Professional Documents

Culture Documents

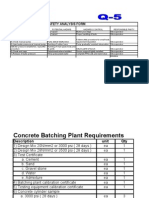

Construction Checklist: Refference YES NO NA SAE SDE Aggregate For Concrete Material: SL. NO. Check Item

Uploaded by

nilesh kumar VermaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction Checklist: Refference YES NO NA SAE SDE Aggregate For Concrete Material: SL. NO. Check Item

Uploaded by

nilesh kumar VermaCopyright:

Available Formats

E.

Concrete1/3

CONSTRUCTION CHECKLIST

Name of the Project: Date of inspection:

Name of the building:

Location of inspection in the building:

Name of the Sub-Division:

Name of the Division:

STEP E-1: CHECKLIST FOR CONCRETEING WORK (Equipment and Material Preparation)

1st Level 2nd Level

SL. Checked Checked

CHECK ITEM

NO.

Refference YES NO NA SAE SDE Comments

1 Aggregate for concrete material:

Excessive dust is screened out from coarse

1)

aggregate.

Size of aggregates is satistifactory as per

2)

specification.

Stone chips must be made of crushed stone or

3)

boulder

Both coarse and fine agreegates are free from all

4)

organic and deleterious materials.

Aggregates are well stored on brick solling

5)

platform.

Percent wear of stone chips is below 30% tested

6)

by Los Angles Abration test.

Compresive stone of stone agreegate shall not be

7)

less than 36.1 MPa or 5240 Psi.

Laboratory tests confirm specifictions mentioned in

8)

Sl. No. (8) and (9)

2 Grading of coarse aggregates:

1) 19mm sieve size- passing 95-100% is confirmed.

2) 9mm sieve size- passing 25-55% is confirmed.

No. 4 (4.76mm) sieve size- passing 0-10% is

3)

confirmed.

No. 8 (2.38mm) sieve size- passing 0-5% is

4)

confirmed.

Sieve analysis is done and the report confirms

5)

above criteria

3 Cement for concrete:

1) Types of cement is CEM-1 as per specification .

2) Quality of cement is satisfied as per specification.

Cements are well stored, not in a moist

3)

environment.

Laboratory test is done and the report confirms

4)

above criteria

4 Other materials for concrete:

1) Admixture as per specification is presented.

2) Water is free from salt and other impurities.

Spare Vibrator machines and vibrator nozzles are

3)

available.

4) Proper levelling Instrument is available at site.

Aggregate measuring box, sand filter are present at

5)

the site.

6) Slump testing aparatus is present at site

7) Cylinder testing equipments are present and in well

condition.

CONTRACTOR : Name- Signature:

SAE : Name- Signature:

SDE: Name- Signature:

EE: Name- Signature:

E. Concrete2/3

CONSTRUCTION CHECKLIST

Name of the Project: Date of inspection:

Name of the building:

Location of inspection in the building:

Name of the Sub-Division:

Name of the Division:

STEP E-2: CHECKLIST FOR CONCRETEING WORK (During Construction) (page 1/2)

1st Level 2nd Level

SL. Checked Checked

CHECK ITEM

NO.

Refference YES NO NA SAE SDE Comments

1 Mix proportion is checked by the engineer:

Volume of concrete is estimated and the target

1)

time is set.

2) Admixture is used as per design specification

2 Manpower for concreting:

SDE, SAE are present while mixing and placing of

1)

concrete.

Work assistant at the mixing point is deputed to

2) count and control the batch as per concrete

pouring slip and load count slip.

3) Manpower for mixing is enough with respect to

volume of work

During casting sufficient shuttering men are kept

4)

for constant watch on prop.

3 Adequacy of materials:

Mixing portion of cement, aggregates and sand are

1)

investigated as per design specification.

Adequate Material such as cement, aggregates

2) and sand are presented with respect to volume of

work.

3) Aggregates are properly soaked

4) Aggregates are well graded.

4 Preparation at the site for concreting:

1) For bonding with old concrete, the edges of old

concrete are to be broken to give a firm bonding.

