Professional Documents

Culture Documents

NLG - Removal Installation

Uploaded by

KeilaeFrancisco ArceOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NLG - Removal Installation

Uploaded by

KeilaeFrancisco ArceCopyright:

Available Formats

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

** ON A/C ALL

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

TASK 32-41-12-000-001-A

Removal of the NLG Wheel

FIN : 2659GM , 2660GM

WARNING: MAKE SURE THAT THE GROUND SAFETY-LOCKS ARE IN POSITION ON THE LANDING GEAR.

1. Reason for the Job

Self explanatory

2. Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR SAFETY CLIP - CIRCUIT BREAKER

No specific AR WARNING NOTICE(S)

(J47548) 1 PROTECTOR NLG

(J47549) 1 ADAPTOR NLG

B. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

711 NOSE GEAR

C. Referenced Information

REFERENCE DESIGNATION

07-12-00-582-001-A Jacking for Nose Gear Wheel Change

32-00-00-481-001-A Installation of the Safety Devices on the Landing Gears

32-41-00-210-003-A Inspection/Check of the Tire Pressure

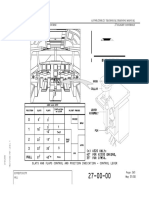

Nose Gear Wheel SHEET 1

3. Job Set-up

Subtask 32-41-12-865-050-A

A. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

121VU DUMMY CB 1GV M31

Subtask 32-41-12-865-053-A

B. Open, safety and tag this(these) circuit breaker(s):

PANEL DESIGNATION FIN LOCATION

121VU DUMMY CB 1GV M31

Subtask 32-41-12-941-050-A

C. Safety Precautions

Print Date: May 11/12 Local Time Page 1 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

(1) Put the wheel chocks in position at the main landing gear.

(2) In the cockpit, put a WARNING NOTICE(S) on the panel 400VU to tell persons not to operate the landing gear.

Subtask 32-41-12-860-050-A

D. Aircraft Maintenance Configuration

(1) Make sure that the safety devices are installed on the landing gears (Ref. AMM TASK 32-00-00-481-001) .

(2) Jacking for nose gear wheel change.

WARNING: MAKE SURE THAT THE AIRCRAFT IS STABLE AND DOES NOT MOVE DURING THE

JACKING OPERATIONS.

IF THERE IS UNWANTED MOVEMENT OF THE AIRCRAFT, THE BALL PAD CAN COME OFF

THE JACK ADAPTER AND INJURY AND/OR DAMAGE CAN OCCUR.

(a) Lift the nose gear (Ref. AMM TASK 07-12-00-582-001) .

NOTE: AIRBUS recommends that you do not do operations that can change the weight or stability of the

aircraft during jacking (gate docking, fueling/defueling, loading/unloading, etc.).

(3) Deflate the tire completely.

NOTE: If you must remove the wheel for access or inspections it is not necessary to deflate the tire if:

- the tire is in correct condition and

- the tire pressure is in the Normal Operating Range. (Ref. AMM TASK 32-41-00-210-003)

If you have not these two conditions you must deflate the tire.

4. Procedure

(Ref. Fig. Nose Gear Wheel SHEET 1)

Subtask 32-41-12-010-051-A

A. Get access

(1) Remove the screws (7) and the washers (8).

(2) Remove the hubcap (6).

Subtask 32-41-12-020-050-A

B. Removal of the NLG wheel

(1) Remove and discard the two cotter pins (4) and the two nuts (3).

(2) Remove the washers (2) and the bolts (5).

(3) Remove and retain the casing (9).

(4) Remove the axle nut (10) with the ADAPTOR NLG (J47549) .

(5) Install the PROTECTOR NLG (J47548) .

(6) Remove the wheel.

TASK 32-41-12-400-001-A

Installation of the NLG Wheel

FIN : 2659GM , 2660GM

WARNING: MAKE SURE THAT THE GROUND SAFETY-LOCKS ARE IN POSITION ON THE LANDING GEAR.

