Professional Documents

Culture Documents

Installation Guide: Smartax Ma5600T Multi-Service Access Module V800R008C02

Uploaded by

houcemOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Installation Guide: Smartax Ma5600T Multi-Service Access Module V800R008C02

Uploaded by

houcemCopyright:

Available Formats

SmartAX MA5600T Multi-service Access Module

V800R008C02

Installation Guide

Issue 01

Date 2011-01-15

HUAWEI TECHNOLOGIES CO., LTD.

Copyright © Huawei Technologies Co., Ltd. 2011. All rights reserved.

No part of this document may be reproduced or transmitted in any form or by any means without prior written

consent of Huawei Technologies Co., Ltd.

Trademarks and Permissions

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective holders.

Notice

The purchased products, services and features are stipulated by the contract made between Huawei and the

customer. All or part of the products, services and features described in this document may not be within the

purchase scope or the usage scope. Unless otherwise specified in the contract, all statements, information,

and recommendations in this document are provided "AS IS" without warranties, guarantees or representations

of any kind, either express or implied.

The information in this document is subject to change without notice. Every effort has been made in the

preparation of this document to ensure accuracy of the contents, but all statements, information, and

recommendations in this document do not constitute the warranty of any kind, express or implied.

Huawei Technologies Co., Ltd.

Address: Huawei Industrial Base

Bantian, Longgang

Shenzhen 518129

People's Republic of China

Website: http://www.huawei.com

Email: support@huawei.com

Issue 01 (2011-01-15) Huawei Proprietary and Confidential i

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide About This Document

About This Document

Intended Audience

This document describes the entire process for installing the N63E-22 cabinet for indoor access

solutions in terms of installation preparations, cabinet installation, cable routing, and power-on

check.

The intended audience of this document is:

l Installation engineers

l Technical support engineers

Symbol Conventions

The following symbols may be found in this document. They are defined as follows.

Symbol Description

Indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

Indicates a hazard with a medium or low level of risk

which, if not avoided, could result in minor or moderate

injury.

Indicates a potentially hazardous situation that, if not

avoided, could cause device damage, data loss, and

performance degradation, or unexpected results.

Indicates a tip that may help you solve a problem or save

your time.

Provides additional information to emphasize or

supplement important points of the main text.

Update History

Updates between document issues are cumulative. Therefore, the latest document issue contains

all updates made in previous issues.

Issue 01 (2011-01-15) Huawei Proprietary and Confidential iii

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

About This Document Installation Guide

Updates in Issue 01 (2011-01-15)

This is the first release.

iv Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide Contents

Contents

About This Document...................................................................................................................iii

1 Equipment Overview................................................................................................................1-1

1.1 Outline and Structure .....................................................................................................................................1-2

1.2 Configuration..................................................................................................................................................1-3

2 Preparing for the Installation...................................................................................................2-1

2.1 Checking the Installation Entry.......................................................................................................................2-2

2.1.1 Tools and Meters....................................................................................................................................2-2

2.1.2 Checking the Construction Environment.............................................................................................2-11

2.1.3 Checking the Power Supply System....................................................................................................2-13

2.1.4 Checking the Grounding System..........................................................................................................2-14

2.1.5 Checking the Cable Tray......................................................................................................................2-15

2.1.6 Checking the Distribution Frame.........................................................................................................2-15

2.2 Unpacking and Accepting Products..............................................................................................................2-16

2.2.1 Checking Before Unpacking................................................................................................................2-17

2.2.2 Unpacking the Wooden Case...............................................................................................................2-17

2.2.3 Unpacking the Carton...........................................................................................................................2-19

2.2.4 Unpacking the Board............................................................................................................................2-20

2.2.5 Accepting the Product..........................................................................................................................2-22

3 Removing the Cabinet Doors...................................................................................................3-1

3.1 Removing the Front Door of the Cabinet........................................................................................................3-2

3.2 Removing Side Covers....................................................................................................................................3-3

4 Installing the Cabinet on a Concrete Floor...........................................................................4-1

4.1 Outline of the Installed Cabinet......................................................................................................................4-3

4.2 Installation Process..........................................................................................................................................4-4

4.3 Recommended Tools.......................................................................................................................................4-6

4.4 Checking Before the Installation.....................................................................................................................4-7

4.5 Marking Reference Lines................................................................................................................................4-7

4.5.1 Marking Reference Lines Based on the Construction Plan Drawing.....................................................4-8

4.5.2 Marking Reference Lines Based on the Marking-off Plate..................................................................4-10

4.6 Drilling Holes................................................................................................................................................4-11

4.7 Installing Expansion Bolts............................................................................................................................4-12

4.8 Placing the Cabinet........................................................................................................................................4-15

Issue 01 (2011-01-15) Huawei Proprietary and Confidential v

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Contents Installation Guide

4.9 Leveling the Cabinet.....................................................................................................................................4-18

4.10 Fastening the Cabinet..................................................................................................................................4-19

4.11 Testing the Resistance.................................................................................................................................4-20

4.12 Attaching Cabinets......................................................................................................................................4-21

5 Installing the Cabinet on an ESD Floor.................................................................................5-1

5.1 Outline of the Installed Cabinet ..................................................................................................................... 5-3

5.2 Installation Process..........................................................................................................................................5-4

5.3 Recommended Tools.......................................................................................................................................5-6

5.4 Checking Before the Installation.....................................................................................................................5-7

