Professional Documents

Culture Documents

A Ir E: Delta Series™ Filters

Uploaded by

giovanni1912Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A Ir E: Delta Series™ Filters

Uploaded by

giovanni1912Copyright:

Available Formats

e

ir

ua

FRL Products and Accessories

Delta Series™ Filters

e

Water Separators 60

3.0 Micron Particulate Filter 61

pn

1.0 Micron Coarse Grade Coalescing Filter 62

0.3 Micron Fine Grade Coalescing Filter 63

0.01 Ultra Fine Grade Coalescing Filter 64

Adsorbing Grade Filter 65

Dimensions 66

Options and accessories 67

FRLs AND ACCESSORIES 59

Numatics Delta Series™ Filters

WATER SEPARATOR

e

F900X Series

Application

The water separator is an ideal solution where water contamination is pre-

sent. Water can damage pneumatic components, degrade your final product,

and cause valves and cylinders to stick.

ir

The F900X series utilizes an internal spinner to remove large quantities of

contamination by centrifugal action. Water, debris, and rust are spun outward

to the inside diameter of the bowl. Gravity then sends the contaminant to the

bottom of the bowl for discharge.

Recommended Uses

• Bulk liquid and solid contamination removal

• Downstream from compressor/aftercoolers

• Protection for coalescing elements from large liquid loading

• Refrigerated compressed air dryers

Specifications

Maximum temperature: 175ºF (80ºC)

ua Maximum pressure: 250 PSIG (17 bar)

Materials of Construction

Body: aluminum Drain: brass Baffle: polyamide

Seals: Viton®

Flow Rates

SCFM based on 60 PSI inlet with .75 PSID SCFM based on 100 PSI inlet with .75 PSID

F900X-12 pictured

SCFM dm3/s SCFM dm3/s

F900X-02 14 6.6 F900X-02 18 8.5

F900X-04 38 18 F900X-04 58 27

F900X-06 76 36 F900X-06 117 55

F900X-08 114 54 F900X-08 176 83

F900X-12 230 109 F900X-12 353 167

F900X-16 460 217 F900X-16 706 333

F900X-24 843 398 F900X-24 1294 611

e

NOTE: Maximum water removal efficiency occurs at stated flows

How to Order

Options (see pg 67):

F 900 X - 16 BN A = auto drain

B = mounting brackets

N = electronic drain valve

Port Size:

pn

Type: 02 = 1/4

Model: X = water

F = Filter 04 = 1/2

separator 06 = 3/4

Series: 08 = 1

900 = Delta 12 = 1 1/2

Threads: 16 = 2

Series™ - = NPTF 24 = 3

G = G tap (BSPP)

NEED MORE PARTS AND INFORMATION?

• See page 119 for information on ordering replacement filters, bowls, etc.

• See page 101 for more information on available options.

60 FRLs AND ACCESSORIES

Numatics Delta Series™ Filters

3.0 MICRONPARTICULATE FILTER

e

ANSI SYMBOL

F900G Series

Application

The particulate filter is designed for heavy dirt loading. Large particles such

as rust, desiccant dust, and debris will rob the life of your pneumatic compo-

nents. Contaminant is generated from desiccant type air dryers, older carbon

ir

steel pipes, and from the intake of a compressor.

The F900G series features a pleated design - folds of cellulose composite

media which provide a large amount of surface area and extend the life of

the element. When air flows - from the outside of the element to the inside -

the particles are trapped in the space between the filter bowl and the ele-

ment.

Recommended Uses

• Solid bulk contamination removal

• Afterfilter to a desiccant dryer

• Protection for coalescers in heavy aerosol applications

• 3 micron particle removal in 'dry' systems

Specifications

ua Options none

Port all

A

1/4-1

A G

1 1/4-3 all

N

all

AG

1/4-1

AG GN

1 1/4-3 all

Max. press. PSIG (bar) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17)

Max. temp. ºF (ºC) 275 (135) 150 (66) 250 (121) 175 (80) 130 (55) 150 (66) 175 (80) 130 (55)

Materials of Construction

Body: aluminum Drain: brass End caps:

Seals: Viton® Tie rod: brass anodized aluminum

Flow Rates

SCFM based on 60 PSI inlet with 1.5 PSID SCFM based on 100 PSI inlet with 1.5 PSID

SCFM dm3/s SCFM dm3/s

F900G-02 70 33 F900G-02 107 51

F900G-03 70 33 F900G-03 107 51

F900G-04 70 33 F900G-04 107 51

e

F900G-06 107 51 F900G-06 165 78

F900G-08 129 61 F900G-08 198 93

F900G-08X 172 81 F900G-08X 264 125

F900G-10 322 152 F900G-10 495 234

F900G-12 387 183 F900G-12 594 280

F900G-16 752 355 F900G-16 1155 545

F900G-20 967 456 F900G-20 1485 701

F900G-24 1209 571 F900G-24 1856 876

F900G-08G pictured

pn

How to Order

Options (see pg 67):

