Professional Documents

Culture Documents

Process Flowsheeting

Uploaded by

Ese FrankOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Flowsheeting

Uploaded by

Ese FrankCopyright:

Available Formats

PROCESS FLOWSHEETING

Starting with academic research in the 1960s and 1970s, two main competing approaches to process flowsheeting

tools emerged, namely sequential modular (SM) and equation oriented (EO). We review these briefly below.

The Sequential Modular (SM) Approach

In the SM approach, each unit operation model is represented by a “module”, i.e. computer code that, given the

input streams to the unit and relevant equipment specifications, solves the underlying model equations to

determine the output streams and other Key Performance Indicators (KPIs) relating to the unit’s design and

operation. Usually manually coded, these modules often incorporate algorithms tailored to the specific equations

being solved, thereby achieving a very high degree of robustness and efficiency within each individual module.

They can also expose highly customised user interfaces (e.g. dialogs for the specification of the information

relevant to this module, or reports for the display of the corresponding results).

Most SM tools provide extensive libraries of unit operation models. They also support mechanisms allowing these

libraries to be extended by the addition of new user-defined unit operations. In most cases, this involves the user

providing a corresponding module which incorporates both the model equations and an appropriate solution

method. The module is typically coded in procedural computer languages such as FORTRAN, C/C++, or Visual

Basic. For the module to be usable within a specific SM flowsheeting tool, it would also need to expose a software

interface conforming to that tool’s proprietary Applications Programming Interface. A more recent development

is the emergence of the CAPE-OPEN standard which defines a standardised interface between Process Modelling

Environments (i.e. flowsheeting tools in this case) and Process Modelling Components (such as unit operation

modules). Modules exposing a CAPE-OPEN Unit Operation interface can be used directly within any

flowsheeting tool that supports the CAPE-OPEN standard; this includes all major commercially-available tools.

In the SM approach, the flowsheeting tool attempts to solve the overall flowsheet model by calling the individual

unit operation modules in sequence. This is straightforward for processes without recycles where the process

input streams and the equipment parameters are fully specified: in this case, the process model can be solved by

tracing a path from raw materials to process products, and calling each unit operation module along this path

exactly once.

The simple “once-through calculation” described above is not possible in processes with recycles of material

and/or energy. In such cases, the recycle streams need to be guessed (“torn”) and the flowsheeting tool calls the

unit operations along the recycle to obtain new values of these recycles. This is repeated in an iterative manner

until the values of these streams converge. Mathematically, this corresponds to a successive substitution approach

that may take many iterations to converge even when starting from a reasonable set of recycle guesses. This

problem typically becomes more acute in processes with multiple interacting recycles; and in some cases the

iterations may fail because the mathematical conditions for convergence of successive substitution are not

satisfied irrespective of the quality of the initial guesses.

Another challenge for SM technology is the handling of non-standard specifications where it is desired to specify

some aspect relating to the product streams or the overall process KPIs (e.g. overall raw material conversion),

and to compute some aspects of equipment design or operation (e.g. reactor volume). This is problematic as the

required information flow is opposite to the fixed input-output structure of the individual modules. The common

way of dealing with these specifications is via the introduction of artificial “controllers” that attempt to

automatically adjust the values of the computed variables so as to match the user specifications. However, this

introduces additional recycles of information that need to be handled in a manner similar to that described above

for material and energy recycles.

As mentioned above, the use of rigorous mathematical optimisation techniques in conjunction with process

flowsheeting can lead to significant benefits over multiple trial-and-error simulations in terms of both the quality

of the solutions obtained and the effort and time required to obtain them. However, the robustness and efficiency

of numerical optimisation algorithms depend crucially on the availability of the gradients of the objective function

and constraints with respect to the decision variables. In the context of the SM approach, obtaining these gradients

would require all unit operation modules to return the partial derivatives of their outputs with respect to their

inputs, something which would imply a substantial increase in coding complexity. As a result, the use of SM

technology for plant optimisation calculations has been somewhat limited in practice.

The Equation Oriented (EO) Approach

The EO approach is conceptually much simpler than the SM one. Given a mathematical model of each unit

operation in the flowsheet in terms of a set of equations and variables, the overall plant model can be formulated

simply by assembling the contributions of all unit operations, together with unit-unit connectivity relations, into

one large system of equations1. Once the user specifies a valid set of degrees of freedom to leave a non-singular

square system of nonlinear algebraic equations, the latter is solved simultaneously via an appropriate numerical

method, such as those based on Newton’s method and its variants, coupled with sparse linear algebra techniques.

