Professional Documents

Culture Documents

Q1Co 3000 Q1Co 3620 3620-DIT - 188

Uploaded by

JHONATAN RODRIGUEZ VENTOOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Q1Co 3000 Q1Co 3620 3620-DIT - 188

Uploaded by

JHONATAN RODRIGUEZ VENTOCopyright:

Available Formats

1 Tag No.

3620-DIT -188 Project Name Q1CO ®

2 P&ID No. MQ11-02-DR-3620-PD1003 Plant Name Q1CO IFC – Issued for Construction

GENERAL

3 Service Cu-Mo CONCENTRATE TO DISTRIBUTION BOX Area Name 3000 Jul 09, 2020

4 1 Unit Name 3620

5 Line No. 3620-7046-AT1N-6"-CT-N Construction Work Package 36200020007

6 Equipment No. 3620-TH-001 Amb. Temp. Min. to Max. -6.1 to +21.7 °C

7 Area Classification Non-Hazardous Altitude Sour Service 3600 m.a.s.l. ---

8 Line Size Schedule Wall Thickeness NPS 6 in STD 0.28 in

PIPE

9 Pipe Material Pipe Insulation PLAIN CARBON STEEL (ANSI B36.19 & B36.10) ---

10 Liner Material S.G. Liner Thickness Neoprene

--- 1.41

--- 6 mm

11 Case Governing Case --- ---

12 Fluid COPPER CONCENTRATE

PROCESS

13 Process Condtions Units @Min @Norm @Max

14 Slurry Density kg/m³ 1000 1970 2300

15 Solidifying Build-up Tend. Solids S.G. Yes No 4.2

16 Design Pressure Design Temperature 1034 kPa-g 37 °C

17 Tag No. Type 3620-DX-188 Radioactive Isotope

18 Container Material Container Paint / Linning Carbon Steel shell filled with lead ALEXIT-Decklack L 401 paint RAL 1007

19 Container Mount Type and Size Mounting Hdw Material & Paint Non-invasive clamp on type pipe Carbon Steel & PU, gray

20 Source Material Source Strenght / Activity Cesium 137 5 mCi

SOURCE

21 Source Factor K Source Radiation Angle 90 μSv/h*m2/GBq 16 Deg.

22 Max Permitted Radiation Rate Source Half Life 5mR/hour at 30cm from source 30.17 years

23 Shutter Locking Mechanism Weight Key and padlock 35 kg

24 Shutter Position Indication (Local) Yes

25 Shutter Design Type Remote Shutter Operation and Indicator Contacts

26 Manufacturer / Model No. Berthold / LB 7440-F-CR

27 Tag No. Sensor Type --- Scintillation Counter Type

DETECT.

