Professional Documents

Culture Documents

Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator Training

Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator Training

Uploaded by

GUESSOUMAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator Training

Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator Training

Uploaded by

GUESSOUMACopyright:

Available Formats

CX501KB Series

TRAINING GAS TURBINES

ROLLS-ROYCE 501KB7

GAS TURBINE

MLN BLOCK 405, ALGERIA

OPERATOR TRAINING

CX501KB Series

TRAINING GAS TURBINES

TURBINE DESCRIPTION

Rolls-Royce Allison 501 KB7

Simple cycle, single shaft engine

Speed = 14571 rpm

Weight = 767kg

Nominal Power = 7500hp

Electrical Output = 5100kW (installed)

Exhaust Temperature = 518°C

Exhaust Gas Mass Flow = 20.6kg/sec

Typical Steam Flow = 12T/h

TURBINE SECTION 2 PAGE 1-2

CX501KB Series

TRAINING GAS TURBINES

Engine looking from the compressor intake end

CX501KB Series

TRAINING GAS TURBINES

ROLLS-ROYCE 501KB7 GAS TURBINE

BOOST MODULE

COMPRESSOR COMBUSTION TURBINE

PTO SHAFT

1 2 3 4 5 6

ACCESSORY ENGINE

DRIVE MOUNT

TOTAL COMPRESSION RATIO APPROX 13.5:1

TURBINE SECTION 2 PAGE 3-4

CX501KB Series

TRAINING GAS TURBINES

KB7 SCHEMATIC

BOOST

MODULE COMPRESSOR FUEL COMBUSTORS TURBINE

OUTPUT

SHAFT

AIR

EXHAUST

GASES

AIR

USABLE COMPRESSOR ENERGY FUEL TURBINE ENERGY

ENERGY

CX501KB Series

TRAINING GAS TURBINES

WORKING CYCLE COMPARISON

AIR INTAKE COMPRESSION COMBUSTION EXHAUST

Continuous

Intermittent

AIR/FUEL INTAKE COMPRESSION COMBUSTION EXHAUST

TURBINE SECTION 2 PAGE 5-6

CX501KB Series

TRAINING GAS TURBINES

PRESSURE,TEMPERATURE & VELOCITY

CX501KB Series

TRAINING GAS TURBINES

ASSEMBLIES

Built up of five major assemblies:

Boost compressor module;

Core compressor module;

Combustion module;

Turbine module;

and the Accessory Drive.

The rotating assemblies of the engine are bolted

and splined together to form a single shaft which is supported by the

transition sections on six main bearings.

A pressure pump within the accessory drive

provides lubrication to the bearings. Scavenge pumps return the oil from

sumps within the engine to the accessory drive.

TURBINE SECTION 2 PAGE 7-8

CX501KB Series

TRAINING GAS TURBINES

MATERIALS

Air Intake and Bearing Support - aluminium casting

Accessory Drive Gear Casing - magnesium

Compressor Casing - cast steel

Compressor Rotor - forged stainless steel

Compressor Blades and Vanes - stainless nickel alloy

Diffuser Casing and Bearing Support - stainless steel

Combustion Casing - titanium

Combustion Inner Casing - stainless steel

Combustion Liners - hastalloy

Turbine Inlet Casing and Bearing Support - hastalloy

Turbine and Rear Bearing Support Casings - steel alloy

Turbine Rotor - stainless steel

Turbine Blades and Vanes - high temperature nickel alloys with electro

phosphoric aluminised coatings and ceramic coating to the first stage vanes

CX501KB Series

TRAINING GAS TURBINES

QUANTITIES

Boost Module Blades:

Zero Stage = 29

Compressor Rotor Blades:

1st Stage = 33 8th Stage = 91

2nd Stage = 33 9th Stage = 95

3rd Stage = 37 10th Stage = 95

4th Stage = 39 11th Stage = 95

5th Stage = 41 12th Stage = 95

6th Stage = 89 13th Stage = 95

7th Stage = 91 14th Stage = 91

Turbine Rotor Blades:

1st Stage = 102 3rd Stage = 89

2nd Stage = 89 4th Stage = 69

TURBINE SECTION 2 PAGE 9-10

CX501KB Series

TRAINING GAS TURBINES

BEARINGS

The 6 bearings provide support for the rotor assembly and are mounted in

the transition sections. All the bearings are sprayed with oil for cooling and

lubrication.