Print Date: May 11/12 Local Time Page 2 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

1. Reason for the Job

Self explanatory

2. Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific AR WARNING NOTICE(S)

No specific Torque wrench: range to between 0.20 and 3.60 m.daN (2.00 and

26.00 lbf.ft)

No specific Torque wrench: range to between 6.00 and 36.00 m.daN (50.00 and

260.00 lbf.ft)

(J47549) 1 ADAPTOR NLG

B. Consumable Materials

REFERENCE DESIGNATION

04-004* COMMON GREASES

SYNTH. ESTER BASED GREASE HIGH PRESSURE

04-022* COMMON GREASES

SYNTH. HYDROCARBON GREASE HIGH PRESSURE

04-035* COMMON GREASES

SYNTHETIC WHEEL BEARING GREASE

05-002* SPECIAL MATERIALS

PUTTY, ZINC CHROMATE GENERAL PURPOSE

11-002* CLEANING AGENTS

DRY CLEANING SOLVENT (VARSOL/WHT SPIRIT)

C. Work Zones and Access Panels

ZONE/ACCESS ZONE DESCRIPTION

711 NOSE GEAR

D. Expendable Parts

FIG.ITEM DESIGNATION IPC-CSN

4 cotter pins 32-21-13-03-060

3 nuts 32-21-13-03-070

E. Referenced Information

REFERENCE DESIGNATION

07-12-00-582-001-A Jacking for Nose Gear Wheel Change

12-14-32-614-001-A Nitrogen Filling of the Tires

32-00-00-481-001-A Installation of the Safety Devices on the Landing Gears

32-41-00-210-003-A Inspection/Check of the Tire Pressure

32-41-00-910-001-A Tire Mixability Precautions

Nose Gear Wheel SHEET 1

3. Job Set-up

(Ref. Fig. Nose Gear Wheel SHEET 1)

Subtask 32-41-12-865-051-A

A. Make sure that this(these) circuit breaker(s) is(are) open, safetied and tagged:

Print Date: May 11/12 Local Time Page 3 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

PANEL DESIGNATION FIN LOCATION

121VU DUMMY CB 1GV M31

Subtask 32-41-12-865-054-A

B. Make sure that this(these) circuit breaker(s) is(are) open, safetied and tagged:

PANEL DESIGNATION FIN LOCATION

121VU DUMMY CB 1GV M31

Subtask 32-41-12-860-052-A

C. Aircraft Maintenance Configuration

(1) Make sure that the wheel chocks are in position at the main landing gear.

(2) Make sure that the NLG is in the correct configuration for the wheel change (Ref. AMM TASK 07-12-00-582-

001) .

(3) Make sure that the WARNING NOTICE(S) is on the panel 400VU to tell persons not to operate the landing gear.

(4) Make sure that the safety devices are installed on the landing gear (Ref. AMM TASK 32-00-00-481-001) .

4. Procedure

(Ref. Fig. Nose Gear Wheel SHEET 1)

NOTE: If the wheel has a pressure-sensor seal cap, make sure that the seal cap is correctly installed and safetied with a

nut and a cotter pin.

NOTE: If the wheel has a Tire Pressure Indicating System (TPIS), the tie-bolt balance weight must be installed 180

degrees from the TPIS sensor holder.

Subtask 32-41-12-210-054-A

A. Tires of different type

(1) Obey the tire mixability precautions . (Ref. AMM TASK 32-41-00-910-001)

Subtask 32-41-12-420-053-A

B. Installation of the NLG Wheel

CAUTION: MAKE SURE THAT THE GREASE USED FOR THE AXLE SLEEVE IS THE SAME AS THE GREASE

USED FOR THE BEARINGS (CONE AND CAGE). IF YOU USE A DIFFERENT GREASE, YOU CAN

CAUSE DAMAGE TO THE BEARINGS.

(1) Preparation for installation

(a) Make sure (if the tire mixability is not permitted) that the wheel for installation has the same type of tire

(radial or cross-ply) as the other wheel on the NLG.

(b) Make sure that the retaining ring (11) is in its housing.

(c) Clean the axle sleeve (1) with Material No. 11-002* (CLEANING AGENTS) and dry it with filtered

compressed air.

(d) Make sure that the axle sleeve (1) is in the correct condition.

(e) Apply a light coat of Material No. 04-004* (COMMON GREASES) or Material No. 04-022* (COMMON

GREASES) or Material No. 04-035* (COMMON GREASES) on the axle sleeve (1) .

Print Date: May 11/12 Local Time Page 4 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

NOTE: You can use Material No. 04-004 as an alternative to Material No. 04-022 or to Material No. 04-

035. It is not permitted to mix Material No. 04-004 with Material No. 04-022 or with Material No. 04-

035. It is necessary to clean and degrease the parts before you use an alternative grease.

(2) Installation of the wheel

(a) Clean the inner surface of the wheel bearings (surface that touches the axle). Do not apply grease on these

surfaces.

