Department of Civil Engineering, IIT Delhi

Soil Engineering Lab

REPORT TITLE (06)

Direct Shear Test

Submitted By:

Abhinav Kumar

Disclaimer: This presentation is for educational purposes only. Opinions or points of

view expressed in this presentation represent the view of the presenter, and does not

necessarily represent the official position or policies of IIT Delhi. Nothing in this

presentation constitutes legal advice. The individuals appearing in this presentation, if

any, are depicted for illustrative purposes only and are presumed innocent until

proven guilty in a court of law. Under no circumstance shall we have any liability to

you for any loss or damage of any kind incurred as a result of the use of the data or

reliance on any information provided. Your use of the document and your reliance on

any information is solely at your own risk

1

�Objective: Method for determination of shear strength of soil (Badarpur Sand) with a maximum

particle size of 4.75 mm in drained conditions using Direct Shear Test apparatus.

Apparatus:

1. Direct Shear Test Apparatus-

Loading Frame, Weights, Proving Ring, Micrometer Dial Gauge, Sample Trimmer or Core Cutter,

Stop Watch, Balance, Spatula, Straight Edge, Shear box grid plates, porous stones, base plates,

loading pad and water jacket shall conform to IS: 11229-1985.

(a) Upper and lower parts

of shear box coupled

together with two pins.

(b) Grid plates - 2 pairs

(c) Stone plates

(d) 4 Base plate

(e) Top plate

(f) Loading pad, and the

balance of 1 kg capacity,

sensitive to 0.1 g.

2. Weights - for providing the

required normal loads.

Testing methods and Procedures:

1. Specimen Preparation (Remoulded)

Cohesionless soil (Badarpur Sand) with relative density 70% was tamped

in the shear box itself with the base plate and grid plate or porous stone

as required in place at the bottom of the box.

2. Undisturbed Specimen -Specimens of required size shall be prepared

from the undisturbed specimen collected from field in accordance with

IS: 2720 (Part 1)-1983.

3. Consolidated Drained Test-The shear box with sample and perforated

grid plates and porous stones was fitted into the load frame. After

application of normal stress which is done in increments [ IS: 2720 (Part

15)-1986, the sample was allowed to consolidate. When the consolidation

has completely occurred, the shear test should be done at such a slow

rate that at least 95 percent pore pressure dissipation occurs during the

test in this calculated time factor. At the end of the test, the specimen

should be removed from the box and the final moisture content

measured. A minimum of three (preferably four) tests were made on

separate specimens of the same density at different normal stresses.

Shear Box Assembly

2

�4. Strain controlled direct shear machine consists of shear box, soil container, loading unit, proving ring,

dial gauge to measure shear deformation and vertical deformation. A proving ring is used to indicate the

shear load taken by the soil along the shearing plane.

Calculations:

1. From the calibration chart of the proving-ring, the loads corresponding to the load dial readings

obtained during the test was calculated. The loads so obtained divided by the corrected cross-sectional

area of the specimen gives the shear stress in the sample. The corrected cross-sectional area shall be

calculated from the following equation:

Corrected Area (Ac) = Ao(1 - (δ/3))

where,

Ao = initial area of the specimen in cm2 and

δ = displacement in cm.

2. The longitudinal displacement at a particular load was either noted directly from the strain dial

readings or calculated as the product of the corresponding time reading and the strain rate, allowing for

the compression of the proving-ring, where applicable. The stress longitudinal displacement readings

were plotted and the maximum stress and corresponding longitudinal displacement together with the

normal load applied during the test recorded.

3. The maximum shear stress and the corresponding longitudinal displacement and applied normal stress

were recorded for each test and the results were presented in the form of a graph in which the applied

normal stress is plotted as abscissa and the maximum shearing stress is plotted as ordinate to the same

scale. The angle which the resulting straight line makes with the horizontal axis and the intercept which

the straight line makes with the vertical axis shall be reported as the angle of shearing resistance and

cohesion intercept respectively.

4. i. Shear Stress = (Proving ring reading x Proving ring constant)/Acorrected

ii. Horizontal displacement = (Horizontal dial gauge reading) x (Least count of horizontal dial gauge)

iii. Vertical displacement = (Vertical dial gauge reading) x (Least count of vertical dial gauge)

5. Shear stress at failure needs to be calculated for all three tests performed at three different normal

stresses to plot the failure envelope.

3

�Load Comp.