F 900 G - 04 AG A = auto drain

B = mounting brackets

G = differential pressure gauge

Port Size: N = electronic drain valve

Element: 02 = 1/4

Model: G = 3.0 micron 03 = 3/8

F = Filter 04 = 1/2

06 = 3/4

Series: 08 = 1

900 = Delta Threads: 08X = 1 high flow

Series™ - = NPTF 10 = 1 1/4

G = BSPP 12 = 1 1/2

16 = 2

20 = 2 1/2

24 = 3

NEED MORE PARTS AND INFORMATION?

• See page 119 for information on ordering replacement filters, bowls, etc.

• See page 101 for more information on available options.

FRLs AND ACCESSORIES 61

Numatics Delta Series™ Filters

1.0 MICRON COARSE COALESCER

e

ANSI SYMBOL

F900H Series

Application

The coarse coalescing filter is utilized when low pressure drop or crude separa-

tion is required. The coarse filter element is preferred in low pressure and vacu-

um application so that the efficiency of the compressor or pump is not sacrificed.

ir

Also, the coalescing element will take out crude amounts of large liquid oil and

water particles, specifically downstream of a compressor to protect a dryer.

The F900H features a unique vacuum-formed process. It utilizes micro-glass

fibers in raw form to create a seamless, depth-loading media. Combined with a

rigid fiber-coating epoxy, the filter element has great strength, high efficiency, and

superior life.

Recommended Uses

• Mainline plant filtration

• Prefilter to refrigerated air dryer

• 1 micron particle removal in 'dry' systems

• Heavy oil concentration removal

Specifications

ua Options none

Port

Max. press. PSIG (bar)

all

A

1/4-1

250 (17) 250 (17)

A G

1 1/4-3 all

N

all

AG

1/4-1

250 (17) 250 (17) 250 (17) 250 (17)

AG GN

1 1/4-3 all

250 (17) 250 (17)

Max. temp. ºF (ºC) 275 (135) 150 (66) 250 (121) 175 (80) 130 (55) 150 (66) 175 (80) 130 (55)

Materials of Construction

Body: aluminum Drain: brass End caps:

Seals: Viton® Tie rod: brass anodized aluminum

Optional Internal Pleated Prefilter

Numatics Delta Series™ filters are premium quality filters which include an

optional 3.0 micron, internal pleated prefilter. This prefilter provides protec-

tion for the fine borosilicate fibers by removing over 99% of 3.0 micron and

larger particles, extending the life of the filter element.

Flow Rates

SCFM based on 60 PSI inlet with 1.5 PSID SCFM based on 100 PSI inlet with 1.5 PSID

e

SCFM dm3/s SCFM dm3/s

F900H-02 68 32 F900H-02 104 49

F900H-03 68 32 F900H-03 104 49

F900H-04 68 32 F900H-04 104 49

F900H-06 104 49 F900H-06 160 76

F900H-08 125 59 F900H-08 192 91

F900H-08X 167 79 F900H-08X 256 121

F900H-10 313 148 F900H-10 480 227

F900H-08G pictured F900H-12 375 177 F900H-12 576 272

pn

F900H-16 729 344 F900H-16 1120 529

F900H-20 938 443 F900H-20 1440 680

F900H-24 1172 553 F900H-24 1800 850

How to Order

Options (see pg 67):

F 900 H - 04 AG A = auto drain

B = mounting brackets

D = internal pleated prefilter

Port Size: G = differential pressure gauge

Element: 02 = 1/4 N = electronic drain valve

Model: H = 1.0 micron 03 = 3/8

F = Filter 04 = 1/2

Series: 06 = 3/4

900 = Delta 08 = 1

Series™ Threads: 08X = 1 high flow

- = NPTF 10 = 1 1/4

G = BSPP 12 = 1 1/2

16 = 2

20 = 2 1/2

24 = 3

NEED MORE PARTS AND INFORMATION?

• See page 119 for information on ordering replacement filters, bowls, etc.

• See page 101 for more information on available options.

62 FRLs AND ACCESSORIES

Numatics Delta Series™ Filters

0.3 MICRON FINE COALESCER

e

ANSI SYMBOL

F900D Series

Application

The fine coalescing filter is utilized when clean air is required and longer

component life is desired. It is recommend in most point-of-use applications

for industrial use. Also, the fine coalescer removes small particles of oil,

ir

water, and rust that can create problems in painting and coating processes.

The F900D features a unique vacuum-formed process. It utilizes micro-glass

fibers in raw form to create a seamless, depth-loading media. Combined with

a rigid fiber-coating epoxy, the filter element has great strength, high efficien-

cy, and superior life.