(b) Install the wheel, with the valve outboard, with a handling tool.

(c) Remove the PROTECTOR NLG (J47548)

(d) Apply a light coat of Material No. 04-004* (COMMON GREASES) or Material No. 04-022* (COMMON

GREASES) or Material No. 04-035* (COMMON GREASES) on the axle.

(e) Install the axle nut (10).

(f) Turn the wheel in the direction of the axle nut rotation and TORQUE the axle nut (10) to 21.80 m.daN

(160.77 lbf.ft) with the ADAPTOR NLG (J47549) .

(g) Prevent rotation of the wheel and loosen the axle nut (10).

(h) Turn the wheel in the direction of the axle nut rotation and TORQUE the axle nut (10) to 10.85 m.daN

(80.01 lbf.ft).

(i) Tighten the axle nut (10) until the holes for the bolts (5) are aligned.

(j) Turn the wheel and make sure that the wheel is installed correctly.

(k) Install the casing (9).

(l) Install the bolts (5), the washers (2) and the new IPC-CSN (32-21-13-03-070) nuts (3) .

(m) TORQUE the nuts (3) to between 0.4 and 0.45 m.daN (35.40 and 39.82 lbf.in) and safety them with the

new IPC-CSN (32-21-13-03-060) cotter pins (4) .

Subtask 32-41-12-410-051-A

C. Close access

(1) Put the hubcap (6) in position.

(2) Apply a thin layer of Material No. 05-002* (SPECIAL MATERIALS) to the screws (7).

(3) Install the screws (7) and the washers (8).

(4) TORQUE the screws (7) to between 0.4 and 0.51 m.daN (35.40 and 45.13 lbf.in).

NOTE: The hubcap attachment holes have screw-lock inserts. It is not necessary to install lockwire on the

screws (7).

Subtask 32-41-12-860-051-A

D. Aircraft Maintenance Configuration

(1) Inflate the tire to the unloaded pressure (Ref. AMM TASK 12-14-32-614-001) .

(2) Lower the aircraft on its wheels (Ref. AMM TASK 07-12-00-582-001) .

(3) Make sure that the pressure of the tire is correct (Ref. AMM TASK 32-41-00-210-003) .

Subtask 32-41-12-865-052-A

E. Make sure that this(these) circuit breaker(s) is(are) closed:

PANEL DESIGNATION FIN LOCATION

Print Date: May 11/12 Local Time Page 5 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

121VU DUMMY CB 1GV M31

5. Close-up

Subtask 32-41-12-942-051-A

A. Removal of the Equipment

(1) Make sure that the work area is clean and clear of tool(s) and other items.

(2) Remove the warning notice(s).

TASK 32-41-12-000-002-A

Removal of the Axle Sleeve

1. Reason for the Job

Self explanatory

2. Job Set-up Information

A. Referenced Information

REFERENCE DESIGNATION

32-41-12-000-001-A Removal of the NLG Wheel

Axle Sleeve SHEET 1

3. Job Set-up

Subtask 32-41-12-010-050-A

A. Get access

(1) Remove the related landing gear wheel (Ref. AMM TASK 32-41-12-000-001) .

4. Procedure

(Ref. Fig. Axle Sleeve SHEET 1)

Subtask 32-41-12-020-051-A

A. Removal of the Axle Sleeve

(1) Remove the retaining ring (3).

(2) Remove the axle sleeve (2).

TASK 32-41-12-400-002-A

Installation of the Axle Sleeve

1. Reason for the Job

Self explanatory

2. Job Set-up Information

A. Consumable Materials

REFERENCE DESIGNATION

04-022* COMMON GREASES

SYNTH. HYDROCARBON GREASE HIGH PRESSURE

11-002* CLEANING AGENTS

DRY CLEANING SOLVENT (VARSOL/WHT SPIRIT)

B. Referenced Information

Print Date: May 11/12 Local Time Page 6 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

REFERENCE DESIGNATION

32-41-12-400-001-A Installation of the NLG Wheel

Axle Sleeve SHEET 1

3. Job Set-up

Subtask 32-41-12-640-052-A

A. Preparation for Installation

(1) Clean the axle (1) with Material No. 11-002* (CLEANING AGENTS) . Dry it with filtered compressed air .