With modern algorithms and computer hardware, solution of systems of many hundreds of thousands of equations

is practically feasible using ordinary desktop computers.

In principle, EO technology can address many of the limitations of the SM approach described in the previous

sections. For example, handling multiple interacting recycles is more efficient as all relevant interactions are taken

into account within the single system of equations. No special mechanisms are necessary for handling of non-

standard specifications provided they also lead to square non-singular systems.

Moreover, extending the model library with a new unit operation model involves only defining the

corresponding model equations; the solution of these equations is handled at the level of the flowsheeting tool.

This opens the way for the use of “declarative” custom model definition languages which allow new models to

be defined in high-level symbolic form rather than in terms of computer code, something which greatly increases

the ease and reduces the cost of both model development and model maintenance. The availability of the model

equations in symbolic form also facilitates complex operations such as symbolic differentiation for obtaining

partial derivative information, which significantly enhances the performance of the solution algorithms, both for

simulation and optimisation.

The main limitation of EO technology has been the robustness of solution process. This is particularly important

at the initial stages of modelling, when the values of the model variables are largely unknown and any initial

guesses may be far away from the solution. Being only locally convergent, Newton-type methods are particularly

prone to failure at this “model initialisation” stage. Attempts to address this problem either by extending the

Newton convergence range using stabilisation techniques or by using alternative solution approaches such as

those based on homotopy-continuation methods, have been only moderately successful. Moreover, given the size

of the system of equations being solved, it is often difficult to locate the causes of a simulation failure, even when

these are associated with errors in user specifications or user-provided models.

You might also like

- Symbolic Incorporation of External Procedures Into Process Modeling EnvironmentsDocument37 pagesSymbolic Incorporation of External Procedures Into Process Modeling EnvironmentsAMITH OKNo ratings yet

- Chapter OneDocument12 pagesChapter OneKelvin CeejayNo ratings yet

- Mi 150105Document8 pagesMi 150105古鹏飞No ratings yet

- Workpackage 4: Optimization: Distributed Modelling ApproachDocument4 pagesWorkpackage 4: Optimization: Distributed Modelling ApproachMelissa MillerNo ratings yet

- A Systematic Approach To Composing and Optimizing Application WorkflowsDocument9 pagesA Systematic Approach To Composing and Optimizing Application WorkflowsLeo Kwee WahNo ratings yet

- Analog Circuit Optimization System Based On Hybrid Evolutionary AlgorithmsDocument12 pagesAnalog Circuit Optimization System Based On Hybrid Evolutionary AlgorithmsashishmanyanNo ratings yet

- Ecos02 Part ADocument8 pagesEcos02 Part Abecool12345No ratings yet

- Article MechanismMachineTheory Budinger PDFDocument17 pagesArticle MechanismMachineTheory Budinger PDFfei312chenNo ratings yet

- PHD Proposal - Heriot - UpscalingDocument2 pagesPHD Proposal - Heriot - UpscalingAkinNo ratings yet

- Next Generation Multi-Scale Process SystemsDocument6 pagesNext Generation Multi-Scale Process SystemsArunNo ratings yet

- Parametric Reconfiguration Improvement in Non-Iterative Concurrent Mechatronic Design Using An Evolutionary-Based ApproachDocument15 pagesParametric Reconfiguration Improvement in Non-Iterative Concurrent Mechatronic Design Using An Evolutionary-Based ApproachIng. Omar SerranoNo ratings yet

- 2007 Wendelstorf Process ModelingDocument7 pages2007 Wendelstorf Process ModelingramizNo ratings yet

- Oredo2Swlpl) Dwlrqri&Khplfdo (Qjlqhhulqj 3Odqwve/Phdqvri (Yroxwlrqdu/$OjrulwkpvDocument13 pagesOredo2Swlpl) Dwlrqri&Khplfdo (Qjlqhhulqj 3Odqwve/Phdqvri (Yroxwlrqdu/$OjrulwkpvMadhavanIceNo ratings yet

- Simulating Performance of Parallel Database SystemsDocument6 pagesSimulating Performance of Parallel Database SystemsKhacNam NguyễnNo ratings yet

- Mathematical Modeling in Chemical EngineeringDocument25 pagesMathematical Modeling in Chemical Engineerings9n9No ratings yet

- A Framework For The Engineering of Reliable Distributed SystemsDocument8 pagesA Framework For The Engineering of Reliable Distributed Systemssurendiran123No ratings yet

