Professional Documents

Culture Documents

Metal Inert Gas Welding (MIG, GMAW)

Uploaded by

Zaky0 ratings0% found this document useful (0 votes)

9 views2 pagesOriginal Title

MIG TS

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesMetal Inert Gas Welding (MIG, GMAW)

Uploaded by

ZakyCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Metal Inert Gas Welding (MIG, GMAW):

This is similar to TIG welding. At the place of non-consumable tungsten electrode, a

consumable metal electrode is used in the form of continuously fed metal wire. The electrode

wire and inert gas are fed through welding gun. Only DCRP is recommended for this type of

welding giving positive polarity to electrode wire. Feeding speed of electrode wire is adjusted

according to the welding speed.

This is used for the welding of carbon steel, low alloys steel, stainless steel and alloys of the

metal exhibiting resistance to heat.

Advantages of Metal Inert Gas Welding (MIG, GMAW):

Continuous weld may be produced (no interruptions);

High level of operators skill is not required;

Slag removal is not required (no slag);

Faster than TIG Due TO continues feed.

Disadvantages of Metal Inert Gas Welding (MIG, GMAW):

Process is complicated than TIG.

Expensive and non-portable equipment is required;

Outdoor application are limited because of effect of wind, dispersing the shielding gas.

You might also like

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Tig MigDocument15 pagesTig Migsatish448No ratings yet

- Electric Welding Machine: Name: Firman Akbar Class: 1E NIM: 2031240122Document2 pagesElectric Welding Machine: Name: Firman Akbar Class: 1E NIM: 2031240122Firman AkbarNo ratings yet

- Difference Between Mig and Tig Welding: Dolfred D'SouzaDocument14 pagesDifference Between Mig and Tig Welding: Dolfred D'SouzaDolfredNo ratings yet

- L31B Gmaw PDFDocument16 pagesL31B Gmaw PDFCrocodileNo ratings yet

- 2 Joining ProcessDocument54 pages2 Joining ProcessIzzah Suhair Binti Sa'AbanNo ratings yet

- JOINING of Metals: 1. WeldingDocument62 pagesJOINING of Metals: 1. WeldingMuhammad Ali BakhtNo ratings yet

- CH 4Document63 pagesCH 4tariku seyoumNo ratings yet

- Gas Metal Arc Welding: AnDocument13 pagesGas Metal Arc Welding: Ansamyfr454No ratings yet

- Group 8, Welding AssignmentDocument11 pagesGroup 8, Welding AssignmentKavish ChandraNo ratings yet

- Gas Metal Arc Welding (MIG) Presented by N.Sankar/Ap /mechDocument50 pagesGas Metal Arc Welding (MIG) Presented by N.Sankar/Ap /mechlastjohnNo ratings yet

- Introduction To Practical Application of Wire Feed WeldingDocument15 pagesIntroduction To Practical Application of Wire Feed WeldingmohitshuklamarsNo ratings yet

- Advanced Welding Process (Welding)Document58 pagesAdvanced Welding Process (Welding)Sk SamsuddinNo ratings yet

- Metal Inert Gas Welding-120526013715-Phpapp01Document2 pagesMetal Inert Gas Welding-120526013715-Phpapp01SanjayNo ratings yet

- Presentation On: Applications of and Welding in ManufacturingDocument27 pagesPresentation On: Applications of and Welding in ManufacturingHope ThemNo ratings yet

- Gas Tungsten-Arc Welding GTAW - Welding TechnologyDocument2 pagesGas Tungsten-Arc Welding GTAW - Welding TechnologyMuhammadNo ratings yet

- Mig Co2Document23 pagesMig Co2Asad Bin Ala Qatari50% (2)

- Online GATE-2020 Coaching Mechanical Engineering Manufacturing/Production Technology Session-8 Welding 20/06/2020Document53 pagesOnline GATE-2020 Coaching Mechanical Engineering Manufacturing/Production Technology Session-8 Welding 20/06/2020Md. Zishanur RahmanNo ratings yet