(2) Lightly lubricate the axle (1) and the axle protective sleeve (2) with Material No. 04-022* (COMMON

GREASES) .

4. Procedure

(Ref. Fig. Axle Sleeve SHEET 1)

Subtask 32-41-12-420-051-A

A. Installation of the Axle Sleeve

(1) Install the axle sleeve (2).

(2) Install the retaining ring (3).

5. Close-up

Subtask 32-41-12-410-050-A

A. Close access

(1) Install the related wheel (Ref. AMM TASK 32-41-12-400-001) .

(2) Make sure that the work area is clean and clear of tool(s) and other items.

Figure 32-41-12-991-00100-A / SHEET 1 - Nose Gear Wheel

Figure 32-41-12-991-00200-A / SHEET 1 - Axle Sleeve

Print Date: May 11/12 Local Time Page 7 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

2660GM

2659GM

N_MM_324112_4_AAM0_01_00

Figure 32-41-12-991-00100-04-A / SHEET 1 - Nose Gear Wheel

** ON A/C ALL

Print Date: May 11/12 Local Time Page 8 of 9

Customer : TAI Manual: AMM

Type : A318/A319/A320/A321 Selected effectivity: 403-403

Rev. Date : Feb 01/12

32-41-12 PB 401 CONF 00 - WHEEL - NLG - REMOVAL/INSTALLATION

2660GM

2659GM

N_MM_324112_4_BAM0_01_00

Figure 32-41-12-991-00200-04-A / SHEET 1 - Axle Sleeve

** ON A/C ALL

Print Date: May 11/12 Local Time Page 9 of 9

You might also like

- Intls of NLGDocument11 pagesIntls of NLGje_carD23No ratings yet

- Wheel CHKDocument24 pagesWheel CHKvietha1990No ratings yet

- JCP TitleDocument14 pagesJCP Titlebilly100% (1)

- V2500 Fan Cowl Lock LatchesDocument19 pagesV2500 Fan Cowl Lock LatchesKevin John PangilinanNo ratings yet

- 32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelDocument40 pages32-41-11-000-006-A Removal of The MLG Wheel 32-41-11-400-006-A Installation of The MLG WheelalfonsofelipesaraviaNo ratings yet

- Engine ControlDocument73 pagesEngine ControlKarthik ReddyNo ratings yet

- Engine Variant: V2527-A5Document12 pagesEngine Variant: V2527-A5Kartika Ningtyas100% (1)

- Water TankDocument10 pagesWater TankRameswar PradhanNo ratings yet

- Amm Quick A320Document9 pagesAmm Quick A320elhamdi710% (1)

- Offwing Alide InstallDocument16 pagesOffwing Alide InstallAndreea MăgureanuNo ratings yet

- Brake InspectionDocument5 pagesBrake InspectionbillyNo ratings yet

- 71-00-00-710-004-B - Engine Manual StartDocument9 pages71-00-00-710-004-B - Engine Manual StartEder LucianoNo ratings yet

- FAA 2012 0721 0009 - Attachment - 5Document119 pagesFAA 2012 0721 0009 - Attachment - 5CHIMONo ratings yet

- Combined Reset Tables Mod6Document275 pagesCombined Reset Tables Mod6Sallak IdrisNo ratings yet

- A319/ A320/ A321 Technical Training ManualDocument58 pagesA319/ A320/ A321 Technical Training ManualEnes ArslanNo ratings yet

- A319... 321 - Ata 46 - Information System - B2 - eDocument33 pagesA319... 321 - Ata 46 - Information System - B2 - esuper_jaizNo ratings yet

- 51-49-00 - Description - Standard Torque ValuesDocument14 pages51-49-00 - Description - Standard Torque ValuesMarijaNo ratings yet

- A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 72-21-20-210-802-A - Visual Inspection of The Fan BladeDocument30 pagesA318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 72-21-20-210-802-A - Visual Inspection of The Fan Bladesaid PalaoNo ratings yet

- 14WN Test 2Document7 pages14WN Test 2Ahsan AvioniqueNo ratings yet

- Ch. 23 - CommunicationDocument4 pagesCh. 23 - CommunicationmohammadnorouzzadehNo ratings yet