- Recursive and Residual Algorithms For The Efficient Numerical Integration of Multi-Body SystemsDocument31 pagesRecursive and Residual Algorithms For The Efficient Numerical Integration of Multi-Body SystemsCleves AxiomaNo ratings yet

- 1Document11 pages1aiadaiadNo ratings yet

- Iowtc2022 98217Document10 pagesIowtc2022 98217Quién SabeNo ratings yet

- METSIM Brochure2 2009 PDFDocument40 pagesMETSIM Brochure2 2009 PDFjaja_5430% (1)

- Hierarchical Design Models in The Mechatronic ProductDocument12 pagesHierarchical Design Models in The Mechatronic ProductLau Yeowhong100% (1)

- Optimization in Design of Electric MachinesDocument10 pagesOptimization in Design of Electric MachinesRituvic PandeyNo ratings yet

- Stanley AssignmentDocument6 pagesStanley AssignmentTimsonNo ratings yet

- Mechatronic System Design Based On An Optimisation Approach: MECHATRONICS DAY 2007 - International WorkshopDocument9 pagesMechatronic System Design Based On An Optimisation Approach: MECHATRONICS DAY 2007 - International WorkshopMradul YadavNo ratings yet

- Implementing A Class of Structural Change Tests: An Econometric Computing ApproachDocument22 pagesImplementing A Class of Structural Change Tests: An Econometric Computing ApproachemiNo ratings yet

- A Gradient-Based Approach For Power System Design Using Electromagnetic Transient SimulationDocument5 pagesA Gradient-Based Approach For Power System Design Using Electromagnetic Transient SimulationBarron JhaNo ratings yet

- Marlin Ch03 Process ControlsDocument47 pagesMarlin Ch03 Process ControlsRagavaaRagavaa100% (1)

- A Method For Cycle Time Estimation of Semiconductor Manufacturing Toolsets With CorrelationsDocument11 pagesA Method For Cycle Time Estimation of Semiconductor Manufacturing Toolsets With CorrelationsDeepak JainNo ratings yet

- Multidisciplinary Aerospace Design Survey of Recent DevelopmentsDocument10 pagesMultidisciplinary Aerospace Design Survey of Recent DevelopmentsSaravanan RNo ratings yet

- Computers and Chemical Engineering: J. Steimel, S. EngellDocument18 pagesComputers and Chemical Engineering: J. Steimel, S. EngellAbubakr KhanNo ratings yet

- Model Based Systems Engineering For Aircraft Systems - How DoesDocument9 pagesModel Based Systems Engineering For Aircraft Systems - How DoesAlmas QasimNo ratings yet

- PB Modelling of Physical Systems FinalDocument56 pagesPB Modelling of Physical Systems FinalKhristilera RodriguezNo ratings yet

- Formal Verification of Distributed Dynamic Thermal ManagementDocument8 pagesFormal Verification of Distributed Dynamic Thermal ManagementFaiq Khalid LodhiNo ratings yet

- MERISEDocument4 pagesMERISEZAKARIA SALHINo ratings yet

- 0Rgho%Dvhg'Ldjqrvwlfviru$Lu+Dqgolqj8Qlwv: Tim Salsbury and Rick DiamondDocument12 pages0Rgho%Dvhg'Ldjqrvwlfviru$Lu+Dqgolqj8Qlwv: Tim Salsbury and Rick DiamondyalllikNo ratings yet

- Multi-Objective Design of Advanced Power Distribution Networks Using Restrictedpopulation-Based Multi-Objective Seekeroptimisation-Algorithm and Fuzzy-OperatorDocument21 pagesMulti-Objective Design of Advanced Power Distribution Networks Using Restrictedpopulation-Based Multi-Objective Seekeroptimisation-Algorithm and Fuzzy-OperatorApikShafieeNo ratings yet

- An Ecient Multiple Shooting Based Reduced SQP Strategy For Large-Scale Dynamic Process OptimizationDocument10 pagesAn Ecient Multiple Shooting Based Reduced SQP Strategy For Large-Scale Dynamic Process OptimizationaminNo ratings yet

- Unit 1 INTRODUCTION TO MECHATRONICS SYSTEM DESIGNDocument8 pagesUnit 1 INTRODUCTION TO MECHATRONICS SYSTEM DESIGN9740177035100% (1)

- A Holistic Approach To Automated Synthesis of Mixed-Technology Digital MEMS SensorsDocument15 pagesA Holistic Approach To Automated Synthesis of Mixed-Technology Digital MEMS SensorstantdvnuNo ratings yet

