Professional Documents

Culture Documents

Kuwait Oil Company (K.S.C.) : Gas Projects Management

Uploaded by

drkongala0 ratings0% found this document useful (0 votes)

37 views3 pagesOriginal Title

EGPM10-AIT-I-DAT-01 Analyzer

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views3 pagesKuwait Oil Company (K.S.C.) : Gas Projects Management

Uploaded by

drkongalaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

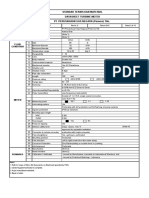

KUWAIT OIL COMPANY (K.S.C.

)

Gas Projects Management

RENOVATION OF AHMADI DOMESTIC & SOUTH EAST AHMADI DOMESTIC FUEL GAS

MANIFOLDS (E,F and V)

INSTRUMENT DATA SHEET

EGPM10-AIT-I-DAT-01

H2S Analyzer

A 3/9/2019 Issued for internal review MC Misra

Rev Date Description By Chkd Apprvd

RENOVATION OF AHMADI DOMESTIC & SOUTH EAST Rev A

AHMADI DOMESTIC FUEL GAS MANIFOLDS (E,F and V) Date 3/9/2019

Doc No: EGPM10-AIT-I-DAT-01

Data Sheet for Online H2S Analyzer Issued for Int. Review

1 Tag Number AIT-1001 & AIT-1002

2 Service As per P& ID

3 Line No. P&ID No. As per P&ID EGPM10-SK-PID-02

4 Hazardous Area Class Ignition Temp Ident Number IECEx / ATEX Zone 1

5 Ambient Temperature Min Max -10 Deg C 60 Deg C

6 Location Gas Polishing Unit at M/F F

7 Line Size Wall Thickness 4"

PIPE LINE

8 Pipe Material Class Pipe Material Asper P&ID C35B

9 Fluid Fluid State HP rich gas gas

10 Corrosive Toxic Build Up Tendancy CO2, H2S, RCH

11 Particulate Quality / Size / Solidifying

12 Min Normal Max

13 Inlet Temperature Deg C 21 45 60

14 Outlet Temperature Deg C 21 45 60

PROCESS 15 Flow Rate MMSCFD 0 2 5

DATA 16 Inlet Sample Pressure Psig 0 200 300

17 Outlet S'ple Pressure Psig 1.5 1.5 1.5

18 Density / Molecular wt g/mol 23 25 28

19 pH / ORP

20 Velocity m/s

21 Viscosity cP

22 Specific Gravity

23 Analyser Type * Extractive TDL 51 Probe Type Online

24 Detector Type * Near Infra red 52 Insertion Mechinism Fixed

SAMPLE

CELL 25 Wetted Body Material * SS316L 53 Insertion Length *

26 Window Matl Sapphire SAMPLE 54 Probe Material SS316

27 Path Length Cell/ Type * 40cm / Multipass PROBE 55 Flange Rating 2 IN , 300#

CRITERIA

28 Output Type 2 nos. 4 - 20 mA 56 Probe Tag No

29 Analogue Signal Isolation Isolated Output 57 Reference Drawing

30 Enclosure Type / Class Ex-d IP 66 58 NACE Compliance MR-01-75

31 Dig Comm Std Modbus RTU 59

32 Power Source 110V AC/240V AC 60 Housing Type SS cabinet

33 Digital Output Volt Free Contact 61 Heating / Cooling * Heated

34 Readout Type LCD 62 Insulation Required

TRANS / 35 Meas Ind LRL NA 63 Encl. Type / Class IP 56/ Zone 1

MONITOR 36 Cert / Approval Type IECex/ATEX zone 1 64 Bypass Valve Type * VTA

37 Mounting Loc / Type Field / Sunshade / Rack SAMPLE

Mounted 65 Block Valve Type * VTA

38 Rem Operation Capability Required COND 66 Tubing / Fitting Material SS316 / Swagelock

39 Diagnostic Capability Required SYSTEM 67 Seal Material * VTA

40 In ValidationMessage Via Serial Link 68 Tubing Traced/material SS316

41 Discrete Output SPDT 69 Validation Filed - automatic

42 Protection class Ex d IIB + H2 T3 70 Validation sample Gas bottle

43 P & T compensation yes 71 Fast loop return to process

44 Response Time 1 sec 72 Sample cell outlet to BD line

45 Contact Rating NA 73 H2S Purge required ? Yes

46 Min Required Accuracy * ACCESSOR

74 Lab Sample Tap No

PERFORM

& DESIGN ±0.5 ppmv or ±2% of Y

CRITERIA 47 Min Required Repeatability Reading 75

48 Measuring Range 0-50ppmv 76 Differential TDL system Yes

49 Minimum Detection Limit Betterthan 1ppmv 77 MR No

PURCHASE

50 Max Response Time 30 sec 78 Item No

Note

* - Vendor to specify/Confirm

1 The analyzer shall be suitable for the ambient conditions stated above with out any active cooling media