Recommended Uses

• Paint spraying

• Pneumatic tools and instrumentation

• Robotics

• 0.3 micron particle removal in 'dry' systems

• Moderate oil concentration removal

Specifications

ua Options none

Port

Max. press. PSIG (bar)

all

A

1/4-1

250 (17) 250 (17)

A G

1 1/4-3 all

N

all

AG

1/4-1

250 (17) 250 (17) 250 (17) 250 (17)

AG GN

1 1/4-3 all

250 (17) 250 (17)

Max. temp. ºF (ºC) 275 (135) 150 (66) 250 (121) 175 (80) 130 (55) 150 (66) 175 (80) 130 (55)

Materials of Construction

Body: aluminum Drain: brass End caps:

Seals: Viton® Tie rod: brass anodized aluminum

Optional Internal Pleated Prefilter

Numatics Delta Series™ filters are premium quality filters which include an

optional 3.0 micron, internal pleated prefilter. This prefilter provides protec-

tion for the fine borosilicate fibers by removing over 99% of 3.0 micron and

larger particles, extending the life of the filter element.

Flow Rates

SCFM based on 60 PSI inlet with 1.5 PSID SCFM based on 100 PSI inlet with 1.5 PSID

e

SCFM dm3/s SCFM dm3/s

F900D-02 42 20 F900D-02 65 31

F900D-03 42 20 F900D-03 65 31

F900D-04 42 20 F900D-04 65 31

F900D-06 65 31 F900D-06 100 47

F900D-08 78 37 F900D-08 120 57

F900D-08X 104 49 F900D-08X 160 76

F900D-10 195 92 F900D-10 300 142

F900D-08G pictured

F900D-12 234 110 F900D-12 360 170

pn

F900D-16 456 215 F900D-16 700 330

F900D-20 586 277 F900D-20 900 425

F900D-24 733 346 F900D-24 1125 531

How to Order

Options (see pg 67):

F 900 D - 16 BN A = auto drain

B = mounting brackets

D = internal pleated prefilter

Port Size: G = differential pressure gauge

Element: 02 = 1/4

Model: N = electronic drain valve

D = 0.3 03 = 3/8

F = Filter micron 04 = 1/2

element 06 = 3/4

Series: 08 = 1

900 = Delta Threads: 08X = 1 high flow

Series™ - = NPTF 10 = 1 1/4

G = G tap (BSPP) 12 = 1 1/2

16 = 2

20 = 2 1/2

24 = 3

NEED MORE PARTS AND INFORMATION?

• See page 119 for information on ordering replacement filters, bowls, etc.

• See page 101 for more information on available options.

FRLs AND ACCESSORIES 63

Numatics Delta Series™ Filters

0.01 MICRONULTRA FINECOALESCER

e

ANSI SYMBOL

F900E Series

Application

The ultra fine coalescing filter is ideal where critically clean air is needed and

pressure drop is not a concern. It is a polishing filter to clean up any remains

of particles or oil that are left over from the compressor room filtration. It is

ir

mainly a point-of-use filter that is targeted specifically for critical processes. It

is also used to protect and extend the life of membrane filters.

The F900E features a unique vacuum-formed process. It utilizes micro-glass

fibers in raw form to create a seamless, depth-loading media. Combined with

a rigid fiber-coating epoxy, the filter element has great strength, high efficien-

cy, and superior life.

Recommended Uses

• Blow molding plastics

• Semiconductor packaging

• Critical instrumentation

• 0.01 micron particle removal in 'dry' systems

• Low oil concentration removal

Specifications

ua Options none

Port all

A

1/4-1

A G

1 1/4-3 all

N

all

AG

1/4-1

AG GN

1 1/4-3 all

Max. press. PSIG (bar) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17) 250 (17)

Max. temp. ºF (ºC) 275 (135) 150 (66) 250 (121) 175 (80) 130 (55) 150 (66) 175 (80) 130 (55)

Materials of Construction

Body: aluminum Drain: brass End caps:

Seals: Viton® Tie rod: brass anodized aluminum

Optional Internal Pleated Prefilter

Numatics Delta Series™ filters are premium quality filters which include an

optional 3.0 micron, internal pleated prefilter. This prefilter provides protec-

tion for the fine borosilicate fibers by removing over 99% of 3.0 micron and

larger particles, extending the life of the filter element.