- OpenFOAM A C++ Library For Complex Physics SimulationsDocument20 pagesOpenFOAM A C++ Library For Complex Physics SimulationsAghajaniNo ratings yet

- 1979 Efficient Solution of Design Problems Using A Sequential-Modular Flowsheeting ProgrammeDocument7 pages1979 Efficient Solution of Design Problems Using A Sequential-Modular Flowsheeting Programmelvjiaze12No ratings yet

- SimulationDocument3 pagesSimulationloubna ghiritiNo ratings yet

- PolyTop PDFDocument29 pagesPolyTop PDFahmed_shaheebNo ratings yet

- Mechanical Systems and Signal Processing: L. Farkas, D. Moens, S. Donders, D. VandepitteDocument10 pagesMechanical Systems and Signal Processing: L. Farkas, D. Moens, S. Donders, D. VandepitteZaid MangalgiriNo ratings yet

- The Guider System For Classical Controller DesignDocument5 pagesThe Guider System For Classical Controller DesignEsmael FloresNo ratings yet

- Modeling of Dynamical Systems: A Survey of Tools and A Case StudyDocument4 pagesModeling of Dynamical Systems: A Survey of Tools and A Case StudyMUHAMMAD ZIKRON -No ratings yet

- Simulation-Based Automatic Generation Signomial and Posynomial Performance Models Analog Integrated Circuit SizingDocument5 pagesSimulation-Based Automatic Generation Signomial and Posynomial Performance Models Analog Integrated Circuit Sizingsuchi87No ratings yet

- Fault Detection Using Machine Learning TechniquesDocument47 pagesFault Detection Using Machine Learning Techniquesmlaxmiprasanna1313No ratings yet

- Control Strategies For Dynamic Systems PDFDocument604 pagesControl Strategies For Dynamic Systems PDFMarcu Sorin100% (2)

- Cover Note Signposting of The PortfolioDocument7 pagesCover Note Signposting of The PortfolioOur Beatiful Waziristan OfficialNo ratings yet

- A Versatile Demonstrator For Distributed RealDocument4 pagesA Versatile Demonstrator For Distributed Realpriyanka1229No ratings yet

- Engineering Applications of Arti Ficial Intelligence: Zeineb Lassoued, Kamel AbderrahimDocument9 pagesEngineering Applications of Arti Ficial Intelligence: Zeineb Lassoued, Kamel AbderrahimEduardo PutzNo ratings yet

- Pareto OptimizationDocument7 pagesPareto OptimizationeandreimariusNo ratings yet

- Applied Econometrics Using MatlabDocument348 pagesApplied Econometrics Using MatlabMichelle WilliamsNo ratings yet

- Models and Analysis for Distributed SystemsFrom EverandModels and Analysis for Distributed SystemsSerge HaddadNo ratings yet

- Co-Evolution of Metamodels and Model Transformations: An operator-based, stepwise approach for the impact resolution of metamodel evolution on model transformations.From EverandCo-Evolution of Metamodels and Model Transformations: An operator-based, stepwise approach for the impact resolution of metamodel evolution on model transformations.No ratings yet

- Mathematical Models and Algorithms for Power System Optimization: Modeling Technology for Practical Engineering ProblemsFrom EverandMathematical Models and Algorithms for Power System Optimization: Modeling Technology for Practical Engineering ProblemsNo ratings yet

- Computer-Controlled Systems: Theory and Design, Third EditionFrom EverandComputer-Controlled Systems: Theory and Design, Third EditionRating: 3 out of 5 stars3/5 (4)

- CHE525 GroupsWorkDocument119 pagesCHE525 GroupsWorkEse FrankNo ratings yet

- Questions: Qualitative Data (Favourite Color, Place)Document12 pagesQuestions: Qualitative Data (Favourite Color, Place)Ese FrankNo ratings yet

- Chapter One 1.1 Background of The StudyDocument32 pagesChapter One 1.1 Background of The StudyEse FrankNo ratings yet

- MY SIWES REPORT ApprovedDocument38 pagesMY SIWES REPORT ApprovedEse FrankNo ratings yet

- CertificationDocument1 pageCertificationEse FrankNo ratings yet

- Franchise Model For Coaching ClassesDocument7 pagesFranchise Model For Coaching ClassesvastuperceptNo ratings yet

- Contoh Teks HortatoryDocument4 pagesContoh Teks HortatoryZonia AlqanitaNo ratings yet