- A320 - SRM - 01-Feb-2020 - TASK 53-00-11-283-005 - Allowable Damage Limits For Dents - GenericDocument6 pagesA320 - SRM - 01-Feb-2020 - TASK 53-00-11-283-005 - Allowable Damage Limits For Dents - GenericJivendra KumarNo ratings yet

- A318 - ATA 38 - WATER & WASTE - Diff To A320 - L3Document13 pagesA318 - ATA 38 - WATER & WASTE - Diff To A320 - L3super_jaizNo ratings yet

- A320 - SRM - 01-Nov-2018 - TASK 55-14-11-300-002 - Zone 01 - Flush Repair PDFDocument5 pagesA320 - SRM - 01-Nov-2018 - TASK 55-14-11-300-002 - Zone 01 - Flush Repair PDFichigo_bleach00No ratings yet

- A319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDocument3 pagesA319/A320/A321 Technical Training Manual 27 Flight Controls Mechanics / Electrics & Avionics CourseDavid OwenNo ratings yet

- A319/A320/A321 ECS - System Schematic: Air Conditioning PneumaticDocument1 pageA319/A320/A321 ECS - System Schematic: Air Conditioning PneumaticvictormaviNo ratings yet

- EfcsDocument4 pagesEfcsJai DeepNo ratings yet

- Advance Trim Balance LEAP 1ADocument7 pagesAdvance Trim Balance LEAP 1AAbhishekprasad royNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument53 pagesA318/A319/A320/A321: Service BulletinGuy Ulrich DouoguiNo ratings yet

- Isi-45.00.00039 01dec2017.p6Document40 pagesIsi-45.00.00039 01dec2017.p6sithuNo ratings yet

- Jet Engine MCQDocument9 pagesJet Engine MCQPrem MauryaNo ratings yet

- Product Overview: Naples, May 25th 2011Document39 pagesProduct Overview: Naples, May 25th 2011Mohd Shahril Abd LatiffNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument692 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Toliss Airbus A321 Neo - Aircraft Manual: Toliss Aeronautical Simulation SolutionsDocument11 pagesToliss Airbus A321 Neo - Aircraft Manual: Toliss Aeronautical Simulation SolutionsQuandale DingleNo ratings yet

- Skin Heat ExchangerDocument1 pageSkin Heat ExchangerAhmed El MahdyNo ratings yet

- How Many Fire/overheat Detectors Does The Engine Fire/overheat Detection System Comprise Of? (Level 2)Document33 pagesHow Many Fire/overheat Detectors Does The Engine Fire/overheat Detection System Comprise Of? (Level 2)Phạm Hà TiếnNo ratings yet

- AIRBUS A320 Series Aircraft Filtration ProductsDocument2 pagesAIRBUS A320 Series Aircraft Filtration ProductsDunia LainNo ratings yet

- (Indigo) Freshers Ame Job Guidance by Aviator-ArifDocument55 pages(Indigo) Freshers Ame Job Guidance by Aviator-ArifShivan AadithyaNo ratings yet

- 各系统彩图Document28 pages各系统彩图zs100% (1)

- 24 Electrical PowerDocument164 pages24 Electrical PowermarkNo ratings yet

- Boeing 737 Parts Inventory Ep Tij MX 2Document6 pagesBoeing 737 Parts Inventory Ep Tij MX 2Bobby Robert MaengkomNo ratings yet

- ATA 05 Limits Maintenance ChecksDocument51 pagesATA 05 Limits Maintenance ChecksRafael Nuñez100% (1)

- Computer Reset AirbusDocument10 pagesComputer Reset AirbusAlexander Aguirre Calderón100% (1)

- GVI Brake Units - 32-40-00-210-801-A PDFDocument4 pagesGVI Brake Units - 32-40-00-210-801-A PDFpannNo ratings yet

- List Boeing 737Document1 pageList Boeing 737sssavNo ratings yet

- Single Aisle Technical Training Manual RAMP & TRANSIT COURSE - M03 (CFM 56) (Level 2&3) Equipment/FurnishingsDocument60 pagesSingle Aisle Technical Training Manual RAMP & TRANSIT COURSE - M03 (CFM 56) (Level 2&3) Equipment/Furnishingsmarshall100% (1)

- CB by Fin: Component Location ManualDocument13 pagesCB by Fin: Component Location ManualvinayNo ratings yet

