Professional Documents

Culture Documents

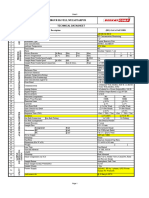

Datasheet for flow transmitter

Uploaded by

trilok corporationOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet for flow transmitter

Uploaded by

trilok corporationCopyright:

Available Formats

Client

Consultant

Project

Doc. Title Datasheet for Flow transmitter

Doc. No

1 Tag Number FIT-03

2 Hazardous Area Classification General

3 P&ID No Service

GENERAL

4 Line No Line Size / Schedule

5 Pipe Class Piping Material

6 Quantity Application 1 No.

7 Fluid Name State Steam

8 Flow ( Min / Norm / Max) , kg/h Min 15 kg/h / No

9 Temperature ( Min / Norm / Max / Design), degC 120

10 Pressure ( Min / Norm / Max / Design), Kg/cm2g 1

11 Density @ Oper., kg/m3 Viscosity @ Oper., cP 1

PROCESS DATA

12 Mol. Weight , Kmol/kg Cp/Cv 18.000

13 Compressibility factor

14 Allowable Dp, kg/cm2

15 Vapour Pressure, Torr

16 Corrosion component

16A Type Location VTA

FLOWMETER BODY 16B Connection Size Rating 1"

16C Body Material (Housing) Flange Material VTA

17 Sensor Type Sensor/ Electrode Material

Body Material Lining Material SS316 **

18 Transmitter Mounting integral type with LCD displa

19 Enclosure Type Enclosure Material IP 65 minimum

20 Certification General

21 Signal type 4-20 mA

TRANSMITTER 22 Power Supply VTA

23 Cable entry 1/2" NPTF for power & signa

24 Differential Pressure @ Full scale

Calibration Flow Range

25 Inst. Range

Min. / Max.

Accuracy LCD display VTA

26 2 Std AI Function Block **

Additional Block Structure requirement

27 PID 1 and 2 with autotune **

28 Mounting Bracket Required

29 Cable Gland Required

ACCESSORIES

30 Tag Plate GA drawing SS304

31 Manifold -TYPE Manifold - MOC -

Notes:

Job Order No.

Date

Rev.

Sheet No.

T-03

eneral

Steam

1"

SS 316

No. Flow Measurement

eam GAS

Min 15 kg/h / Normal 20 kg/h / Max 30 kg/h

120 150 200 250

1 2.5 3 5

1

18.000

TA Field

150#

TA SS 316

SS 316 L **

SS316 **

tegral type with LCD display

65 minimum VTA

eneral

20 mA

TA

2" NPTF for power & signal **

0 - 30 kg/h

TA Required

Std AI Function Block ** LCD display block **

D 1 and 2 with autotune ** **

equired

equired

S304 Required

- -

You might also like

- KSB MIL Steam Vent Valve Spec SheetDocument36 pagesKSB MIL Steam Vent Valve Spec SheetNutan PowerNo ratings yet

- Datasheet For Pressure Transmitter - Process DataDocument4 pagesDatasheet For Pressure Transmitter - Process DataLai HuynhNo ratings yet

- High pressure steam flow measurementDocument1 pageHigh pressure steam flow measurementhendra hermawanNo ratings yet

- Specification For Pressure TransmitterDocument1 pageSpecification For Pressure TransmitterHarish GundaNo ratings yet

- Pressure TransmitterDocument66 pagesPressure Transmittersswahyudi100% (1)

- Shut Down Valve Sample DatasheetsDocument6 pagesShut Down Valve Sample DatasheetsBABILIN V100% (1)

- OnScreen B2 Quiz 2ADocument2 pagesOnScreen B2 Quiz 2ALaura B.100% (1)

- TG Temperature GaugeDocument2 pagesTG Temperature GaugeAr RahmanNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- E-Way BillDocument1 pageE-Way BillShriyans DaftariNo ratings yet