No 1 Boost Compressor Front Bearing - roller bearing to allow axial

expansion;

No 2 Boost Compressor Thrust Bearing - ball bearing to anchor the zero

stage compressor

No 3 Core Compressor Front Bearing - roller

No 4 Turbine and Compressor Thrust Bearing - anchors both compressor

and turbine.

No 5 Front Turbine Bearing - roller

No 6 Rear Turbine Bearing - roller

Thrust for the compressors is towards the inlet and for the turbine is towards

the exhaust

Thermal expansion is approximately 7mm

CX501KB Series

TRAINING GAS TURBINES

Engine Shutdowns

C.I.T. SENSOR FAULT Open or short circuit of either CIT sensors Check

and replace sensors - inspect for cause of damage

THERMOCOUPLE FAULT Open or short circuit of thermocouple sensors .

Check and replace sensors - inspect engine internally for cause of

damage.

Open circuit = High reading

Short circuit = Low reading

SPEED SENSOR FAULT Failure of either speed sensors while the

engine is running - auto shutdown as Underspeed. Check and replace

sensors - inspect engine internally for cause of damage.

TURBINE FAILED TO LIGHT CTIT temp. < 316°C or TOT <180°C at

turbine speed <13000 during accelerative schedule. Check for igniter

fault; - Insufficient fuel :Fuel supply fault; gas-regulator or valve fault.;

Compressor bleed valve position.

TURBINE STAGNATION Turbine acceleration < 40rpm/sec

speed<13000rpm.- insufficient fuel. Check:Gas regulator; Hydraulic start

system; Compressor bleed valve position

TURBINE SECTION 2 PAGE 11-12

CX501KB Series

TRAINING GAS TURBINES

Engine Shutdowns

AUX.GEARBOX CHIP DETECTED Metallic debris on magnetic plug in

turbine auxiliary gearbox - Turbine gear or bearing damage. Check and

retain debris and refer to Centrax before restarting the turbine.

TURBINE OIL PRESSURE LOW Turbine oil pressure < 1.38 bar g whilst

running at > 13000rpm . Check turbine auxiliary gearbox oil

pump;regulator fault or oil leaks.

TURBINE VIBRATION HIGH Turbine vibration >31µm peak to peak

running or >62µm starting - operation of this channel indicates a turbine

rotor imbalance, this may be bearing failure or blade damage. Refer to

Centrax before restarting the turbine

CX501KB Series

TRAINING COMPRESSOR SECTIONS GAS TURBINES

Boost

Compressor

Blow Off Valve

Boost (duct) Core

Diffuser

Compressor Compressor

5th & 10th

Stage Blow Off

Valves (8)

Magnetic Chip Accessory

Detectors (2) Drive

TURBINE SECTION 2 PAGE 13-14

CX501KB Series

TRAINING GAS TURBINES

KB7 BOOST MODULE

SINGLE STAGE,

AXIAL FLOW BOOST BLOW OFF VALVE: PREVENTS

COMPRESSOR SURGING DURING THE STARTING

DIRECTLY AND STOPPING SEQUENCES:

CONNECTED TO THE CLOSES AT APPROX 12,500 RPM

CORE COMPRESSOR.

PRESSURE RATIO

1.464:1.0

Boost compressor

thrust (ball) bearing

PTO SHAFT rear shaft CORE COMPRESSOR

Boost compressor

front (roller) bearing

CX501KB Series

TRAINING GAS TURBINES

CORE COMPRESSOR

14 STAGE, AXIAL FLOW CORE COMPRESSOR HAS A COMPRESSION RATIO OF 9.175:1.0 .

EIGHT BLOW OF VALVES RELEASE PRESSURE DURING THE START AND SHUT DOWN

SEQUENCES. THE VALVES ARE CLOSED DURING COMPRESSOR CLEANING. ACCESSORY

DRIVE RUNS THE TURBINE'S INTERNAL LUBE OIL SYSTEM. COMPRESSOR DRUM DIRECTLY

CONNECTED TO THE TURBINE SECTION.