(kN) Division Calibration for Proving Ring No- 15927

0 0

1600

0.3 141 1400

0.6 282 1200

Comp. Division

0.9 425 1000

1.2 567 800

1.5 712 600

1.8 856 400

2.1 1002 200

2.4 1145 0

2.7 1291 0 1 2 3 4

3 1438 Load (kN)

Loading Yoke Proving Ring

Vertical Dial Gauge

Holding Screw

Frame

Motor

Counter Weight Horizontal Dial Gauge

Lever Arm

Direct Shear Test Assembly

4

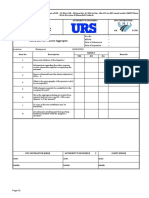

�Data Table

DIRECT SHEAR TEST

Proving Ring

Soil Weight 160 gm No. 15927

Length (L) 60 mm

Normal Load Least Count

Width (B) 59.90 mm (kN): 0.17970 of

Normal Stress

Height (h1) 36.5 mm (kPa): 50 PR (mm) 0.002

Badarpur

h2 9.2425 mm Soil Type : Sand VDG (mm) 0.002

Sample

Thickness

(H) 27.26 mm Density(gm/cc) 1.633 HDG (mm) 0.002

Vertical Proving Horizontal Vertical Cummulative Shear

Horizontal SF

Dial Ring displ. displ. Divisions of Stress

Dial Guage (kN)

Guage Reading (mm) (mm) PR (KPa)