- Temperature Transmitter Datasheet Provides Process DetailsDocument18 pagesTemperature Transmitter Datasheet Provides Process DetailssswahyudiNo ratings yet

- Construction of Mercury Removal Unit Data SheetDocument5 pagesConstruction of Mercury Removal Unit Data SheetMohamed hamza souissiNo ratings yet

- ORIFICEDocument1 pageORIFICEhardavNo ratings yet

- Self-test on the COSO ERM frameworkDocument6 pagesSelf-test on the COSO ERM frameworkLady BirdNo ratings yet

- Gray Iron Castings: Standard Specification ForDocument6 pagesGray Iron Castings: Standard Specification Forsafak kahramanNo ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- Pressure Differential Transmitter Datasheet for LNG Terminal ProjectDocument3 pagesPressure Differential Transmitter Datasheet for LNG Terminal ProjectsswahyudiNo ratings yet

- Gas Detector DatasheetDocument1 pageGas Detector Datasheetjenish parekh100% (1)

- Coriolis Mass Flow MeterDocument2 pagesCoriolis Mass Flow MeterSreejesh SundaresanNo ratings yet

- Data Sheet Meter Turbin G.65Document1 pageData Sheet Meter Turbin G.65HerruSetiawanNo ratings yet

- Home BMW F11 530D Xdrive Touring Wiring Diagrams and Functional DescriptionDocument1 pageHome BMW F11 530D Xdrive Touring Wiring Diagrams and Functional DescriptionOliver AlfaroNo ratings yet

- KNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6Document4 pagesKNT-002-TS-IA2-DS-018 - 1 - DATASHEET FOR WATERCUT METER-trang-3-6hoapro537817No ratings yet

- Desalt Water Distribution RotameterDocument1 pageDesalt Water Distribution RotameterLibyanManNo ratings yet

- 85000FI608Document1 page85000FI608LibyanManNo ratings yet

- 85000FI610Document1 page85000FI610LibyanManNo ratings yet

- PT Pressure TransmitterDocument1 pagePT Pressure TransmitterAr RahmanNo ratings yet

- FTDocument1 pageFTmanodipNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument2 pagesPressure Transmitter Specification Sheet: GeneralCesar Santiago Marquez YanezNo ratings yet

- Pressure Safety Valve Data SheetDocument4 pagesPressure Safety Valve Data SheetŁukasz BolewskiNo ratings yet

- Pressure Transmitter Data Sheet For Air Cooled CondenserDocument11 pagesPressure Transmitter Data Sheet For Air Cooled CondenserDhananjay BhaldandNo ratings yet

- Hojas de Datos Valvulas de ControlDocument4 pagesHojas de Datos Valvulas de ControlMauricio Cuevas HinojosaNo ratings yet

- Pressure Transmitter Specification Sheet: GeneralDocument1 pagePressure Transmitter Specification Sheet: GeneralFranklin J Talero BNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Specification Sheets For On-Off Manual ValvesDocument5 pagesSpecification Sheets For On-Off Manual ValvesMichell TurbayNo ratings yet

- K 61 33 PR DTS 20009 - 0001 - 0Document6 pagesK 61 33 PR DTS 20009 - 0001 - 0santhoshkrishnaNo ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- Datasheet of Gas AnalyserDocument1 pageDatasheet of Gas Analyserk singhNo ratings yet

- Instrument data sheet magnetic flow transmitterDocument1 pageInstrument data sheet magnetic flow transmitterCruz Alberto Romero GarciaNo ratings yet

- Temperature Client Transmitter Project Specification Sheet Unit LocationDocument2 pagesTemperature Client Transmitter Project Specification Sheet Unit LocationFranklin J Talero BNo ratings yet

- Level Transmitter - DP TypeDocument1 pageLevel Transmitter - DP TypeSreejesh SundaresanNo ratings yet

- A307 Ius DPG DS 2202Document2 pagesA307 Ius DPG DS 2202muddisetty umamaheswarNo ratings yet

