Professional Documents

Culture Documents

PressureGaugesSettingValve DIESSE DS PM18

PressureGaugesSettingValve DIESSE DS PM18

Uploaded by

JavierOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PressureGaugesSettingValve DIESSE DS PM18

PressureGaugesSettingValve DIESSE DS PM18

Uploaded by

JavierCopyright:

Available Formats

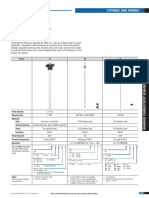

Technical data

Service conditions

Max Pressure: PN40

Max Temperature: 300°C

CYLINDRICAL PLUG Description

MANOMETER SETTING VALVE The DIESSE manometer setting valve type PM18 is a cylindrical plug cock with control flange.

It is suitable for the manometers installation.

PN40 It has a little flange provided with a screw that avoids losses when a control manometer is not

connected.

The seal is soft and is achieved by fitting a case between the vessel and the plug cock.

DS PM18

Handling

Quick 90° opening/closing

Code: DS PM18 - …/…/…/40 - CS/CS

Materials (Standard)

Execution: CS/CS

Body: ASTM A105

Trim: AISI 303

Stuffing box: Carbon steel galvanized

Handle: Carbon steel galvanized

Handle cover: PP

Bolt and washer: Carbon steel galvanized

Option: different materials available

Nominal passageway diameter

ND: 8 mm

Nominal passageway diameter for control manometer

ND: 5 mm

Gasket

Standard: graphite case with passageway rings in stainless steel 316

Option: PTFE case with passageway rings in stainless steel 316

Process connections

Type:

M x F - threaded male / female

Threaded connections type (Standard):

BSP (GAS) 3/8” - 1/2"

Options: connections NPT threaded, welding type or flanged type

Weight

Cock type DS DS PM18: Kg. 1,2 approx.

Spare parts

Case with 3 holes: see page 1.72

Operating instructions

When starting the installation or after the case (3) replacement, before opening the cock, wait until

the instrument reaches the room temperature.

After the opening, should any leakage occur, softly tighten the stuffing box (4) several times until

the leakage stop.

Instructions for the case removal and replacement

Assumptions:

o The replacement of the cock case requires such specific devices and tools that operations

by personnel not specifically trained to do so is not advisable

o The cock has been designed so that dismounting is possible solely by means of specific

tools in order to avoid the opening of its part by accident

In the case where the customer decides to proceed with his own personnel ant tools for

maintenance operations, it is IMPORTANT:

o To envision a skill operator with good technical and maintenance knowledge

o To contact the manufacturer for the best way to proceed and the suitable spare parts

o To be sure that operators wear appropriate individual personal protective means, and all

necessary precautions are be taken to avoid accidents

Before starting any operation wait until the instrument reach the room temperature.

Before disassembling be sure that the pipe is not under pressure.

1) Screw off the stuffing box (4) and the handle bolt (7)

2) Remove the handle (6)

3) To extract the cylindrical plug (2), by a soft extension (best a wooden one) gently beat on it

several times paying attention that it does not fall off.

Any scrape would compromise the cock sealing.

4) Clean the components with no-abrasive substances

Assembling:

1) Insert the cylindrical plug (2) into the case (3) until it blocks against the split ring (5)

2) Insert the case (3) in the cock body (1) utilising the guide

3) Fix the handle (6) and gently tighten the stuffing box (4)

Rev.1 Specifications and design can be subject to change without notice 3.5

You might also like

- Music Production 1Document62 pagesMusic Production 1Bruno Vázquez100% (2)

- Game of Coaching EbookDocument97 pagesGame of Coaching EbookasklorraineNo ratings yet

- Yokogawa As-Schneider 2601 Ed1Document24 pagesYokogawa As-Schneider 2601 Ed1kaka_patoNo ratings yet

- Wheels Defects in Indian RailwaysDocument25 pagesWheels Defects in Indian RailwaysTapas kumarNo ratings yet

- Jyotish - Ersnt Wilhem - Upadesa Sutras 1Document122 pagesJyotish - Ersnt Wilhem - Upadesa Sutras 1pm plassanalNo ratings yet

- WRC For NozzleDocument43 pagesWRC For NozzleSachin55860% (1)

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- Advanced Offshore EngineeringDocument8 pagesAdvanced Offshore EngineeringVikas KatiyarNo ratings yet

- Guiding Principles of Asset ManagementDocument16 pagesGuiding Principles of Asset ManagementRm1262100% (2)

- Brochure Rhosonics Clamp-InDocument2 pagesBrochure Rhosonics Clamp-InBambang AmingNo ratings yet