5.5 Marking Reference Lines................................................................................................................................5-8

5.5.1 Marking Reference Lines Based on the Construction Plan Drawing.....................................................5-8

5.5.2 Marking Reference Lines Based on the Marking-off Plate..................................................................5-10

5.6 Drilling Holes................................................................................................................................................5-11

5.7 Installing Expansion Bolts............................................................................................................................5-12

5.8 Installing the Support....................................................................................................................................5-15

5.9 Placing the Cabinet........................................................................................................................................5-17

5.10 Leveling the Cabinet...................................................................................................................................5-20

5.11 Fastening the Cabinet..................................................................................................................................5-21

5.12 Testing the Resistance.................................................................................................................................5-22

5.13 Attaching Cabinets......................................................................................................................................5-24

5.14 Recovering the ESD Floor..........................................................................................................................5-24

6 Routing Cables ..........................................................................................................................6-1

6.1 Rules for Routing Cables................................................................................................................................ 6-2

6.2 Routing External Power Cables and Ground Cables for the B-Type PDU ....................................................6-8

6.3 Routing External Power Cables and Ground Cables for the C3-Type PDU.................................................6-10

6.4 Routing External Power Cables and Ground Cables for the I-Type PDU ...................................................6-11

6.5 Routing Clock Cable ....................................................................................................................................6-13

6.6 Routing Subscriber Cables for the 32-channel service board ......................................................................6-15

6.7 Routing Subscriber Cables for 64-channel service board ............................................................................6-16

6.8 Routing 2-in-1 Subscriber Cables.................................................................................................................6-17

6.9 Routing Interconnection Cables ...................................................................................................................6-18

6.10 Routing Trunk Cables ................................................................................................................................6-20

6.11 Routing Network Cables ............................................................................................................................6-21

6.12 Notes for Routing Optical Fibers ...............................................................................................................6-23

6.13 Routing Optical Fibers (MSAN).................................................................................................................6-24

6.14 Routing Optical Fibers (GPON)..................................................................................................................6-25

6.15 Routing Optical Fibers (P2P)......................................................................................................................6-26

6.16 Routing Optical Fibers (P2P, Detail)..........................................................................................................6-27

7 Ending Installation....................................................................................................................7-1

7.1 Sealing Cable Holes........................................................................................................................................7-2

7.1.1 Sealing Holes for Power Cables and Ground Cables.............................................................................7-2

vi Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide Contents

7.1.2 Sealing Holes for Optical Fibers............................................................................................................7-2

7.2 Installing the Cabinet Door.............................................................................................................................7-2

7.2.1 Installing the Front Door of the Cabinet................................................................................................7-2

7.2.2 Installing Side Covers............................................................................................................................7-5

7.3 Marking the Cabinet........................................................................................................................................7-6

7.4 Checking the Installation.................................................................................................................................7-7

7.4.1 Checking the Cabinet Installation..........................................................................................................7-7

7.4.2 Checking the Internal Connections (MSAN).........................................................................................7-9

7.4.3 Checking the Signal Cable Routing.....................................................................................................7-10

7.4.4 Checking the Installation of Terminal, Alarm box, and NMS.............................................................7-12

7.4.5 Checking the Power and the Grounding..............................................................................................7-13

7.4.6 Checking the Installation Environment................................................................................................7-14

7.4.7 Checking the Telecommunications Room...........................................................................................7-15

7.4.8 Checking the Connectivity of the Cables.............................................................................................7-16

7.5 Powering On the Device ..............................................................................................................................7-17

A Specifications of the N63E-22 Cabinet.................................................................................A-1

B Installing an Indoor Cable Rack............................................................................................B-1

B.1 Introduction to an Indoor Cable Rack............................................................................................................B-2

B.2 Process for Installing an Indoor Cable Rack..................................................................................................B-4

B.3 Installing an Indoor Cable Rack....................................................................................................................B-6

B.3.1 Ceiling-Based Installation.....................................................................................................................B-6

B.3.2 Installing an Indoor Cable Rack on the Ground...................................................................................B-9

B.3.3 Installing an Indoor Cable Rack Against the Wall.............................................................................B-11

B.4 Installing a Grounding Cable.......................................................................................................................B-13

B.5 Other Methods for Connecting Cable Ladders............................................................................................B-13

B.5.1 Assembling Cable Ladders.................................................................................................................B-14

B.5.2 Turning Cable Ladders.......................................................................................................................B-15

B.5.3 Connecting the Cable Ladder to the Wall...........................................................................................B-16

B.5.4 Jointing Cable Ladders.......................................................................................................................B-16

B.5.4.1 Front Jointing...................................................................................................................................B-17

B.5.4.2 Side Jointing.....................................................................................................................................B-17

B.5.4.3 Oblique Jointing...............................................................................................................................B-18

B.6 Installing a Cable Tray.................................................................................................................................B-18

B.6.1 Overview of a Cable Tray...................................................................................................................B-19

B.6.2 Connecting Cable Trays......................................................................................................................B-19

B.6.3 Installing a Cable Tray on a 200 mm or 400 mm Wide Cable Ladder...............................................B-19

B.6.4 Installing a Cable Tray Sideways.......................................................................................................B-20

B.7 Installing Accessories..................................................................................................................................B-22

B.7.1 Overview.............................................................................................................................................B-22

B.7.2 Installing Cable-Through Racks.........................................................................................................B-23