Boost compressor Compressor and turbine

thrust (ball) bearing thrust (ball) bearing

BOOST COMBUSTION

compressor tie bolt SECTION

MODULE

compressor front

(roller) bearing

ACCESSORY BLOW OFF VALVES

DRIVE

TURBINE SECTION 2 PAGE 15-16

CX501KB Series

TRAINING GAS TURBINES

COMPRESSOR ROTOR ASSEMBLY

TURBINE SECTION 2 PAGE 17-18

CX501KB Series

TRAINING GAS TURBINES

COMBUSTION SECTION

COMPRESSOR AIR PASSES THROUGH A DIFFUSER TO SIX CANNULAR COMBUSTION

CHAMBERS WHERE FUEL IS ADDED THROUGH SIX GASEOUS FUEL NOZZLES.

THE MIXTURE IS IGNITED BY TWO IGNITER PLUGS DURING THE START SEQUENCE AND IS

SELF SUSTAINING WHILST RUNNING.

THE FUEL/AIR MIXTURE BURNS AND THE RESULTING GASES DRIVE THE TURBINE.

Igniter plug

Fuel nozzle

Compressor and turbine front

turbine thrust (roller) bearing

(ball) bearing

COMPRESSOR turbine and compressor tie bolt POWER TURBINE

Combustion can

TURBINE SECTION 2 PAGE 19-20

CX501KB Series

TRAINING GAS TURBINES

COMBUSTION LINERS

LE1 LE2 LE3 LE4

LE = Low Emission

CX501KB Series

TRAINING GAS TURBINES

COMBUSTION LINER

72% SECONDARY COOLING AIR FORMS A CUSHION

TO KEEP THE LINERS AND CASING AS COOL AS POSSIBLE - 200 TO

320°C

FUEL

1057°C

1775 - 2000°C 1100°C

25% PRIMARY 3% FOR TUBINE BLADE AND VANE

COMBUSTION AIR - COOLING -

290 TO 320°C APPROX 200 °C

TURBINE SECTION 2 PAGE 21-22

CX501KB Series

TRAINING GAS TURBINES

COMBUSTION AND TURBINE ASSEMBLY

Combustion Turbine

Section Section

Turbine

Exhaust

Turbine to

Compressor

Shaft

Turbine front

bearing oil

supply

Turbine Outlet

Temperature

Thermocouples

Bearing oil (12)

return Liner Supports

or Turbine Inlet

Temperature

Combustion 4 Liner Thermocouples

Liner (6) Supports and 2 (18) when fitted

Ignitors

CX501KB Series

TRAINING GAS TURBINES

TURBINE SECTION

4 STAGE TURBINE EXPANDS THE GASES, CONVERTING THE THERMAL ENERGY INTO

KINETIC ENERGY TO DRIVE THE COMPRESSOR AND THE PTO SHAFT. THE GASES THEN

EXIT THROUGH THE EXHAUST SYSTEM AT APPROX 518°C WHERE HEAT IS NORMALLY

EXTRACTED FOR AN INDUSTRIAL PROCESS (TYPICALLY THROUGH A BOILER TO

PROVIDE 12t/h OF STEAM AT 10 barg) .

turbine front

(roller) bearing turbine rear

(roller) bearing

COMBUSTION

SECTION EXHAUST

TURBINE SECTION 2 PAGE 23-24

CX501KB Series

TRAINING GAS TURBINES

TURBINE ROTOR ASSEMBLY

Labyrinth Seal

Turbine Rear

Bearing

Support

Turbine Rear

Bearing

Assembly

Turbine Rotor

CX501KB Series

TRAINING GAS TURBINES

INTERNAL LUBRICATION

The turbine oil pump is mounted on the front of the

Accessory Drive Housing and is supplied with oil from the common genset

lubrication system.

Internal filtration and regulation is provided at 3.8bar.

Oil passes through grooves and ducts within the shaftsand casings and is

sprayed onto the six main bearings and splined couplings.

Sumps are provided in the lower casing beneath the bearings and a

scavenge pump returns the oil to the Accessory Drive Housing and pump

feed.

Two metallic chip detectors wired in parallel are mounted in the turbine, one

in the scavenge outlet and one in the Accessory Drive Housing.