15.00 0.00 0.00 0.00 0.000 0.00 0.00 0.000 0.000 0.0000

15.03 25.00 11.00 0.05 -0.006 11.00 0.02 6.512 0.130 -0.0002

15.05 50.00 20.00 0.10 -0.010 20.00 0.04 11.860 0.237 -0.0004

15.04 75.00 28.00 0.15 -0.008 28.00 0.06 16.632 0.332 -0.0003

15.03 100.00 33.00 0.20 -0.006 33.00 0.07 19.634 0.391 -0.0002

15.01 125.00 38.00 0.25 -0.002 38.00 0.08 22.647 0.450 -0.0001

14.99 150.00 42.00 0.30 0.002 42.00 0.09 25.073 0.497 0.0001

14.98 175.00 46.00 0.35 0.004 46.00 0.10 27.508 0.545 0.0001

14.95 200.00 50.00 0.40 0.010 50.00 0.11 29.950 0.592 0.0004

14.93 225.00 53.00 0.45 0.014 53.00 0.11 31.801 0.628 0.0005

14.88 250.00 56.00 0.50 0.024 56.00 0.12 33.658 0.663 0.0009

14.84 275.00 58.00 0.55 0.032 58.00 0.12 34.919 0.687 0.0012

14.80 300.00 61.00 0.60 0.040 61.00 0.13 36.788 0.722 0.0015

14.75 325.00 63.00 0.65 0.050 63.00 0.13 38.059 0.746 0.0018

14.71 350.00 65.00 0.70 0.058 65.00 0.14 39.334 0.770 0.0021

14.65 375.00 67.00 0.75 0.070 67.00 0.14 40.613 0.793 0.0026

14.58 400.00 68.00 0.80 0.084 68.00 0.14 41.290 0.805 0.0031

14.52 425.00 70.00 0.85 0.096 70.00 0.15 42.578 0.829 0.0035

14.47 450.00 72.00 0.90 0.106 72.00 0.15 43.869 0.852 0.0039

14.40 475.00 73.00 0.95 0.120 73.00 0.16 44.555 0.864 0.0044

14.33 500.00 74.00 1.00 0.134 74.00 0.16 45.243 0.876 0.0049

14.26 525.00 76.00 1.05 0.148 76.00 0.16 46.546 0.900 0.0054

14.20 550.00 77.00 1.10 0.160 77.00 0.16 47.240 0.912 0.0059

14.13 575.00 78.00 1.15 0.174 78.00 0.17 47.937 0.924 0.0064

14.05 600.00 78.00 1.20 0.190 78.00 0.17 48.020 0.924 0.0070

13.99 625.00 79.00 1.25 0.202 79.00 0.17 48.720 0.935 0.0074

13.93 650.00 80.00 1.30 0.214 80.00 0.17 49.423 0.947 0.0079

13.85 675.00 80.00 1.35 0.230 80.00 0.17 49.509 0.947 0.0084

5

�13.78 700.00 80.00 1.40 0.244 80.00 0.17 49.596 0.947 0.0090

13.71 725.00 81.00 1.45 0.258 81.00 0.17 50.304 0.959 0.0095

13.64 750.00 81.00 1.50 0.272 81.00 0.17 50.392 0.959 0.0100

13.56 775.00 82.00 1.55 0.288 82.00 0.17 51.104 0.971 0.0106

13.47 800.00 82.00 1.60 0.306 82.00 0.17 51.194 0.971 0.0112

13.42 825.00 83.00 1.65 0.316 83.00 0.18 51.909 0.983 0.0116

13.32 850.00 84.00 1.70 0.336 84.00 0.18 52.628 0.995 0.0123

13.26 875.00 84.00 1.75 0.348 84.00 0.18 52.721 0.995 0.0128

13.18 900.00 84.00 1.80 0.364 84.00 0.18 52.814 0.995 0.0134

13.14 925.00 85.00 1.85 0.372 85.00 0.18 53.538 1.006 0.0136

13.07 950.00 84.00 1.90 0.386 84.00 0.18 53.002 0.995 0.0142

13.00 975.00 84.00 1.95 0.400 84.00 0.18 53.097 0.995 0.0147

12.95 1000.00 84.00 2.00 0.410 84.00 0.18 53.191 0.995 0.0150

12.87 1025.00 84.00 2.05 0.426 84.00 0.18 53.287 0.995 0.0156

12.81 1050.00 84.00 2.10 0.438 84.00 0.18 53.382 0.995 0.0161

12.76 1075.00 84.00 2.15 0.448 84.00 0.18 53.478 0.995 0.0164

12.69 1100.00 83.00 2.20 0.462 83.00 0.18 52.936 0.983 0.0169

12.65 1125.00 83.00 2.25 0.470 83.00 0.18 53.032 0.983 0.0172

12.55 1150.00 82.00 2.30 0.490 82.00 0.17 52.487 0.971 0.0180

12.53 1175.00 83.00 2.35 0.494 83.00 0.18 53.224 0.983 0.0181

12.45 1200.00 81.00 2.40 0.510 81.00 0.17 52.035 0.959 0.0187

12.38 1225.00 82.00 2.45 0.524 82.00 0.17 52.773 0.971 0.0192

12.32 1250.00 81.00 2.50 0.536 81.00 0.17 52.224 0.959 0.0197

12.25 1275.00 81.00 2.55 0.550 81.00 0.17 52.319 0.959 0.0202

12.19 1300.00 81.00 2.60 0.562 81.00 0.17 52.415 0.959 0.0206

12.13 1325.00 81.00 2.65 0.574 81.00 0.17 52.511 0.959 0.0211

12.07 1350.00 80.00 2.70 0.586 80.00 0.17 51.957 0.947 0.0215

12.02 1375.00 80.00 2.75 0.596 80.00 0.17 52.053 0.947 0.0219

11.97 1400.00 80.00 2.80 0.606 80.00 0.17 52.149 0.947 0.0222

6

� Soil Proving Ring

Weight 160 gm No. 15927

Length (L) 60 mm

Width (B) 59.90 mm Normal Load (kN): 0.35940 Least Count of

Height Normal Stress

(h1) 36.5 mm (kPa): 100 PR (mm) 0.002

Badarpur

h2 9.2425 mm Soil Type : Sand VDG (mm) 0.002

Sample

Thickness

(H) 27.26 mm Density(gm/cc) 1.633 HDG (mm) 0.002

Vertical Horizontal Proving Horizontal Vertical Cummulative Shear

SF

Dial Dial Ring displ. displacement Divisions of Stress

(kN)

Guage Guage Reading (mm) (mm) PR (KPa)