28 Housing Material Mounting 304 SS Non-Invasive, Clamp-on type

29 Cooling Temperature Rating No -40° to +60° C

30

31 Electrical Certification Enclosure Rating General Purpose TYPE 4X

32 Housing Material Housing Paint 304 SS ---

33 Power Supply Full Load Current External 120 V AC 60 Hz 5A

TRANSMITTER

34 Remote / Integral Mounting Type Integral to Detector ---

35 Electrical Conduit Connection Wiring Connection Type 4x 3/4" FNPT Screwed

36 Control System I/O Type PCS ProfibusPA

37 Failure Mode Accuracy User Selectable 0.5% Of Span

38 Temp / Press Compensation Repeatability Yes 0.04 %MR

39 Autom. Source Decay Compens. Response Time Yes 0.5s to 300s, recommended in 20s

40 Instrument Range Local Display 1000 to 2300 kg/m³ ---

41 Calibrated Range DCS Range 1000 to 2300 kg/m³ 0 to 74 %W

42

43 Tag No. Type 3620-DI-188A LCD, Remote Display Only

DISPLAY

44 Communication Power Supply 4 to 20 mA Loop Powered from Transmitter

45 Display to Tx Cable Type Cable Lenght PLTC, Standard (By Others) ---

46 Manufacturer / Model No. Electrical Conduit Connection Yokogawa MLX-A11-12/X2/ENG/SST 2x 1/2" FNPT

47 Shutter Position Switch Type Quantity Mechanical Type 2 (Open/Closed)

AUTOM. SHUTTER

48 Hermetically Sealed Form Yes, Type 4X Enclosure SPDT

49 Contacts Rating (Amps/Volts) Switch Tag No(s) 2 Amp. at 120 Vac, 60 Hz 3620-ZSSO-188 / 3620-ZSSC-188

50 Pneumatic or Electric Drive Drive Tag No Air Actuated 3620-YSV-188

51 Available Air Supply Air Connection 550 to 690 kPa-g 1x 1/2" FNPT

52 Available Electric Supply Cable Entry 120 VAC / 60 Hz 2x M20

53 Accs. Electrical Certification Air filter regulator General Purpose Yes

54 Manufacturer / Model No. Berthold / Model Kinetrol 054

55 Surge Protection Device (Note 7) 2x 929 970 + 1x 920 327 + 1x 920 389 + 2x 920 300

OPTIONS

56 Calibration Kit Tag Nameplate --- SS Tag Plate

57 Mounting Brackets Yes, 2" Pipe (For Remote Display)

58 Electrical Fitting (Note 14)

59 Radiography Magnetic Particle --- ---

60 Liquid Penetrant Ultrasonic --- ---

TESTS & CERTS

61 Brinnell Hardness Delta Ferrite Content --- ---

62 Visual Examination by Mfr Hydrostatic Test Yes ---

63 CMTR-Pressure Retaining Comp CMTR-Wetted Components --- ---

64 PMI-Pressure Retaining Comp PMI-Wetted Components --- ---

65 Certificate of Compliance to PO Post Weld Heat Treatment (PWHT) --- ---

66 Calibration Certificate Configuration Certificate --- ---

67 Canadian Registration Number Dose Rate Test Report --- Yes

68 Manufacturer BERTHOLD

NOT. PURCHASE

69 Model No. LB 491 NaI Scintil. Detector

70 P.O. No. Item No. 700505-01

71 Serial No. After Manufacturing

72

See notes

INSTRUMENT DATA SHEET

Nuclear Density Meter

0 7/7/2020 Issued for Construction DP GA AC PLANT: Q1CO

A 6/30/2020 Issued for Internal Review DP GA AC DOCUMENT NO SHEET REV

REV DATE DESCRIPTION BY CHK APP PRO MQ13-02-DS-3620-INDIT188 1 OF 2 0

Printed:7/8/2020 Form: 1320 TEMPLATE REV - 1.01.01 - 16-Feb-2015

Tag Number : 3620-DIT -188

1."---": Not applicable.

2. Yokogawa confirms that the instrument complies with the following specifications: Field Instruments - MQ13-02-TE-0000-IN0505, Site Conditions -

MQ11-02-TE-0000-ME0001 and Paint - MQ11-02-TE-0000-GA0001.

3.Yokogawa confirms that all tagged elements are supplied with a SS tag plate.

4.Yokogawa confirms that all cable entries will supplied with suitably rated plugs to maintain the IP66 rating during shipping and storage.

5.Yokogawa confirms that the all transmitters will maintain the configuration using a segment of non-volatile memory control system.

6.Yokogawa confirms that it will support to solve any eventual issue related to Profibus PA interoperability with the specified DCS version (Siemens

Simatic PDM PCS7 V9.1).

7.Supply include a combined lightning current and surge arrester (DEHN brand) for power supply and signal circuits. For mandatory specifications and

wiring see drawing No. MQ13-02-DR-0000-IN1071, MQ13-02-DR-0000-IN1076 and MQ13-02-DR-0000-IN1077.

8.Yokogawa confirms that supply include a separate fiberglass reinforced Type 4X Junction Box, fully assembled containing the DIN rail surge arresters.

9.Yokogawa confirms that automatic shutter system is assembled at the factory.

10.Pneumatic actuators shall be designed to operate with 550 kPa to 690 kPa instrument air signal.

11.Air/Gas supply must be reasonably clean and dry and to a quality class 4.5.5 (according to ISO standard 8573.1). This implies 25 micron maximum

particle size, 7°C dew point maximum (or lower than ambient temp. below 7°C) and 25 mg/cubic metre maximum oil content.

12.All interconnection pneumatic tubing must be of SS and 0.049 inch wall thickness with double ferrule type SS fittings.

13.Yokogawa issues a calibration report after the instrument installed and calibrated.