Flow Rates

e

SCFM based on 60 PSI inlet with 1.5 PSID SCFM based on 100 PSI inlet with 1.5 PSID

SCFM dm3/s SCFM dm3/s

F900E-02 25 12 F900E-02 39 18

F900E-03 25 12 F900E-03 39 18

F900E-04 25 12 F900E-04 39 18

F900E-06 39 18 F900E-06 60 28

F900E-08 47 22 F900E-08 72 34

F900E-08X 63 30 F900E-08X 96 45

F900E-08G pictured F900E-10 117 55 F900E-10 180 85

pn

F900E-12 141 67 F900E-12 216 102

F900E-16 274 129 F900E-16 420 198

F900E-20 352 166 F900E-20 540 255

F900E-24 440 208 F900E-24 675 319

How to Order

Options (see pg 67):

F 900 E - 24 AB A = auto drain

B = mounting brackets

D = internal pleated prefilter

Port Size: G = differential pressure gauge

Element: 02 = 1/4

Model: N = electronic drain valve

E = 0.01 03 = 3/8

F = Filter micron 04 = 1/2

element 06 = 3/4

Series: 08 = 1

900 = Delta Threads: 08X = 1 high flow

Series™ - = NPTF 10 = 1 1/4

G = G tap (BSPP) 12 = 1 1/2

16 = 2

20 = 2 1/2

24 = 3

NEED MORE PARTS AND INFORMATION?

• See page 119 for information on ordering replacement filters, bowls, etc.

• See page 101 for more information on available options.

64 FRLs AND ACCESSORIES

Numatics Delta Series™ Filters

ADSORBING GRADE FILTER

e

F900F Series

Application

The adsorbing filter removes oil and larger hydrocarbon vapor from the com-

pressed air stream. Since it only removes vapor, a coalescing element -

specifically the F900D - should be used immediately upstream of the adsorb-

ir

ing filter. Since optimum adsorption occurs at lower temperatures, it is rec-

ommended to apply the filter as close to the point-of-use as possible.

The F900F features fine activated charcoal impregnated on polyester. The

activated carbon particles have a high affinity to vapor and are extremely effi-

cient due to the tremendous amount of surface area present. The adsorbing

element and the coalescing element should be changed every 3 to 6 months

depending on the application.

Recommended Uses

• Breathing air applications

• Food and drug industries having direct product contact with exhaust air

• Odor-free air applications

• Heavier hydrocarbon vapor removal

ua Specifications

Maximum temperature: 150ºF (66ºC)

Maximum pressure: 250 PSIG (17 bar)

Materials of Construction

Body: aluminum Drain: brass End caps:

Seals: Viton® Tie rod: brass anodized aluminum

F900F-04 pictured Flow Rates

SCFM based on 60 PSI inlet with 1.5 PSID SCFM based on 100 PSI inlet with 1.5 PSID

SCFM dm3/s SCFM dm3/s

F900F-02 42 20 F900F-02 65 31

F900F-03 42 20 F900F-03 65 31

F900F-04 42 20 F900F-04 65 31

F900F-06 65 31 F900F-06 100 47

F900F-08 78 37 F900F-08 120 57

F900F-08X 104 49 F900F-08X 160 76

e

F900F-10 195 92 F900F-10 300 142

F900F-12 234 110 F900F-12 360 170

F900F-16 456 215 F900F-16 700 330

F900F-20 586 276 F900F-20 900 425

F900F-24 733 346 F900F-24 1125 531

How to Order

Options (see pg 67):

F 900 F - 06 B

pn

B = mounting brackets

Port Size:

Element: 02 = 1/4

Model: F = adsorbing 03 = 3/8

F = Filter grade 04 = 1/2

element 06 = 3/4

Series: 08 = 1

900 = Delta Threads: 08X = 1 high flow

Series™ - = NPTF 10 = 1 1/4

G = G tap (BSPP) 12 = 1 1/2

16 = 2

20 = 2 1/2

24 = 3

NEED MORE PARTS AND INFORMATION?

• See page 119 for information on ordering replacement filters, bowls, etc.

• See page 101 for more information on available options.

FRLs AND ACCESSORIES 65

Numatics Delta Series™ Filters Dimensional drawings

Dimensions (in inches; millimeters in parenthesis)

e

Delta Series™ FIlters Differential Pressure Indicators

Slide Pressure Indicator

(for port sizes 1/4, 3/8, & 1/2 only)

ir

Square Dial Indicator

(for port sizes 3/4 through 3 only)

ua

Mounting Bracket

e

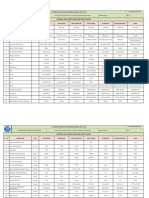

A B C D E F G H J K L

BRK9001 1.13 .32 Ø.88 1.38 .82 1.63 4.0 1.0 .5 .62 .38

(29) (8) (Ø22) (35) (21) (41) (102) (25) (13) (16) (10)

BRK9002 1.5 .27 Ø1.94 2.5 1.24 2.47 5.0 1.0 .4 1.5 .5

(38) (7) (Ø42) (64) (31) (63) (127) (25) (10) (38) (13)

Automatic Drain

pn

Model A B C D E*

F900*-02 3.8 (97) 0.9 (23) 0.7 (18) 9.3 (236) 5.9 (150)