The system is vented to prevent a build up of pressure in the oil.

TURBINE SECTION 2 PAGE 25-26

CX501KB Series LUBE SYSTEM BLOCK DIAGRAM

TRAINING GAS TURBINES

CX501KB Series

TRAINING

ACCESSORY DRIVE HOUSING GAS TURBINES

TURBINE SECTION 2 PAGE 27-28

CX501KB Series

TRAINING GAS TURBINES

ENGINE CONTROL

Turbine temperature control is based on Control Temperature (CT) which is

determined by obtaining the Turbine Outlet Temperature (TOT) with 12

thermocouples connected in parallel and converting this average

temperature to an equivalent Turbine Inlet Temperature (TIT).

During starting, fuel and ignition are programmed automatically by the

digital control via the open loopstart schedule as a function of compressor

inlet temperature (CIT), engine speed, control temperature(CT), and

closed-loop control via the CT.

CX501KB Series

TRAINING GAS TURBINES

ENGINE CONTROL UNIT (ECU)

The HSDE ECU is mounted within the Turbine Control Panel and incorporates

all the functions necessary to start and operate the engine. The ECU

provides the following functions:

Start logic

Start Sequencing

Fuel flow control during starting

Monitoring of engine speed and temperature

Fault detection and protection logic to prevent engine damage

Indication signals for engine speed, turbine temperature, fault detection and

status.

TURBINE SECTION 2 PAGE 29-30

CX501KB Series

TRAINING GAS TURBINES

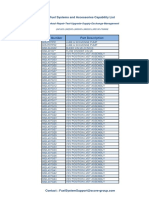

OPERATING PARAMETERS

CX501KB Series

TRAINING GAS TURBINES

OPERATING LIMITS

Notes:

1. Turbine outlet temperature (TOT)

over-temperature backup is >1400°F (760°C) and

N1 is <13,000 rpm.

2. TOT run-over temperature backup when N1 is

>13,000 rpm.

3. The symbol > means more than

and the symbol < means less than.

TURBINE SECTION 2 PAGE 31-32

CX501KB Series

TRAINING GAS TURBINES

OPERATING THEORY

CX501KB Series DIGITAL ENGINE CONTROL

TRAINING SYSTEM SCHEMATIC GAS TURBINES

TURBINE SECTION 2 PAGE 33-34

CX501KB Series

TRAINING GAS TURBINES

FUEL CONTROL VALVE (FCV)

The Fuel Control Valve position is dictated by the output signal from the ECU

The FCV's electronics provide a position feeback signal to the ECU which will

initiate an engine shutdown if the valve position signal does not track the

demand signal.

TURBINE SECTION 2 PAGE 35-36

You might also like

- A First Course in Atmospheric Radiation 2edDocument429 pagesA First Course in Atmospheric Radiation 2edHugo AndradeNo ratings yet

- Nigeria Gas Specification - GACNDocument1 pageNigeria Gas Specification - GACNOlusegun OyebanjiNo ratings yet

- Siemens Gas Turbines - Final PDFDocument202 pagesSiemens Gas Turbines - Final PDFQahtan Adnan100% (6)

- Rolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingDocument18 pagesRolls-Royce 501Kb7 Gas Turbine: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Asp Sterrad NX Service Access Guide PDFDocument57 pagesAsp Sterrad NX Service Access Guide PDFandrea lizeth martinez camacho100% (1)

- Astm D5291Document7 pagesAstm D5291Nadia SalemNo ratings yet

- Datasheet Industrial 501 Kb7sDocument2 pagesDatasheet Industrial 501 Kb7sNebojsa100% (1)

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNo ratings yet

- Brayton Cycle Experiment - Jet EngineDocument10 pagesBrayton Cycle Experiment - Jet EngineAsif MohammedNo ratings yet

- A Systematic Approach To Rehabilitations in Power PlantsDocument35 pagesA Systematic Approach To Rehabilitations in Power PlantsalifacebNo ratings yet

- Datasheet lm500 PDFDocument2 pagesDatasheet lm500 PDFvcharlesNo ratings yet

- Overview of SCF6 ExchangeDocument2 pagesOverview of SCF6 Exchangechdi100% (1)

