Professional Documents

Culture Documents

12.4 Capacitive Sensor Array For Localization of Bioparticles in CMOS Lab-on-a-Chip

Uploaded by

Alex WongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

12.4 Capacitive Sensor Array For Localization of Bioparticles in CMOS Lab-on-a-Chip

Uploaded by

Alex WongCopyright:

Available Formats

ISSCC 2004 / SESSION 12 / BIOMICROSYSTEMS / 12.

12.4 Capacitive Sensor Array for Localization of voltage (t1). A voltage step on the lid will induce in Vocell a volt-

Bioparticles in CMOS Lab-on-a-Chip age variation which is proportional to the input and feedback

capacitance ratio Ci/Cr and to the step amplitude. In t3 the out-

put voltage is sampled again by the readout stage which ampli-

Aldo Romani1, Nicolò Manaresi2, Luca Marzocchi1, Gianni Medoro2,

fies and outputs the sensed variation. An equal duration opposite

Andrea Leonardi1, Luigi Altomare1, Marco Tartagni1, Roberto Guerrieri1

voltage pulse is applied to the lid to prevent the build-up of a DC

University of Bologna, Bologna, Italy

1 electric field in the liquid. DEP forces must be restored before

Silicon Biosystems, Bologna, Italy

2 particles significantly change their positions or stick to the sur-

face.

The design of integrated CMOS sensors/actuators for applica-

tions in molecular and cell biology is a challenging issue on the An auxiliary capacitance Caux is included to subtract a program-

road towards automating of biological analyses. Recent papers mable offset (t2) to avoid saturating the charge amplifier when

about CMOS labs-on-a-chip [1][2] have presented different kinds higher voltage pulses are applied on the lid to maximize the out-

of strategies for implementing sensors and reducing the need of put voltage swing.

bulky and expensive external equipment such as microscopes

and cameras. Moreover, contributions in the area of CMOS sen- This elementary unit is replicated to form a 320x320 array. The

sors for accurate localization of cells or particles are emerging. In pitch of each site is 20µm. A block diagram of the chip is shown

[3] a CMOS lab-on-a-chip (LOAC) makes use of embedded opti- in Fig. 12.4.3. Each microsite is addressed by specific control sig-

cal sensors to detect particle positions. However, external equip- nals generated by the row and column decoders through the row

ment (i.e. special lamps, optical fiber, etc.) is still necessary and and column circuits. The readout stage mainly consists of a fully

labelling of cells with fluorescent markers may also be needed to differential charge integrator based on a folded cascode SC oper-

boost detection sensitivity. Other works [4][5] describe imped- ational amplifier with common mode feedback. The gain is pro-

ance sensing as a suitable approach for characterization of indi- grammable and an offset (Voff) can be subtracted during readout

vidual biological cells. However, sensitivity is strongly limited by in order to boost sensitivity while preventing saturation.

the possibility of shrinking the devices implemented in those

technologies. Figures 12.4.4 and 12.4.5 show comparisons of sensors and opti-

cal microscope images. In Fig. 12.4.4, 50µm polystyrene beads

This paper describes a CMOS capacitive sensor array which is

are individually detected. Detection of 10µm beads, Yarrowia

able to detect overlying particles. Moreover, the circuit imple-

lipolytica yeasts and human erythro-leukaemia K562 cells is

ments the moving DEP-cages approach described in [3] for par-

shown in Fig. 12.4.5. The worst case measured output voltage

ticle manipulation. Capacitive sensing overcomes the limits of

variation associated to particle presence was 145mV, correspon-

optical detection and does not rely on any external equipment.

ding to a SNR of 39dB and to a 0.42fF input capacitance varia-

The device consists of a CMOS chip covered by a conductive glass tion.

lid and separated by 100µm. A pierced piece of double adhesive

tape acts as a gasket. In the resulting closed micro-chamber, par- The circuit noise measured on the output voltage (Voutdiff) is, in

ticles and cells in their suspending medium can be injected 90% of the pixels, below the 1.6mV resolution of the external 12b

through holes in the glass. ADC, which is equivalent to 15 electrons on the input of the

charge amplifier.