- A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 01 GeneralDocument97 pagesA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 01 GeneralJimmyNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument58 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- Airbus A318/A319/A320/A321 General Familiarization Training: (CFM56 & IAE V2500 & PW1100G & CFM LEAP-1A)Document2 pagesAirbus A318/A319/A320/A321 General Familiarization Training: (CFM56 & IAE V2500 & PW1100G & CFM LEAP-1A)John Emeil Llemit0% (1)

- Ecam Bscu Sys 2 Fault Airbus TfuDocument3 pagesEcam Bscu Sys 2 Fault Airbus TfuEduardo MercadejasNo ratings yet

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) GeneralDocument8 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) Generalripan thakurNo ratings yet

- AMM - A318, A319, A320, A321 - PGT - Rev. Num 34 - 01-Aug-2021 - 71-11-00-000-041-A - Removal of The Air Intake Cowl. MSN 05879Document1 pageAMM - A318, A319, A320, A321 - PGT - Rev. Num 34 - 01-Aug-2021 - 71-11-00-000-041-A - Removal of The Air Intake Cowl. MSN 05879hamdNo ratings yet

- Pushback and Towing of Aircraft IttDocument5 pagesPushback and Towing of Aircraft IttfpcaeroinsNo ratings yet

- A320 - 28 Fuel System - GFC-1Document39 pagesA320 - 28 Fuel System - GFC-1belinda koyaiyeNo ratings yet

- Erj 170-190 Mmel Faa Rev 9Document139 pagesErj 170-190 Mmel Faa Rev 9mh.hiliryNo ratings yet

- MLG - Removal InstallationDocument14 pagesMLG - Removal InstallationKeilaeFrancisco ArceNo ratings yet

- On A/C All: Reference Qty DesignationDocument6 pagesOn A/C All: Reference Qty DesignationMak OrNo ratings yet

- Winsheld PDFDocument34 pagesWinsheld PDFAnonymous FAa4A3akdNo ratings yet

- 32-41!11!400-801-A - Installation of The MLG WheelDocument10 pages32-41!11!400-801-A - Installation of The MLG Wheelrüşdi işlerNo ratings yet

- SUBJECT BRAKE (2641GM, 2642GM, 2643GM, 2644GM) - REMOVAL Comments: A、ReferencesDocument4 pagesSUBJECT BRAKE (2641GM, 2642GM, 2643GM, 2644GM) - REMOVAL Comments: A、ReferencesSuman BajracharyaNo ratings yet

- Towing and TaxiingDocument82 pagesTowing and TaxiingKeilaeFrancisco ArceNo ratings yet

- Tire Pressure Inspection CheckDocument4 pagesTire Pressure Inspection CheckKeilaeFrancisco ArceNo ratings yet

- APU Shutdown by Batteries (131-9 (A) )Document1 pageAPU Shutdown by Batteries (131-9 (A) )KeilaeFrancisco ArceNo ratings yet

- A320 Flight Deck and Systems BriefingDocument223 pagesA320 Flight Deck and Systems Briefingpontoo100% (6)

- APU Start by External PowerDocument6 pagesAPU Start by External PowerKeilaeFrancisco ArceNo ratings yet

- 1neo Ata - 70Document352 pages1neo Ata - 70KeilaeFrancisco Arce100% (1)

- MLG - Removal InstallationDocument14 pagesMLG - Removal InstallationKeilaeFrancisco ArceNo ratings yet

- Single Aisle Technical Training Manual T1 (CFM 56) (LVL 2&3) Auto FlightDocument30 pagesSingle Aisle Technical Training Manual T1 (CFM 56) (LVL 2&3) Auto FlightBùi Đức XuânNo ratings yet

- Ata 100Document109 pagesAta 100KeilaeFrancisco ArceNo ratings yet

- Single Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) CommunicationsDocument120 pagesSingle Aisle Technical Training Manual T1 (IAE V2500) (LVL 2&3) CommunicationsKeilaeFrancisco ArceNo ratings yet

- Console A320Document1 pageConsole A320KeilaeFrancisco ArceNo ratings yet

- EE205 DC Machines N TransformersDocument2 pagesEE205 DC Machines N TransformersAshik AhmedNo ratings yet

- Boiler maintenance typesDocument9 pagesBoiler maintenance typesMd Aamir ImamNo ratings yet

