Professional Documents

Culture Documents

Towing TD15

Towing TD15

Uploaded by

wawan0 ratings0% found this document useful (0 votes)

19 views4 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views4 pagesTowing TD15

Towing TD15

Uploaded by

wawanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

SECTION 3 MACHINE TRANSPORT

PAGE 6 AND STORAGE

3.3. MOVING A DISABLED MACHINE

is properly secured to the drawbar pins or tow hooks (if equipped). Do not use cables

having broken wires, thin spots or loops. Do not use a chain for towing, The strength

of the towing line or of the bar should be at least 150 percent of the gross weight of

the towing machine.

() CAUTION! When using a cable, be sure it is strong enough for the expected load and

A cable, which fails under load, can whip and cause serious injury. Stand clear. Do

not pull or tow unless the operator's compartment is guarded against or out of reach

of a whipping cable. Attach only to the machine pull hook or drawbar. Failure to

follow these instructions could cause serious injury.

( WARNING! When towing with a cable, take up the slack slowly to avoid jerking.

incorrectly. Block the machine to prevent movement before and after releasing the

brakes. When the pinion gears of final drives are removed, the machine has NO

brakes. The machine can roll freely and cause personal injury or death.

( WARNING! Personal injury or death could result when towing a disabled machine

IMPORTANT: A machine MUST NOT be towed if the steering drive and/ or final drive are out of order.

It must be transported to avoid further damage.

To avoid the possibility of power train damage, limit towing to a distance of 1.0 [km] and limit its

velocity to 2.0 [km/h]. The brakes on this machine are springs’ applied automatically when the engine

is stopped or the steering hydraulic system fails.

Keep the tow line or bar angle to a minimum. Do not exceed a 30 degree angle from the straight

ahead position.

Do not allow an operator to be on the machine that is being towed unless the operator can control the

steering and/or the braking

If the tractor can be towed and engine and steering hydraulic system can be operated, the machine

can be towed with a rope or rigid tow bar following the procedure described below:

1. Lock the drive train with a lock lever.

2. Altach a towing cable or a drawbar of a sufficient strength to a pull hook (1, Fig. 3.5) or drawbar (1,

Fig. 3.6).

3. Start the engine and unlock the drive train lock lever.

4, Release the brake pedal and tow the machine for a short distance only.

TD-15M EXTRA, DRESSTA.

MACHINE TRANSPORT SECTION 3

AND STORAGE PAGE 7

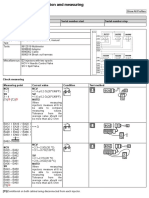

Fig, 3.5. Front Pull Hook Location at Machine

1. Front Pull Hook

Fig. 3.6. Rigid Drawbar Location at Machine

1. Rigid Drawbar

If the tractor can be towed but the engine and/or steering hydraulic system are inoperable, than the

brakes are applied and machine cannot be moved.

The machine can be towed following the procedure described below:

1. Lock the drive train with a lock lever.

2. Ifthe machine is on a slope, than

- with a small grade and hard ground, block the machine track chains with wooden throngs

- with a steep slope, block the machine with a tow bar attached to a drawbar or hitch and the

towing machine. Make sure that the towing machine has enough brake capacity, enough

weight and enough power; the towing machine must be as large as the disabled machine or

larger. When towing a disabled machine on a slope, one or more towing machines must be

able to provide good steering control and braking capacity. This can demand a larger towing

machine and extra machines attached at the back. This will prevent uncontrolled machine

rollover down the slope.

3, Release the brake pedal.

DRESSTA ‘TD-15M EXTRA,

SECTION 3 MACHINE TRANSPORT

PAGE 6 AND STORAGE

4,

In the machines S/N 33596 and below, release the brakes, remove pinion gears from final drives

and reconnect them following the procedure described in Service Manual, Section 7F. In machines

SIN: 33597 and up, release the brakes, supplying the pressurized grease to the L.H and RH side

brakes. Follow the procedure provided below:

a. remove rear shield, that is located between rear frame and fuel reservoir,

b. shift the tow valve lever (1, Fig. 3.7) to upright position — actuated (ON).

©. tee in two pressure gauges (having a reading range of 0 - 4 [MPal) to quick disconnects

(1 and 2, Fig. 3.8) at the drive train diagnostic center, to take a reading of pressurized pumped

grease

d, attach a hand lubricator to one of the quick disconnects (2, Fig. 3.7). Pump a sufficient amount

of grease to release the brakes. The teed pressure gauge is to read a pressure ranging from

1500 to 1800 [kPa]. The amount of grease required depends on the amount of pressure

dissipation in the system,

repeat the operation from step “a” for the other quick disconnect (2).

pumping an extra grease to a quick disconnect (2) may prove necessary to compensate for the

pressure dissipation as the pressure drop below 700 [kPa] will cause that the brakes will apply

automatically.

NOTE: Bear in mind that applied brake pedal will cause that the system pressure will dissipate and,

consequently, the brakes will apply.

g._ once the towing completed and the hand lubricator removed, disconnect the tow bar and shift

the tow valve lever (1, Fig. 3.7) to its level (horizontal) position — OFF.

h. restore rear shield, that is located between rear frame and fuel reservoir,

i. once the machine repaired, start the engine, apply the brake pedal until all grease has been

removed from the brake system and both brake pressure will dissipate to zero with a brake

pedal applied):

j. remove grease from hydraulic lines and fittings hooked to quick disconnects

(1 and 2, Fig. 3.8),

earlier version later version

Fig. 3.7. Tow Valve and Quick Disconnects (machine rear)

1. Valve Lever in the OFF Position 2. Quick Disconnect

TD-15M EXTRA, DRESSTA.