2 Vendor to indicate the utlity requirement and its consumption rate

3 The range shall be 0-500 ppmv with extended upto 5000ppmv.

4 Field validation through gas bottles shall be included

5 Sampling system and analyzer enclosure shall be SS316L

6 Analyzer shall be suitable to install in Zone 1 area

7 H2S concentration, cell pressure, temperature & diagnostics shall be available in LCD display

8 Analyzer shall be easy field maintanable, cell mirror shall be field replacable

9 Performance test of analyzer with sample conitioning system shall be done at factory and

report shall be submitted to KOC

10 Parts of analyzer with sampling system shall be fixed with SS identification TAGs

11 Dimensional drawings, Explosion proof certificates, Material Test certificates, O&M Manuals,

wiring Diagram, flow diagram, modbus mapping list shall be provided.

12 Field training shall be provided for maintenance of analyzer and samling system

13 Vendor service shall include site testing and demonstration of performance

14 Mounting accessories if any shall be included in the scope of supply

15 There is no Instrument air available at site

You might also like

- Datasheet For Pressure TransmitterDocument8 pagesDatasheet For Pressure TransmitterVenkatesan ManikandanNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Shut Down Valve Sample DatasheetsDocument6 pagesShut Down Valve Sample DatasheetsBABILIN V100% (1)

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- FD ISA Form S20.50 Rev 1 - OriginalDocument1 pageFD ISA Form S20.50 Rev 1 - OriginalRaphael AndradeNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Singapore Math Kangaroo 2015 ProblemsDocument7 pagesSingapore Math Kangaroo 2015 ProblemsTang Hooi JooNo ratings yet

- PT Pressure TransmitterDocument1 pagePT Pressure TransmitterAr RahmanNo ratings yet

- Datasheet of Gas AnalyserDocument1 pageDatasheet of Gas Analyserk singhNo ratings yet

- CO AnalyzerDocument1 pageCO AnalyzeruzairNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- Transmisores de Presión y TemperaturaDocument6 pagesTransmisores de Presión y TemperaturaCh LoNo ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- Hojas de Datos Valvulas de ControlDocument4 pagesHojas de Datos Valvulas de ControlMauricio Cuevas HinojosaNo ratings yet

- TG Temperature GaugeDocument2 pagesTG Temperature GaugeAr RahmanNo ratings yet

- Specification For Pressure TransmitterDocument1 pageSpecification For Pressure TransmitterHarish GundaNo ratings yet

- Gas Detector DatasheetDocument1 pageGas Detector Datasheetjenish parekh100% (1)

- Actuated Ball Valve 357 D - BDKDocument4 pagesActuated Ball Valve 357 D - BDKfarhanakhtar ansariNo ratings yet

- Actuated Ball Valve 357 D - BDKDocument5 pagesActuated Ball Valve 357 D - BDKfarhanakhtar ansariNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 188Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 188JHONATAN RODRIGUEZ VENTONo ratings yet

- High pressure steam flow measurementDocument1 pageHigh pressure steam flow measurementhendra hermawanNo ratings yet

- Pressure Transmitter SpecificationDocument1 pagePressure Transmitter SpecificationLibyanManNo ratings yet

- DS DPLTDocument2 pagesDS DPLTYENDRU LALITHAKUMARINo ratings yet

- Pressure Transmitter DatasheetDocument1 pagePressure Transmitter DatasheetsurendharNo ratings yet

- FTDocument1 pageFTmanodipNo ratings yet

- Analyzer Data SheetDocument3 pagesAnalyzer Data Sheetsokrat sebtiNo ratings yet

- Actuated Ball Valve 357 A - BDKDocument3 pagesActuated Ball Valve 357 A - BDKfarhanakhtar ansariNo ratings yet

- Actuated Ball Valve 357 A - BDKDocument4 pagesActuated Ball Valve 357 A - BDKfarhanakhtar ansariNo ratings yet