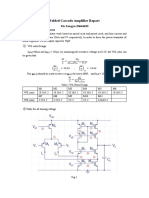

A highly parallel array of sensors and actuators is the core of the

device described herein. A closer view of each microsite is shown The chip has been fabricated in a 0.35µm 2P 3M standard CMOS

in Fig. 12.4.1. The aim is to detect variations in dielectric permit- technology with a supply voltage of 3.3V. The chip micrograph is

tivity caused by the presence of particles in the region above shown in Fig. 12.4.6. Superficial electrodes have been realized

superficial electrodes, which affects the coupling capacitance with the top metal layer of the CMOS process. The feedback (Cr)

with the lid. and auxiliary capacitance (Caux) are poly capacitors. Vlid is

external and can range between +/- 9V. No further processing nor

The circuit operates as a sensor or as a DEP actuator. During the micromachining have been used.

actuation phase ROWS and COLS are inactive. The circuit gen-

erates the electric fields necessary to deploy DEP forces by con- Acknowledgements:

necting the superficial metal electrode through CMOS transfer This work has been supported by the European Community 5th FP (IST-

gates to an in-phase (Vphip) or to a counter-phase sinusoidal 2001-32437), and by Italian MIUR-PRIN 2000. The authors acknowledge

A. Fuchs of CEA, P. Marche of INSERM for their suggestions on biological

voltage (Vphim), while the lid is connected to Vphim. Once a

aspects and S. Ronconi of University of Bologna for his valuable contribu-

microsite (i,j) is addressed, the selection is controlled by a mem- tion to the test board design.

ory element driven by ROWW, COLW and BROW.

References:

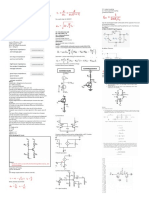

During the sensing phase the sinusoidal voltages are halted and [1] M.Xue et al., “A High Density Conduction Based Micro-DNA-

the electrode of the addressed cell is disconnected from Vphip Identification Array Fabricated in a CMOS Compatible Process,” ISSCC

and Vphim. Figure 12.4.2 shows a schematic view of the featured Dig. Tech. Papers, pp.198-199, Feb., 2003.

sensing scheme. The input capacitance Ci can be thought of as [2] B. Eversmann, et al., “A 128 x 128 CMOS Bio-Sensor Array for

the coupling capacitance between the lid and the microsite elec- Extracellular Recording of Neural Activity,” ISSCC Dig. Tech. Papers, pp.

trode. The cascode inverter implements a charge amplifier. The 222-223, Feb., 2003.

[3] N. Manaresi et al., “A CMOS Chip for Individual Cell Manipulation

output of the sensor array Voarr is generated by a source follow-

and Detection,” ISSCC Dig. Tech. Papers, pp.192-193, Feb., 2003.

er driving an active load through the addressed row multiplexer. [4] S. Gawad et al., “Micromachined Impedance Spectroscopy Flow

By activating RESCOL the output of the charge amplifier is Cytometer for Cell Analysis and Particle Sizing,” Lab on a Chip, vol. 1, pp.

brought to the reference value Vbn, corresponding to the thresh- 76-82, 2001.

old voltage of the cascode inverter. Then, RESCOL is deactivat- [5] G. Medoro et al., “A Lab-on-a-Chip for Cell Detection and

ed and after charge injection the readout stage samples the reset Manipulation,” IEEE Sensors J., vol. 3, pp.317-325, June 2003.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

ISSCC 2004 / February 17, 2004 / Salon 1-6 / 3:15 PM

Figure 12.4.1: Schematic view of the micro-site circuit. Figure 12.4.2: Capacitive sensing scheme and principle.

Figure 12.4.4: Sensor images of 50µm polystyrene beads in a 280mM

Figure 12.4.3: Block diagram of the chip. mannitol solution are compared with optical microscope images.