- Kurzke Achieving Maximum Thermal Efficiency enDocument12 pagesKurzke Achieving Maximum Thermal Efficiency enbfehrmNo ratings yet

- 04alt PDFDocument9 pages04alt PDFGUESSOUMANo ratings yet

- Enclosure and Intake System Description: Operator Training MLN Block 405, AlgeriaDocument7 pagesEnclosure and Intake System Description: Operator Training MLN Block 405, AlgeriaGUESSOUMANo ratings yet

- Lube Oil System: MLN Block 405, Algeria Operator TrainingDocument10 pagesLube Oil System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- 501 Gas Turbines: Performance Demonstrated by SuccessDocument10 pages501 Gas Turbines: Performance Demonstrated by SuccessGS RATHORENo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument62 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- Avon UTC 1535c5Document32 pagesAvon UTC 1535c5juana100% (1)

- Equipment Available From SJ Turbine Inc.: LM Package Parts LM Package Parts High VoltageDocument59 pagesEquipment Available From SJ Turbine Inc.: LM Package Parts LM Package Parts High VoltageAnibal QuezadaNo ratings yet

- VBR Strategic Spare Parts Planning-2Document18 pagesVBR Strategic Spare Parts Planning-2jampukNo ratings yet

- Avon UTC 1535c3Document9 pagesAvon UTC 1535c3juanaNo ratings yet

- Avon UTC 1535c1Document35 pagesAvon UTC 1535c1juanaNo ratings yet

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiNo ratings yet

- Hydraulic Start System: MLN Block 405, Algeria Operator TrainingDocument5 pagesHydraulic Start System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- Avon UTC 1535c8Document19 pagesAvon UTC 1535c8juanaNo ratings yet

- PEi 20110301 Mar 2011Document180 pagesPEi 20110301 Mar 2011Iván Camilo DíezNo ratings yet

- LM6000-InD-239 - Improved LPT Coupling NutDocument9 pagesLM6000-InD-239 - Improved LPT Coupling NutIqbal UsmaniNo ratings yet

- Avon UTC 1535c6Document85 pagesAvon UTC 1535c6juanaNo ratings yet

- Spare Parts For Gas Turbine F9E For Instrument & Control - RehabDocument1 pageSpare Parts For Gas Turbine F9E For Instrument & Control - RehabhakimsalimiNo ratings yet

- Gek105060 File0060 PDFDocument12 pagesGek105060 File0060 PDFHelton OliveiraNo ratings yet

- Compressor Wash System: MLN Block 405, Algeria Operator TrainingDocument19 pagesCompressor Wash System: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- 8277e200 g004Document38 pages8277e200 g004CRUCUERNo ratings yet

- Industrial Gas Generator Illustrated Parts CatalogueDocument10 pagesIndustrial Gas Generator Illustrated Parts CataloguejuanaNo ratings yet

- SBLM2500 Ind 162Document6 pagesSBLM2500 Ind 162Daniil SerovNo ratings yet

- 47841ILustrated Part ListDocument229 pages47841ILustrated Part ListRidwanNo ratings yet

- Vol III Supplementary DataDocument19 pagesVol III Supplementary DatamargaretramosNo ratings yet

- Rolls-Royce 501 TurbinesDocument2 pagesRolls-Royce 501 Turbinesdescargacojuda100% (1)

- NIC - 07-37 - Rev-01 Technical Updates Web Portal GEDocument47 pagesNIC - 07-37 - Rev-01 Technical Updates Web Portal GEManuel L LombarderoNo ratings yet

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDocument2 pagesGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza LNo ratings yet

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranNo ratings yet

- LM6000 DatasheetDocument2 pagesLM6000 DatasheetpatrialvamelNo ratings yet

- Protection and Condition Monitoring of The LM5000 Gas TurbineDocument9 pagesProtection and Condition Monitoring of The LM5000 Gas TurbineSudeshNo ratings yet

- CapabilityList Score Part NumbersDocument150 pagesCapabilityList Score Part NumbersEDBNo ratings yet

- المواد المرمزة والمطلوبة ترميزها بملف واحدDocument247 pagesالمواد المرمزة والمطلوبة ترميزها بملف واحدMahdi HassanNo ratings yet

