Professional Documents

Culture Documents

Aluminium Conical Mounting Technical Specification

Uploaded by

Tayfun SezişOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Conical Mounting Technical Specification

Uploaded by

Tayfun SezişCopyright:

Available Formats

DOCUMENTATION SHEET General

The aluminium RD 214 conical mounting has a static load range from 16 kN to 115 kN. The

Conical Mountings conical design provides high deflection and load capacity combined with long service life.

Type RD 214 Although originally designed for main engine, auxiliary engine and generator installations, the

mountings are particularly versatile and can be equally used for exhaust gas boilers and si-

lencers. For applications like the suspension of deckhouses, accommodation rooms and con-

RD 214

trol cabins, this mounting is an excellent isolator against structure borne vibration and noise,

( p assive isolation ) . The acoustic properties of this type of mounting are excellent. The re-

sults of the measured structure borne vibration and noise transmission are available. In both

vertical and horizontal directions the transfer functions show a decrease of 12 dB/octave in the

low frequency range, an ‘ ideal mass-less spring characteristic ’ .

Remark

It is our intention to maintain the excellent standard of our products. Modifications and im-

provements may be made from time to time, therefore we advise to contact us before order-

ing.

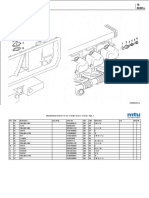

DIMENSIONS

1 CM / RD 214 / AUG 2012

RD 214

Specification

The characteristics of the mounting are provided by a conical rubber element designed to

carry the vertical load in a combination of compression and shear. The

The rubber elements are manufactured in six ‘ standard ’ rubber mixes: 45NR, 50NR, 55NR,

60NR, 65NR, 70NR and consequently cover a wide range of load / deflection requirements.

Applicable up to 70°C continuous and 90°C peak temperatures. Next to that, for the high tem-

peratures applications, there are special developed compounds for 90°C continuous and 110°

C peak temperature - and 110°C continuous and 130°C peak temperature available in the

above mentioned shore hardness.

The mounting castings are manufactured in a seawater resisting aluminum-silicon alloy. They

are designed to protect the rubber element against oil and physical damage. An adjustable

central buffer ( spindle ) , manufactured in high tensile steel, controls the mounted equipment

displacements due to e.g. ship movements, both vertically and horizontally within defined

limits and so eliminates the need for separate buffers. The cut out in the bottom casting allows

the buffer adjustment to be checked. All mounting inserts are both individual tested and se-

lected on stiffness by Rubber Design.

Direction Vertical up Vertical down Radial

Displacement limiter clearance [mm] 4 4 3

CLEARANCE

Rubber Hardness [°Sh. A] 45 50 55 60 65 70

Max Marine load [kN] 54 57 64 71 83 95

Max Static load [kN] 60 67 75 85 100 115

Max Static vert. defl. [mm] 15 14,5 14 13,5 12,5 11,5

CHARACTERISTICS

Max Shockload 150 kN ( all directions )

SHOCKLOAD

Mounting selection

The characteristics table is ideal for initial selection; however, it is advisable to seek expert

advice before finalizing an installation design. In practice most installations will be subjected to

both translational and rotational excitations and in consequence an analysis of all six degrees

of freedom will be necessary. We will be pleased to advise on mountings numbers, rubber mix

and mounting positions to ensure a ‘ faultless ’ flexible mounted installation. Before we can

commence the design of a mounting system detailed information is required. Vibration calcula-

tions are carried out using our specially developed computer programs to meet new standards

for both crews and passengers.

Rubber Design B.V.

Industrieweg 21

2995BE Heerjansdam

The Netherlands

Phone: +31 ( 0 ) 78 677 87 78

Fax: +31 ( 0 ) 78 677 10 38

Email: info@rubberdesign.nl

TYPE APPROVALS

Web: www.rubberdesign.nl

2 CM / RD 214 / AUG 2012

You might also like

- Sheet CM RD 244 ALUDocument2 pagesSheet CM RD 244 ALUSea Man MktNo ratings yet

- Soportes de Fijacion de Motores CatDocument2 pagesSoportes de Fijacion de Motores CatURBANO CONTRERASNo ratings yet

- Sheet CM RD 214 GGG HRDocument2 pagesSheet CM RD 214 GGG HRSea Man MktNo ratings yet

- Sheet CM RD 215 GGG HRDocument2 pagesSheet CM RD 215 GGG HRSea Man MktNo ratings yet

- Sheet CM RD 214x AluDocument2 pagesSheet CM RD 214x AluSea Man MktNo ratings yet

- Sheet CM RD 214x GGG HRDocument2 pagesSheet CM RD 214x GGG HRSea Man MktNo ratings yet

- Sheet SM RD 35m1Document2 pagesSheet SM RD 35m1Sea Man MktNo ratings yet

- Booklet Conical MountingsDocument41 pagesBooklet Conical MountingsRogerio SalvagniNo ratings yet