20.00 0.00 0.00 0.00 0.000 0.00 0.00 0.000 0.000 0.0000

20.01 25.00 18.00 0.05 -0.002 18.00 0.04 10.656 0.107 -0.0001

20.02 50.00 32.00 0.10 -0.004 32.00 0.07 18.976 0.189 -0.0001

20.03 75.00 44.00 0.15 -0.006 44.00 0.09 26.135 0.260 -0.0002

20.05 100.00 55.00 0.20 -0.010 55.00 0.12 32.724 0.326 -0.0004

20.05 125.00 64.00 0.25 -0.010 64.00 0.14 38.143 0.379 -0.0004

20.05 150.00 72.00 0.30 -0.010 72.00 0.15 42.983 0.426 -0.0004

20.05 175.00 79.00 0.35 -0.010 79.00 0.17 47.241 0.468 -0.0004

20.05 200.00 86.00 0.40 -0.010 86.00 0.18 51.514 0.509 -0.0004

20.05 225.00 92.00 0.45 -0.010 92.00 0.20 55.202 0.545 -0.0004

20.05 250.00 96.00 0.50 -0.010 96.00 0.20 57.699 0.568 -0.0004

20.05 275.00 101.00 0.55 -0.010 101.00 0.21 60.807 0.598 -0.0004

20.05 300.00 104.00 0.60 -0.010 104.00 0.22 62.720 0.616 -0.0004

20.04 325.00 108.00 0.65 -0.008 108.00 0.23 65.243 0.639 -0.0003

20.03 350.00 111.00 0.70 -0.006 111.00 0.24 67.170 0.657 -0.0002

20.01 375.00 112.00 0.75 -0.002 112.00 0.24 67.891 0.663 -0.0001

19.98 400.00 116.00 0.80 0.004 116.00 0.25 70.436 0.687 0.0001

19.96 425.00 118.00 0.85 0.008 118.00 0.25 71.774 0.699 0.0003

19.93 450.00 120.00 0.90 0.014 120.00 0.26 73.115 0.710 0.0005

19.91 475.00 124.00 0.95 0.018 124.00 0.26 75.683 0.734 0.0007

19.87 500.00 125.00 1.00 0.026 125.00 0.27 76.425 0.740 0.0010

19.84 525.00 127.00 1.05 0.032 127.00 0.27 77.781 0.752 0.0012

19.80 550.00 128.00 1.10 0.040 128.00 0.27 78.530 0.758 0.0015

19.77 575.00 129.00 1.15 0.046 129.00 0.27 79.280 0.764 0.0017

19.73 600.00 130.00 1.20 0.054 130.00 0.28 80.033 0.770 0.0020

19.68 625.00 133.00 1.25 0.064 133.00 0.28 82.023 0.787 0.0023

19.65 650.00 134.00 1.30 0.070 134.00 0.29 82.784 0.793 0.0026

19.60 675.00 137.00 1.35 0.080 137.00 0.29 84.785 0.811 0.0029

19.57 700.00 138.00 1.40 0.086 138.00 0.29 85.553 0.817 0.0032

19.53 725.00 140.00 1.45 0.094 140.00 0.30 86.945 0.829 0.0034

19.50 750.00 140.00 1.50 0.100 140.00 0.30 87.097 0.829 0.0037

7

�19.45 775.00 141.00 1.55 0.110 141.00 0.30 87.873 0.835 0.0040

19.41 800.00 142.00 1.60 0.118 142.00 0.30 88.652 0.841 0.0043

19.35 825.00 143.00 1.65 0.130 143.00 0.30 89.434 0.847 0.0048

19.32 850.00 143.00 1.70 0.136 143.00 0.30 89.592 0.847 0.0050

19.28 875.00 143.00 1.75 0.144 143.00 0.30 89.751 0.847 0.0053

19.24 900.00 143.00 1.80 0.152 143.00 0.30 89.910 0.847 0.0056

19.19 925.00 143.00 1.85 0.162 143.00 0.30 90.070 0.847 0.0059

19.16 950.00 144.00 1.90 0.168 144.00 0.31 90.861 0.852 0.0062

19.11 975.00 144.00 1.95 0.178 144.00 0.31 91.023 0.852 0.0065

19.06 1000.00 144.00 2.00 0.188 144.00 0.31 91.185 0.852 0.0069

19.02 1025.00 143.00 2.05 0.196 143.00 0.30 90.714 0.847 0.0072

18.97 1050.00 144.00 2.10 0.206 144.00 0.31 91.512 0.852 0.0076

18.92 1075.00 142.00 2.15 0.216 142.00 0.30 90.403 0.841 0.0079

18.89 1100.00 142.00 2.20 0.222 142.00 0.30 90.566 0.841 0.0081

18.84 1125.00 142.00 2.25 0.232 142.00 0.30 90.729 0.841 0.0085

18.81 1150.00 142.00 2.30 0.238 142.00 0.30 90.893 0.841 0.0087

18.76 1175.00 141.00 2.35 0.248 141.00 0.30 90.416 0.835 0.0091

18.72 1200.00 141.00 2.40 0.256 141.00 0.30 90.580 0.835 0.0094

18.69 1225.00 139.00 2.45 0.262 139.00 0.30 89.457 0.823 0.0096

18.67 1250.00 137.00 2.50 0.266 137.00 0.29 88.330 0.811 0.0098

18.60 1275.00 136.00 2.55 0.280 136.00 0.29 87.845 0.805 0.0103

18.59 1300.00 135.00 2.60 0.282 135.00 0.29 87.358 0.799 0.0103

18.55 1325.00 135.00 2.65 0.290 135.00 0.29 87.518 0.799 0.0106

18.52 1350.00 134.00 2.70 0.296 134.00 0.29 87.029 0.793 0.0109

18.50 1375.00 133.00 2.75 0.300 133.00 0.28 86.538 0.787 0.0110

18.45 1400.00 130.00 2.80 0.310 130.00 0.28 84.741 0.770 0.0114

8

� Soil Proving Ring

Weight 160 gm No. 15927

Length (L) 60 mm

Least Count

Width (B) 59.90 mm Normal Load (kN): 0.53910 of

Height Normal Stress

(h1) 36.5 mm (kPa): 150 PR (mm) 0.002

Badarpur

h2 9.2425 mm Soil Type : Sand VDG (mm) 0.002

Sample

Thickness

(H) 27.26 mm Density(gm/cc) 1.633 HDG (mm) 0.002

Vertical Horizontal Proving Horizontal Vertical Cummulative Shear

SF

Dial Dial Ring displ. dispL. Divisions of Stress

(KN)

Guage Guage Reading (mm) (mm) PR (KPa)