14. Yokogawa confirms the following electrical fitting, 2x(M20x3/4" FNPT) + 1x(1/2"x3/4")(MNPTxFNPT) + 1x (1/2"x3/4")(FNPTxMNPT).

15.Calibration shall be done at site.

INSTRUMENT SPECIFICATION

Nuclear Density Meter

0 DP 7/7/2020 Issued for Construction

A DP 6/30/2020 Issued for Internal Review Sheet 2 of 2

No. By Date Revision Code: 1320 Dwg. No.: MQ13-02-DS-3620-INDIT188 Rev.: 0

You might also like

- Datasheet For Pressure TransmitterDocument8 pagesDatasheet For Pressure TransmitterVenkatesan ManikandanNo ratings yet

- Project Quality Plan Rev. 01Document101 pagesProject Quality Plan Rev. 01raj75% (4)

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- ORIFICEDocument1 pageORIFICEhardavNo ratings yet

- Shut Down Valve Sample DatasheetsDocument6 pagesShut Down Valve Sample DatasheetsBABILIN V100% (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Consultancy Agreement Design ServicesDocument15 pagesConsultancy Agreement Design ServicesMahata PriyabrataNo ratings yet

- BD 74 00 FoundationsDocument49 pagesBD 74 00 FoundationsShawn Mckenzie100% (1)

- 031Document5 pages031Mohamad ShafeyNo ratings yet

- FDS0019 GAP0080 O2C GTS Commercial InvoiceDocument22 pagesFDS0019 GAP0080 O2C GTS Commercial Invoicesomusatish100% (1)

- EVO28 - Data Migration DesignDocument19 pagesEVO28 - Data Migration DesignDickson AllelaNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 288Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 288JHONATAN RODRIGUEZ VENTONo ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Q1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionDocument2 pagesQ1Co 3000 Q1Co 3510 3510-LIT - 201: IFC - Issued For ConstructionJHONATAN RODRIGUEZ VENTONo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- High pressure steam flow measurementDocument1 pageHigh pressure steam flow measurementhendra hermawanNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- Transmisores de Presión y TemperaturaDocument6 pagesTransmisores de Presión y TemperaturaCh LoNo ratings yet

- Datasheet TCDocument4 pagesDatasheet TCroys.techconsultantNo ratings yet

- Pressure Safety Valve Data SheetDocument4 pagesPressure Safety Valve Data SheetŁukasz BolewskiNo ratings yet

- DS DPLTDocument2 pagesDS DPLTYENDRU LALITHAKUMARINo ratings yet

- 3.3. Datasheet Pressure Transmitters (23nov2021)Document2 pages3.3. Datasheet Pressure Transmitters (23nov2021)Eliyanto E BudiartoNo ratings yet

- 312-Data Sheet For Pressure TransmitterDocument3 pages312-Data Sheet For Pressure TransmittervyasathNo ratings yet

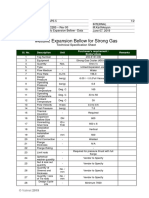

- Strong Gas Cooler - Metallic Expansion Bellow - Data Sheet - Rev 00Document2 pagesStrong Gas Cooler - Metallic Expansion Bellow - Data Sheet - Rev 00Anonymous Ywevve5HNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- TG Temperature GaugeDocument2 pagesTG Temperature GaugeAr RahmanNo ratings yet

- PT Pressure TransmitterDocument1 pagePT Pressure TransmitterAr RahmanNo ratings yet

- Ku-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityDocument5 pagesKu-Twk-20-Me-Dts-0006 - Data Sheet For Diesel Tank-5m3 CapacityAbdur RehmanNo ratings yet

- DS RotDocument1 pageDS RotYENDRU LALITHAKUMARINo ratings yet

- Pressure Vessel Data Sheet for TEG ContactorDocument2 pagesPressure Vessel Data Sheet for TEG ContactorElias EliasNo ratings yet

- Surge DiverterDocument2 pagesSurge DiverterKa TranNo ratings yet

- PS - Temperature ElementDocument2 pagesPS - Temperature ElementAmit Ranjan KumarNo ratings yet

- Kuwait Oil Company (K.S.C.) : Gas Projects ManagementDocument3 pagesKuwait Oil Company (K.S.C.) : Gas Projects ManagementdrkongalaNo ratings yet

- 315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevADocument3 pages315020-DOC-7003 - (Instrument Datasheets - Magnetic Level Gauge) - RevAanwar sadatNo ratings yet