MACHINE TRANSPORT SECTION 3

AND STORAGE PAGE 9

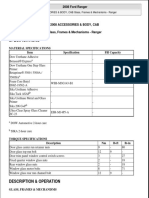

Fig, 3.8, Diagnostic Center (machine L.H side)

1. Quick Disconnect RB 2. Quick Disconnect LB

3.4. MACHINE STORAGE

3.4.1. PREPARING FOR STORAGE

When a machine is taken out of service and stored for more than 30 days, steps must be taken to

protect the machine, Leaving machine outdoors exposed to the elements will materially shorten its life.

An enclosure will protect the machine from rapid temperature changes and lesson the amount of

condensation that forms in hydraulic components, engine, fuel tank and final drives. If it is not possible

to put the machine in an enclosure, cover it with a tarpaulin

After the machine has been positioned for storage and the engine shutdown, perform the following

operations:

1. Visually inspect the machine for external leakage and other defects.

2, Clean the radiator Refer to “RADIATOR’ in Section 5.

3, Thoroughly clean the machine; be sure to rinse off any corrosive deposits.

4. Correct any defects found. Consult Authorized Distributor of Construction Equipment

5

Clean or replace the air cleaner elements. Refer to “ENGINE INLET AIR CLEANING AND

EXHAUST SYSTEM" in Section 5.

6. The cooling system should be completely drained, chemically flushed, and refilled with

a conditioned water/antifreeze solution suitable for the lowest temperature anticipated. Refer to

Section 5 “REPLACEMENT LUBRICANTS AND FLUIDS" for the proper antifreeze and conditioner

concentrations.

IMPORTANT: Under no circumstances should the vehicle be stored with a dry cooling system.

7. Drain the water from the fuel tank

8. Replace the fuel filters. Refer to "FUEL SYSTEM" in Section 5.

DRESSTA ‘TD-15M EXTRA,

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 3.0L EngineDocument182 pages3.0L EnginewawanNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- d6r Priority Valve TM TestadjustDocument5 pagesd6r Priority Valve TM TestadjustwawanNo ratings yet

- Trouble CodesDocument171 pagesTrouble Codeswawan100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- d6r Priority Valve TM OperationDocument2 pagesd6r Priority Valve TM Operationwawan0% (1)

- Hub Reduction, InstallingDocument16 pagesHub Reduction, InstallingwawanNo ratings yet

- Hydraulic Pressure, SpecificationsDocument2 pagesHydraulic Pressure, SpecificationswawanNo ratings yet

- Wiring Diagram A25: 1F2501, Activation Engine Brake (EMS)Document1 pageWiring Diagram A25: 1F2501, Activation Engine Brake (EMS)wawanNo ratings yet

- 2F4204, Control of TransmissionDocument3 pages2F4204, Control of TransmissionwawanNo ratings yet

- Hub Reduction, RemovingDocument5 pagesHub Reduction, RemovingwawanNo ratings yet

- 19F3702 Bus Communication Open CircuitDocument1 page19F3702 Bus Communication Open CircuitwawanNo ratings yet

- 19F3701 Bus Communication ReducedDocument1 page19F3701 Bus Communication ReducedwawanNo ratings yet

- AC System, SpecificationsDocument2 pagesAC System, SpecificationswawanNo ratings yet

- MA2301-MA2306 Description and MeasuringDocument2 pagesMA2301-MA2306 Description and MeasuringwawanNo ratings yet

- Axles, Tightening TorquesDocument2 pagesAxles, Tightening TorqueswawanNo ratings yet

- Hydraulic Pressure, SpecificationsDocument2 pagesHydraulic Pressure, SpecificationswawanNo ratings yet

- Specifications: 2008 Ford Ranger 2008 Ford RangerDocument8 pagesSpecifications: 2008 Ford Ranger 2008 Ford RangerwawanNo ratings yet

- d6r Oil Pump TM OperationDocument3 pagesd6r Oil Pump TM OperationwawanNo ratings yet

- Acceleration ControlDocument10 pagesAcceleration ControlwawanNo ratings yet

- Specifications: 2008 Ford Ranger 2008 Ford RangerDocument37 pagesSpecifications: 2008 Ford Ranger 2008 Ford RangerwawanNo ratings yet

- Auto Trans ControlsDocument26 pagesAuto Trans ControlswawanNo ratings yet

- Specifications: 2008 Ford Ranger 2008 Ford RangerDocument15 pagesSpecifications: 2008 Ford Ranger 2008 Ford RangerwawanNo ratings yet

- Excavator 320D Excavator BZP 320D Excavator BZP00001-UP (MACHINE) POWERED BY C6.4 EngineDocument2 pagesExcavator 320D Excavator BZP 320D Excavator BZP00001-UP (MACHINE) POWERED BY C6.4 EnginewawanNo ratings yet

- Auto Trans CoolingDocument15 pagesAuto Trans CoolingwawanNo ratings yet

- 260-8015 Lines Gp-Front - Medium PressureDocument3 pages260-8015 Lines Gp-Front - Medium PressurewawanNo ratings yet

- 352-7138 Valve Gp-Control - Boom, Stick, Swing, TravelDocument6 pages352-7138 Valve Gp-Control - Boom, Stick, Swing, TravelwawanNo ratings yet