F900*-03 3.8 (97) 0.9 (23) 0.7 (18) 9.3 (236) 5.9 (150)

F900*-04 3.8 (97) 0.9 (23) 0.7 (18) 9.3 (236) 5.9 (150)

F900*-06 4.6 (117) 2.3 (58) 1.3 (33) 14.8 (376) 9.8 (250)

F900*-08 4.6 (117) 2.3 (58) 1.3 (33) 14.8 (376) 9.8 (250)

F900*-08X 4.6 (117) 2.3 (58) 1.3 (33) 18.3 (465) 11.8 (300)

F900*-10 4.6 (117) 2.3 (58) 1.3 (33) 21 (533) 16.7 (425)

F900*-12 4.6 (117) 2.3 (58) 1.3 (33) 21 (533) 16.7 (425)

F900*-16 6.1 (155) 2.3 (58) 1.7 (43) 26.8 (681) 21.7 (550)

F900*-20 9.3 (236) 2.3 (58) 2.9 (74) 31.3 (795) 21.7 (550)

F900*-24 9.3 (236) 2.3 (58) 2.9 (74) 31.3 (795) 21.7 (550)

* The “E” dimension refers to the amount of space needed below the

bottom of the bowl in order to remove the bowl.

66 FRLs AND ACCESSORIES

Numatics Delta Series™ Filters Options and accessories

e

Auto Drains

The Auto Drain (“A” option) is installed into the bottom of the filter bowl.

As the liquid level inside the bowl increases, the tire-like float lifts,

allowing the liquid to drain.

AKF60 - for port sizes 1/4 through 1 (high flow) only

ir

Maximum Temperature: 150º F (65º C)

Maximum Pressure: 250 PSIG (17 bar)

AKF90 - for port sizes 1 1/4 through 3 only

Maximum Temperature: 250º F (125º C)

Maximum Pressure: 250 PSIG (17 bar)

Pressure Indicators

Allows exact determination of pressure drop across an element. On the

dial indicator, pressure drop is easily monitored during the life of the ele-

ment. On the slide indicator, necessary element change is indicated by

ua the green area turning red. The casing and sight dome are constructed

of polyamide.

PDI90 - Slide Indicator (‘G’ option) for port sizes 1/4, 3/8, & 1/2 only

Max. Temp.: 176º F (80º C) Max. Pres.: 230 PSIG (16 bar)

PDI91 - Square Dial Indicator (‘G’ option) for port sizes 3/4 through 3 only

Max. Temp.: 176º F (80º C) Max. Pres.: 230 PSIG (16 bar)

AMounting Brackets

Mounting brackets (“B” option) are used to fix Delta Series™ filters to

a panel. The brackets, made of sturdy stainless steel, are screwed

e

into the bracket mounting holes located on both the in and out ports.

BRK9001 for port sizes 1/4 through 1/2 only

BRK9002 for port sizes 3/4 through 1 1/2 onl

NOTE: There is no bracket available for port sizes 2, 2 1/2, or 3

pn

Electronic Drain Valve

The Electronic Drain Valve (‘N’ option) offers automatic draining of bowl con-

tents in a timed sequence. Easy-to-use controls on the drain’s face allow the

user to set the drain open and closed time. Its large orifice allows even the

largest rust and pipe scale particles to be easily expelled. Includes a 110 volt

AC solenoid, 6 ft (2 m) power cord, grounded plug, and elbow for attaching

to bowl.

EDV-04-110AC 110v AC, 1/2 NPTF Electronic Drain Valve with adapter

(for other voltages, please contact your local distributor)

Max. Press./Max. Temp: 300 PSIG (21 bar) / 130ºF (54ºC)

FRLs AND ACCESSORIES 67

Numatics Delta Series™ Filters Notes

e

ir

e ua

pn

68 FRLs AND ACCESSORIES

You might also like

- Freeware PDF UnlockerDocument116 pagesFreeware PDF UnlockerManjunath HrmNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- En7936 4 09 17 - Ofu PDFDocument4 pagesEn7936 4 09 17 - Ofu PDFJhonny Velasquez PerezNo ratings yet

- 042032-1001-A - GB - Operating & Maintenance ManualDocument20 pages042032-1001-A - GB - Operating & Maintenance ManualRonald RoblesNo ratings yet

- Filtro HaywardDocument4 pagesFiltro HaywardalmacidNo ratings yet

- XDS Range BrochureDocument8 pagesXDS Range BrochureJose QuincosNo ratings yet

- Industrial FRP Tank Water Media FilterDocument4 pagesIndustrial FRP Tank Water Media FilterT Nagaraju AF VetaranNo ratings yet

- Hayw - s311sx S 360sxc ManualsDocument4 pagesHayw - s311sx S 360sxc Manuals薛泽绵No ratings yet

