

- DS350G8658701Document76 pagesDS350G8658701ANTONIONo ratings yet

- Electrical Component LocationDocument5 pagesElectrical Component LocationNova kurniawan 34No ratings yet

- Utran: Radio Subsystem Versatile Multilayer Handling - Compressed Mode FD012224A - UMR3.5Document16 pagesUtran: Radio Subsystem Versatile Multilayer Handling - Compressed Mode FD012224A - UMR3.5Anonymous g8YR8b9No ratings yet

- Maintenance: Base Station Controller MMN:BSCDocument233 pagesMaintenance: Base Station Controller MMN:BSCRachidNo ratings yet

- SINAMICS G130-G150 Drive ManualDocument1,510 pagesSINAMICS G130-G150 Drive ManualSubhendu JanaNo ratings yet

- 3WT98836AC10 Datasheet enDocument2 pages3WT98836AC10 Datasheet enRaphaël Koffi KLIBANo ratings yet

- User Manual: GSM/GPRS/GPS TrackerDocument15 pagesUser Manual: GSM/GPRS/GPS TrackerOthman AbdillahiNo ratings yet

- Startdrive MotorData FAQ enDocument7 pagesStartdrive MotorData FAQ enpatulakeNo ratings yet

- Displaying Engine Data Using SAE J1939Document28 pagesDisplaying Engine Data Using SAE J1939Tiến Lâm NguyễnNo ratings yet

- Mk8-MM-Manual-19.05.2020 - ENG - 1-79Document79 pagesMk8-MM-Manual-19.05.2020 - ENG - 1-79Eduardo JoseNo ratings yet

- Mk8 MM Manual 19.05.2020Document395 pagesMk8 MM Manual 19.05.2020Navin RobertNo ratings yet

- PC 3.3 Commissioning Guidelines Ver 1.3Document34 pagesPC 3.3 Commissioning Guidelines Ver 1.3NikkikumarNo ratings yet

- BA 5859 EnglischDocument180 pagesBA 5859 EnglischAlanNo ratings yet

- VTI - A318/A319/A320/ A321 Tail Number - MSN - FSN VT-TTB - 06223 - 001Document6 pagesVTI - A318/A319/A320/ A321 Tail Number - MSN - FSN VT-TTB - 06223 - 001PiyushNo ratings yet

- Siemens Front ConnectorsDocument16 pagesSiemens Front Connectorsrobertz_tolentino014No ratings yet

- Pmac NC Pro2Document174 pagesPmac NC Pro2ramjoceNo ratings yet

- Sim300 An Deskphone Design v1.02Document22 pagesSim300 An Deskphone Design v1.02Vinay BabuNo ratings yet

- T63 1 M-Tco 1324 81991984832 EngDocument80 pagesT63 1 M-Tco 1324 81991984832 EngGonçalo PereiraNo ratings yet

- Ap9mk3 Ume 20169223eDocument206 pagesAp9mk3 Ume 20169223etecnicoeemNo ratings yet

- Siemens Profinet CMMT PN 1 20ENDocument26 pagesSiemens Profinet CMMT PN 1 20ENsabicytNo ratings yet

- Special Functions 840D 840di 810DDocument722 pagesSpecial Functions 840D 840di 810Dstanalina00100% (1)

- MSeries Manual enDocument40 pagesMSeries Manual enshamim shamimNo ratings yet

- Utran: Radio Subsystem Node B CC Redundancy FD012226A - UMR3.5Document20 pagesUtran: Radio Subsystem Node B CC Redundancy FD012226A - UMR3.5Anonymous g8YR8b9No ratings yet

- Simatic Et200s PDFDocument272 pagesSimatic Et200s PDFWalter JosephNo ratings yet

- Supplement To The Operating Instructions For Simoreg Dc-Master Series 6ra70 For Software Release 3.2Document12 pagesSupplement To The Operating Instructions For Simoreg Dc-Master Series 6ra70 For Software Release 3.2Ravindra AngalNo ratings yet

- Samsung HT C5500Document120 pagesSamsung HT C5500359briNo ratings yet

- 03.2114.010.71e TRT800A-OLED OI Rev4.00 210427 WEBDocument56 pages03.2114.010.71e TRT800A-OLED OI Rev4.00 210427 WEBAerotec SvlNo ratings yet

- E532304 - 00E - ADEC and SAM Connection InterfaseDocument202 pagesE532304 - 00E - ADEC and SAM Connection InterfaseAlex Robledo Olarte92% (12)

- An - SWT 3000 C37.94Document14 pagesAn - SWT 3000 C37.94René San Martín PérezNo ratings yet