- MCL-135-Welding and Allied Processes - Class 11-15Document58 pagesMCL-135-Welding and Allied Processes - Class 11-15mHmNo ratings yet

- Metal Inert GasDocument7 pagesMetal Inert GasAshok PradhanNo ratings yet

- Workshop Case StudyDocument13 pagesWorkshop Case Study1071Vishal kumarNo ratings yet

- Experiments 7Document2 pagesExperiments 7Deep SasaniNo ratings yet

- And Welding in Manufacturing: TIG MIGDocument27 pagesAnd Welding in Manufacturing: TIG MIGHope ThemNo ratings yet

- Types of WeldingDocument66 pagesTypes of WeldingLee Shi HongNo ratings yet

- JJ205 Workshop Technology Tic&Mic WeldingDocument47 pagesJJ205 Workshop Technology Tic&Mic WeldingAh TiangNo ratings yet

- Comprensión Lectora Estructuras MetálicasDocument1 pageComprensión Lectora Estructuras MetálicasNATALIA ARCE INOJOSANo ratings yet

- Arc WeldingDocument23 pagesArc WeldingZerohumidity 123100% (1)

- 6 GmawDocument19 pages6 Gmawalinader20022No ratings yet

- Unit 2 PDFDocument21 pagesUnit 2 PDFravikumarsharma2412No ratings yet

- Experiment No 3 Tungsten Inert Gas (TIG) Welding: ObjectiveDocument7 pagesExperiment No 3 Tungsten Inert Gas (TIG) Welding: ObjectiveUsman Saeed KianiNo ratings yet

- Presentation On WeldingDocument103 pagesPresentation On WeldingBharath KumarNo ratings yet

- Lecture 21: GTAG Welding: Fundamental of Welding Science and TechnologyDocument24 pagesLecture 21: GTAG Welding: Fundamental of Welding Science and TechnologyNavneet KumarNo ratings yet

- TIG & MIG Welding ProcessDocument2 pagesTIG & MIG Welding ProcessRIYA SHARMANo ratings yet

- WeldingDocument62 pagesWeldingAbhishek AnandNo ratings yet

- A TIG Unit Consists ofDocument5 pagesA TIG Unit Consists ofZaky MuzaffarNo ratings yet

- Mig Gmaw Welding 1Document26 pagesMig Gmaw Welding 1HAZEL BELLONo ratings yet

- Adyapeath Annada Polytechnic CollegeDocument5 pagesAdyapeath Annada Polytechnic CollegeArunavaNo ratings yet

- Tig Mig PlasmaDocument29 pagesTig Mig PlasmaManojKumarNo ratings yet

- Welding MachinesDocument53 pagesWelding MachinesDeepak Kumar Kant Kesri100% (2)

- UnitDocument41 pagesUnitsawravkblNo ratings yet

- Pengelasan GMAWDocument29 pagesPengelasan GMAWLintas Laut SamuderaNo ratings yet

- Mig WeldingDocument8 pagesMig WeldingSiddharth PradhanNo ratings yet

- Welding Procedure & Welder Qualification: Pak-Arab Refinery LimitedDocument70 pagesWelding Procedure & Welder Qualification: Pak-Arab Refinery LimitedRizwan BangashNo ratings yet

- MIG Vs TIG Vs Stick Vs Flux Core Welding ProcessesDocument8 pagesMIG Vs TIG Vs Stick Vs Flux Core Welding ProcessesCalvin YeohNo ratings yet

- Manufacturing Technology: Tig Welding - Process AnalysisDocument8 pagesManufacturing Technology: Tig Welding - Process AnalysisshubhamNo ratings yet

- Welder's Handbook (Air Products Co.)Document48 pagesWelder's Handbook (Air Products Co.)Patrick DominguezNo ratings yet

- Engineering Welding Handbook99 PDF TigDocument48 pagesEngineering Welding Handbook99 PDF TigSorin Stanescu100% (1)