- Muskeg Cabinet ListsDocument20 pagesMuskeg Cabinet ListsAnkit Patel100% (1)

- Aiaa/Asme/Sae/Asee 24Th Joint Propulsion ConferenceDocument7 pagesAiaa/Asme/Sae/Asee 24Th Joint Propulsion ConferenceMorgen GumpNo ratings yet

- CPU945 6ES5998-3UF21 06 e OCR PDFDocument673 pagesCPU945 6ES5998-3UF21 06 e OCR PDFfabyanoNo ratings yet

- RT48SDocument11 pagesRT48SRonald Marcano100% (1)

- Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingDocument4 pagesCustomer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- 3 U 141 IplDocument346 pages3 U 141 IplGAS PLANTNo ratings yet

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air Systemmilad100% (1)

- Coatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbineDocument1 pageCoatings Guide: Air Intake Air Intake Exhaust Compressor Compressor Combustor Combustor Turbine TurbinefrdnNo ratings yet

- Rolls-Royce Industrial AvonDocument7 pagesRolls-Royce Industrial AvonRiswan SaputraNo ratings yet

- GT (Unit-01) Overhauling (Store Report)Document30 pagesGT (Unit-01) Overhauling (Store Report)Farrukh AhmedNo ratings yet

- 9e PDFDocument12 pages9e PDFgayani100% (1)

- 6F.03 Fact Sheet 2016 PDFDocument2 pages6F.03 Fact Sheet 2016 PDFashok33% (3)

- DETC2009-86080: The Use of Interference Diagrams To Avoid Impeller Resonance: An Application To Igv DesignDocument8 pagesDETC2009-86080: The Use of Interference Diagrams To Avoid Impeller Resonance: An Application To Igv DesignRajesh KachrooNo ratings yet

- Stopping Procedure: MLN Block 405 Algeria Operator TrainingDocument10 pagesStopping Procedure: MLN Block 405 Algeria Operator TrainingGUESSOUMA100% (1)

- 11-Presentation MitchCohen PDFDocument32 pages11-Presentation MitchCohen PDFbigsteve9088No ratings yet

- Start Sequence: MLN Block 405, Algeria Operator TrainingDocument13 pagesStart Sequence: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- GT Frame 9 ManualDocument102 pagesGT Frame 9 ManualSSC & GSC of Lebanon100% (1)

- Robin Subaru Ec12 PDFDocument66 pagesRobin Subaru Ec12 PDFStan Marius VictorNo ratings yet

- Advantech HMI User Guide: CX501-KB7Document23 pagesAdvantech HMI User Guide: CX501-KB7GUESSOUMANo ratings yet

- Stopping Procedure: MLN Block 405 Algeria Operator TrainingDocument10 pagesStopping Procedure: MLN Block 405 Algeria Operator TrainingGUESSOUMA100% (1)

- Compressor Wash System: MLN Block 405, Algeria Operator TrainingDocument19 pagesCompressor Wash System: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Dual Fuel System: MLN Block 405, Algeria Operator TrainingDocument19 pagesDual Fuel System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Control System: MLN Block 405 Algeria Operator TrainingDocument14 pagesControl System: MLN Block 405 Algeria Operator TrainingGUESSOUMANo ratings yet

- Customer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingDocument4 pagesCustomer Maintenance and Daily Log: MLN Block 405, Algeria Operator TrainingGUESSOUMA100% (1)

- Hydraulic Start System: MLN Block 405, Algeria Operator TrainingDocument5 pagesHydraulic Start System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Start Sequence: MLN Block 405, Algeria Operator TrainingDocument13 pagesStart Sequence: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Hydraulic Start System: MLN Block 405, Algeria Operator TrainingDocument5 pagesHydraulic Start System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Compressed Air System: MLN Block 405, Algeria Operator TrainingDocument6 pagesCompressed Air System: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Epicyclic Speed Reduction Gears: MLN Block 405, Algeria Operator TrainingDocument8 pagesEpicyclic Speed Reduction Gears: MLN Block 405, Algeria Operator TrainingGUESSOUMANo ratings yet

- Solar Photovoltaic Water Pumping System For Irrigation PDFDocument7 pagesSolar Photovoltaic Water Pumping System For Irrigation PDFGUESSOUMA100% (1)