2) Grouting is used for construction joint.

3) Electrical conduit is ensured in proper place.

4) Rain protection is arranged.

Clear cover are monitored before placing of

5)

concrete.

Casting sequence are decided as per consent of

6)

engineer in charge.

5 Adequacy of equipments:

Chutes, concrete buckets are cleaned and ready

1)

for use.

Adequate Vibrator nozles are checked and ready

2)

for use.

3) Tower crane for vertical lifting is provided.

4) Thickness checking device is provided.

6 Mixing of Concrete:

Measured quantity of materials as per proportion

1)

are dumped in the drum of mixture machine.

Mixiing is executed with required quantity of water

2) for a period of not less than 2 minutes after all

material including the water are in the drum.

Proper water cement ratio is ensured by measuring

3)

slump as mentioned below:

a. Footing, pile cap, mass concrete 2" maximum

b. Precast pile, column, beam, slab 2.5" maximum

c. Ready mix concrete (with admixture) 4.0"

maximum

E. Concrete3/3

CONSTRUCTION CHECKLIST

Name of the Project: Date of inspection:

Name of the building: Which part of the building:

Name of the Sub-Division:

Name of the Division:

STEP E-2: CHECKLIST FOR CONCRETEING WORK (During Construction) (page-2/2)

1st Level 2nd Level

SL. Checked Checked

CHECK ITEM

NO.

Refference YES NO NA SAE SDE Comments

7 After mixing concrete:

Workability of concrete is adequate (slump is

1)

proper).

Cubes/ Cylinders are taken from the mixing for

2)

testing.

3) Slump test is conducted and found OK.

8 Placing of concrete:

Water is sprayed on surface of shutter/ steel

1)

shutter.

2) Concrete is placed within 30 minutes after mixing

the water.

3) Height of free fall concrete is within 3 feet.

Concrete is layed from one end, then continuously

4)

proceeded to the other end.

Fresh concrete is deposited against concrete which

5)

is in position within 45 minutes.

6) Thickness is checked @ 3’-0’’ interval over the

concrete slab.

Frequent movement of labours/others over

reinforcement is avoided during casting. Use of

7)

plain sheet as walk way for carrying concrete at

place.

During casting, immediate remedial measure are

8)

taken in case props get loosened.

9 Compacation of Concrete:

For beam and column, concrete compaction is

1)

done properly by vibrator.

Compaction is done within the 15 minutes after the

2)

fresh concrete is placed in position.

Vibrating is stopped as soon as laitance of mortar

3) appears on the surface. (Excessive vibration

segregates the mix.)

4) Vibrating is executed properly in vertical placement

of vibrator.

5) Vibrating is executed without touching the re-bar.

Proper surface vibration of slab surface with thick

6)

& plain wooden plank.

STEP E-3: CHECKLIST FOR CONCRETEING WORK (After concreting)

Movement over concrete surface is avoided within

1

24 hours.

Concrete surface is kept wet with water till the

2

removal of form work.

Keys in the column-lift are provided for subsequent

3

concreting in the proceeding days.

CONTRACTOR : Name- Signature:

SAE : Name- Signature:

SDE: Name- Signature:

EE: Name- Signature:

You might also like

- Construction Checklist for Shuttering WorkDocument2 pagesConstruction Checklist for Shuttering Workenjoy begening lifeNo ratings yet

- Checklist For Shuttering WorkDocument6 pagesChecklist For Shuttering WorkfbellimamNo ratings yet

- Construction Checklist: SL. No. Check Item Refference Yes No NA SAE SDE Material, Type of ShutteringDocument2 pagesConstruction Checklist: SL. No. Check Item Refference Yes No NA SAE SDE Material, Type of ShutteringAnimesh Narayan SinghNo ratings yet

- Sample QAPDocument7 pagesSample QAPzeniths011No ratings yet

- Construction Checklist: Check Item SL. NODocument3 pagesConstruction Checklist: Check Item SL. NOkrishnaakhil777No ratings yet

- Construction Checklist: SL. NO. Check ItemDocument2 pagesConstruction Checklist: SL. NO. Check Itemalif100% (1)