- GSM BTS3900A Onsite Engineer Operation Guide-20080730-IsSUE1 (1) .0Document23 pagesGSM BTS3900A Onsite Engineer Operation Guide-20080730-IsSUE1 (1) .0larbi gharouchNo ratings yet

- M (A) - 28 Piping ErDocument62 pagesM (A) - 28 Piping ErhamzehNo ratings yet

- Interactive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768Document15 pagesInteractive Schematic: This Document Is Best Viewed at A Screen Resolution of 1024 X 768hamzehNo ratings yet

- M (A) - 21 Shafting PlanDocument17 pagesM (A) - 21 Shafting PlanhamzehNo ratings yet

- 18 - +ga06 1FP0602 Main Propulsion PortDocument3 pages18 - +ga06 1FP0602 Main Propulsion PorthamzehNo ratings yet

- Oil Recovery Vessel Main SwitchboardDocument3 pagesOil Recovery Vessel Main SwitchboardhamzehNo ratings yet

- Project: Båtservice Mandal AS - Iran Yard No.80 55,5 M Multi-Purpose Oil Recovery VesselDocument1 pageProject: Båtservice Mandal AS - Iran Yard No.80 55,5 M Multi-Purpose Oil Recovery VesselhamzehNo ratings yet

- 07 - +ga01 1DK01 Emerg. Stop System (Bow THR)Document2 pages07 - +ga01 1DK01 Emerg. Stop System (Bow THR)hamzehNo ratings yet

- Handleiding Flexball 3500 Tot 4500 SeriesDocument73 pagesHandleiding Flexball 3500 Tot 4500 SerieshamzehNo ratings yet

- 00-1 IndexDocument1 page00-1 IndexhamzehNo ratings yet

- 10 - +ga03 1DN01 Bustie - ControlDocument5 pages10 - +ga03 1DN01 Bustie - ControlhamzehNo ratings yet

- 05 - +ga01 1FP0101 Small Feeders STBDDocument2 pages05 - +ga01 1FP0101 Small Feeders STBDhamzehNo ratings yet

- 10 - +GB03 2de01 Bustie BreakerDocument4 pages10 - +GB03 2de01 Bustie BreakerhamzehNo ratings yet

- Fuel Coil Commander: Generator From Mains Optional As Per OrderDocument1 pageFuel Coil Commander: Generator From Mains Optional As Per OrderhamzehNo ratings yet

- 09 - +ga03 1de01 Bustie BreakerDocument7 pages09 - +ga03 1de01 Bustie BreakerhamzehNo ratings yet

- 17 - +ga06 1FP0601 Small Feeders PortDocument1 page17 - +ga06 1FP0601 Small Feeders PorthamzehNo ratings yet

- 18 - +ga06 1FP0602 Main Propulsion PortDocument3 pages18 - +ga06 1FP0602 Main Propulsion PorthamzehNo ratings yet

- 16 - +ga05 1da01 Diesel Generator 1Document15 pages16 - +ga05 1da01 Diesel Generator 1hamzehNo ratings yet

- 11 - +GB03 2DN01 Incomer From 690 - 400V Transf. 2Document4 pages11 - +GB03 2DN01 Incomer From 690 - 400V Transf. 2hamzehNo ratings yet

- +++03 PO03020-13-Hxxx ZDocument22 pages+++03 PO03020-13-Hxxx Zhamzeh100% (1)

- 02 PO03020-13-Rxxx ZDocument7 pages02 PO03020-13-Rxxx ZhamzehNo ratings yet

- 05 - +GB01 2ha01 Harbour GeneratorDocument13 pages05 - +GB01 2ha01 Harbour GeneratorhamzehNo ratings yet

- 11 - +GB03 2DN01 Incomer From 690 - 400V Transf. 2Document4 pages11 - +GB03 2DN01 Incomer From 690 - 400V Transf. 2hamzehNo ratings yet

- Shore - Connection Box: Date DrawnDocument5 pagesShore - Connection Box: Date DrawnhamzehNo ratings yet

- 21 PO03020-13-H001 Z FeederlistDocument2 pages21 PO03020-13-H001 Z FeederlisthamzehNo ratings yet

- 09 - +GB03 2FP03 Small Feeders PortDocument2 pages09 - +GB03 2FP03 Small Feeders PorthamzehNo ratings yet

- 06 - '+GB01 2DK01 Contactor Contr. Thd-Filt.Document1 page06 - '+GB01 2DK01 Contactor Contr. Thd-Filt.hamzehNo ratings yet

- Shore - Connection Box: Date DrawnDocument5 pagesShore - Connection Box: Date DrawnhamzehNo ratings yet

- 02 PO03020-14-Rxxx ZDocument2 pages02 PO03020-14-Rxxx ZhamzehNo ratings yet

- Main switchboard diagramDocument2 pagesMain switchboard diagramhamzehNo ratings yet