Figure 12.4.5: Sensor and microscope images of 10µm polystyrene beads,

Yarrowia lipolytica yeasts and human erythro-leukaemia K562 cells in a

280mM mannitol solution. Particles brighter than the background have εparticle

> εmedium, while darker ones have εparticle < εmedium. Figure 12.4.6: Micrograph of the sensor array.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

Figure 12.4.1: Schematic view of the micro-site circuit.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

Figure 12.4.2: Capacitive sensing scheme and principle.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

Figure 12.4.3: Block diagram of the chip.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

Figure 12.4.4: Sensor images of 50µm polystyrene beads in a 280mM mannitol solution are compared with optical microscope images.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

Figure 12.4.5: Sensor and microscope images of 10µm polystyrene beads, Yarrowia lipolytica yeasts

and human erythro-leukaemia K562 cells in a 280mM mannitol solution. Particles brighter than the

background have εparticle > εmedium, while darker ones have εparticle < εmedium.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

Figure 12.4.6: Micrograph of the sensor array.

• 2004 IEEE International Solid-State Circuits Conference 0-7803-8267-6/04 ©2004 IEEE

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Low-Dropout Voltage Regulator (LDO)Document30 pagesLow-Dropout Voltage Regulator (LDO)jashvenepally100% (1)

- Electronic Circuits - I Lecture Notes For B.E. (ECE) (High Resolution)Document315 pagesElectronic Circuits - I Lecture Notes For B.E. (ECE) (High Resolution)cmkmangai93% (45)

- 350W AmplifierDocument5 pages350W AmplifiermoisesNo ratings yet

- (ELECS2) Exp3 - Darlington and Cascode Amplifier CircuitsDocument17 pages(ELECS2) Exp3 - Darlington and Cascode Amplifier CircuitsFrodolfre Reginald Lazo100% (2)

- Capacitive: Laboratory-On-Chip ApplicationsDocument4 pagesCapacitive: Laboratory-On-Chip ApplicationsAlex WongNo ratings yet

- Charge-Based Capacitive Sensor Array For CMOS-Based Laboratory-on-Chip ApplicationsDocument8 pagesCharge-Based Capacitive Sensor Array For CMOS-Based Laboratory-on-Chip ApplicationsAlex WongNo ratings yet

- Y9. DataHandlingCheckoutDocument5 pagesY9. DataHandlingCheckoutAlex WongNo ratings yet

- Charge-Based Capacitive Sensor Array For CMOS-Based Laboratory-on-Chip ApplicationsDocument8 pagesCharge-Based Capacitive Sensor Array For CMOS-Based Laboratory-on-Chip ApplicationsAlex WongNo ratings yet

- Novel Direct-Write CMOS-based Laboratory-On-Chip: Design, Assembly and Experimental ResultsDocument10 pagesNovel Direct-Write CMOS-based Laboratory-On-Chip: Design, Assembly and Experimental ResultsAlex WongNo ratings yet

- An On-Chip, Interconnect Capacitance Characterization Method With Sub-Femto-Farad ResolutionDocument7 pagesAn On-Chip, Interconnect Capacitance Characterization Method With Sub-Femto-Farad ResolutionAlex WongNo ratings yet

- High Accuracy Differential Capacitive Circuit For Bioparticles Sensing ApplicationsDocument4 pagesHigh Accuracy Differential Capacitive Circuit For Bioparticles Sensing ApplicationsAlex WongNo ratings yet

- A Noise-Shaping Accelerometer Interface Circuit For Two-Chip ImplementationDocument4 pagesA Noise-Shaping Accelerometer Interface Circuit For Two-Chip ImplementationAlex WongNo ratings yet

- An On-Chip, Attofarad Interconnect Charge-Based Capacitance Measurement (CBCM) TechniqueDocument4 pagesAn On-Chip, Attofarad Interconnect Charge-Based Capacitance Measurement (CBCM) TechniqueAlex WongNo ratings yet

- A Hybrid Microfluidic/CMOS Capacitive Sensor Dedicated To Lab-on-Chip ApplicationsDocument8 pagesA Hybrid Microfluidic/CMOS Capacitive Sensor Dedicated To Lab-on-Chip ApplicationsAlex WongNo ratings yet