- Hydac Mobile Filter Systems1Document76 pagesHydac Mobile Filter Systems1bee1406763181No ratings yet

- KATALOG Fertigation 2010 PDFDocument44 pagesKATALOG Fertigation 2010 PDFsanitermNo ratings yet

- Pureaqua Multimedia FilterDocument4 pagesPureaqua Multimedia FilterRaul VelizNo ratings yet

- PuROMax Commercial RO Instructions 2015Document49 pagesPuROMax Commercial RO Instructions 2015Jcc ChoNo ratings yet

- Wellforce PDFDocument2 pagesWellforce PDFMark Joey David0% (1)

- V3.5.04.02 Micro Cartridge FilterDocument14 pagesV3.5.04.02 Micro Cartridge FilterAlaa SalemNo ratings yet

- 01 Pool FiltrationDocument34 pages01 Pool FiltrationFor AccounNo ratings yet

- Gfps-Dk-Technical Data Metal Butterfly Valve Type 039Document7 pagesGfps-Dk-Technical Data Metal Butterfly Valve Type 039Omar GuillenNo ratings yet

- Product Catalog: Compact Screen, Single Screen & Multi Screen FiltersDocument26 pagesProduct Catalog: Compact Screen, Single Screen & Multi Screen FiltersLuan NguyenNo ratings yet

- Technical Proposal For Olympic Pool PDFDocument10 pagesTechnical Proposal For Olympic Pool PDFAlma DerajNo ratings yet

- Twin Tank Water SoftenerDocument2 pagesTwin Tank Water SoftenerCHOUKRI KamalNo ratings yet

- Dokumen - Tips - Tabla de Especificaciones Tcnicas Condensador de Especificaciones Tcnicas CondensadorDocument1 pageDokumen - Tips - Tabla de Especificaciones Tcnicas Condensador de Especificaciones Tcnicas CondensadorMisael EstevezNo ratings yet

- ITT N-Series Pump CurveDocument8 pagesITT N-Series Pump CurvePumpdesignNo ratings yet

- Compatible Releasing Device ListDocument2 pagesCompatible Releasing Device ListKen yimNo ratings yet

- Aro PumpDocument8 pagesAro PumpRizalino BrazilNo ratings yet

- Chemical Feeder: Maintains Chlorine Level AutomaticallyDocument2 pagesChemical Feeder: Maintains Chlorine Level AutomaticallyMG9RNo ratings yet

- Waterboy RO Unit PamphletDocument7 pagesWaterboy RO Unit PamphletDhiren DayaNo ratings yet

- Gasoline Fuel Filters: For Marine ApplicationsDocument4 pagesGasoline Fuel Filters: For Marine Applicationsayush bansalNo ratings yet

- Ek Series Hermetic Liquid Line Filter Driers Catalog en Us 1620596Document4 pagesEk Series Hermetic Liquid Line Filter Driers Catalog en Us 1620596agus sutiawanNo ratings yet

- Dynapak 2000 Ver 09092002Document24 pagesDynapak 2000 Ver 09092002DiegoNo ratings yet

- Product Attribute Specifications: MEDIA Available Micron Ratings AvailableDocument2 pagesProduct Attribute Specifications: MEDIA Available Micron Ratings AvailableLord KrsnikNo ratings yet

- Aft Catalog TotDocument704 pagesAft Catalog TotcoelhoclaudiosNo ratings yet

- DMBF Full en Metric LetterDocument4 pagesDMBF Full en Metric LetterRonaldNo ratings yet

- 7447 B Owners ManualDocument348 pages7447 B Owners ManualDimitar NovakNo ratings yet

- Amnon: Heavy-Wall EmitterlineDocument12 pagesAmnon: Heavy-Wall EmitterlineAbraham Tirado TapullinaNo ratings yet

- SDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMDocument4 pagesSDB Series Blower Purge Desiccant Dryers 1200-12000 SCFMramiro alvarezNo ratings yet

- Daf PDFDocument16 pagesDaf PDFMurukan PadmanabhanNo ratings yet

- Parker 3 Way SolenoidDocument8 pagesParker 3 Way SolenoidFlavius DumitrescuNo ratings yet

- Filson Product CatalogDocument9 pagesFilson Product CatalogDaniel Sandoval FernándezNo ratings yet

- Amadrainer A..pump CatalogueDocument16 pagesAmadrainer A..pump CatalogueMohamad Aboelsoud HessenNo ratings yet

- Automatic Hydraulic Screen Filter - LCA SeriesDocument2 pagesAutomatic Hydraulic Screen Filter - LCA SeriesLuan Nguyen100% (1)

- DBAFMCV924 Full en Metric LetterDocument6 pagesDBAFMCV924 Full en Metric LetterMechanical2022No ratings yet