- HD RFT Mty Ope 003Document5 pagesHD RFT Mty Ope 003Anonymous AtAGVssJNo ratings yet

- Venturi Specification: Client Project Area UnitDocument1 pageVenturi Specification: Client Project Area UnithaisamsarwarNo ratings yet

- Specification For Pressure TransmitterDocument1 pageSpecification For Pressure TransmitterHarish GundaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- FTDocument1 pageFTmanodipNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- PT APOTIK KATODIK Cathodic - Protection - CAEDCDocument2 pagesPT APOTIK KATODIK Cathodic - Protection - CAEDCCahyo Hening Pamardi STNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- J041A0088-Magnetic Level GaugeDocument3 pagesJ041A0088-Magnetic Level GaugesamboopathiNo ratings yet

- Buffer Vessel Data SheetDocument4 pagesBuffer Vessel Data SheetUmair A. KhanNo ratings yet

- Data Sheet of Magnetic Level Gauge For Feed Coalescer PackageDocument1 pageData Sheet of Magnetic Level Gauge For Feed Coalescer PackageHemant NimaseNo ratings yet

- Macolla 11, Fase I: Vialidad de Acceso, Plataforma Y Definición de Equipos Mayores de La Macolla 11 en El Centro Operativo Petromonagas (Copem)Document2 pagesMacolla 11, Fase I: Vialidad de Acceso, Plataforma Y Definición de Equipos Mayores de La Macolla 11 en El Centro Operativo Petromonagas (Copem)vacarrizaNo ratings yet

- Pressure Transmitter Data SheetDocument2 pagesPressure Transmitter Data SheetDavinder Singh BhattiNo ratings yet

- Q-Chem Ethylene Project welding procedure specificationDocument1 pageQ-Chem Ethylene Project welding procedure specificationS GoudaNo ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Document2 pagesCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- Slip StreamDocument1 pageSlip StreamvietsdsNo ratings yet

- 540402diga01015 Na: 0d206-Dma-I-797-La-0001Document16 pages540402diga01015 Na: 0d206-Dma-I-797-La-0001patilrohan4444No ratings yet

- Gas Detector DatasheetDocument1 pageGas Detector Datasheetjenish parekh100% (1)

- T-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight GlassDocument3 pagesT-25-2018-00-Pe-Das-1048 - Rev-2 - Datasheet For Sight Glassvinoj chandranNo ratings yet

- Pressure Transmitter DatasheetDocument1 pagePressure Transmitter DatasheetsurendharNo ratings yet

- Vessel Backup Condenser CDocument4 pagesVessel Backup Condenser CAzhar BudimanNo ratings yet

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomNo ratings yet

- Restrictor Valve Flow ControlDocument2 pagesRestrictor Valve Flow ControlJHONATAN RODRIGUEZ VENTONo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- Ultrasonic Level Transmitter: AREA: 3510Document9 pagesUltrasonic Level Transmitter: AREA: 3510JHONATAN RODRIGUEZ VENTONo ratings yet

- Binder Package: Doc. No.: MQ13-02-DS-3510-INSJ004 Rev.: 1Document10 pagesBinder Package: Doc. No.: MQ13-02-DS-3510-INSJ004 Rev.: 1JHONATAN RODRIGUEZ VENTONo ratings yet

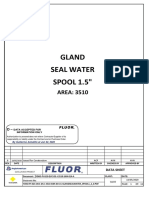

- Gland Seal Water SPOOL 1.5": AREA: 3510Document12 pagesGland Seal Water SPOOL 1.5": AREA: 3510JHONATAN RODRIGUEZ VENTONo ratings yet

- Milk of lime storage tank discharge valveDocument2 pagesMilk of lime storage tank discharge valveJHONATAN RODRIGUEZ VENTONo ratings yet

- Gland Seal Water SPOOL 1.5": AREA: 3510Document12 pagesGland Seal Water SPOOL 1.5": AREA: 3510JHONATAN RODRIGUEZ VENTONo ratings yet

- MQ13 02 DS 3510 Inhv142b - R0Document2 pagesMQ13 02 DS 3510 Inhv142b - R0JHONATAN RODRIGUEZ VENTONo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Milk of lime storage tank discharge valveDocument2 pagesMilk of lime storage tank discharge valveJHONATAN RODRIGUEZ VENTONo ratings yet