- Improve An Engine Cooling Fan Using Design For Six Sigma Techniques PDFDocument7 pagesImprove An Engine Cooling Fan Using Design For Six Sigma Techniques PDFGUESSOUMANo ratings yet

- Three Phase Appliance ProtectorDocument40 pagesThree Phase Appliance ProtectorJeevan PreethuNo ratings yet

- Travelling Salesman ProblemDocument27 pagesTravelling Salesman ProblemrafsantetoNo ratings yet

- Nissan R33 To Wolf V500 Pinouts With LinkDocument1 pageNissan R33 To Wolf V500 Pinouts With Linkwolfems100% (4)

- Ansa Model Checks For Ls-DynaDocument5 pagesAnsa Model Checks For Ls-DynaShailesh SainiNo ratings yet

- Jakab Gabor PHDDocument120 pagesJakab Gabor PHDEmrE GöktuĞNo ratings yet

- Unit 7 Discussion ForumDocument2 pagesUnit 7 Discussion ForumMelash workNo ratings yet

- SOF Sample Paper Class 9Document8 pagesSOF Sample Paper Class 9NishantNo ratings yet

- Pneumatics Vs HydraulicsDocument19 pagesPneumatics Vs HydraulicsGebBerheNo ratings yet

- CrossBorder PaymentsDocument378 pagesCrossBorder PaymentsDewa AsmaraNo ratings yet

- 8.5 Curved Surface Correction (CSC) - Olympus IMSDocument4 pages8.5 Curved Surface Correction (CSC) - Olympus IMSTHIRU.SNo ratings yet

- Eastron SDM120CT-Modbus User Manual 2016 V1 3Document7 pagesEastron SDM120CT-Modbus User Manual 2016 V1 3Santosh NayakNo ratings yet

- New Opportunities Offshore West EgyptDocument4 pagesNew Opportunities Offshore West EgyptMOHAMED ALi IBRAHIM HASSANNo ratings yet

- SST Binder 1Document14 pagesSST Binder 1Erick Francis Suárez VelásquezNo ratings yet

- Electronics & Communication: Institute of Engineering Studies Mock Test-IDocument13 pagesElectronics & Communication: Institute of Engineering Studies Mock Test-IInstitute of Engineering Studies (IES)No ratings yet

- DMRB Hd2908 Data For Pavement AssessmentDocument94 pagesDMRB Hd2908 Data For Pavement AssessmentLebo.emx MathosaNo ratings yet

- No. 11.7 HBI - Hot Briquetting of Direct Reduced Iron Technology and Status of Industrial ApplicationDocument16 pagesNo. 11.7 HBI - Hot Briquetting of Direct Reduced Iron Technology and Status of Industrial Applicationravi00098No ratings yet

- Homopolar MachinesDocument9 pagesHomopolar MachinesCarlosAugustoDaSilveiraDeJesusNo ratings yet

- Fuji Computed Radiography: The High-Performance CR That's Easy To UseDocument3 pagesFuji Computed Radiography: The High-Performance CR That's Easy To UseGuyphard NdombasiNo ratings yet

- FC1 General Part RadimatDocument11 pagesFC1 General Part Radimatpk cfctkNo ratings yet

- Banking Management System VB ProjectDocument123 pagesBanking Management System VB ProjectSudershan Thaiba100% (1)

- Math 8 2nd QRT ScaffoldDocument1 pageMath 8 2nd QRT ScaffoldSimmy DhaliwalNo ratings yet

- E560 Cig10 DSDocument11 pagesE560 Cig10 DSNITHIANo ratings yet

- MATHLAA DP1 Test 2 - Binomials and QuadraticsDocument5 pagesMATHLAA DP1 Test 2 - Binomials and QuadraticsDaniil SHULGANo ratings yet

- Chapter 6 - Metal WorkDocument27 pagesChapter 6 - Metal WorkIjal HaizalNo ratings yet

- Birhanu Mohammed & Fekadu 2022 (J)Document5 pagesBirhanu Mohammed & Fekadu 2022 (J)birhanuNo ratings yet

- UmbrellaDocument30 pagesUmbrellaconair911No ratings yet