- Inspection ChecklistDocument2 pagesInspection Checklistgilbert cruzNo ratings yet

- Construction Method and Quality Control Planning For Concrete WorkDocument8 pagesConstruction Method and Quality Control Planning For Concrete Workibal_farhan67% (3)

- Cast in Place ConcreteDocument16 pagesCast in Place ConcreteabdouNo ratings yet

- BALJOT IndustrialDocument44 pagesBALJOT IndustrialHarmeet Singh100% (1)

- ConcretingDocument5 pagesConcretingAmila Priyadarshana DissanayakeNo ratings yet

- DN NAGAR - ReportDocument112 pagesDN NAGAR - ReportPRASHANT MOTWANINo ratings yet

- Civil - Bureau of Indian StandardsDocument168 pagesCivil - Bureau of Indian StandardsH.V. PatilNo ratings yet

- 01DCivil Jab SafetyDocument6 pages01DCivil Jab Safetymd sarfaraz khanNo ratings yet

- Master Specification - Part St-Re-C2 - Soil NailingDocument10 pagesMaster Specification - Part St-Re-C2 - Soil NailingHugo FernandezNo ratings yet

- Tests Required For Construction of A BuildingDocument2 pagesTests Required For Construction of A BuildingaenanrocksNo ratings yet

- CHECKLIST FOR WATERPROOFING TOILETSDocument1 pageCHECKLIST FOR WATERPROOFING TOILETSBipin SarodeNo ratings yet

- MS 12 Masonry WorksDocument6 pagesMS 12 Masonry WorksMarwa FaroukNo ratings yet

- CK List CEMDocument16 pagesCK List CEMxoham57089No ratings yet

- Concrete PropertiesDocument14 pagesConcrete PropertiesIm ChinithNo ratings yet

- SPECIFICATIONDocument25 pagesSPECIFICATIONkingcedsNo ratings yet

- 14) Structure Guideline August 2017Document40 pages14) Structure Guideline August 2017lwin_oo2435No ratings yet

- Installing Concrete Surface BedDocument3 pagesInstalling Concrete Surface BedAmigowzz Hood100% (1)

- Biaya Tidak Langsung ProyekDocument42 pagesBiaya Tidak Langsung ProyekfadliNo ratings yet

- Structural Failures Case StudiesDocument33 pagesStructural Failures Case StudiesRakesh7770No ratings yet

- Concrete Work CheklistDocument2 pagesConcrete Work Cheklistchristopher AdajoNo ratings yet

- MS 03e Concrete Work Method statement-Measurement-Rev 02Document9 pagesMS 03e Concrete Work Method statement-Measurement-Rev 02Abdullah Al MarufNo ratings yet

- Condition Assessment of a College BuildingDocument19 pagesCondition Assessment of a College BuildingAkibNo ratings yet

- Tata Consulting Engineers Limited: Building Vitrified Tiling ChecklistDocument1 pageTata Consulting Engineers Limited: Building Vitrified Tiling ChecklistSandip PaulNo ratings yet

- 1.1 Consumable Materials (All Details To Be in Appendix)Document17 pages1.1 Consumable Materials (All Details To Be in Appendix)Thimira Bandara EkanayakeNo ratings yet

- Soil Test Report of 128 No. Brojopur Purba para BangladeshDocument38 pagesSoil Test Report of 128 No. Brojopur Purba para BangladeshWUB STUDENTS 68G100% (3)

- Job Safety Analysis Form HydrotestDocument4 pagesJob Safety Analysis Form HydrotestMarvin BerrensteinNo ratings yet

- Patimban Port Rock Works SpecificationsDocument4 pagesPatimban Port Rock Works SpecificationsAlbarraMotorNo ratings yet

- 08 OPD-F-008 Request For PouringRev01Document2 pages08 OPD-F-008 Request For PouringRev01ISH-QUENo ratings yet