- SizingDocument3 pagesSizingheinfongNo ratings yet

- Ultrasonic Flowmeter: Doc Number: Rev No: 1Document1 pageUltrasonic Flowmeter: Doc Number: Rev No: 1Mohammad BabazadehNo ratings yet

- Data Sheet For Flow TransmitterDocument1 pageData Sheet For Flow TransmitterNilesh ChavanNo ratings yet

- Proyectos de Instrumentaci On "Flotation / Rougher" "Informe N#2"Document4 pagesProyectos de Instrumentaci On "Flotation / Rougher" "Informe N#2"luis alvarezNo ratings yet

- Datasheet TCDocument4 pagesDatasheet TCroys.techconsultantNo ratings yet

- DS BiRotor Plus Single Case R13Document4 pagesDS BiRotor Plus Single Case R13eka pramudia santosoNo ratings yet

- DS 02995Document2 pagesDS 02995Giovanni ValentinoNo ratings yet

- Q1Co 3000 Q1Co 3520 3520-LIT - 381Document3 pagesQ1Co 3000 Q1Co 3520 3520-LIT - 381Jhonatan RodriguezNo ratings yet

- AICL-144-2122 Gulbrandsen TechnologiesDocument2 pagesAICL-144-2122 Gulbrandsen TechnologiesNikunj PatelNo ratings yet

- Filtro RFM ON 185 V D 10 E 1.x (Hydac)Document2 pagesFiltro RFM ON 185 V D 10 E 1.x (Hydac)OARIASCONo ratings yet

- Hoja de Datos - Válvulas de Control (ISBL) : RLP-HTNCB-HDD-J-YD-3CILP17.14-0020-H1Document1 pageHoja de Datos - Válvulas de Control (ISBL) : RLP-HTNCB-HDD-J-YD-3CILP17.14-0020-H1Cristhian RuizNo ratings yet

- DS Pressure Transmitter PDFDocument3 pagesDS Pressure Transmitter PDFadrian bargasNo ratings yet

- Hydrus UltrasonicDocument9 pagesHydrus UltrasonicMohammad ZeeshanNo ratings yet

- Cooling air blower VSDDocument1 pageCooling air blower VSDcv.ekaputra 04No ratings yet

- Kuwait Oil Company (K.S.C.) : Gas Projects ManagementDocument3 pagesKuwait Oil Company (K.S.C.) : Gas Projects ManagementdrkongalaNo ratings yet

- NSDocument1 pageNSXemtintuc Xem TinNo ratings yet

- Transmisores de Presión y TemperaturaDocument6 pagesTransmisores de Presión y TemperaturaCh LoNo ratings yet

- Usonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionDocument3 pagesUsonic Level Transmitter Instrument Data Sheet: IFC - Issued For ConstructionJhonatan RodriguezNo ratings yet

- Thermal Mass_Catalog_ENDocument16 pagesThermal Mass_Catalog_ENphuc nguyenNo ratings yet

- Density MeterDocument1 pageDensity Metervijaykumar.narayanaswamyNo ratings yet

- How To Create Datasheet For Pressure TransmitterDocument2 pagesHow To Create Datasheet For Pressure TransmitterGaber AmmarNo ratings yet

- 540402diga01015 Na: 0d206-Dma-I-797-La-0001Document16 pages540402diga01015 Na: 0d206-Dma-I-797-La-0001patilrohan4444No ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- TC Tip PD 003Document1 pageTC Tip PD 003trilok corporationNo ratings yet

- PG 04Document1 pagePG 04trilok corporationNo ratings yet

- LCV 01Document4 pagesLCV 01trilok corporationNo ratings yet

- Datasheet for flow transmitterDocument2 pagesDatasheet for flow transmittertrilok corporationNo ratings yet