- Chilled Water Fan Coil Unit (FWW-VC)Document19 pagesChilled Water Fan Coil Unit (FWW-VC)Ramadan AliNo ratings yet

- Everpure SSFM 100M 25 orDocument2 pagesEverpure SSFM 100M 25 orbigcee64No ratings yet

- Titan CF Filter Manual 2014Document4 pagesTitan CF Filter Manual 2014Yareli de la CruzNo ratings yet

- Dripline Product Selection Guide - Rain BirdDocument2 pagesDripline Product Selection Guide - Rain Birdalaa sadikNo ratings yet

- Condensing Unit Vertical Discharge 60 HZ R410A: 36KBTU Model Has A Different GrillDocument1 pageCondensing Unit Vertical Discharge 60 HZ R410A: 36KBTU Model Has A Different GrilljuanNo ratings yet

- Dfu Ti D148 01 BRDocument2 pagesDfu Ti D148 01 BRNoo SokiNo ratings yet

- Strainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionDocument3 pagesStrainer Y-Type: Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatNo ratings yet

- Sand Filters Datasheet PDFDocument2 pagesSand Filters Datasheet PDFJamesStenhouseNo ratings yet

- LISH - Submittal For OutdoorDocument20 pagesLISH - Submittal For OutdoorJimmy AnticonaNo ratings yet

- MAN600 Rev KDocument18 pagesMAN600 Rev KMarco EscobedoNo ratings yet

- Item 4 - (P-110) - RASDocument7 pagesItem 4 - (P-110) - RASanse1No ratings yet

- AA SelecionadoDocument3 pagesAA SelecionadoJosé Luis ColmenarezNo ratings yet

- Drrdock Repair Jobs (Excluding DD Routines) No 3Document25 pagesDrrdock Repair Jobs (Excluding DD Routines) No 3Amit Raj AnandNo ratings yet

- Pressure VesselsDocument16 pagesPressure VesselsahmedNo ratings yet

- Valley Dealer Customer: Agrolmos S.A. Agrolmos S.ADocument31 pagesValley Dealer Customer: Agrolmos S.A. Agrolmos S.AJesús Albert Leyva MarínNo ratings yet

- European Catalog Air Preparation Delta Filter 901 G 3 8 g2 Asco en 7003046Document12 pagesEuropean Catalog Air Preparation Delta Filter 901 G 3 8 g2 Asco en 7003046giovanni1912No ratings yet

- Delta Series FiltersDocument12 pagesDelta Series Filtersgiovanni1912No ratings yet

- ASCO - F901 Series - CatalogDocument19 pagesASCO - F901 Series - Cataloggiovanni1912No ratings yet

- Catalogo Motores Siemens PDFDocument176 pagesCatalogo Motores Siemens PDFgiovanni1912No ratings yet

- Vibration Diagnostic GuideDocument32 pagesVibration Diagnostic Guidegiovanni1912100% (1)

- A4 Structural Vibration and Ways To Avoid It ArticleDocument4 pagesA4 Structural Vibration and Ways To Avoid It Articlegiovanni1912No ratings yet

- Basic Condition Monitoring KitDocument1 pageBasic Condition Monitoring Kitgiovanni1912No ratings yet

- The Sludge Incineration ProcessDocument11 pagesThe Sludge Incineration ProcessvzgscribdNo ratings yet

- RB211 Lube System (Ssloc) DescriptionDocument6 pagesRB211 Lube System (Ssloc) DescriptionmuazmaslanNo ratings yet

- Knock Out Pot Sizing ExampleDocument8 pagesKnock Out Pot Sizing ExampleYamen SleimanNo ratings yet

- Depressuring SystemDocument32 pagesDepressuring SystemMohamadamin TarkhanehNo ratings yet

- Modeling of Spray InfectionDocument5 pagesModeling of Spray InfectionHarshdeep BrarNo ratings yet

- Process Flow Diagram Ammonia Plant Pusri IiiDocument18 pagesProcess Flow Diagram Ammonia Plant Pusri IiiAde KurnadiNo ratings yet

- Reservoir Engineering (Kaiser A. Jasim 2019) اساسيات هندسة المكامنDocument90 pagesReservoir Engineering (Kaiser A. Jasim 2019) اساسيات هندسة المكامنShakerMahmoodNo ratings yet

- Ethylene BalanceDocument29 pagesEthylene BalanceCraigUnderwood100% (2)

- ED SCI 401 Fluid Mechanics SyllabusDocument14 pagesED SCI 401 Fluid Mechanics SyllabusRaeh YooNo ratings yet

- Turbomachinery and Propulsion MECH 6171Document26 pagesTurbomachinery and Propulsion MECH 6171md arifNo ratings yet