- Temperature Client Transmitter Project Specification Sheet Unit LocationDocument2 pagesTemperature Client Transmitter Project Specification Sheet Unit LocationFranklin J Talero BNo ratings yet

- PT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaDocument13 pagesPT Panca Amara Utama 1900 MTPD Ammonia Project Central Sulawesi, IndonesiaJan Richardo GultomNo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- EGPM10-PIT-I-DAT-001 Pressure TransmitterDocument2 pagesEGPM10-PIT-I-DAT-001 Pressure TransmitterdrkongalaNo ratings yet

- Datasheet for flow transmitterDocument2 pagesDatasheet for flow transmittertrilok corporationNo ratings yet

- Hoja de Datos - Válvulas de Control (ISBL) : RLP-HTNCB-HDD-J-YD-3CILP17.14-0020-H1Document1 pageHoja de Datos - Válvulas de Control (ISBL) : RLP-HTNCB-HDD-J-YD-3CILP17.14-0020-H1Cristhian RuizNo ratings yet

- Temperature Transmitter and RTD Assembly Specification SheetsDocument2 pagesTemperature Transmitter and RTD Assembly Specification SheetsFranklin J Talero BNo ratings yet

- Extracted pages from 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIADocument2 pagesExtracted pages from 1.2 P2B-00-52-ABB-273-001 REV.1 INSTRUMENT DATA SHEET AMMONIALoolooNo ratings yet

- Data Sheet Meter Turbin G.65Document1 pageData Sheet Meter Turbin G.65HerruSetiawanNo ratings yet

- KSB MIL Steam Vent Valve Spec SheetDocument36 pagesKSB MIL Steam Vent Valve Spec SheetNutan PowerNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- SizingDocument4 pagesSizingAlberto ReyesNo ratings yet

- Pressure Safety Valve Data SheetDocument4 pagesPressure Safety Valve Data SheetŁukasz BolewskiNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- 3.3. Datasheet Pressure Transmitters (23nov2021)Document2 pages3.3. Datasheet Pressure Transmitters (23nov2021)Eliyanto E BudiartoNo ratings yet

- 312-Data Sheet For Pressure TransmitterDocument3 pages312-Data Sheet For Pressure TransmittervyasathNo ratings yet

- 85000FI610Document1 page85000FI610LibyanManNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- TT 453Document3 pagesTT 453Manuel Rodriguez CNo ratings yet

- EGPM10-H2S-I-DAT-001 H2S DetectorsDocument1 pageEGPM10-H2S-I-DAT-001 H2S DetectorsdrkongalaNo ratings yet

- Specification Sheets For On-Off Manual ValvesDocument5 pagesSpecification Sheets For On-Off Manual ValvesMichell TurbayNo ratings yet

- PS - Temperature ElementDocument2 pagesPS - Temperature ElementAmit Ranjan KumarNo ratings yet

- Data Sheet: DQ-180229 - Sierra Gorda Tailings ThickenerDocument6 pagesData Sheet: DQ-180229 - Sierra Gorda Tailings ThickenerTalca CalderónNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332Document2 pagesQ1Co 3000 Q1Co 3620 3620-AIT - 114: 8/7/2020 Printed: TEMPLATE REV - 1.01.01 - 16-Apr-2015 Form: 1332JHONATAN RODRIGUEZ VENTONo ratings yet

- Pengadaan Meter Turbin Tahun 2021: PonoDocument2 pagesPengadaan Meter Turbin Tahun 2021: PonoArfan NNo ratings yet

- Ras Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JRDocument1 pageRas Gahreb Gas Treatment Plant: EN 10025-2-S355JR EN 10025-2-S355 JR ASTM A53/A106 ASTM A53/A106 EN 10025-2-S355 JROmar WardehNo ratings yet

- file5Document1 pagefile5VENKATACHALAM SUBBARAJNo ratings yet

- Diesel fuel storage tank data sheetDocument2 pagesDiesel fuel storage tank data sheetwado11No ratings yet

- Desalt Water Distribution RotameterDocument1 pageDesalt Water Distribution RotameterLibyanManNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument2 pagesPressure Transmitter Specification Sheet: GeneralCesar Santiago Marquez YanezNo ratings yet

- 3ya Automation IntroDocument43 pages3ya Automation IntrodrkongalaNo ratings yet

- 3yasvcs2021055 - R1Document4 pages3yasvcs2021055 - R1drkongalaNo ratings yet

- Managerial and HR QuestionsDocument5 pagesManagerial and HR Questionsshubham_narkhedeNo ratings yet