- MF (1) 1Document24 pagesMF (1) 1Suranga ManuNo ratings yet

- Construction Checklist: SL. NO. Check ItemDocument4 pagesConstruction Checklist: SL. NO. Check ItemMd Imran Khan SohanNo ratings yet

- MS 9 Pile CapsDocument6 pagesMS 9 Pile CapsMarwa FaroukNo ratings yet

- T Proc Notices Notices 010 K Notice Doc 6692 55080652Document42 pagesT Proc Notices Notices 010 K Notice Doc 6692 55080652devedavedoNo ratings yet

- Quality Control & TestsDocument72 pagesQuality Control & TestsAnonymous ciKyr0t100% (4)

- Work MethodDocument22 pagesWork MethodQianlei ZhuNo ratings yet

- Concrete Pavement Procedures Rev 3Document2 pagesConcrete Pavement Procedures Rev 3Rose ManipolNo ratings yet

- Section 02300 Earthworks R2Document21 pagesSection 02300 Earthworks R2MØhãmmed ØwięsNo ratings yet

- Summary of Revised Codes For Concrete in 2018Document4 pagesSummary of Revised Codes For Concrete in 2018Vijayakrishna SingamsettiNo ratings yet

- Soil Test Report Greater NodiaDocument21 pagesSoil Test Report Greater NodiaSomesh Siddharth100% (2)

- Evaluation of The Causes of Concrete Kerbs Fast DaDocument8 pagesEvaluation of The Causes of Concrete Kerbs Fast Dayamanta_rajNo ratings yet

- Job Safety Analysis Form HydrotestDocument3 pagesJob Safety Analysis Form Hydrotestyayongjcs100% (4)

- Blank BOQDocument58 pagesBlank BOQThushan Madu0% (1)

- MS 22 Fin Berlin Wall Soldier PilesDocument14 pagesMS 22 Fin Berlin Wall Soldier PilesMohamed AlhadidyNo ratings yet

- m01 Construction ProceduresDocument2 pagesm01 Construction ProceduresRose ManipolNo ratings yet

- S-000-3115-001 - 2B - 0010 Const Spec For Earth WorkDocument8 pagesS-000-3115-001 - 2B - 0010 Const Spec For Earth WorkPieter Harry100% (1)

- Spec ShortcreateDocument5 pagesSpec ShortcreatenalakasaNo ratings yet

- SECTION 03 30 00 Cast-In-Place ConcreteDocument36 pagesSECTION 03 30 00 Cast-In-Place ConcreteJuanPaoloYbañezNo ratings yet

- Technical Specification RECDocument742 pagesTechnical Specification RECHooghly IPDSNo ratings yet

- BT-SPECS-finalDocument25 pagesBT-SPECS-finalDUMLAO, ANGELIE M.No ratings yet

- Share Gs RRRDocument9 pagesShare Gs RRRGanga gangaNo ratings yet

- Slab, Coloumn Check ListDocument8 pagesSlab, Coloumn Check ListsuniljhilmilNo ratings yet

- Construction Method Statement: Concrete WorksDocument6 pagesConstruction Method Statement: Concrete Worksmohammad_reza_49No ratings yet

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceFrom EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNo ratings yet

- Pre and Post Pour Inspection ChecklistDocument2 pagesPre and Post Pour Inspection Checklistnilesh kumar VermaNo ratings yet

- Click Here To Enter A Date.: Page 1 of 5Document5 pagesClick Here To Enter A Date.: Page 1 of 5nilesh kumar VermaNo ratings yet

- Appendix C7 - Pre-Construction ChecklistDocument6 pagesAppendix C7 - Pre-Construction Checklistnilesh kumar VermaNo ratings yet

- Pre-Construction ChecklistDocument2 pagesPre-Construction Checklistnilesh kumar VermaNo ratings yet

- 54LS138/DM54LS138/DM74LS138, 54LS139/DM54LS139/DM74LS139 Decoders/DemultiplexersDocument8 pages54LS138/DM54LS138/DM74LS138, 54LS139/DM54LS139/DM74LS139 Decoders/DemultiplexersakulNo ratings yet