- Wika Type M93X.D1 Pressure Gauge Data SheetDocument5 pagesWika Type M93X.D1 Pressure Gauge Data SheetTrEnD SeT vicky rioNo ratings yet

- Type 1279 Duragauge Pressure Gauge Available With Performance OptionDocument2 pagesType 1279 Duragauge Pressure Gauge Available With Performance OptionrohmadNo ratings yet

- Diseño de MaquinaDocument18 pagesDiseño de MaquinaMiguel DominguezNo ratings yet

- Barbed Fitting CNDocument21 pagesBarbed Fitting CNnyuvaraj603No ratings yet

- Sitesgfilescozyhq596files2020 093300XL20Transducer20Accessories20Datasheet20 20145668.pDocument15 pagesSitesgfilescozyhq596files2020 093300XL20Transducer20Accessories20Datasheet20 20145668.pqdzungNo ratings yet

- d2-035 Diaphragm Pres - Gauge Per en 837-3 Chemical Design Dn100-160Document2 pagesd2-035 Diaphragm Pres - Gauge Per en 837-3 Chemical Design Dn100-160jepri purwantoNo ratings yet

- TCB All Fluids High Flow Couplings Staubli UsDocument12 pagesTCB All Fluids High Flow Couplings Staubli UsEdemirNo ratings yet

- Unifire Nozzle SpecificationsDocument16 pagesUnifire Nozzle Specificationskothat82No ratings yet

- DS DS9901 GB 2317Document4 pagesDS DS9901 GB 2317mohsenhfdNo ratings yet

- Rosemount Temperature Surface Sensors: Product Description ConsiderationsDocument10 pagesRosemount Temperature Surface Sensors: Product Description ConsiderationshamedNo ratings yet

- C13ST - Valve Manifold - Yokogawa - AS-Schneider - 2601 - Ed1Document24 pagesC13ST - Valve Manifold - Yokogawa - AS-Schneider - 2601 - Ed1Fernando RodríguezNo ratings yet

- Thermowell Type 20Document2 pagesThermowell Type 20Robert ArnoldNo ratings yet

- DY150Document16 pagesDY150Armando Castro FloresNo ratings yet

- Differential Pressure Recorder Data SheetDocument8 pagesDifferential Pressure Recorder Data SheetEdmund LimNo ratings yet

- Firelock V34, K8.0 Model V3428 Quick Response: See Victaulic Publication 10.01 For More DetailsDocument4 pagesFirelock V34, K8.0 Model V3428 Quick Response: See Victaulic Publication 10.01 For More DetailscesarNo ratings yet

- Cryogenic Stainless Steel Globe Valve DN6 DN50Document2 pagesCryogenic Stainless Steel Globe Valve DN6 DN50Anonymous rRGTKl6z4No ratings yet

- HydroMax Weld NippleDocument12 pagesHydroMax Weld NippleAyman AlhalfawyNo ratings yet

- D ESD Series Installation&Maintenance PDFDocument20 pagesD ESD Series Installation&Maintenance PDFPablo GarcíaNo ratings yet

- PMT Hps Installation Manual Pressure Transmitters pl3700x Series Mi5098e Rev3Document34 pagesPMT Hps Installation Manual Pressure Transmitters pl3700x Series Mi5098e Rev3Control Cia LtdaNo ratings yet

- 31000, 32000 Proximity Probe Housings: DescriptionDocument9 pages31000, 32000 Proximity Probe Housings: Descriptionmehdi227No ratings yet

- WIKA Temp GaugeDocument18 pagesWIKA Temp GaugelpczyfansNo ratings yet

- NTTDocument8 pagesNTTIon FloareaNo ratings yet

- Process Specification: Docmaster: Uncontrolled Copy When PrintedDocument30 pagesProcess Specification: Docmaster: Uncontrolled Copy When PrintedCemre BağbozanNo ratings yet

- Norgren Push-In FittingsDocument9 pagesNorgren Push-In Fittingsalex.lenagroNo ratings yet

- FLENDER Standard Couplings: Flexible Couplings - N-EUPEX and N-EUPEX DS SeriesDocument7 pagesFLENDER Standard Couplings: Flexible Couplings - N-EUPEX and N-EUPEX DS SeriesDavid ChirinosNo ratings yet

- Talbot Straps and FerrulesDocument8 pagesTalbot Straps and Ferrulesphiliptoh1No ratings yet

- 1109 Process Pressure Gauge: Data SheetDocument2 pages1109 Process Pressure Gauge: Data SheetchienncNo ratings yet