- The Future of Humanity ProjectDocument8 pagesThe Future of Humanity Projectapi-563597519No ratings yet

- Glazing Risk AssessmentDocument6 pagesGlazing Risk AssessmentKaren OlivierNo ratings yet

- 106資優特訓班Document96 pages106資優特訓班utaNo ratings yet

- 03 Vertical Pump Test ANSI HI 2.6 2000Document48 pages03 Vertical Pump Test ANSI HI 2.6 2000Benny RivasNo ratings yet

- Installing TrollStore - iOS Guide PDFDocument2 pagesInstalling TrollStore - iOS Guide PDFThanh NgoNo ratings yet

- Rough Translation of Emil Stejnar's Schutzengel BookDocument119 pagesRough Translation of Emil Stejnar's Schutzengel BookJustA Dummy100% (1)

- Topic 1: Introduction To Telecommunication: SPM1012: Telecommunication and NetworkingDocument22 pagesTopic 1: Introduction To Telecommunication: SPM1012: Telecommunication and Networkingkhalfan athmanNo ratings yet

- Syncronex Single Copy 3.1 Users GuideDocument208 pagesSyncronex Single Copy 3.1 Users GuideTony BoscoNo ratings yet

- Name: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CDocument7 pagesName: Maturan, Renz Myko B. Date: November 28, 2022 Subject & Section: EE 330 AC/DC Machineries - CRenz MykoNo ratings yet

- The Journal of The Acoustical Society of AmericaDocument12 pagesThe Journal of The Acoustical Society of Americadr01dNo ratings yet

- Lesson Plan PRKADocument2 pagesLesson Plan PRKAAmieer Abdul RahimNo ratings yet

- Lesson 1-02 Data Collection and Analysis STATDocument12 pagesLesson 1-02 Data Collection and Analysis STATallan.manaloto23No ratings yet

- Electronic Transformer For 12 V Halogen LampDocument15 pagesElectronic Transformer For 12 V Halogen LampWin KyiNo ratings yet

- Calculation of Pipe SupportDocument6 pagesCalculation of Pipe Supportnaveen_86No ratings yet

- HRM Chapt 4 With AnswersDocument3 pagesHRM Chapt 4 With Answersjoebloggs1888No ratings yet

- Data Center Cooling SolutionsDocument24 pagesData Center Cooling SolutionsGemelita Ortiz100% (1)

- Deiparine, Jr. vs. Court of Appeals, 221 SCRA 503, G.R. No. 96643 April 23, 1993Document9 pagesDeiparine, Jr. vs. Court of Appeals, 221 SCRA 503, G.R. No. 96643 April 23, 1993CherNo ratings yet

- ADMModule - STEM - GP12EU Ia 7Document27 pagesADMModule - STEM - GP12EU Ia 7Jel SuarezNo ratings yet

- Ramana Cell: +91 7780263601 ABAP Consultant Email Id: Professional SummaryDocument4 pagesRamana Cell: +91 7780263601 ABAP Consultant Email Id: Professional SummaryraamanNo ratings yet

- Samgroup: Unli Vocab Now LearningDocument20 pagesSamgroup: Unli Vocab Now LearningBrixter MangalindanNo ratings yet

- Highway Weigh-In-Motion (WIM) Systems With User Requirements and Test MethodsDocument18 pagesHighway Weigh-In-Motion (WIM) Systems With User Requirements and Test MethodsFayyaz Ahmad KhanNo ratings yet

- Core Vendor PDFDocument215 pagesCore Vendor PDFSakar EngitechNo ratings yet

- Electrolytic Manganese Dioxide White PaperDocument9 pagesElectrolytic Manganese Dioxide White PaperPSahuNo ratings yet

- Why Are You Applying For Financial AidDocument2 pagesWhy Are You Applying For Financial AidqwertyNo ratings yet

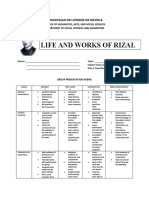

- Rubrics - Reporting - RizalDocument2 pagesRubrics - Reporting - RizaljakeNo ratings yet

- Ericsson - Cell PlanningDocument5 pagesEricsson - Cell PlanningBassem AbouamerNo ratings yet

- 71 SubmissionDocument4 pages71 Submissionmohamed aliNo ratings yet

- Why Facts Don't Change Our MindsDocument13 pagesWhy Facts Don't Change Our MindsNadia Sei LaNo ratings yet