- SOLAR PV SYSTEM MAINTENANCE-finalDocument48 pagesSOLAR PV SYSTEM MAINTENANCE-finaldrkongala100% (1)

- 36th Indian Engineering Congress Online Technical Sessions 15-16 December 2021Document9 pages36th Indian Engineering Congress Online Technical Sessions 15-16 December 2021drkongalaNo ratings yet

- InstructionsDocument1 pageInstructionsdrkongalaNo ratings yet

- Solar InstrumentationDocument43 pagesSolar InstrumentationdrkongalaNo ratings yet

- Quotation - SO - 2122 - 04886Document2 pagesQuotation - SO - 2122 - 04886drkongalaNo ratings yet

- Lecturer) in (Information Systems and Technology) DepartmentDocument2 pagesLecturer) in (Information Systems and Technology) DepartmentdrkongalaNo ratings yet

- Quotation - SO - 2122 - 04886Document2 pagesQuotation - SO - 2122 - 04886drkongalaNo ratings yet

- MBBS - BDS Admissions Under CAQ Notification of Schedule For Evaluation of PWD CandidatesDocument1 pageMBBS - BDS Admissions Under CAQ Notification of Schedule For Evaluation of PWD CandidatesdrkongalaNo ratings yet

- Din Pid Controller - Flow ControlDocument1 pageDin Pid Controller - Flow ControldrkongalaNo ratings yet

- Light - 13042311001 PDFDocument8 pagesLight - 13042311001 PDFArunNo ratings yet

- TCS C, C++ & Data Structures QuestionsDocument8 pagesTCS C, C++ & Data Structures Questionsshubham_narkhedeNo ratings yet

- TCS C, C++ & Data Structures QuestionsDocument8 pagesTCS C, C++ & Data Structures Questionsshubham_narkhedeNo ratings yet

- Blakeborough®, Batley Valve®, MAC® & Tricentric® Control, Butterfly & Check ValvesDocument8 pagesBlakeborough®, Batley Valve®, MAC® & Tricentric® Control, Butterfly & Check ValvesdrkongalaNo ratings yet

- Pump Data SheetsDocument1 pagePump Data SheetsdrkongalaNo ratings yet

- Datasheet # Egpm10-Dat-M-Ad-001Document3 pagesDatasheet # Egpm10-Dat-M-Ad-001drkongalaNo ratings yet

- EGPM10-PIT-I-DAT-001 Pressure TransmitterDocument2 pagesEGPM10-PIT-I-DAT-001 Pressure TransmitterdrkongalaNo ratings yet

- EGPM-10-DAS-MOV-01 - Datasheet For MOV ActuatorDocument7 pagesEGPM-10-DAS-MOV-01 - Datasheet For MOV Actuatordrkongala100% (1)

- BTech Electrical and Electronics Engineering Academic Regulations and Detailed SyllabusDocument175 pagesBTech Electrical and Electronics Engineering Academic Regulations and Detailed Syllabusअनीश कुमारNo ratings yet

- Telugu EnglishDictionary PDFDocument510 pagesTelugu EnglishDictionary PDFmegastar0604No ratings yet

- EGPM10-H2S-I-DAT-001 H2S DetectorsDocument1 pageEGPM10-H2S-I-DAT-001 H2S DetectorsdrkongalaNo ratings yet

- EGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatorDocument4 pagesEGPM-10-DAS-MOV-ISO-01 - Datasheet For MOV IsolatordrkongalaNo ratings yet

- Technical and Vocational Education in KuwaitDocument10 pagesTechnical and Vocational Education in KuwaitdrkongalaNo ratings yet

- UCL SAS Advanced Programming CourseDocument1 pageUCL SAS Advanced Programming CoursedrkongalaNo ratings yet

- Delta PLC-Program O en 20130530Document753 pagesDelta PLC-Program O en 20130530Vaibhav PurnaleNo ratings yet

- Anti Aging PracticesDocument48 pagesAnti Aging PracticesJayti Srivastava67% (6)

- FluteDocument55 pagesFluteJulia Tam100% (6)

- Arithmetic-Geometric Mean Inequality Proof by Induction and CalculusDocument2 pagesArithmetic-Geometric Mean Inequality Proof by Induction and CalculusRitoprovo RoyNo ratings yet

