Lecture 5 - Construction Methods & Operation

Uploaded by

Jubillee MagsinoLecture 5 - Construction Methods & Operation

Uploaded by

Jubillee MagsinoCommon questions

Powered by AIEffective construction project management involves robust planning, collaboration across multiple disciplines, and consideration of key factors such as zoning requirements, environmental impact, scheduling, budgeting, and safety . It also requires the integration of legal, design, and financial aspects to ensure a project is viable and compliant with regulations .

Integrating financial and legal expertise in construction planning ensures that projects are economically viable and legally compliant. Financial planning addresses potential cash flow issues and underbidding , while legal expertise ensures adherence to zoning laws and building codes, preventing costly legal issues down the line . This integration facilitates smoother project execution and reduces risks associated with non-compliance and financial mismanagement .

Modern construction projects require significant integration of financial and legal strategies to ensure success. Financial planning must be robust and include contingency plans to prevent issues such as underbids and cash flow problems . Legal frameworks govern construction projects by imposing regulations like zoning laws and building codes, which must be adhered to avoid legal repercussions . The overlap of design, finance, and legal aspects means that each element must complement the others; a design must be structurally sound, financially viable, and legally compliant .

Inadequate planning during the construction phase can lead to several challenges, such as cost overruns, project delays, and safety issues. Poor planning might overlook zoning and environmental regulations, leading to legal disputes . Financial mismanagement can result in underbidding or cash flow problems, impacting the project's timeline and increasing the risk of bankruptcy . Additionally, failure to plan for logistical challenges can cause disruption and inefficiencies on-site, further escalating costs and timelines .

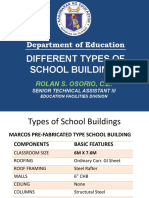

Different construction methods like precast, modular, and hybrid approaches significantly enhance efficiency and cost-effectiveness in large-scale projects. Precast methods save time and reduce waste by using factory-produced elements , while modular construction offers rapid assembly and consistency across units, boosting productivity and reducing on-site labor costs . Hybrid construction combines precast and in-situ benefits, ensuring quick yet custom adaptations to project needs, thus optimizing both speed and cost .

Design teams play a crucial role in translating project visions into reality. They consist of various specialists such as architects, engineers, and consultants who ensure the project design is structurally sound and aligns with client requirements . Their work impacts project outcomes by determining whether designs are feasible within financial and legal constraints, directly affecting the project's success and functionality .

Modern construction procurement methods like Design-Build and Management Contracting streamline project efficiency by fostering cooperative relationships between stakeholders and eliminating traditional bottlenecks associated with separate design and construction phases . These methods enable faster project turnaround and can potentially reduce costs by integrating responsibilities and facilitating clear communication among parties involved .

The tunneling form construction method is significant due to its ability to create monolithic walls and slabs rapidly through a daily cycle, enhancing the economy and speed of construction in repetitive cellular projects like hotels and apartments . It leverages the advantages of concrete, such as sound and fire resistance, and integrates the quality and accuracy of off-site production with the benefits of in-situ casting .

Precast and volumetric construction methods enhance sustainability by reducing on-site waste and construction time. Precast components, produced off-site, offer high quality and accuracy, reducing material waste . Volumetric construction (modular construction) allows for modules to be fabricated in controlled environments, minimizing site disruptions and improving energy efficiency through better insulation and reduced thermal bridging .

Hybrid Concrete Construction (HCC) combines precasting with cast in-situ methods. It benefits projects by enhancing construction speed, quality, and economy due to the combination of precision from precasting and flexibility from in-situ casting . However, challenges may include coordinating the two methods effectively on-site and ensuring a seamless integration that maximizes the advantages of each method .