- Gas-Actuated Thermometer Stainless Steel Version Model 73: ApplicationsDocument18 pagesGas-Actuated Thermometer Stainless Steel Version Model 73: ApplicationsAhmed MoharramNo ratings yet

- Cataloge-P253Document6 pagesCataloge-P253Nhi VanNo ratings yet

- Type 330 All-Welded Flush Mini Diaphragm Seal: Product FeaturesDocument2 pagesType 330 All-Welded Flush Mini Diaphragm Seal: Product FeatureshdrNo ratings yet

- Hexagonal Bar Stock Needle Valve: HBNV SeriesDocument6 pagesHexagonal Bar Stock Needle Valve: HBNV SeriesMohamed RaafatNo ratings yet

- Product Data Sheet Triplexpro-210 Advanced Plasma Spray Gun: What'S New?Document8 pagesProduct Data Sheet Triplexpro-210 Advanced Plasma Spray Gun: What'S New?kartalizmatik54No ratings yet

- Model: P252 Series: Euro Gauge Industrial Service Pressure GaugeDocument4 pagesModel: P252 Series: Euro Gauge Industrial Service Pressure GaugeJavedNo ratings yet

- Wise - P252Document6 pagesWise - P252Vũ PhươngNo ratings yet

- Catalogo Machuelos Threading Tools To Jis StandardDocument68 pagesCatalogo Machuelos Threading Tools To Jis StandardnabilahanakhairunnidaNo ratings yet

- 74 Plastic Pressure Gauge FinalDocument1 page74 Plastic Pressure Gauge FinalROBERTONo ratings yet

- Needle Valves Series Bs03Document6 pagesNeedle Valves Series Bs03Uzair AnsariNo ratings yet

- PublicationDocument28 pagesPublicationSamrat GuptaNo ratings yet

- Jigs and Tools Specification: Model of Special Production ToolsDocument7 pagesJigs and Tools Specification: Model of Special Production ToolsRafaelNo ratings yet

- Unbrako CatalogDocument16 pagesUnbrako CatalogAvinash BorigiNo ratings yet

- Hydraulic Cylinder Types Cdt3... F / Cgt3... F: Series 1X Nominal Pressure: 160 Bar (16 Mpa)Document44 pagesHydraulic Cylinder Types Cdt3... F / Cgt3... F: Series 1X Nominal Pressure: 160 Bar (16 Mpa)Siew Hiong JongNo ratings yet

- Product Category 00-TMT Thermocouple Assemblies With Metal Protective TubeDocument4 pagesProduct Category 00-TMT Thermocouple Assemblies With Metal Protective TubeNami Atta AssadiNo ratings yet

- Global Valves BrochureDocument12 pagesGlobal Valves BrochureBOUZAIDANo ratings yet

- NOLH NT ENG 50Hz PDFDocument50 pagesNOLH NT ENG 50Hz PDFarielbankiNo ratings yet

- Bimetal Thermometer Process Version Per ASME B40.200 Model TG53Document10 pagesBimetal Thermometer Process Version Per ASME B40.200 Model TG53SAM AZNo ratings yet

- Features: Series Type ThreadDocument5 pagesFeatures: Series Type ThreadWira Nur IndrawanNo ratings yet

- Bossard Key Locking Inserts - ENDocument12 pagesBossard Key Locking Inserts - ENthulasimani subramanianNo ratings yet

- Square Bar Stock Needle Valve: BNV SeriesDocument3 pagesSquare Bar Stock Needle Valve: BNV SeriesMohamed RaafatNo ratings yet

- Convoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R1Document2 pagesConvoluted - Bore PTFE Hose, Series C-CON (MS-02-351) R1herysyam1980No ratings yet

- Saint Gobain Valves & Hydrants - FH - DatascheetDocument4 pagesSaint Gobain Valves & Hydrants - FH - DatascheetMohammed sabatinNo ratings yet

- 01Document9 pages01Agnaldo JulioNo ratings yet

- Technical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDDocument5 pagesTechnical Data Sheet Ecotrol Rotary Control Valve TD 8CD 6HDagus trionoNo ratings yet

- PT100Document1 pagePT100aneleyNo ratings yet

- Topworx DXP - Installation and ConfigurationDocument52 pagesTopworx DXP - Installation and ConfigurationJames Dawe100% (1)

- Input ValuesDocument5 pagesInput ValuesmasoodNo ratings yet

- 19-E3862AA0 Wiring DiagramDocument19 pages19-E3862AA0 Wiring DiagramJavierNo ratings yet