19.00 0.00 0.00 0.00 0.000 0.00 0.00 0.000 0.000 0.0000

-

19.03 25.00 13.00 0.05 -0.006 13.00 0.03 7.696 0.051 0.0002

-

19.04 50.00 22.00 0.10 -0.008 22.00 0.05 13.046 0.087 0.0003

-

19.05 75.00 35.00 0.15 -0.010 35.00 0.07 20.790 0.138 0.0004

-

19.07 100.00 49.00 0.20 -0.014 49.00 0.10 29.154 0.193 0.0005

-

19.09 125.00 62.00 0.25 -0.018 62.00 0.13 36.951 0.245 0.0007

-

19.11 150.00 73.00 0.30 -0.022 73.00 0.16 43.580 0.288 0.0008

-

19.13 175.00 84.00 0.35 -0.026 84.00 0.18 50.231 0.332 0.0010

-

19.14 200.00 95.00 0.40 -0.028 95.00 0.20 56.905 0.375 0.0010

-

19.15 225.00 104.00 0.45 -0.030 104.00 0.22 62.402 0.410 0.0011

-

19.17 250.00 114.00 0.50 -0.034 114.00 0.24 68.518 0.450 0.0012

-

19.18 275.00 122.00 0.55 -0.036 122.00 0.26 73.451 0.481 0.0013

-

19.19 300.00 131.00 0.60 -0.038 131.00 0.28 79.003 0.517 0.0014

-

19.19 325.00 139.00 0.65 -0.038 139.00 0.30 83.971 0.549 0.0014

-

19.21 350.00 145.00 0.70 -0.042 145.00 0.31 87.745 0.572 0.0015

-

19.21 375.00 154.00 0.75 -0.042 154.00 0.33 93.350 0.608 0.0015

-

19.21 400.00 159.00 0.80 -0.042 159.00 0.34 96.546 0.628 0.0015

-

19.21 425.00 168.00 0.85 -0.042 168.00 0.36 102.186 0.663 0.0015

-

19.21 450.00 174.00 0.90 -0.042 174.00 0.37 106.017 0.687 0.0015

-

19.21 475.00 180.00 0.95 -0.042 180.00 0.38 109.862 0.710 0.0015

-

19.21 500.00 185.00 1.00 -0.042 185.00 0.39 113.108 0.730 0.0015

9

� -

19.21 525.00 189.00 1.05 -0.042 189.00 0.40 115.754 0.746 0.0015

-

19.20 550.00 194.00 1.10 -0.040 194.00 0.41 119.021 0.766 0.0015

-

19.20 575.00 199.00 1.15 -0.040 199.00 0.42 122.300 0.785 0.0015

-

19.18 600.00 204.00 1.20 -0.036 204.00 0.43 125.591 0.805 0.0013

-

19.17 625.00 209.00 1.25 -0.034 209.00 0.44 128.893 0.825 0.0012

-

19.15 650.00 212.00 1.30 -0.030 212.00 0.45 130.971 0.837 0.0011

-

19.12 675.00 216.00 1.35 -0.024 216.00 0.46 133.675 0.852 0.0009

-

19.11 700.00 220.00 1.40 -0.022 220.00 0.47 136.388 0.868 0.0008

-

19.08 725.00 224.00 1.45 -0.016 224.00 0.48 139.111 0.884 0.0006

-

19.05 750.00 227.00 1.50 -0.010 227.00 0.48 141.222 0.896 0.0004

-

19.02 775.00 230.00 1.55 -0.004 230.00 0.49 143.340 0.908 0.0001

18.99 800.00 234.00 1.60 0.002 234.00 0.50 146.089 0.924 0.0001

18.97 825.00 237.00 1.65 0.006 237.00 0.50 148.223 0.935 0.0002

18.93 850.00 241.00 1.70 0.014 241.00 0.51 150.991 0.951 0.0005

18.89 875.00 246.00 1.75 0.022 246.00 0.52 154.397 0.971 0.0008

18.85 900.00 249.00 1.80 0.030 249.00 0.53 156.557 0.983 0.0011

Shear Stress vs Horizontal Displacement

50KPa 100KPa 150KPa

200

Badarpur Sand

180

160

140

Shear Stress (kPa)

120

100

80

60

40

20

0

0.00 0.50 1.00 1.50 2.00 2.50 3.00

Horizontal Displacent (mm)