B.7.3 Installing End Covers, Movable Bushings, and Baffle Rings............................................................B-24

Issue 01 (2011-01-15) Huawei Proprietary and Confidential vii

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Contents Installation Guide

C Making Cables and Connectors.............................................................................................C-1

C.1 Making External Power Cables and Ground Cables with Cord End Terminals............................................C-2

C.2 Making External Power Cables and Ground Cables with OT Terminals......................................................C-4

C.3 Making Ordinary Network Cables.................................................................................................................C-7

C.4 Making Shielded Network Cables...............................................................................................................C-10

C.5 Making the E1 Cable...................................................................................................................................C-13

C.5.1 Making the E1 Cable with the Straight SMB Female Connector....................................................... C-13

C.5.2 Making the E1 Cable with the Straight SMB Male Connector..........................................................C-18

C.5.3 Making the E1 Cable with the Bent SMB Female Connector............................................................C-23

D Installing the Internal Components of the Cabinet..........................................................D-1

D.1 Installing and Removing the Subrack............................................................................................................D-2

D.1.1 Materials and Tools..............................................................................................................................D-2

D.1.2 Precautions...........................................................................................................................................D-2

D.1.3 Installing the Subrack...........................................................................................................................D-2

D.1.4 Removing the Subrack.........................................................................................................................D-3

D.2 Installing and Removing the Board...............................................................................................................D-4

D.2.1 Materials and Tools..............................................................................................................................D-4

D.2.2 Precautions...........................................................................................................................................D-4

D.2.3 Installing the Board..............................................................................................................................D-5

D.2.4 Removing the Board.............................................................................................................................D-6

D.3 Installing and Removing the Fan Tray..........................................................................................................D-7

D.3.1 Materials and Tools..............................................................................................................................D-7

D.3.2 Precautions...........................................................................................................................................D-8

D.3.3 Installing the Fan Tray..........................................................................................................................D-8

D.3.4 Removing the Fan Tray........................................................................................................................D-8

E Cable Labels...............................................................................................................................E-1

E.1 Introduction to Labels....................................................................................................................................E-3

E.2 Filling Labels..................................................................................................................................................E-5

E.3 Usage of Labels..............................................................................................................................................E-7

E.4 Attaching Labels.............................................................................................................................................E-9

E.5 Label for External Alarm Cables..................................................................................................................E-11

E.6 Label for Network Cables............................................................................................................................ E-12

E.7 Labels for Optical Fibers..............................................................................................................................E-14

E.8 Labels for Trunk Cables...............................................................................................................................E-16

E.9 Label for Subscriber Cables......................................................................................................................... E-19

E.10 Labels for DC Power Cables......................................................................................................................E-20

E.11 Labels for AC Power Cables......................................................................................................................E-22

F Environment Requirements.....................................................................................................F-1

F.1 Storage Environment Requirements...............................................................................................................F-2

F.2 Transportation Environment Requirements....................................................................................................F-4

viii Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide Contents

F.3 Running Environment.....................................................................................................................................F-6

Issue 01 (2011-01-15) Huawei Proprietary and Confidential ix

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide Figures

Figures

Figure 1-1 Configuration of the N63E-22 cabinet installed with one service subrack .......................................1-4

Figure 1-2 Configuration of the N63E-22 cabinet installed with two service subracks ..................................... 1-5

Figure 1-3 Configuration of the N63E-22 cabinet installed with one service subrack and one SPL subrack

...............................................................................................................................................................................1-6

Figure 2-1 Straightening the tongue...................................................................................................................2-18

Figure 2-2 Removing the cover..........................................................................................................................2-18

Figure 2-3 Removing the wooden panels...........................................................................................................2-19

Figure 2-4 Unpacking the carton........................................................................................................................2-20

Figure 2-5 Unpacking the board.........................................................................................................................2-21

Figure 3-1 Removing the front door of the cabinet..............................................................................................3-2

Figure 3-2 Removing the screws on side covers..................................................................................................3-3

Figure 4-1 A cabinet installed on a concrete floor...............................................................................................4-3

Figure 4-2 Several cabinets installed on a concrete floor.....................................................................................4-4

Figure 4-3 Process of installing the cabinet on a concrete floor.......................................................................... 4-5

Figure 4-4 Construction plan drawing for installing a single cabinet on a concrete floor...................................4-8

Figure 4-5 Construction plan drawing for installing cabinets side by side on a concrete floor...........................4-9

Figure 4-6 Construction plan drawing for installing cabinets back to back on a concrete floor..........................4-9

Figure 4-7 Marking-off plate for a concrete floor..............................................................................................4-10

Figure 4-8 Drilling a hole...................................................................................................................................4-12

Figure 4-9 Components of an expansion bolt....................................................................................................4-13

Figure 4-10 Installing an expansion bolt............................................................................................................4-14

Figure 4-11 Removing the spring washer, flat washer, and nut.........................................................................4-14

Figure 4-12 Removing the front door of the cabinet..........................................................................................4-16

Figure 4-13 Removing the air filter....................................................................................................................4-17

Figure 4-14 Placing the cabinet..........................................................................................................................4-18

Figure 4-15 Leveling the cabinet........................................................................................................................4-19

Figure 4-16 Fastening the cabinet......................................................................................................................4-20

Figure 4-17 Testing the resistance......................................................................................................................4-21