- Ultra Low Capacitance Measurements in Multilevel Metallisation CMOS by Using Built-In Electron-MeterDocument4 pagesUltra Low Capacitance Measurements in Multilevel Metallisation CMOS by Using Built-In Electron-MeterAlex WongNo ratings yet

- Cmos Circuits For On-Chip Capacitance Ratio Testing or Sensor ReadoutDocument4 pagesCmos Circuits For On-Chip Capacitance Ratio Testing or Sensor ReadoutAlex WongNo ratings yet

- Lockinamplifier Based CapmeasurementDocument8 pagesLockinamplifier Based CapmeasurementAlex WongNo ratings yet

- Use of Test Structures For Characterization and Modeling of Inter-And Intra-Layer Capacitances in A CMOS ProcessDocument9 pagesUse of Test Structures For Characterization and Modeling of Inter-And Intra-Layer Capacitances in A CMOS ProcessAlex WongNo ratings yet

- Monolayers: Voltage-Dependent Capacitance in Lipid Bilayers FromDocument17 pagesMonolayers: Voltage-Dependent Capacitance in Lipid Bilayers FromAlex WongNo ratings yet

- Sylvester 2Document5 pagesSylvester 2Alex WongNo ratings yet

- The Wes 2007Document9 pagesThe Wes 2007Alex WongNo ratings yet

- Detection of Vesicular Stomatitis Virus Using A Capacitive ImmunosensorDocument4 pagesDetection of Vesicular Stomatitis Virus Using A Capacitive ImmunosensorAlex WongNo ratings yet

- Var Cap MeasureDocument5 pagesVar Cap MeasureAlex WongNo ratings yet

- The C-Terminus of Prestin Influences Nonlinear Capacitance and Plasma Membrane TargetingDocument10 pagesThe C-Terminus of Prestin Influences Nonlinear Capacitance and Plasma Membrane TargetingAlex WongNo ratings yet

- A New Test Structure For Interconnect Capacitance MonitoringDocument4 pagesA New Test Structure For Interconnect Capacitance MonitoringAlex WongNo ratings yet

- A Fully Differential Rail-to-Rail Capacitance Measurement Circuit For Integrated Cell SensingDocument4 pagesA Fully Differential Rail-to-Rail Capacitance Measurement Circuit For Integrated Cell SensingAlex WongNo ratings yet

- Cochlear Function in Mice With Only One Copy of The Prestin GeneDocument13 pagesCochlear Function in Mice With Only One Copy of The Prestin GeneAlex WongNo ratings yet

- Determination of Cell Capacitance Using The Exact Empirical Solution of @Y/@C and Its Phase AngleDocument14 pagesDetermination of Cell Capacitance Using The Exact Empirical Solution of @Y/@C and Its Phase AngleAlex WongNo ratings yet

- Noise Analysis and Characterization of A Sigma-Delta Capacitive MicroaccelerometerDocument10 pagesNoise Analysis and Characterization of A Sigma-Delta Capacitive MicroaccelerometerAlex WongNo ratings yet

- Interconnect Capacitance Characterization Using Charge-Injection-Induced Error-Free (CIEF) Charge-Based Capacitance Measurement (CBCM)Document7 pagesInterconnect Capacitance Characterization Using Charge-Injection-Induced Error-Free (CIEF) Charge-Based Capacitance Measurement (CBCM)Alex WongNo ratings yet

- A Simple Method For On-Chip, Sub-Femto Farad Interconnect Capacitance MeasurementDocument3 pagesA Simple Method For On-Chip, Sub-Femto Farad Interconnect Capacitance MeasurementAlex WongNo ratings yet

- Calculatemobility CBCMDocument4 pagesCalculatemobility CBCMAlex WongNo ratings yet

- Crosstalk-Based Capacitance Measurements: Theory and ApplicationsDocument11 pagesCrosstalk-Based Capacitance Measurements: Theory and ApplicationsAlex WongNo ratings yet