- High Speed and Low Space Complexity FPGA Based ECC ProcessorDocument3 pagesHigh Speed and Low Space Complexity FPGA Based ECC ProcessorNsrc Nano ScientifcNo ratings yet

- Computer Network Uses and ExamplesDocument14 pagesComputer Network Uses and ExamplesUmaira ZafarNo ratings yet

- K Durga RamanjaneyuluDocument4 pagesK Durga RamanjaneyuluKAPIL ARORANo ratings yet

- Gabion Walls Presentation FijiDocument38 pagesGabion Walls Presentation FijiHuy ChungNo ratings yet

- Parallels RAS GPU Accelerated Application PublishingDocument42 pagesParallels RAS GPU Accelerated Application PublishingRichardNo ratings yet

- Panel Dual Polarization Half-Power Beam Width Adjust. Electrical DowntiltDocument3 pagesPanel Dual Polarization Half-Power Beam Width Adjust. Electrical DowntiltYarinaNo ratings yet

- Current Loop (4-20 Ma) OUTPUT: SourceDocument1 pageCurrent Loop (4-20 Ma) OUTPUT: SourceMatiasNo ratings yet

- Machine Design of Hoists, Derricks and Cranes by HessDocument440 pagesMachine Design of Hoists, Derricks and Cranes by HessDickson Leong67% (3)

- 12-LS6 DL Identify The Process of Inserting Symbols or Special CharactersDocument14 pages12-LS6 DL Identify The Process of Inserting Symbols or Special CharactersjosefadrilanNo ratings yet

- MKKL 2063Document10 pagesMKKL 2063Anas Abd RahmanNo ratings yet

- Lin e Hanratty 1986 Prediction PDFDocument20 pagesLin e Hanratty 1986 Prediction PDFFrancisco OppsNo ratings yet

- An Evolutionary Algorithm To Solve Crypt Arithmetic ProblemDocument3 pagesAn Evolutionary Algorithm To Solve Crypt Arithmetic ProblemSaniya RathoreNo ratings yet

- Quarterly Assessment Report in Mathematics Grade 1 First Quarter, SY 2019-2020Document5 pagesQuarterly Assessment Report in Mathematics Grade 1 First Quarter, SY 2019-2020William Felisilda100% (1)

- Energies 14 02285Document28 pagesEnergies 14 02285David Gustavo Duran TangoNo ratings yet

- Power Electronics Switch SelectionDocument32 pagesPower Electronics Switch SelectionSyed AfzalNo ratings yet

- Manual Controls C807Document40 pagesManual Controls C807Felipe Aguilar Rivera100% (1)

- Bodymeasurement 200525182452Document21 pagesBodymeasurement 200525182452Christine RodriguezNo ratings yet

- Aws C5.6-89Document75 pagesAws C5.6-89venkateshNo ratings yet

- Reaffirmed 2002Document29 pagesReaffirmed 2002Manish Kumar Singh100% (1)

- Electronics Plan PDFDocument3 pagesElectronics Plan PDFRogelio MendozaNo ratings yet

- CHE3044F Reactor Design 1 Tutorial 7 Equilibrium Calculations and Reactor SelectionDocument2 pagesCHE3044F Reactor Design 1 Tutorial 7 Equilibrium Calculations and Reactor SelectionnmhatityeNo ratings yet

- Uts MetpenDocument3 pagesUts MetpenJihan NazifaNo ratings yet

- Gaseous State PDFDocument4 pagesGaseous State PDFramanji1021No ratings yet

- Probability and Statistics: Integrated Math 1Document26 pagesProbability and Statistics: Integrated Math 1johnNo ratings yet

- Study Scheme & Syllabus Of: IK Gujral Punjab Technical UniversityDocument28 pagesStudy Scheme & Syllabus Of: IK Gujral Punjab Technical UniversityvijiNo ratings yet

- KAN Pd-01.04 Interpretation N Guidance On Estimation Uncertainty Measurement in TestingDocument19 pagesKAN Pd-01.04 Interpretation N Guidance On Estimation Uncertainty Measurement in Testingwahyuni buamonaNo ratings yet

- Crossword Puzzle: Solve The Crossword Puzzle, With The Help of Given CluesDocument1 pageCrossword Puzzle: Solve The Crossword Puzzle, With The Help of Given CluesAnas Ahmad GhaziNo ratings yet

- Coordinate Plane Performance CoachDocument10 pagesCoordinate Plane Performance CoachGeraldane SebuaNo ratings yet