- 3 Phase Auto Change Over SwitchDocument23 pages3 Phase Auto Change Over Switchajaykeshav100% (3)

- Variable displacement pumps technical dataDocument1 pageVariable displacement pumps technical dataVipin GuptaNo ratings yet

- 2017 H2O Catalog Low ResDocument44 pages2017 H2O Catalog Low ResDarko MarjanovicNo ratings yet

- JLR Diagnosis and Testing 1Document14 pagesJLR Diagnosis and Testing 1Richard Andrianjaka LuckyNo ratings yet

- EM2 - Final - Lecture 06ADocument16 pagesEM2 - Final - Lecture 06AShoaib KhanNo ratings yet

- (After Installation) : Tikaria Expansion Project, ACC Checklist For Tower CraneDocument2 pages(After Installation) : Tikaria Expansion Project, ACC Checklist For Tower CraneRajuNo ratings yet

- Electrical Design Machine 1 Final - Asilo Justine Troy D.Document14 pagesElectrical Design Machine 1 Final - Asilo Justine Troy D.Hok HokNo ratings yet

- Hydraulic Ver (Eng) Yoshida KaizoDocument78 pagesHydraulic Ver (Eng) Yoshida KaizoRoyen83% (6)

- Ma-3643 (Rev. 0) - Control Panel For Goggle Valve ND 2135 MMDocument15 pagesMa-3643 (Rev. 0) - Control Panel For Goggle Valve ND 2135 MMamanNo ratings yet

- Seal Kit Catalog August 2019Document78 pagesSeal Kit Catalog August 2019Tres Generaciones RomeroNo ratings yet

- SSP+27+Octavia+1 4+l+engine+and+gearbox+002 PDFDocument42 pagesSSP+27+Octavia+1 4+l+engine+and+gearbox+002 PDFAbhiboy Abhi SagarNo ratings yet

- Paint Booth Design Review Checklist: Means of EgressDocument6 pagesPaint Booth Design Review Checklist: Means of EgressFranciscoVicenteNo ratings yet

- Butterfly Valve User ManualDocument10 pagesButterfly Valve User ManualEduardoAscencioNo ratings yet

- MANN & HUMMEL Heavy Segment Parts List-1Document8 pagesMANN & HUMMEL Heavy Segment Parts List-1Tarun50% (2)

- Studies On The Benefits of Using Linear Motors Insted To Ball Screws Used in Drive of The Machine ToolsDocument8 pagesStudies On The Benefits of Using Linear Motors Insted To Ball Screws Used in Drive of The Machine ToolsVASILIINo ratings yet

- Citroen Bosch EDC16 PDFDocument104 pagesCitroen Bosch EDC16 PDFNenad Chip Tuning Aleksic100% (2)

- FMECA Worksheet: No. Functional Failures Failure Modes Causes EffectDocument15 pagesFMECA Worksheet: No. Functional Failures Failure Modes Causes EffectBarathNo ratings yet

- Caterpillar Gas EngineDocument4 pagesCaterpillar Gas Enginecandra100% (1)

- SVM 05036 2Document78 pagesSVM 05036 2calvin.bloodaxe4478No ratings yet

- MCR (2019 Version2)Document8 pagesMCR (2019 Version2)scribdumpreeNo ratings yet

- Refrigeration Lab ReportDocument27 pagesRefrigeration Lab ReportLeejat Pradhan78% (27)

- Practical Study of Borewell PumpDocument6 pagesPractical Study of Borewell PumpGray FullbusterNo ratings yet

- White or Grey Smoke Fault TracingDocument4 pagesWhite or Grey Smoke Fault TracingGeorgeNo ratings yet

- Parts IdentificationDocument6 pagesParts IdentificationHariyanto oknesNo ratings yet

- Hyster C002 S40C-P Military Service & Parts ManualDocument284 pagesHyster C002 S40C-P Military Service & Parts ManualÁrpád AndrisNo ratings yet

- LM 75 - Partes - 4Document17 pagesLM 75 - Partes - 4Raul VergarayNo ratings yet

- MAR 851 - Advanced Marine Engines & Power Plants NEWDocument71 pagesMAR 851 - Advanced Marine Engines & Power Plants NEWViolet PellyNo ratings yet

- 913E (Stage IIIA) - CumminsDocument2 pages913E (Stage IIIA) - CumminsMichael Wang XinbinNo ratings yet