Figure 4-18 Connecting the connecting plates...................................................................................................4-22

Figure 5-1 A single cabinet installed on an ESD floor.........................................................................................5-3

Figure 5-2 A row of cabinets installed on an ESD floor......................................................................................5-4

Figure 5-3 Process of installing the cabinet on an ESD floor..............................................................................5-5

Figure 5-4 Construction plan drawing for installing a single cabinet on an ESD floor.......................................5-8

Figure 5-5 Construction plan drawing for installing cabinets side by side on an ESD floor...............................5-9

Issue 01 (2011-01-15) Huawei Proprietary and Confidential xi

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Figures Installation Guide

Figure 5-6 Construction plan drawing for installing cabinets back to back on an ESD floor..............................5-9

Figure 5-7 Marking-off plate for the ESD floor of the cabinet..........................................................................5-11

Figure 5-8 Drilling a hole...................................................................................................................................5-12

Figure 5-9 Components of an expansion bolt....................................................................................................5-13

Figure 5-10 Installing an expansion bolt............................................................................................................5-14

Figure 5-11 Removing the spring washer, flat washer, and nut.........................................................................5-14

Figure 5-12 Position of the height-locking bolt.................................................................................................5-15

Figure 5-13 Installing the support......................................................................................................................5-16

Figure 5-14 Leveling and fastening the support.................................................................................................5-17

Figure 5-15 Removing the front door of the cabinet..........................................................................................5-18

Figure 5-16 Removing the air filter....................................................................................................................5-19

Figure 5-17 Placing the cabinet..........................................................................................................................5-20

Figure 5-18 Leveling the cabinet........................................................................................................................5-21

Figure 5-19 Fastening the cabinet......................................................................................................................5-22

Figure 5-20 Testing the resistance......................................................................................................................5-23

Figure 5-21 Connecting the connecting plates...................................................................................................5-24

Figure 5-22 Process of recovering the ESD floor..............................................................................................5-25

Figure 5-23 Installing the floor holder...............................................................................................................5-25

Figure 6-1 Installing the OT terminals.................................................................................................................6-3

Figure 6-2 Bundling the cables at the bending radius..........................................................................................6-4

Figure 6-3 Leading the cables through the cable ladder.......................................................................................6-5

Figure 6-4 Leading the cables downwards from the side of the cable trough......................................................6-6

Figure 7-1 Installing the air filter.........................................................................................................................7-3

Figure 7-2 Installing the front door of the cabinet...............................................................................................7-4

Figure 7-3 Connecting the ground cable..............................................................................................................7-5

Figure 7-4 Installing the screws on side covers...................................................................................................7-6

Figure B-1 Process for installing an indoor cable rack........................................................................................B-5

Figure B-2 Distance between bracket angles.......................................................................................................B-6

Figure B-3 Drilling holes.....................................................................................................................................B-7

Figure B-4 Ceiling-based installation..................................................................................................................B-8

Figure B-5 Ceiling-based installation when there is an obstacle on the ceiling..................................................B-9

Figure B-6 Distance between bracket angles.......................................................................................................B-9

Figure B-7 Drilling holes...................................................................................................................................B-10

Figure B-8 Ground-based installation...............................................................................................................B-11

Figure B-9 Fixing a U-steel as the beam onto the cable ladder.........................................................................B-11

Figure B-10 Distance between deltoid frames...................................................................................................B-12

Figure B-11 Drilling holes.................................................................................................................................B-12

Figure B-12 Installing the cable rack against the wall.......................................................................................B-13

Figure B-13 Installing a grounding cable..........................................................................................................B-13

Figure B-14 Assembling cable ladders..............................................................................................................B-14

Figure B-15 Turning the cable ladders (without cable trays) on the same level...............................................B-15

Figure B-16 Turning the cable ladders on different levels................................................................................B-16

xii Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide Figures

Figure B-17 Connecting the cable ladder to the wall........................................................................................B-16

Figure B-18 Front jointing of cable ladders......................................................................................................B-17

Figure B-19 Side jointing of cable ladders........................................................................................................B-18

Figure B-20 Oblique jointing of cable ladders..................................................................................................B-18

Figure B-21 Connecting cable trays..................................................................................................................B-19

Figure B-22 Installing the cable tray on the cable ladder.................................................................................. B-20

Figure B-23 Cutting off the connecting rib of the triangle aperture..................................................................B-20

Figure B-24 Installing the cable tray sideways..................................................................................................B-21

Figure B-25 Cable tray installed sideways onto the cabling ladder..................................................................B-22

Figure B-26 Installing a cable-through rack when the cable rack is not equipped with a cable tray................B-23

Figure B-27 Installing a cable-through rack when the cable rack is equipped with a cable tray......................B-24

Figure B-28 Installing an end cover on a cable ladder......................................................................................B-24

Figure B-29 Installing a movable bushing on a cable tray................................................................................B-24

Figure B-30 Installing a baffle ring on a cable tray...........................................................................................B-25

Figure C-1 Peeling the insulation layer off the power cable...............................................................................C-2

Figure C-2 Inserting the conductor into the cord end terminal...........................................................................C-3

Figure C-3 Clamping the cord end terminal........................................................................................................C-4

Figure C-4 Peeling off the insulation layer of the power cable...........................................................................C-5

Figure C-5 Installing heat shrink tubing and bare crimping terminal.................................................................C-6