10

� Shear stress vs Normal stress

160.00

140.00

120.00

Shear Stress (kPa)

100.00

80.00

y = 0.9266x + 4.4213

60.00

40.00

20.00

0.00

0 20 40 60 80 100 120 140 160

Normal Stress (kPa)

Normal stress (kPa) Shear stress (kPa)

50 53.538

100 91.51

150 146.20

Cohesion (C) 4.42 kPa

Angle of Shearing Resistance (Ø) 42.82°

11

� Vertical Vs Horizontal Displ. Curve

50 kPa 100 kPa 150 kPa

0.5

0.4

0.3

Vertical Displ. (mm)

0.2

0.1

0

0.00 0.50 1.00 1.50 2.00 2.50 3.00

-0.1

Horizontal Displ. (mm)

Individual Discussion:

1. The loading cap tilted downwards (as shown in fig) on the

motor side (opposite to proving ring) from where horizontal

displacement was applied, due to removal of the sand sample

from the gap created due to shearing of upper half and lower

half shear box.

2. It is a Floating Box type test in which upper half box is floating

due to application of vertical loading resulting in lateral

confinement thus generating sufficient friction which holds the

upper half of shear box. Tilting of Loading Cap

12

� 3. In the shear box test, the specimen is not failing along its weakest plane but along a

predetermined or induced failure plane i.e. horizontal plane separating the two halves of the

shear box. This is the main drawback of this test.

Moreover, during loading, the state of stress cannot be evaluated. It can be evaluated only at

failure condition. Also, failure is progressive.

4. The angle of shearing resistance of sands depends on state of compaction, coarseness of grains,

particle shape and roughness of grain surface and grading. It varies between 28° (uniformly

graded sands with round grains in very loose state) to 46° (well graded sand with angular grains in

dense state).

5.

Soil Type Angle of Shearing Resistance Cohesion (C)

(Ø)

Badarpur Sand 42.82° 4.42 kPa

Yamuna Sand 31.70° 18.9 kPa

6. Direct shear test is simple and faster to operate. As thinner specimens are used in shear box, they

facilitate drainage of pore water from a saturated sample in less time. This test is also useful to

study friction between two materials – one material in lower half of box and another material in

the upper half of box.

7. In general, loose sands expand and dense sands contract in volume on shearing. There is a void

ratio at which either expansion contraction in volume takes place. This void ratio is called critical

void ratio. Expansion or contraction can be inferred from the movement of vertical dial gauge

during shearing.

References:

1. IS: 2720 (Part 13):1986 Methods of test for soils: Direct shear test. Reaffirmed- 2016.

2. IS: 11229-1985.

3. IS: 2720 (Part 15)-1986

4. ASTM D 3080 - 04

13