- IFA - Issued For ApprovalDocument12 pagesIFA - Issued For ApprovalJHONATAN RODRIGUEZ VENTONo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- Certified: Master Document List (MDL)Document1 pageCertified: Master Document List (MDL)JHONATAN RODRIGUEZ VENTONo ratings yet

- Cam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetDocument2 pagesCam Characteristic Air Consumption: Control Valve Air Act. Instrument Data SheetJHONATAN RODRIGUEZ VENTONo ratings yet

- PDF Test Medical Nitrile Exam GloveDocument13 pagesPDF Test Medical Nitrile Exam GloveRicha RohillaNo ratings yet

- Astm B 316 Acero InoxidableDocument9 pagesAstm B 316 Acero InoxidableMajo BárcenasNo ratings yet

- Serviceability AISC ASCEDocument3 pagesServiceability AISC ASCErpb10100% (1)

- TLE ExaminationDocument4 pagesTLE ExaminationLea CardinezNo ratings yet

- Technical Specifications MCMSDocument223 pagesTechnical Specifications MCMSAmit100% (1)

- Legal Opinion - NewDocument4 pagesLegal Opinion - NewMarcos Ariel Celli CorcobaNo ratings yet

- 3-Digital Governor GTP SainjDocument5 pages3-Digital Governor GTP Sainjpavankumar001No ratings yet

- Pile Load Test PDFDocument11 pagesPile Load Test PDFAjit P. SinghNo ratings yet

- Preservation and Represervation PDFDocument51 pagesPreservation and Represervation PDFAnonymous gr5Pr9AVNo ratings yet

- Rift Valley Water Works Development Agency: Tender Document ForDocument152 pagesRift Valley Water Works Development Agency: Tender Document ForJustus OtungaNo ratings yet

- Engineermind.comDocument3 pagesEngineermind.comErwiyan Fajar AnsoriNo ratings yet

- Structural Glazing SpecsDocument5 pagesStructural Glazing SpecsAnonymous IwqK1NlNo ratings yet

- International StandardsDocument1 pageInternational StandardsRind Bergh DevelosNo ratings yet

- FYP FINAL Documentation TemplateV 1.0Document42 pagesFYP FINAL Documentation TemplateV 1.0Sumbal zamanNo ratings yet

- Peiner: Fasteners For Wind TurbinesDocument8 pagesPeiner: Fasteners For Wind TurbinesmivanoNo ratings yet

- AAMA 502-08: Voluntary Specification For Field Testing of Newly Installed Fenestration ProductsDocument10 pagesAAMA 502-08: Voluntary Specification For Field Testing of Newly Installed Fenestration Productsjesonelite0% (1)

- EGR244 Digital Logic Design Lab Vending Machine ProjectDocument4 pagesEGR244 Digital Logic Design Lab Vending Machine Projectosama mahyoubNo ratings yet

- Analog Input Module AI 4xi 2-/4-Wire ST (6ES7134-6GD01-0BA1)Document40 pagesAnalog Input Module AI 4xi 2-/4-Wire ST (6ES7134-6GD01-0BA1)TCP.MT.2014 TCP.MT.2014No ratings yet

- Quality Control Manual for Road & Bridge ConstructionDocument220 pagesQuality Control Manual for Road & Bridge ConstructionsriNo ratings yet

- MIL-C-85043A: $@trsmii GDocument13 pagesMIL-C-85043A: $@trsmii GBowser DoskaNo ratings yet

- ASTM A6 - What Recent Changes Mean For Designers and FabricatorsDocument2 pagesASTM A6 - What Recent Changes Mean For Designers and FabricatorsAngel Arturo Castellanos SantamariaNo ratings yet

- A276A 276M.17 Norma Aceros Inoxidables Composicion PDFDocument8 pagesA276A 276M.17 Norma Aceros Inoxidables Composicion PDFalucard375No ratings yet

- SS 595-1-2014 - PreviewDocument11 pagesSS 595-1-2014 - PreviewpierreguessNo ratings yet

- iRAP Coding Manual Drive On Left - Vida-1-48-13-24 PDFDocument12 pagesiRAP Coding Manual Drive On Left - Vida-1-48-13-24 PDFMarco DanielNo ratings yet