Figure C-6 Clamping the tail of the bare crimping terminal with the contact part of the conductor..................C-6

Figure C-7 Installing the heat shrink tubing........................................................................................................C-7

Figure C-8 Ordinary network cable.....................................................................................................................C-8

Figure C-9 Installing the boot for the RJ-45 connector.......................................................................................C-8

Figure C-10 Peeling the jacket............................................................................................................................C-9

Figure C-11 Assigning the wires to the network cable.......................................................................................C-9

Figure C-12 Pushing the boot to cover the RJ-45 connector.............................................................................C-10

Figure C-13 Shielded network cable.................................................................................................................C-11

Figure C-14 Components of a shielded RJ-45 connector..................................................................................C-11

Figure C-15 Installing the boot for the RJ-45 connector and the shielded metal cover.................................... C-12

Figure C-16 Installing the wires........................................................................................................................C-12

Figure C-17 Crimping the RJ-45 connector......................................................................................................C-13

Figure C-18 Components..................................................................................................................................C-14

Figure C-19 Structure of the coaxial cable........................................................................................................C-15

Figure C-20 Lengths of connectors and the peeled part of cables.....................................................................C-16

Figure C-21 Putting a coaxial cable into a sleeve.............................................................................................C-16

Figure C-22 Expanding the outer conductor of a coaxial cable........................................................................C-16

Figure C-23 Inserting a coaxial cable into a connector plug.............................................................................C-17

Figure C-24 Soldering the inner conductor.......................................................................................................C-17

Figure C-25 Press-fitting the outer conductor...................................................................................................C-17

Figure C-26 Installing the components of a coaxial cable................................................................................C-18

Figure C-27 Components..................................................................................................................................C-19

Figure C-28 Structure of the coaxial cable........................................................................................................C-20

Issue 01 (2011-01-15) Huawei Proprietary and Confidential xiii

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Figures Installation Guide

Figure C-29 Lengths of connectors and the peeled part of cables.....................................................................C-20

Figure C-30 Putting a coaxial cable into a sleeve.............................................................................................C-21

Figure C-31 Expanding the outer conductor of a coaxial cable........................................................................C-21

Figure C-32 Inserting a coaxial cable into a connector plug.............................................................................C-21

Figure C-33 Soldering the inner conductor.......................................................................................................C-22

Figure C-34 Press-fitting the outer conductor...................................................................................................C-22

Figure C-35 Installing the components of a coaxial cable................................................................................C-23

Figure C-36 Components..................................................................................................................................C-24

Figure C-37 Structure of the coaxial cable........................................................................................................C-24

Figure C-38 Lengths of connectors and the peeled part of cables.....................................................................C-25

Figure C-39 Putting a coaxial cable into a sleeve.............................................................................................C-26

Figure C-40 Inserting a coaxial cable into a connector plug.............................................................................C-26

Figure C-41 Soldering the inner conductor.......................................................................................................C-26

Figure C-42 Press-fitting the outer conductor...................................................................................................C-27

Figure C-43 Press-fitting the upper cover on the connector..............................................................................C-27

Figure C-44 Installing the components of a coaxial cable................................................................................C-28

Figure D-1 Fixing the panel screws.....................................................................................................................D-3

Figure D-2 Removing the subrack......................................................................................................................D-4

Figure D-3 Wearing an ESD wrist strap correctly..............................................................................................D-5

Figure D-4 Installing the board...........................................................................................................................D-6

Figure D-5 Removing the board..........................................................................................................................D-7

Figure D-6 Installing the fan tray........................................................................................................................D-8

Figure D-7 Removing the fan tray.......................................................................................................................D-9

Figure E-1 Label for the signal cable...................................................................................................................E-4

Figure E-2 Label for the power cable..................................................................................................................E-5

Figure E-3 Warning prompt before the printing..................................................................................................E-6

Figure E-4 Writing direction on the label............................................................................................................E-7

Figure E-5 Printing parts on the label for the signal cables.................................................................................E-8

Figure E-6 Attaching the label to the signal cable at a proper position...............................................................E-9

Figure E-7 Attaching the label to the signal cable.............................................................................................E-10

Figure E-8 Appearance of the label attached to the power cable......................................................................E-11

Figure E-9 Example of the label on the alarm cable..........................................................................................E-12

Figure E-10 Example of the label for the network cable...................................................................................E-13

Figure E-11 Example of the label on the optical fiber connecting two cabinets............................................... E-15

Figure E-12 Example of the label on the optical fiber connecting the cabinet to the ODF...............................E-16

Figure E-13 Labels for the trunk cable connecting two cabinets......................................................................E-17

Figure E-14 Example of the label on the trunk cable connecting the cabinet to the DDF................................E-19

Figure E-15 Example of the label for the subscriber cable................................................................................E-20

Figure E-16 Example of the labels on the DC power cable...............................................................................E-21

Figure E-17 Example of the labels on the AC power cable...............................................................................E-22

xiv Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide Tables

Tables

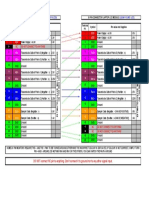

Table 2-1 Measuring and marking tools to be arranged before the installation...................................................2-3

Table 2-2 Drilling tools to be arranged before the installation.............................................................................2-3

Table 2-3 Fastening tools to be arranged before the installation..........................................................................2-4

Table 2-4 Pliers to be arranged before the installation.........................................................................................2-5