- Designed For OEM: Fittings and ProbesDocument3 pagesDesigned For OEM: Fittings and ProbesJavierNo ratings yet

- Baltur Wiring DiagramDocument2 pagesBaltur Wiring DiagramJavierNo ratings yet

- Baltur TPL160 - enDocument41 pagesBaltur TPL160 - enJavierNo ratings yet

- DiffPressure Switches BCP5 - En-EsDocument21 pagesDiffPressure Switches BCP5 - En-EsJavierNo ratings yet

- Flowvalves KSB Va Pn16Document11 pagesFlowvalves KSB Va Pn16JavierNo ratings yet

- Check Valve Flowserve RK76 - En-EsDocument24 pagesCheck Valve Flowserve RK76 - En-EsJavierNo ratings yet

- Experiment 6Document11 pagesExperiment 6Issa Marie BuenaNo ratings yet

- Sylllabus of 4th Semester - 25062022Document26 pagesSylllabus of 4th Semester - 25062022Suman GhoshNo ratings yet

- The Ancient Andean World 3.982 Fall 2018 Syllabus: Lechtman@mit - EduDocument5 pagesThe Ancient Andean World 3.982 Fall 2018 Syllabus: Lechtman@mit - EduShubhangaNo ratings yet

- Virtual Forum Theater DissertationDocument397 pagesVirtual Forum Theater DissertationAisha Bilqis SoteriaNo ratings yet

- Ucalgary 2013 Narvaez Jose PDFDocument867 pagesUcalgary 2013 Narvaez Jose PDFMeche AlvariñoNo ratings yet

- Convenient Method of Esterification of Fatty Acids: An Undergraduate Organic Laboratory ExperimentDocument1 pageConvenient Method of Esterification of Fatty Acids: An Undergraduate Organic Laboratory ExperimentAndrew LondonNo ratings yet

- Chapter 2. Portland CementDocument14 pagesChapter 2. Portland CementKhaled Al-SwairkiNo ratings yet

- Conduits PDFDocument12 pagesConduits PDFAnonymous PYEzEEVzNo ratings yet

- Experiment 4 RLC SERIES TRANSIENT CIRCUITDocument3 pagesExperiment 4 RLC SERIES TRANSIENT CIRCUITkah02No ratings yet

- Advances in Topographic Mapping ProgrammeDocument2 pagesAdvances in Topographic Mapping ProgrammeMiloš BasarićNo ratings yet

- Jurongville Secondary Mid Year 2019 Sec 2 NT ScienceDocument15 pagesJurongville Secondary Mid Year 2019 Sec 2 NT ScienceGilbert ChiaNo ratings yet

- Buku Panduan Bengkel 2 - Sesi 20182019Document55 pagesBuku Panduan Bengkel 2 - Sesi 20182019Cheng Ching HaoNo ratings yet

- Bristol Port PESTEL and SWOT AnalysisDocument4 pagesBristol Port PESTEL and SWOT AnalysisLynne Farrugia100% (1)

- 23 6418 Oil Free Centrifugal Water Chillers 111001Document11 pages23 6418 Oil Free Centrifugal Water Chillers 111001Mohd RizalNo ratings yet

- PhilosophyDocument14 pagesPhilosophyXYuri Vidallon PererasNo ratings yet

- Titan Drive P SeriesDocument137 pagesTitan Drive P SeriesMiguel LoorNo ratings yet

- Murdoch University Auslandssemester Study Abroad BrochureDocument30 pagesMurdoch University Auslandssemester Study Abroad BrochureEdson PrataNo ratings yet

- Homeostasis Concept MapDocument1 pageHomeostasis Concept MapMarjorie RonquilloNo ratings yet

- I. Objectives: Fort Pilar ST., Zamboanga CityDocument10 pagesI. Objectives: Fort Pilar ST., Zamboanga CityDanizelle Kaye Cadocoy BernardoNo ratings yet

- Trenton Mayor Writes To Starbucks CEO About Store ClosingDocument2 pagesTrenton Mayor Writes To Starbucks CEO About Store ClosingThe TrentonianNo ratings yet

- Eight Little LeprechaunsDocument3 pagesEight Little LeprechaunsVic RabayaNo ratings yet

- Edlm 580Document1 pageEdlm 580api-260828132No ratings yet

- Prehistoric Life The Definitive Visual History of Life On EarthDocument4 pagesPrehistoric Life The Definitive Visual History of Life On EarthSayantan De0% (1)

- Jelinek1984 Article EmptyCategoriesCaseAndConfigurDocument38 pagesJelinek1984 Article EmptyCategoriesCaseAndConfigureryheNo ratings yet