- M/s. Grasim Industries Limited: Wilden Usa Make Aodd PumpDocument2 pagesM/s. Grasim Industries Limited: Wilden Usa Make Aodd Pumppradeep Kumar AgarwalNo ratings yet

- CDS Presentation 11-14-02aDocument60 pagesCDS Presentation 11-14-02adoraq7975No ratings yet

- Distillation Tower DesignDocument65 pagesDistillation Tower DesignNicholaus ShawNo ratings yet

- SS Pipe Fab & Erect CostsDocument5 pagesSS Pipe Fab & Erect Costswally55bear67% (3)

- Refrigerants R407F For R22 and R404A Replacement17 - 129770Document4 pagesRefrigerants R407F For R22 and R404A Replacement17 - 129770Stipe VučetićNo ratings yet

- Kane 458s ManualDocument36 pagesKane 458s ManualAnresNo ratings yet

- GL XX Mobil DTE Oil Double Letter SeriesDocument3 pagesGL XX Mobil DTE Oil Double Letter SeriesMuhammad RipandiNo ratings yet

- V80956 Hydroll Piston Accumulator HPS-11 140Document8 pagesV80956 Hydroll Piston Accumulator HPS-11 140Miguel GonzalezNo ratings yet

- Process Flow SheetDocument22 pagesProcess Flow Sheetranger cleetusNo ratings yet

- Spare Parts 210420 - v1.2. - Eur-MdlDocument1 pageSpare Parts 210420 - v1.2. - Eur-MdlTudor RacuNo ratings yet

- A03 Hydrocarbon Dew Point Control1Document2 pagesA03 Hydrocarbon Dew Point Control1Olusegun OyebanjiNo ratings yet

- Auxiliary Steam SystemDocument15 pagesAuxiliary Steam SystemSwaroop KumarNo ratings yet

- Review of Related Literature and StudiesDocument15 pagesReview of Related Literature and StudiesPatrick AlimuinNo ratings yet

- VDF Vacuum Dehydration Oil Purification System - ACORE Filtration Co - LTDDocument5 pagesVDF Vacuum Dehydration Oil Purification System - ACORE Filtration Co - LTDArghya deyNo ratings yet

- Vacuum Leaf FilterDocument4 pagesVacuum Leaf Filterinstrutech100% (1)

- Eclipse Tube Firing Burner: Model TFB030Document4 pagesEclipse Tube Firing Burner: Model TFB030Ing. Rodolfo Rincon GarciaNo ratings yet

- Safety Valve ListDocument3 pagesSafety Valve ListYair Alexis Muñoz RojasNo ratings yet

- Selective Hydrogenation Processes: Beth Mcculloch, Charles Luebke, and Jill MeisterDocument6 pagesSelective Hydrogenation Processes: Beth Mcculloch, Charles Luebke, and Jill MeisterBharavi K SNo ratings yet

- Spe 17741 PDFDocument8 pagesSpe 17741 PDFbibiNo ratings yet

- Problem 1: 1.0 Bar 288 K 150 M/s 60 CM 50 CM 100 Rps 30.2 Degree 1.2 6Document22 pagesProblem 1: 1.0 Bar 288 K 150 M/s 60 CM 50 CM 100 Rps 30.2 Degree 1.2 6Utkarsh VermaNo ratings yet

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (51)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CFrom EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CNo ratings yet

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- Hybrid Electric Vehicles: Principles and Applications with Practical PerspectivesFrom EverandHybrid Electric Vehicles: Principles and Applications with Practical PerspectivesNo ratings yet

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsFrom EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Theory and Calculation of Heat Transfer in FurnacesFrom EverandTheory and Calculation of Heat Transfer in FurnacesRating: 3 out of 5 stars3/5 (4)

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityFrom EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNo ratings yet

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)From EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Rating: 4 out of 5 stars4/5 (12)

- Troubleshooting and Repairing Diesel Engines, 5th EditionFrom EverandTroubleshooting and Repairing Diesel Engines, 5th EditionRating: 2.5 out of 5 stars2.5/5 (2)

- Machinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeFrom EverandMachinery Failure Analysis Handbook: Sustain Your Operations and Maximize UptimeRating: 3.5 out of 5 stars3.5/5 (4)

- Bulk Material Handling: Practical Guidance for Mechanical EngineersFrom EverandBulk Material Handling: Practical Guidance for Mechanical EngineersRating: 5 out of 5 stars5/5 (1)

- Machinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionFrom EverandMachinery's Handbook Pocket Companion: Quick Access to Basic Data & More from the 31st EditionNo ratings yet

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchFrom EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchRating: 4 out of 5 stars4/5 (10)

- Piping Design for Industrial Facilities: Understanding Codes and StandardsFrom EverandPiping Design for Industrial Facilities: Understanding Codes and StandardsRating: 4 out of 5 stars4/5 (1)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)