Table 2-5 Auxiliary tools to be arranged before the installation..........................................................................2-7

Table 2-6 Special tools to be arranged before the installation..............................................................................2-9

Table 2-7 Meters to be arranged before the installation.....................................................................................2-10

Table 2-8 Checklist of the construction environment........................................................................................2-11

Table 2-9 Checklist for the power supply system..............................................................................................2-13

Table 2-10 Checklist of the grounding system...................................................................................................2-14

Table 2-11 Checklist for the cable tray..............................................................................................................2-15

Table 2-12 Checklist for the distribution frame.................................................................................................2-16

Table 2-13 Checking requirements before unpacking the products...................................................................2-17

Table 7-1 Checklist of the cabinet installation.....................................................................................................7-7

Table 7-2 Internal connections of the N63E-22 cabinet that is configured with two service subracks (I-type PDU

adopted).................................................................................................................................................................7-9

Table 7-3 Internal connections of the N63E-22 cabinet that is configured with two service subracks (B-type PDU

adopted)...............................................................................................................................................................7-10

Table 7-4 Checklist of signal cables...................................................................................................................7-10

Table 7-5 Checklist of the terminal installation.................................................................................................7-12

Table 7-6 Checklist of power cables and ground cables....................................................................................7-13

Table 7-7 Checklist of the installation environment..........................................................................................7-14

Table 7-8 Checklist of the telecommunications room........................................................................................7-15

Table 7-9 Checklist of the connectivity of cables..............................................................................................7-16

Table A-1 Dimensions and weight of the N63E-22 cabinet................................................................................A-1

Table B-1 Components for installing a cable rack...............................................................................................B-2

Table B-2 Tools for installing a cable rack..........................................................................................................B-4

Table C-1 Mapping between the cross-sectional area and the length of insulation layer to be peeled off (L1)

..............................................................................................................................................................................C-3

Table C-2 Mapping between the cross-sectional area and the length of the insulation layer to be peeled off (L1)

..............................................................................................................................................................................C-5

Table C-3 Wires assigned to the network cable..................................................................................................C-9

Table C-4 Peeled lengths of commonly used coaxial cables.............................................................................C-15

Table C-5 Peeled lengths of commonly used coaxial cables.............................................................................C-20

Issue 01 (2011-01-15) Huawei Proprietary and Confidential xv

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Tables Installation Guide

Table C-6 Peeling lengths of commonly used coaxial cables...........................................................................C-25

Table E-1 Standard typeface for handwriting......................................................................................................E-7

Table E-2 Information on the label for the external alarm cable....................................................................... E-11

Table E-3 Information on the label for the network cable.................................................................................E-12

Table E-4 Information on the label for the optical fiber connecting two cabinets............................................E-14

Table E-5 Information on the label for the optical fiber connecting the cabinet to the ODF............................ E-15

Table E-6 Information on the labels for the trunk cable connecting two cabinets............................................E-17

Table E-7 Information on labels for the trunk cable connecting the cabinet to the DDF..................................E-18

Table E-8 Information on the labels for the subscriber cable............................................................................ E-19

Table E-9 Meaning of the label for the DC power cables.................................................................................E-20

Table E-10 Meaning of the label for the AC power cable................................................................................. E-22

Table F-1 Climatic requirements.........................................................................................................................F-2

Table F-2 Restrictions on the density of mechanically active materials in the air for storage............................F-3

Table F-3 Restrictions on the density of chemically active materials in the air for storage................................F-3

Table F-4 Restrictions on mechanical stress imposed on the device that is stored..............................................F-3

Table F-5 Climatic requirements.........................................................................................................................F-4

Table F-6 Restrictions on the density of mechanically active materials in the air for transportation..................F-5

Table F-7 Restrictions on the density of chemically active materials in the air for transportation.....................F-5

Table F-8 Restrictions on the mechanical stress imposed on the device that is transported................................F-6

Table F-9 Climatic requirements.........................................................................................................................F-6

Table F-10 Restrictions on the density of mechanically active materials in the air for storage..........................F-7

Table F-11 Restrictions on the density of chemically active materials in the air for storage..............................F-7

Table F-12 Requirements on mechanical stress imposed on the device that is stored.........................................F-8

Table F-13 Requirements on the electromagnetic environment..........................................................................F-8

Table F-14 Requirements on lightning proof grounding.....................................................................................F-9

Table F-15 Requirements on the AC voltage and the frequency....................................................................... F-11

Table F-16 Specifications for the DC power supply..........................................................................................F-13

xvi Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 1 Equipment Overview

1 Equipment Overview

About This Chapter

This topic provides the dimensions of the N63E-22 cabinet and describe the application,

appearance, and configuration of the indoor N63E-22 cabinet for the MA5600T.

1.1 Outline and Structure

1.2 Configuration

The N63E-22 cabinet adopts the DC power. This topic describes the service subrack

configuration of the N63E-22 cabinet, and lists the maximum number of subscribers of the

cabinet.

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 1-1

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

1 Equipment Overview Installation Guide

1.1 Outline and Structure

1-2 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 1 Equipment Overview

1.2 Configuration

The N63E-22 cabinet adopts the DC power. This topic describes the service subrack

configuration of the N63E-22 cabinet, and lists the maximum number of subscribers of the

cabinet.

The N63E-22 cabinet has the following configurations:

l Configuration of one service subrack

l Configuration of two service subracks

l Configuration of one service subrack and one SPL subrack

Configuration of One Service Subrack

Figure 1-1 shows the configuration of the N63E-22 cabinet installed with one service subrack.

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 1-3

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

1 Equipment Overview Installation Guide

Figure 1-1 Configuration of the N63E-22 cabinet installed with one service subrack

82

PDU (100 mm) 81

79

Empty (1000 mm)

Part Installation Hole

38

82, 79 (I-type)

PDU 82, 79 (C3-type)

33

81, 79 (B-type)

30

Service shelf (450 mm) 29

Service shelf 38, 33, 26, 21

26

Cabling space 20, 19, 18, 17

21

20

Cabling space (100 mm) 19

18

17

Empty (400 mm)

NOTE

l In Figure 1-2, the filled holes are for floating nuts to fasten subracks.

l In Figure 1-2, installation holes 29, and 30 are used to fasten coils.

Configuration of Two Service Subracks

Figure 1-2 shows the configuration of the N63E-22 cabinet installed with two service subracks.

1-4 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 1 Equipment Overview

Figure 1-2 Configuration of the N63E-22 cabinet installed with two service subracks

82

PDU (100 mm) 81

79

Empty (50 mm)

76

71

Service shelf 2 (450 mm) 68

67

64

59

58

57

Cabling space 2 (100 mm) 56

55

Empty (250 mm)

Air deflector (150 mm) 42 Part Installation Hole

39

38

82, 79 (I-type)

PDU 82, 79 (C3-type)

33

81, 79 (B-type)

30

Service shelf 1 (450 mm) 29

Cabling space 2 76, 71, 64, 59

26

Cabling space 2 58, 57, 56, 55

21

20

Cabling space 1 (100 mm) 19

18 Air deflector 39, 42

17

Service shelf 1 38, 33, 26, 21

Empty (400 mm) Cabling space 1 20, 19, 18, 17

NOTE

l In Figure 1-2, the filled holes are for floating nuts to fasten subracks.

l In Figure 1-2, installation holes 29, 30, 67, and 68 are used to fasten coils.

l In Figure 1-2when the High-density service boards are installed, the air deflector is required. When

the other boards are installed, the air deflector is not required.

Configuration of One Service Subrack and One SPL Subrack

Figure 1-3 shows the configuration of the N63E-22 cabinet installed with one service subrack

and one SPL subrack.

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 1-5

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

1 Equipment Overview Installation Guide

Figure 1-3 Configuration of the N63E-22 cabinet installed with one service subrack and one

SPL subrack

82

PDU (100 mm) 81

79

Empty (50 mm)

76

71

Service shelf (450 mm) 68

67

64

59

58

53

SPL shelf (400 mm) 51

50

48

43

42

41

Part Installation Hole

Cabling space (100 mm)

82, 79 (I-type)

PDU 82, 79 (C3-type)

81, 79 (B-type)

Service shelf 76, 71, 64, 59

SPL shelf 58, 53, 48, 43

Cabling space 42, 41

NOTE

l In Figure 1-3, the filled holes are for floating nuts to fasten subracks.

l In Figure 1-3, installation holes 50, 51, 67, and 68 are used to fasten coils.

1-6 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 2 Preparing for the Installation

2 Preparing for the Installation

About This Chapter

Prepare the tools and the meters before installing the cabinet, and check the installation

environment to ensure that the device is installed properly.

2.1 Checking the Installation Entry

Before the installation, check whether the construction environment, power supply system,

grounding system, and distribution frame meet the installation requirement.

2.2 Unpacking and Accepting Products

After the packing case arrives at the site, you need to unpack and accept products to facilitate

the subsequent installation.

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 2-1

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

2 Preparing for the Installation Installation Guide

2.1 Checking the Installation Entry

Before the installation, check whether the construction environment, power supply system,

grounding system, and distribution frame meet the installation requirement.

The project supervisor must check the installation entry on site. The files to be prepared and the

precautions to be taken are as follows:

l Fill in the Checklist of the Construction Environment according to the actual conditions.

l Sign the Kickoff Agreement with the customer and draft the Project Installation Plan if all

the items are available.

l If requirements are not met, fill in the Onsite Work Liaison Form and specify the reason

for postponing the kickoff.

l Sign a memo for any engineering project that cannot be rectified or that does not meet the

requirements even after it is rectified.

2.1.1 Tools and Meters

This topic lists the tools and meters specified in the contract, which need to be arranged by the

owner. Test and adjust the meters before using them.

2.1.2 Checking the Construction Environment

This topic describes how to check the construction environment against the checklist before the

installation.

2.1.3 Checking the Power Supply System

This topic describes how to check the power supply against the checklist before the installation.

2.1.4 Checking the Grounding System

This topic describes how to check the grounding system against the checklist before the

installation.

2.1.5 Checking the Cable Tray

This topic describes how to check the cable tray against the checklist before the installation.

2.1.6 Checking the Distribution Frame

This topic describes how to check the distribution frame against the checklist before the

installation.

2.1.1 Tools and Meters

This topic lists the tools and meters specified in the contract, which need to be arranged by the

owner. Test and adjust the meters before using them.

Measuring and Marking Tools

Table 2-1 lists the measuring and marking tools to be arranged before the installation.