- Booklet Conical MountingsDocument41 pagesBooklet Conical MountingsAhmet HamamcıoğluNo ratings yet

- Booklet Sandwich MountingsDocument11 pagesBooklet Sandwich MountingsSea Man MktNo ratings yet

- Gearbox MountingsDocument2 pagesGearbox Mountingsroni_arsyahNo ratings yet

- HAT Product PortfolioDocument44 pagesHAT Product PortfolioEmrah MertyürekNo ratings yet

- Ceralag-01: Ceramic Lagging SheetingDocument2 pagesCeralag-01: Ceramic Lagging SheetingARUN KUMAR DASNo ratings yet

- Documentation TT2Document2 pagesDocumentation TT2roni_arsyahNo ratings yet

- Folleto HAT 2019 MarchDocument44 pagesFolleto HAT 2019 MarchJean MoralesNo ratings yet

- E-Catalogue (Rock Splitter 2009-01) PDFDocument6 pagesE-Catalogue (Rock Splitter 2009-01) PDFhenry vegaNo ratings yet

- Excavator Attachments: Demolition, Recycling and Earth-Moving. Experience Our Hydraulic Attachment ToolsDocument8 pagesExcavator Attachments: Demolition, Recycling and Earth-Moving. Experience Our Hydraulic Attachment ToolsSilvio CeolNo ratings yet

- REMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesDocument16 pagesREMAGRIP REMASLEEVE Pulley Laggings and Belt Idler SleevesBaihaki StNo ratings yet

- Sikasil 728 SLDocument5 pagesSikasil 728 SLJesusFloresRodriguezNo ratings yet

- Goodyear Omnitrac RangeDocument6 pagesGoodyear Omnitrac Rangemark pretoriusNo ratings yet

- Hydro-Mechanical Anderreamer Tech SummaryDocument2 pagesHydro-Mechanical Anderreamer Tech SummaryYaqoob Ibrahim100% (1)

- Technical Data Sheet: High Performance Rail Grease With GraphiteDocument1 pageTechnical Data Sheet: High Performance Rail Grease With GraphiteDon HowardNo ratings yet

- Jib Cranes 20875644 Colour CatalogueDocument30 pagesJib Cranes 20875644 Colour Cataloguepsingh1996No ratings yet

- H010995 WellheadDesanderDocument2 pagesH010995 WellheadDesanderslbclqrkNo ratings yet

- Hydraulic Rock Breaker MontabertDocument4 pagesHydraulic Rock Breaker MontabertSam ManutençãoNo ratings yet

- Berco Products DetailDocument12 pagesBerco Products DetailDilip BhargavaNo ratings yet

- WINKEL-Datasheet 4.055 + AP 1-Q-200.052.001Document2 pagesWINKEL-Datasheet 4.055 + AP 1-Q-200.052.001Sandip KadamNo ratings yet

- Tds Atlantic Hydraulic OilsDocument1 pageTds Atlantic Hydraulic Oilsmgamal1080No ratings yet

- DR KAISER Grinding WheelsDocument20 pagesDR KAISER Grinding Wheelsnestor333No ratings yet

- GB 2H Fills For Cross Flow CTDocument2 pagesGB 2H Fills For Cross Flow CTShahab Z AhmedNo ratings yet

- MasterSeal 940 TDSDocument4 pagesMasterSeal 940 TDSbayuargad100% (1)

- V Clamp DatasheetDocument4 pagesV Clamp DatasheetnovtomyNo ratings yet

- Elegance Raingutters 210408Document32 pagesElegance Raingutters 210408Yong QingNo ratings yet

- GSF PresentationDocument25 pagesGSF PresentationebrahimNo ratings yet

- Montabert Silver Clip RangeDocument6 pagesMontabert Silver Clip RangeGeorge Kwamina AnamanNo ratings yet

- 10 Wit-Vm 250 RDocument24 pages10 Wit-Vm 250 RMarko ŠimićNo ratings yet

- Product Flyer 320 525 01 2023Document2 pagesProduct Flyer 320 525 01 2023Beltazor HellboyNo ratings yet

- 50 Years Manufacturing ExcellenceDocument6 pages50 Years Manufacturing ExcellenceRaj hegdeNo ratings yet

- En CTL Range Brochure B4500130 04-2018 LowResDocument8 pagesEn CTL Range Brochure B4500130 04-2018 LowResVinod GuptaNo ratings yet

- Technologies Customized To: Every Part of The GlobeDocument4 pagesTechnologies Customized To: Every Part of The GlobeLucyan IonescuNo ratings yet

- Caliber M TDS 2051Document1 pageCaliber M TDS 2051dhowardjNo ratings yet

- BVD 2462 GBDocument2 pagesBVD 2462 GBAnonymous P18XRitOPPNo ratings yet

- