Professional Documents

Culture Documents

Product Datasheet: P2110 - 915 MHZ RF Powerharvester™ Receiver

Uploaded by

hejikihOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Datasheet: P2110 - 915 MHZ RF Powerharvester™ Receiver

Uploaded by

hejikihCopyright:

Available Formats

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

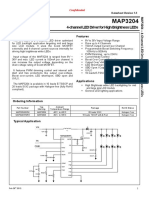

DESCRIPTION APPLICATIONS

The Powercast P2110 Powerharvester Battery-free wireless sensors

receiver is an RF energy harvesting device - Industrial Monitoring

that converts RF to DC. Housed in a compact - Smart Grid

SMD package, the P2110 receiver provides - Structural Health Monitoring

RF energy harvesting and power - Defense

management for battery-free, micro-power - Building automation

devices. The P2110 converts RF energy to - Agriculture

DC and stores it in a capacitor. When a - Oil & Gas

charge threshold on the capacitor is - Location-aware services

achieved, the P2110 boosts the voltage to Wireless trigger

the set output voltage level and enables the Low power electronics

voltage output. When the charge on the

capacitor declines to the low voltage FUNCTIONAL BLOCK DIAGRAM

threshold the voltage output is turned off. A

VCAP

NC

NC

NC

microprocessor can be used to optimize the

power usage from the P2110 and obtain

other data from the component for

improving overall system operation.

FEATURES

High conversion efficiency

Converts low-level RF signals enabling

GND

GND

GND

DOUT

DSET

long range applications

Regulated voltage output up to 5.25V

Up to 50mA output current PIN CONFIGURATION

Received signal strength indicator

No external RF components required - 1

NC 14

NC

Internally matched to 50 ohms

2 13

GND

Wide RF operating range DOUT

Operation down to -11.5 dBm input RFIN 3 12

VOUT

power GND

4 11

GND

Externally resettable for microprocessor

control

DSET 5

P2110 10

VSET

6 9

INT NC

Industrial temperature range XXXXXX

7 8 VCAP

RoHS compliant RESET

Powerharvester and Powercast are registered trademarks of Powercast Corporation. All other trademarks are the property of their respective owners.

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 1

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

ABSOLUTE MAXIMUM RATINGS

TA = 25°C, unless otherwise noted.

Parameter Rating Unit

RF Input Power 23 dBm Exceeding the

RFIN to GND 0 V absolute maximum

DSET to GND 6 V ratings may cause

RESET to GND 6 V

permanent

damage to the

VCAP to GND 2.3 V

device.

VOUT to GND 6 V

VOUT Current 100 mA

Operating Temperature Range -40 to 85 °C

Storage Temperature Range -40 to 140 °C

ESD CAUTION

This is an ESD (electrostatic discharge) sensitive device. Proper ESD

precautions should be taken to avoid degradation or damage to the

component.

PIN FUNCTIONAL DESCRIPTION

Pin Label Function

1 NC No Connection.

2 GND RF Ground. Connect to analog ground plane.

3 RFIN RF Input. Connect to 50Ω antenna through a 50Ω transmission line. Add a DC block

if antenna is a DC short.

4 GND RF Ground. Connect to analog ground plane.

5 DSET Digital Input. Set to enable measurement of harvested power. If this function is not

desired leave NC.

6 INT Digital Output. Indicates that voltage is present at VOUT.

7 RESET Digital Input. Set to disable VOUT. If this function is not desired leave NC.

8 VCAP Connect to an external capacitor for energy storage.

9 NC No Connection.

10 VSET Output Voltage Adjustment. Sets the output voltage by connecting a resistor to VOUT

or GND. Leave NC for 3.3V.

11 GND DC Ground. Connect to analog ground plane.

12 VOUT DC Output. Connect to external device. The output is preset to 3.3V but can be

adjusted with an external resistor.

13 DOUT Analog Output. Provides an analog voltage level corresponding to the harvested

power.

14 NC No Connection.

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 2

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

SPECIFICATIONS

TA = 25°C, VOUT = 3.3V unless otherwise noted.

Parameter Symbol Condition Min Typ Max Unit

1

RF Characteristics

Input Power RFIN -10 10 dBm

Frequency 902 928 MHz

DC Characteristics

Output Voltage VOUT 1.8 3.3 5.25 V

Output Current IOUT 50 mA

VCAP Maximum VMAX 1.25 V

VCAP Minimum VMIN 1.02 V

Signal Strength DOUT RFIN = 0dBm 275 mV

Boost Efficiency IOUT = 20mA 85 %

Maximum INT Current 0.1 mA

Digital Characteristics

RESET Input High 1 V

DSET Input High INT 1.8 V

Output High VMIN VMIN V

Timing Characteristics

DSET Delay 50 s

RESET Delay 6.6 s

RESET Pulse Width 20 ns

1

See typical performance graphs for operation at other frequencies or power levels.

TIMING DIAGRAM

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 3

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

FUNCTIONAL DESCRIPTION

RF INPUT (RFIN)

The RF input is an unbalanced input from When using the RESET function, the size of

the antenna. Any standard or custom 50 the capacitor is less important. A larger

antenna may be used with the receiver. capacitor can be used to facilitate

The P2110 has been optimized for intermittent functions that require more

operation in the 902-928MHz band but will energy. The RESET will control the amount

operate outside this band with reduced of energy removed from the capacitor

efficiency. Contact Powercast for custom during operation which will minimize the

frequency requirements. required recharge time. It should be noted

that when RESET is used, a larger capacitor

The RF input must be isolated from ground. will not affect charge time during operation,

For antennas that are a DC short, a high-Q but it will require more time to initially

DC blocking capacitor should be added in charge from a completely discharged state.

series with the antenna.

The voltage on the VCAP pin under normal

STORAGE CAPACITOR SELECTION (VCAP) operation will vary between approximately

The P2110 requires an external storage 1.25V and 1.02V. If the harvested energy

capacitor. The value of the capacitor will becomes too large, the voltage on the CAP

determine the amount of energy available pin will be internally clamped to protect low

from the VOUT pin. The capacitor should voltage supercapacitors. Clamping will

have a leakage current as small as possible. begin at approximately 1.8V and will limit

It is recommended that the leakage current the voltage to less than 2.3V at the

of the capacitor be less than 1μA at 1.2V. maximum rated input power.

The capacitor ESR should be 200m or less.

RSSI OPERATION (DOUT, DSET)

Smaller capacitors will charge more quickly The RSSI functionality allows the sampling

but will result in shorter operation cycles. of the received signal to provide an

Larger capacitors will charge more slowly, indication of the amount of energy being

but will provide for longer operation cycles. harvested. When DSET is driven high the

The required capacitor value can be harvested DC power will be directed to an

estimated using the following equation. internal sense resistor, and the

corresponding voltage will be provided to

C 15VOUT IOUTtON the DOUT pin. The voltage on the DOUT pin

can be read after a 50μs settling time.

Where,

When the RSSI functionality is being used,

VOUT - Output voltage of the P2110 the harvested DC power is not being stored.

IOUT - Average output current from the P2110

tON - On-time of the output voltage

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 4

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

The DOUT pin provides indirect access to the can be used in more sophisticated systems

storage capacitor. Under certain circum- that contain other storage elements and

stances, an unpowered microprocessor can be used as an external interrupt to

connected to this pin can provide a bring a device such as microcontroller out

significant load to the storage capacitor. To of a deep sleep mode. The digital high level

eliminate this leakage current, an external of the INT pin will be between VMIN and

NMOS should be connected between the VMAX. The INT pin can provide a maximum

DOUT pin and the microprocessor. The gate of 0.1mA of current.

of the NMOS should be tied to the DSET pin.

The drain should be tied to the DOUT pin and If the INT functionality is not used, the INT

the source to the microprocessor. The pin should be left as a no connect.

threshold voltage of the NMOS should be

one volt or less. SETTING THE OUTPUT VOLTAGE (VOUT)

The DC output voltage from the P2110 is

If the RSSI functionality is not used, the DOUT preset to 3.3V. However, it can be adjusted

and DSET pins should be left as no connects. by adding an external resistor to increase or

The DSET pin has an internal pull down. decrease the output voltage using the

following equations.

RESET

The RESET function allows the voltage from To decrease the output voltage, place a

VOUT to be turned off before the storage resistor calculated by the following

capacitor reaches the lower threshold, VMIN, equation from VSET to VOUT. The voltage can

thereby saving energy and improving the be set to a minimum of 1.8V.

recharge time back to the activation

threshold, VMAX. The RESET function can be 249k VOUT 1.195

implemented by a microcontroller. When R

3.32 VOUT

the function of the microcontroller is

completed, driving the RESET pin high will

disable the voltage from VOUT. Care should To increase the output voltage, place a

be taken to ensure that the microcontroller, resistor calculated by the following

especially during power-on, does not equation from VSET to GND. The voltage can

inadvertently drive this pin high. This will be set to a maximum of 5.25V.

immediately shutdown the output voltage.

297.47k

R

If the RESET functionality is not used, the VOUT 3.32

RESET pin should be left as a no connect.

The RESET pin has an internal pull down. LAYOUT CONSIDERATIONS

The RFIN feed line should be designed as a

INTERRUPT (INT) 50Ω trace and should be as short as

The INT pin provides a digital indication that possible to minimize feed line losses. The

voltage is present at the VOUT pin. This pin following table provides recommended

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 5

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

dimensions for 50Ω feed lines (CPWG) for

different circuit board configurations.

PCB Side View

Material Thickness Trace Width Spacing

(H) (S) (W)

FR4 62 50 9

(εr = 4.2)

FR4 31 50 20

(εr = 4.2)

*All dimensions are in mils.

The GND pins on each side of the RFIN pin

should be connected to the PCB ground

plane through a via located next to the pads

under the receiver.

When setting the output voltage, the

resistor connected to the VSET pin should be

as close as possible to the pin. No external

capacitance should be added to this pin.

The DOUT pin can contain low-level analog

voltage signals. If a long trace is connected

to this pin, additional filtering capacitance

next to the A/D converter may be required.

Additional capacitance on this pin will

increase the DSET delay time.

The trace from VCAP to the storage capacitor

should be as short as possible and have a

width of greater than 20mils to minimize

the series resistance of the trace.

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 6

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

TYPICAL PERFORMANCE GRAPHS TA = 25°C, VOUT = 3.3V, VCAP = 1.2V, unless otherwise noted.

Powerharvester Efficiency Powerharvester Efficiency

vs. RFIN (dBm) vs. RFIN (mW)

Powerharvester Efficiency Powerharvester Efficiency

vs. Frequency vs. Frequency

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 7

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

TYPICAL PERFORMANCE GRAPHS TA = 25°C, VOUT = 3.3V, VCAP = 1.2V, unless otherwise noted.

Received Signal Strength Indicator Received Signal Strength Indicator

vs. RFIN (dBm) vs. RFIN (mW)

Initial CAP Charge Time to First Initial CAP Charge Time to First

Activation vs. RFIN (dBm) Activation vs. RFIN (mW)

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 8

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

TYPICAL APPLICATION

A typical application for the P2110 is to provide power for low-power, battery-free wireless

sensors. Charge is stored in an external capacitor and when the activation threshold, VMAX, is

reached, VOUT is switched on to the configured voltage until the lower threshold, VMIN, is

reached or a RESET is applied, at which point VOUT is turned off.

The typical circuit shown was tested with a common microprocessor and 2.4GHz radio module.

The circuit included temperature, humidity, and light level sensors. The microprocessor, when

powered from the P2110, would read data from the three sensors. This data was transmitted

along with a node ID and the RSSI value back to a computer. The battery-free wireless sensor

used approximately 15mA of average current at 3.3V for 10ms. The performance data can be

seen in the following figures.

Power Receiving

Antenna

VOUT

Communication

RFIN

Antenna

RESET

DSET

P2110

DOUT

Microprocessor Radio module

INT

CAP GND

Sensors

Rev B –2015/08 © 2015 Powercast Corporation, All rights reserved. +1 412-455-5800

www.powercastco.com Page 9

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

PERFORMANCE DATA FROM TYPICAL APPLICATION TA = 25°C, VOUT = 3.3V

Packet Transmissions per Hour Packet Transmissions per Hour

vs. RFIN (dBm) vs. RFIN (mW)

Time between Packets using RESET Time between Packets using RESET

vs. RFIN (dBm) vs. RFIN (mW)

Rev A –2010/04 © 2010 Powercast Corporation, All rights reserved. +1 800-963-6538

www.powercastco.com P a g e 10

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

MECHANICAL SPECIFICATIONS

0.125 ± 0.010

0.156 ± 0.015

0.031 ± 0.005

0.550 ± 0.010 0.015 ± 0.010

0.025 ± 0.010

Pin 1 Mark

0.530 ± 0.010

P2110

0.065

xxxxxx

0.070

0.625

0.550

1 14

2 13

3 12

P2110

Recommended

4 11 0.390 0.440 0.530

Land Pattern

5 10

0.065

0.015

6 9

0.050 7 Component Outline 8

0.045

0.075

*Dimensions in inches

Rev A –2010/04 © 2010 Powercast Corporation, All rights reserved. +1 800-963-6538

www.powercastco.com P a g e 11

Product Datasheet

P2110 – 915 MHz RF Powerharvester™ Receiver

IMPORTANT NOTICE

Information furnished by Powercast Corporation (Powercast) is believed to be accurate and

reliable. However, no responsibility is assumed by Powercast for its use, nor for any

infringements of patents or other rights of third parties that may result from its use.

Specifications are subject to change without notice.

No license is granted by implication or otherwise under any patent or patent rights of

Powercast. Trademarks and registered trademarks are the property of their respective owners.

POWERCAST PRODUCTS (INCLUDING HARDWARE AND/OR SOFTWARE) ARE NOT DESIGNED OR

INTENDED TO BE FAIL-SAFE, FAULT TOLERANT OR FOR USE IN ANY APPLICATION THAT COULD

LEAD TO DEATH, PERSONAL INJURY OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE

(INDIVIDUALLY AND COLLECTIVELY, “CRITICAL APPLICATIONS”), SUCH AS LIFE-SUPPORT OR

SAFETY DEVICES OR SYSTEMS, CLASS III MEDICAL DEVICES, NUCLEAR FACILITIES, APPLICATIONS

THAT AFFECT CONTROL OF A VEHICLE OR AIRCRAFT, APPLICATIONS RELATED TO THE

DEPLOYMENT OF AIRBAGS, OR ANY OTHER CRITICAL APPLICATIONS. CUSTOMER AGREES, PRIOR

TO USING OR DISTRIBUTING ANY SYSTEMS THAT INCORPORATE POWERCAST PRODUCTS, TO

THOROUGHLY TEST THE SAME FOR SAFETY PURPOSES. CUSTOMER ASSUMES THE SOLE RISK AND

LIABILITY OF ANY USE OF POWERCAST PRODUCTS IN CRITICAL APPLICATIONS, SUBJECT

ONLY TO APPLICABLE LAWS AND REGULATIONS GOVERNING LIMITATIONS ON PRODUCT

LIABILITY.

Powercast warrants its products in accordance with Powercast’s standard warranty available at

www.powercastco.com.

Rev A –2010/04 © 2010 Powercast Corporation, All rights reserved. +1 800-963-6538

www.powercastco.com P a g e 12

You might also like

- Zig-Zag Transformer Application in 20 KV SystemDocument19 pagesZig-Zag Transformer Application in 20 KV SystemGansar Kharismawan100% (1)

- Electrical Control For Machines 7th Edition Lobsiger Test BankDocument2 pagesElectrical Control For Machines 7th Edition Lobsiger Test Banka814509361100% (1)

- Firelli Submarine ProposalDocument23 pagesFirelli Submarine ProposalAct PornlapusNo ratings yet

- BS EN IEC 62305 Lightning Protection StandardDocument31 pagesBS EN IEC 62305 Lightning Protection StandardWilson100% (1)

- MA181-004 Ethos Up-EASY Service ManualDocument156 pagesMA181-004 Ethos Up-EASY Service ManualMichael Michaelides100% (2)

- High Voltage Reference ManualDocument88 pagesHigh Voltage Reference ManualnrasoolNo ratings yet

- High Voltage On Ships, Safety, Equipment Testing: (Adapted from:D.T. Hall:Practical Marine Electrical Knowledge)Document18 pagesHigh Voltage On Ships, Safety, Equipment Testing: (Adapted from:D.T. Hall:Practical Marine Electrical Knowledge)World GamesNo ratings yet

- Study of Optimisation - Railway route-TNDocument137 pagesStudy of Optimisation - Railway route-TNEmir Jusić100% (1)

- Guide Transformer Spec IssuesDocument95 pagesGuide Transformer Spec IssuesE PenaNo ratings yet

- 7SJ62 Manual PDFDocument39 pages7SJ62 Manual PDFhotmit_86100% (3)

- P2110B Datasheet Rev 3 PDFDocument11 pagesP2110B Datasheet Rev 3 PDFvertNo ratings yet

- Sky65170-11: 860 - 900 MHZ, 0.5 W High Power Power AmplifierDocument10 pagesSky65170-11: 860 - 900 MHZ, 0.5 W High Power Power AmplifiercopslockNo ratings yet

- Sky65171-11: 1930 - 1990 MHZ, 0.5 W High Power Power AmplifierDocument10 pagesSky65171-11: 1930 - 1990 MHZ, 0.5 W High Power Power AmplifiercopslockNo ratings yet

- Monolithic Amplifier: Dc-6 GHZDocument23 pagesMonolithic Amplifier: Dc-6 GHZЕвгений ИвановNo ratings yet

- CATV/TV/Cable Modem Upconverter Mmic: FeaturesDocument8 pagesCATV/TV/Cable Modem Upconverter Mmic: FeaturesaledangieNo ratings yet

- Embedded ASIC Macrocell: Power Management RE028 Fixed 4.5V 30 Ma LDO Voltage RegulatorDocument9 pagesEmbedded ASIC Macrocell: Power Management RE028 Fixed 4.5V 30 Ma LDO Voltage RegulatorHILLNo ratings yet

- QPA9501 Data SheetDocument10 pagesQPA9501 Data SheetAlexis XavierNo ratings yet

- Step-Up DC-DC MAX8752Document13 pagesStep-Up DC-DC MAX8752Peter PicalNo ratings yet

- Linhkien QuangDocument20 pagesLinhkien QuangHiếuNo ratings yet

- 4 X 18W Bridge Car Radio Amplifier: Protections: DescriptionDocument10 pages4 X 18W Bridge Car Radio Amplifier: Protections: DescriptionvetchboyNo ratings yet

- Onsm S A0013302101 1Document16 pagesOnsm S A0013302101 1123No ratings yet

- DS8816ADocument21 pagesDS8816AAgustin AyalaNo ratings yet

- Rt8816a-06 Gtx1070 Gigabyte MemoriasDocument21 pagesRt8816a-06 Gtx1070 Gigabyte Memoriastechgamebr85No ratings yet

- Dual-Phase PWM Controller With PWM-VID Reference: General Description FeaturesDocument21 pagesDual-Phase PWM Controller With PWM-VID Reference: General Description FeaturesДмитрий НичипоровичNo ratings yet

- 4-Channel Led Driver For High Brightness Leds: General Description FeaturesDocument11 pages4-Channel Led Driver For High Brightness Leds: General Description FeaturesTeles SilvaNo ratings yet

- Ds8204a 05Document19 pagesDs8204a 05marcelo Chiu LeonNo ratings yet

- Rt913a RichtekDocument11 pagesRt913a RichtekRagavan RagavanNo ratings yet

- Single 12V Input Supply Dual Regulator - Synchronous-Buck-PWM and Linear-Regulator ControllerDocument15 pagesSingle 12V Input Supply Dual Regulator - Synchronous-Buck-PWM and Linear-Regulator ControllerBabei IlieNo ratings yet

- Monolithic Amplifier: Dc-2 GHZDocument23 pagesMonolithic Amplifier: Dc-2 GHZAnonymous G92Uz65FHNo ratings yet

- HF920Document26 pagesHF920anon_14062780No ratings yet

- 2A, 4.2V-16V Input, Fast Transient Synchronous Step-Down ConverterDocument18 pages2A, 4.2V-16V Input, Fast Transient Synchronous Step-Down ConverterCesarS100% (1)

- SC900Document23 pagesSC900Robert PNo ratings yet

- EM5305Document12 pagesEM5305marcelo Chiu LeonNo ratings yet

- RFPA5542 RevA AN PK090Document11 pagesRFPA5542 RevA AN PK090xxxtoxicxxxNo ratings yet

- MAX16840 LED Driver With Integrated MOSFET For MR16 and Other 12V AC Input LampsDocument12 pagesMAX16840 LED Driver With Integrated MOSFET For MR16 and Other 12V AC Input Lampszuffflor_925748656No ratings yet

- 1.0 Features 2.0 Description: Digital PWM Current-Mode Controller For Quasi-Resonant OperationDocument20 pages1.0 Features 2.0 Description: Digital PWM Current-Mode Controller For Quasi-Resonant OperationMisael GonzalezNo ratings yet

- P2110 DatasheetDocument12 pagesP2110 DatasheetR Bonifacio DaitanNo ratings yet

- RT8204-DS8204-06 Single Synchronous Buck With LDO ControllerDocument19 pagesRT8204-DS8204-06 Single Synchronous Buck With LDO ControllerMaks ProstNo ratings yet

- Recommended FOR NEW Design: Dual Synchronous Buck Pseudo Fixed Frequency DDR Power Supply ControllerDocument17 pagesRecommended FOR NEW Design: Dual Synchronous Buck Pseudo Fixed Frequency DDR Power Supply ControllerCarlos AntonioNo ratings yet

- LNK312P: Features General DescriptionDocument11 pagesLNK312P: Features General DescriptionRemy MendozaNo ratings yet

- 3A, 1Mhz, Synchronous Step-Down Converter: General Description FeaturesDocument12 pages3A, 1Mhz, Synchronous Step-Down Converter: General Description FeatureskiryanoffNo ratings yet

- Infineon ILD2111 DS v01 - 00 ENDocument66 pagesInfineon ILD2111 DS v01 - 00 ENИван КумбровNo ratings yet

- DUAL-BAND GSM900/DCS1800 Transmit Module: Package Style: Module 6.63mmx5.24mmx1.0mmDocument16 pagesDUAL-BAND GSM900/DCS1800 Transmit Module: Package Style: Module 6.63mmx5.24mmx1.0mmMohammad UsmanNo ratings yet

- Mp1022arev1 6Document4 pagesMp1022arev1 6juanNo ratings yet

- 2576 LDocument9 pages2576 LclanonNo ratings yet

- 300ma, Ultra-Low Noise, Ultra-Fast CMOS LDO Regulator: General Description FeaturesDocument12 pages300ma, Ultra-Low Noise, Ultra-Fast CMOS LDO Regulator: General Description FeaturesPierpaolo GustinNo ratings yet

- Nb679a MpsDocument19 pagesNb679a MpswarkeravipNo ratings yet

- Op XC410 Op033-V06Document1 pageOp XC410 Op033-V06yaserNo ratings yet

- MIP2K4 Panasonic PDFDocument2 pagesMIP2K4 Panasonic PDFRoberto Mendes0% (1)

- IDT ZMID520x Short Form Datasheet SDS 20170524Document2 pagesIDT ZMID520x Short Form Datasheet SDS 20170524dineshNo ratings yet

- MST9220B: General Description FeaturesDocument8 pagesMST9220B: General Description FeaturespepenitoNo ratings yet

- M7635C - 7608 - 7612 QigDocument2 pagesM7635C - 7608 - 7612 QigVictor BitarNo ratings yet

- L6203 Chip InfoDocument20 pagesL6203 Chip InfoShane PentzNo ratings yet

- Rfsa2013 Product Data SheetDocument17 pagesRfsa2013 Product Data SheetSelvakumar NatarajanNo ratings yet

- NCP51810 DDocument20 pagesNCP51810 DArun Rajkumar K PNo ratings yet

- Nu Horizons Electroncis Portal - EuropeDocument12 pagesNu Horizons Electroncis Portal - EuropeNu HorizonsNo ratings yet

- U2270B TEMICSemiconductorsDocument13 pagesU2270B TEMICSemiconductorsВячеслав ГлушакNo ratings yet

- Sc900a PDFDocument23 pagesSc900a PDFgoguNo ratings yet

- Features General Description: 3A Ultra Low Dropout Linear RegulatorDocument13 pagesFeatures General Description: 3A Ultra Low Dropout Linear RegulatorVi Tính Hoàng LânNo ratings yet

- Datasheet Ic CE DEDocument15 pagesDatasheet Ic CE DEBersama UkhuwahNo ratings yet

- 5-V Low-Drop Voltage Regulator TLE 4263: FeaturesDocument17 pages5-V Low-Drop Voltage Regulator TLE 4263: FeaturesWelleyNo ratings yet

- Display Panel Voltmeter DMS-40PC PDFDocument6 pagesDisplay Panel Voltmeter DMS-40PC PDFafonsomoutinhoNo ratings yet

- RS232 转USB 方案DIY资料,已做成功Document2 pagesRS232 转USB 方案DIY资料,已做成功李宏观No ratings yet

- Dying Gasp Storage and Release Control IC: Description FeaturesDocument13 pagesDying Gasp Storage and Release Control IC: Description FeaturesSALAH NETNo ratings yet

- TPS7101Q PDFDocument40 pagesTPS7101Q PDFlittledropNo ratings yet

- Port Pin Outs: Pin # Function I/ODocument6 pagesPort Pin Outs: Pin # Function I/OHector VillarrealNo ratings yet

- Snaa 348Document6 pagesSnaa 348RyanNo ratings yet

- MFL58486305 10Document254 pagesMFL58486305 10Luis AndrésNo ratings yet

- Qubino ZW+ Safety ReportDocument21 pagesQubino ZW+ Safety ReportpaulNo ratings yet

- MKC-520 Operation Manual Ver02Document149 pagesMKC-520 Operation Manual Ver02Matias LonzallesNo ratings yet

- IM Heat Pump VAHPB342SDocument84 pagesIM Heat Pump VAHPB342Shector arturo dominguez tecnico aires acondicionadoNo ratings yet

- Owner's Manual: APS Series DC-to-AC Inverter/ChargerDocument24 pagesOwner's Manual: APS Series DC-to-AC Inverter/ChargerEzequielNo ratings yet

- T&C Procedure Grease Interceptors Vida Ok 13sept2020Document115 pagesT&C Procedure Grease Interceptors Vida Ok 13sept2020Gopa KumarNo ratings yet

- DOC3435290690 4edDocument68 pagesDOC3435290690 4edDereck SeckmanNo ratings yet

- 2018 08 14-Pkg - 1 Volume 1 Part 2 Works Requirement-SmallDocument88 pages2018 08 14-Pkg - 1 Volume 1 Part 2 Works Requirement-SmallTun Nay Aung100% (1)

- Lab Gruppen Lab 1300c Manual de UsuarioDocument12 pagesLab Gruppen Lab 1300c Manual de UsuarioAndoniainaRakotoarimananaNo ratings yet

- 42LG710H UaDocument55 pages42LG710H UaBob ThorneNo ratings yet

- Negative 48 Volt Power What Why and HowDocument2 pagesNegative 48 Volt Power What Why and HowRK KNo ratings yet

- BA6209Document9 pagesBA6209sontuyet82No ratings yet

- Oil-Less Rotary Vane Vacuum Pumps & Compressors: Peration Aintenance AnualDocument8 pagesOil-Less Rotary Vane Vacuum Pumps & Compressors: Peration Aintenance AnualTiam StoneNo ratings yet

- Ba 9043Document3 pagesBa 9043Aziz Sultan0% (1)

- Fluke 1750 Calibration ManualDocument28 pagesFluke 1750 Calibration ManualborescopeNo ratings yet

- Moog ServoDrives DS2110 Manual enDocument312 pagesMoog ServoDrives DS2110 Manual enRajesh KumarNo ratings yet

- Kohler ManualDocument44 pagesKohler Manualjmh488100% (1)

- CenseDocument14 pagesCenseteja sri rama murthyNo ratings yet

- The Accord On Fire and Building SafetyDocument4 pagesThe Accord On Fire and Building SafetyMashrur RahmanNo ratings yet

- Question Bank Technical Helper (Distribution) : Sector: Power Reference ID: PSS/ Q 0101Document38 pagesQuestion Bank Technical Helper (Distribution) : Sector: Power Reference ID: PSS/ Q 01019853318441No ratings yet