2-2 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 2 Preparing for the Installation

Table 2-1 Measuring and marking tools to be arranged before the installation

Name Description Illustration

Steel tape Used for

measuring the

length

Angle square Used for

measuring the

length or

drawing a right

angle

Marker pen Used for

marking when

you draw lines

Spirit level Used for

checking

whether the

cabinet is

leveled

Drilling Tools

Table 2-2 lists the drilling tools to be arranged before the installation.

Table 2-2 Drilling tools to be arranged before the installation

Name Description Illustration

Punch tool Used for

locating the bit

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 2-3

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

2 Preparing for the Installation Installation Guide

Name Description Illustration

Hammer Used for drilling

drill holes before you

install the

cabinet

Bit Different bits

for holes with

different depths

and diameters

Vacuum Used for

cleaner cleaning the

dust and drill

cuttings during

the drilling

Fastening Tools

Table 2-3 lists the fastening tools to be arranged before the installation.

Table 2-3 Fastening tools to be arranged before the installation

Name Description Illustration

Flat-head l Used for

screwdriver fastening small

screws and bolts

l Rarely used for

fastening nuts

l With a flat head

Phillips l Used for

screwdriver fastening small

screws and bolts

l Rarely used for

fastening nuts

l With a cross

head

2-4 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 2 Preparing for the Installation

Name Description Illustration

Socket ring Used in a small

wrench enclosure

Adjustable Used for socket ring

wrench or square bolts and

nuts of a certain size

range because the

hole of the wrench

can be adjusted

Socket wrench Used with various

sockets for

fastening socket

ring or square bolts

and nuts of different

sizes

Pliers

Table 2-4 lists the pliers to be arranged before the installation.

Table 2-4 Pliers to be arranged before the installation

Name Description Illustration

Toolkit for 75- Used for making E1

ohm trunk cables of coaxial

cable type on site

Hydraulic Used for making

pliers power cables with

cord end terminals

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 2-5

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

2 Preparing for the Installation Installation Guide

Name Description Illustration

Sharp-nose Used for picking

pliers small parts or

turning and

twisting fine wires

in a small enclosure

Diagonal pliers Used for stripping

and cutting

insulating tubes or

cable ties

Wire clipper Used for cutting

wires, wire-rod

rolls, barbed wire,

and cables with a

large cross-

sectional area and

the hardness of

these materials

should not be more

than 30 HRC

Crowbar Used for lifting the

cabinet

Auxiliary Tools

Table 2-5 lists the auxiliary tools to be arranged before the installation.

2-6 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 2 Preparing for the Installation

Table 2-5 Auxiliary tools to be arranged before the installation

Name Description Illustration

Rubber Used for knocking

hammer expansion bolts

Claw hammer Used for knocking

and removing nails

Brush Used for cleaning

the air filter

Paper cutter Used for peeling off

the jacket of the

cable when cables

are made on site

Electric Used for soldering a

soldering iron conductor with

small cross-

sectional area to the

connector

Tin wire Solder wire

Hot air gun Used to heat a heat-

shrink tubing

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 2-7

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

2 Preparing for the Installation Installation Guide

Name Description Illustration

Ladder Used for working at

heights

Forklift Used for carrying

cabinets

Powder Used for marking

marker construction plan

drawing

Special Tools

Table 2-6 lists the special tools to be arranged before the installation.

2-8 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 2 Preparing for the Installation

Table 2-6 Special tools to be arranged before the installation

Name Description Illustration

Wire stripper Used for peeling off the

shield layer and jacket of

the communication

cable with small cross-

sectional area

RJ-45 Used for crimping the RJ

connector connector of the phone

crimping cable or the network

pliers cable

Wire cutter l Used for installing

subscriber cables or

trunk cables to the

main distribution

frame (MDF)/digital

distribution frame

(DDF)

l Used for connecting

the cables, blocks,

and MDFs/DDFs

Wire crimping Used for crimping the

tool tail metal jacket when

making coaxial cables

on site

ESD gloves Used to prevent the

electrostatic discharge

from damaging the

equipment

ESD wrist Used to prevent the

strap electrostatic discharge

from damaging the

equipment. One end of

the ESD wrist strap

should be connected to

the ESD jack on the

cabinet.

Issue 01 (2011-01-15) Huawei Proprietary and Confidential 2-9

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

2 Preparing for the Installation Installation Guide

Meters

Table 2-7 lists the meters to be arranged before the installation.

Table 2-7 Meters to be arranged before the installation

Name Description Illustration

Network cable Used for testing the

tester connectivity and the

connections of the

network cable

Optical power Used for measuring

meter the optical power

2M bit error Used for testing the

tester 2M bit errors

Optical Used for adjusting

attenuator the power level of an

optical signal by

adjusting the

attenuation.

2-10 Huawei Proprietary and Confidential Issue 01 (2011-01-15)

Copyright © Huawei Technologies Co., Ltd.

SmartAX MA5600T Multi-service Access Module

Installation Guide 2 Preparing for the Installation

Name Description Illustration

Multimeter Used for testing the

cabinet insulation,

cable connectivity,

and specifications of

the electrical

parameters of a

device, such as

voltage, current, and

resistance

2.1.2 Checking the Construction Environment

This topic describes how to check the construction environment against the checklist before the

installation.

Table 2-8 provides the checklist of the construction environment.

Table 2-8 Checklist of the construction environment

No. Item Requirement

1 Civil l The telecommunications room must be sufficiently large for the

engineering installation and future expansion of the device.