- VR PatelDocument23 pagesVR Pateltrilok corporationNo ratings yet

- Regeneration Section of CO Capture Plant by MEA Scrubbing With A Rate-Based ModelDocument6 pagesRegeneration Section of CO Capture Plant by MEA Scrubbing With A Rate-Based Modeltrilok corporationNo ratings yet

- Us 3486743Document7 pagesUs 3486743trilok corporationNo ratings yet

- Higee DeaeratorDocument4 pagesHigee Deaeratortrilok corporationNo ratings yet

- Fault ModelingDocument21 pagesFault ModelingRamarao ChNo ratings yet

- Literature Review On Waste Management in NigeriaDocument9 pagesLiterature Review On Waste Management in NigeriajzneaqwgfNo ratings yet

- The Brain from Inside Out Chapter 4 SummaryDocument20 pagesThe Brain from Inside Out Chapter 4 SummaryjuannnnNo ratings yet

- A Very Rare Type of NeuralgiaDocument2 pagesA Very Rare Type of NeuralgiarosaNo ratings yet

- SAP ABAP Interview Questions and AnswersDocument8 pagesSAP ABAP Interview Questions and AnswersKarthi ThirumalaisamyNo ratings yet

- INTELLISPEC SERIE V-Páginas-31-46Document16 pagesINTELLISPEC SERIE V-Páginas-31-46Antonio Valencia VillejoNo ratings yet

- ID Strategi Integrated Marketing Communication Imc Untuk Meningkatkan Loyalitas AngDocument17 pagesID Strategi Integrated Marketing Communication Imc Untuk Meningkatkan Loyalitas AngAiman AzhariNo ratings yet

- Audit Chapter 7Document5 pagesAudit Chapter 7Addi Såïñt George100% (2)

- Filed & Entered: SBN 143271 SBN 165797 SBN 259014Document8 pagesFiled & Entered: SBN 143271 SBN 165797 SBN 259014Chapter 11 DocketsNo ratings yet

- Design Report For Proposed 3storied ResidentialbuildingDocument35 pagesDesign Report For Proposed 3storied ResidentialbuildingMohamed RinosNo ratings yet

- Finite Element Analysis (FEA) Software MarketDocument3 pagesFinite Element Analysis (FEA) Software Marketsurendra choudharyNo ratings yet

- AP Poetry TermsDocument8 pagesAP Poetry TermsTEACHER BARAY LLCE ANGLAISNo ratings yet

- 32 Productivity Increase in A PeirceSmith Convert 153013Document14 pages32 Productivity Increase in A PeirceSmith Convert 153013amirlpNo ratings yet

- Hajipur Resume GVVDocument2 pagesHajipur Resume GVVRajnish JhaNo ratings yet

- Define steradian, radian, density, and luminanceDocument16 pagesDefine steradian, radian, density, and luminancesunshaniNo ratings yet

- TEFL I Course Prepares Students to Teach EnglishDocument8 pagesTEFL I Course Prepares Students to Teach EnglishErma DomosNo ratings yet

- Advantages and Disadvantages of Becoming EntrepreneurDocument2 pagesAdvantages and Disadvantages of Becoming EntrepreneurbxndNo ratings yet

- Strategic Management and Municipal Financial ReportingDocument38 pagesStrategic Management and Municipal Financial ReportingMarius BuysNo ratings yet

- Hatsun Supplier Registration RequestDocument4 pagesHatsun Supplier Registration Requestsan dipNo ratings yet

- E VTOLDocument12 pagesE VTOLsaikumar raviNo ratings yet

- The 9 Building Blocks of Business ModelsDocument3 pagesThe 9 Building Blocks of Business ModelsTobeFrankNo ratings yet

- Acoustic Emission InspectionDocument7 pagesAcoustic Emission InspectionAntonio PerezNo ratings yet

- Chapter Three: Business Plan PreparationDocument26 pagesChapter Three: Business Plan PreparationwaqoleNo ratings yet

- X-Plane Installer LogDocument3 pagesX-Plane Installer LogMarsala NistoNo ratings yet