- Head Movement and the Extension RequirementDocument13 pagesHead Movement and the Extension RequirementSufia SultanaNo ratings yet

- Cognizant Training FacilityDocument1 pageCognizant Training FacilityPiyush SinhaNo ratings yet

- Staad Design CodesDocument7 pagesStaad Design CodespanjumuttaiNo ratings yet

- Piping Class B31Document142 pagesPiping Class B31interx00No ratings yet

- Selecion de Fusibles para Proteccion de TransformadoresDocument14 pagesSelecion de Fusibles para Proteccion de TransformadoresfreddyriveraNo ratings yet

- CounterACT Console User Manual 7.0.0Document756 pagesCounterACT Console User Manual 7.0.0bkshrestha69100% (2)

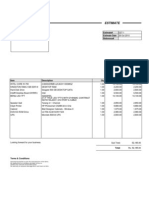

- Est 1Document1 pageEst 1kanak2No ratings yet

- rr321201 Multimedia and Web DesignDocument4 pagesrr321201 Multimedia and Web DesignSRINIVASA RAO GANTANo ratings yet

- Modul STEM Sifat Koligatif Larutan Pages 1-50 - Flip PDF Download - FlipHTML5Document76 pagesModul STEM Sifat Koligatif Larutan Pages 1-50 - Flip PDF Download - FlipHTML5Manawa MulkNo ratings yet

- Precision 6T70 Parts Catalog 2024Document4 pagesPrecision 6T70 Parts Catalog 2024Альфир АптикаевNo ratings yet

- Data Mining:: Concepts and TechniquesDocument69 pagesData Mining:: Concepts and TechniquesaymanNo ratings yet

- 13 10 01LE-Seriesv3Document6 pages13 10 01LE-Seriesv3achyuthramayyaNo ratings yet

- Animal Farm Timeline ProjectDocument2 pagesAnimal Farm Timeline Projectapi-222057179No ratings yet

- Vodafone Case FinalDocument25 pagesVodafone Case FinalpavanbhatNo ratings yet

- 2010-2011 CatalogDocument378 pages2010-2011 CatalogHouston Community College91% (43)

- Copper-Brazed Steel Tubing: Standard Specification ForDocument4 pagesCopper-Brazed Steel Tubing: Standard Specification ForMartuaHaojahanSaragihSidabutarNo ratings yet

- Aeroflex Metric Catalogue and SubmittalDocument8 pagesAeroflex Metric Catalogue and SubmittalZeeshanNo ratings yet

- Bom Cno175925Document15 pagesBom Cno175925Yuvraj BappiNo ratings yet

- Guide To ISO 20121Document1 pageGuide To ISO 20121Ljupco TrajkovskiNo ratings yet

- The 4 Ms of OperationDocument14 pagesThe 4 Ms of OperationGodwill Jireh L. Patindol100% (7)

- Lesson Plan WoodworkDocument4 pagesLesson Plan Woodworkapi-223390716No ratings yet

- Automated Planning For Tomorrow AIDocument7 pagesAutomated Planning For Tomorrow AIColin LewisNo ratings yet

- PP Navlog PDFDocument2 pagesPP Navlog PDFHector IbarraNo ratings yet

- Intro to Data Comms & Computer NetworksDocument52 pagesIntro to Data Comms & Computer NetworksFerlyn Maye Angeles BenavidesNo ratings yet

- CCNA Exploration Network Chapter 11Document28 pagesCCNA Exploration Network Chapter 11GµårÐïåñNo ratings yet

- Proc. For Radiographic Profile Thk. MeasurementDocument7 pagesProc. For Radiographic Profile Thk. MeasurementSergey KichenkoNo ratings yet

- Service Manual Vision Recumbent BikeDocument16 pagesService Manual Vision Recumbent BikeCary BriefNo ratings yet

- Floor plan of a cottage with two bedrooms and living areaDocument1 pageFloor plan of a cottage with two bedrooms and living areaNithinNo ratings yet

- Noise Control Sound Absorption GuideDocument32 pagesNoise Control Sound Absorption GuideRukminiPriyankaNo ratings yet