- Charge-Based On-Chip Measurement Technique For The Selective Extraction of Cross-Coupling CapacitancesDocument3 pagesCharge-Based On-Chip Measurement Technique For The Selective Extraction of Cross-Coupling CapacitancesAlex WongNo ratings yet

- Distortion in Power AmplifiersDocument38 pagesDistortion in Power AmplifiersMortenGundersenNo ratings yet

- 22W Bridge / Stereo Audio Amplifier With Clipping Detector: ProtectionsDocument22 pages22W Bridge / Stereo Audio Amplifier With Clipping Detector: ProtectionsManase RomeoNo ratings yet

- Practical Mosfet Testing For Audio: by Nelson Pass, (C) 2003 Pass LaboratoriesDocument11 pagesPractical Mosfet Testing For Audio: by Nelson Pass, (C) 2003 Pass Laboratoriesanon-306355100% (1)

- Wide Swing Cascode Current MirrorDocument4 pagesWide Swing Cascode Current MirrorSunil M. PaiNo ratings yet

- Ec3361 Edc Lab ManualDocument50 pagesEc3361 Edc Lab ManualjerlinNo ratings yet

- Designing A Low Dropout (LDO) Linear Regulator With The Cadence Virtuoso IC617Document11 pagesDesigning A Low Dropout (LDO) Linear Regulator With The Cadence Virtuoso IC617carpet909No ratings yet

- Supper Cascode CircuitDocument1 pageSupper Cascode Circuitapi-3701386No ratings yet

- Ch5 - AmplifiersDocument149 pagesCh5 - AmplifiersRaghav AroraNo ratings yet

- Folded Cascode Amplifier ReportDocument4 pagesFolded Cascode Amplifier Report马宗宇No ratings yet

- Cascode AmplifierDocument6 pagesCascode AmplifierRajesh NatarajanNo ratings yet

- Chapter13 Transceiver Design ExampleDocument72 pagesChapter13 Transceiver Design ExampleFernando Martinez100% (1)

- Sem Q Paper - Analog CMOS D - T - 2021Document5 pagesSem Q Paper - Analog CMOS D - T - 2021SOHAN DEBNATHNo ratings yet

- Lecture - 2 Single Ended AmplifiersDocument78 pagesLecture - 2 Single Ended AmplifiersMadhumitha VetrivelNo ratings yet

- Lecture 7 Transistor Compound ConfigurationDocument4 pagesLecture 7 Transistor Compound ConfigurationIan EbonesNo ratings yet

- ECE102 - F12 LecSet 6Document17 pagesECE102 - F12 LecSet 6Sri KanthNo ratings yet

- III and IV Semester 207 Credits PDFDocument48 pagesIII and IV Semester 207 Credits PDFSRI RUDRANo ratings yet

- Government College of Engineering, Yavatmal: 1. EmailDocument9 pagesGovernment College of Engineering, Yavatmal: 1. EmailKim D'souzaNo ratings yet

- Ee618 PDFDocument39 pagesEe618 PDFfilmfilmfNo ratings yet

- Elec Help SheetDocument2 pagesElec Help SheetPhi NguyenNo ratings yet

- Eletronics Lab Report - Current MirrorDocument3 pagesEletronics Lab Report - Current MirrorThan Lwin AungNo ratings yet

- Electronic Devices: FloydDocument33 pagesElectronic Devices: FloydArman KhanNo ratings yet

- Cascode Amp Design (Nelson Pass)Document4 pagesCascode Amp Design (Nelson Pass)Ipate EugenNo ratings yet

- The Current-Steering Dac: A Circuit For All SeasonsDocument5 pagesThe Current-Steering Dac: A Circuit For All SeasonsCarlos ManuelNo ratings yet

- A 77-GHz CMOS Automotive Radar TransceiverDocument9 pagesA 77-GHz CMOS Automotive Radar TransceiverAbderrahimNo ratings yet

- Cap 6 Modificado PDFDocument84 pagesCap 6 Modificado PDFMilton EspinozaNo ratings yet