- L2-Arc - Welding - Process - PPTX Filename UTF-8''L2-Arc Welding ProcessDocument18 pagesL2-Arc - Welding - Process - PPTX Filename UTF-8''L2-Arc Welding Process222-020-651No ratings yet

- Metal Inert Gas and Metal Active Gas Welding-Ir FazrulDocument9 pagesMetal Inert Gas and Metal Active Gas Welding-Ir FazrulEmmy NadiaNo ratings yet

- Experiment - TIGDocument5 pagesExperiment - TIGAl Anood Al AmeriNo ratings yet

- MigDocument6 pagesMigPensel KoNtotNo ratings yet

- (Gmaw) Gas Metal Arc Welding (Mig - Mag)Document11 pages(Gmaw) Gas Metal Arc Welding (Mig - Mag)buttuverma18102No ratings yet

- Welding Technology Unit 1 NotesDocument58 pagesWelding Technology Unit 1 NotesVasanthakumar B.E;No ratings yet

- Classification of Welding ProcessesDocument25 pagesClassification of Welding ProcessesvelavansuNo ratings yet

- Proceso de Soldadura Gmaw. Presentado Por: Fatima Del Rosario Choquehunaca Cutipa Fatima Docente: Ing Larico Grupo: Lunes 2-4Pm 1. ObjetivosDocument8 pagesProceso de Soldadura Gmaw. Presentado Por: Fatima Del Rosario Choquehunaca Cutipa Fatima Docente: Ing Larico Grupo: Lunes 2-4Pm 1. ObjetivosBel BarretoNo ratings yet

- Study of Tig WeldingDocument11 pagesStudy of Tig WeldingChandan Srivastava100% (1)

- Overview of Advanced Welding ProcessesDocument55 pagesOverview of Advanced Welding ProcessesSaravanan RajendranNo ratings yet

- Srno Application Name Father Name Scheme Name Course Name Application Renewed or NotDocument5 pagesSrno Application Name Father Name Scheme Name Course Name Application Renewed or NotZakyNo ratings yet

- Design Procedure Socket and SpigotDocument4 pagesDesign Procedure Socket and SpigotZakyNo ratings yet

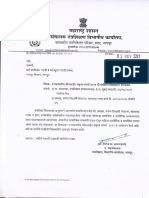

- Rashtrasant Tukadoji Maharaj Nagpur UniversityDocument5 pagesRashtrasant Tukadoji Maharaj Nagpur UniversityZakyNo ratings yet

- Censure 20of 20ibn 20aqilDocument45 pagesCensure 20of 20ibn 20aqilZakyNo ratings yet

- Form Scholarship 2020 21 eDocument2 pagesForm Scholarship 2020 21 eZakyNo ratings yet

- Press Working Operation NOTESDocument6 pagesPress Working Operation NOTESZakyNo ratings yet

- Dome-Unit 1. Machine DesignDocument6 pagesDome-Unit 1. Machine DesignZakyNo ratings yet

- DME Unit 2 WELD QuestionDocument2 pagesDME Unit 2 WELD QuestionZakyNo ratings yet

- 35Thfà/Atrit/155: TRTTR Faarierer Fifaa A Y A Hiigh-Iufa/ (U./154Document1 page35Thfà/Atrit/155: TRTTR Faarierer Fifaa A Y A Hiigh-Iufa/ (U./154ZakyNo ratings yet

- MPSCDocument2 pagesMPSCZakyNo ratings yet

- FM MCQDocument7 pagesFM MCQZakyNo ratings yet

- 3099 MergedDocument4 pages3099 MergedZakyNo ratings yet

- Knuckle Joint NumericalDocument3 pagesKnuckle Joint NumericalZakyNo ratings yet

- Anjuman College of Engineering and Technology Design of Machine Elements'Document2 pagesAnjuman College of Engineering and Technology Design of Machine Elements'ZakyNo ratings yet

- EC-I Unit 2 Q Bank 2021-22Document2 pagesEC-I Unit 2 Q Bank 2021-22ZakyNo ratings yet