- 04 - +GB01 2DC01 Shore ConnectionDocument3 pages04 - +GB01 2DC01 Shore ConnectionhamzehNo ratings yet

- ANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODDocument9 pagesANALYSIS OF TRANSFORMER OIL TESTING USING GAS CHROMATOGRAPHY METHODmuhammad yaminNo ratings yet

- Mktech PDFDocument7 pagesMktech PDFAlexander WieseNo ratings yet

- Storm Water Drainage GuidelinesDocument16 pagesStorm Water Drainage GuidelinesSeeni GovindNo ratings yet

- Suvarnaprashan Sanskar EnglishDocument4 pagesSuvarnaprashan Sanskar EnglishLifecare Ayurveda Drnikul PatelNo ratings yet

- Kumiko Jigs Japanese Woodworking PDFDocument9 pagesKumiko Jigs Japanese Woodworking PDFJaime Montiel100% (1)

- Irrigation Project ManualDocument66 pagesIrrigation Project ManualHorace Prophetic DavisNo ratings yet

- Overview of Metal Forming ProcessesDocument19 pagesOverview of Metal Forming ProcessesAnonymous 7yN43wjlNo ratings yet

- Wood Turning NotesDocument36 pagesWood Turning Notestheodrosyo0% (1)

- Methyl methacrylate allergy case study in dentistry studentDocument3 pagesMethyl methacrylate allergy case study in dentistry studentDaniela CapitanuNo ratings yet

- 09a50205 PowerelectronicsDocument8 pages09a50205 PowerelectronicsPaone KalyanNo ratings yet

- Technical ReportDocument184 pagesTechnical Reportomen2ng88% (17)

- Water Cycle Cer 002Document2 pagesWater Cycle Cer 002api-434008934No ratings yet

- Banaba Tea Aids Weight LossDocument5 pagesBanaba Tea Aids Weight LossAveriAlonzoNo ratings yet

- Plant Associated Biofilms: Causes and ConsequencesDocument32 pagesPlant Associated Biofilms: Causes and ConsequencesGarima DhirNo ratings yet

- Introduction To Well Completion: (Part - IV)Document36 pagesIntroduction To Well Completion: (Part - IV)Mohamed MahmoudNo ratings yet

- Company & Project Information for Electrical, Instrumentation ServicesDocument28 pagesCompany & Project Information for Electrical, Instrumentation ServicesMrudul PatilNo ratings yet

- Mnemonics Anatomy 1st SemDocument4 pagesMnemonics Anatomy 1st SemNastassja Callmedoctor Douse67% (3)

- Upper Gastro Intestinal BleedingDocument13 pagesUpper Gastro Intestinal BleedingmuniningmicanNo ratings yet

- Dynamic Simulation of Insulin-Glucose Interaction in Type 1 Diabetes With MATLAB Simulink®Document11 pagesDynamic Simulation of Insulin-Glucose Interaction in Type 1 Diabetes With MATLAB Simulink®Jonas KristantoNo ratings yet

- Chennai Public School: CH 3 Coordinate Geometry Multiple AssessmentDocument3 pagesChennai Public School: CH 3 Coordinate Geometry Multiple Assessment11F10 RUCHITA MAARANNo ratings yet

- Saa6d170e-5 HPCR Egr Sen00190-04Document415 pagesSaa6d170e-5 HPCR Egr Sen00190-04Ahmad Mubarok100% (4)

- ABC Oilfield Services Emergency Drill RecordDocument1 pageABC Oilfield Services Emergency Drill RecordJaijeev PaliNo ratings yet

- GY HM 100 Service ManualDocument36 pagesGY HM 100 Service Manualvideoengr100% (1)

- Transfer Case MP 3023Document103 pagesTransfer Case MP 3023jackson vivasNo ratings yet

- Axial SpA Guideline 2019 ACRDocument15 pagesAxial SpA Guideline 2019 ACRTurboNo ratings yet

- DR Vatsal Patel AhmedabadDocument30 pagesDR Vatsal Patel AhmedabadSayali PhansekarNo ratings yet

- English 8-Quiz On Context CluesDocument2 pagesEnglish 8-Quiz On Context CluesMELINDA FERRERNo ratings yet

- Angles of Elevation and Depression, Bearings NotesDocument4 pagesAngles of Elevation and Depression, Bearings Notesroddyeal100% (2)

- F 25 Sensor Family Miniature Sensors for Precision DetectionDocument34 pagesF 25 Sensor Family Miniature Sensors for Precision DetectionAlex GarduñoNo ratings yet

- An Example of A HypothesisDocument2 pagesAn Example of A HypothesisAjibade TaofikNo ratings yet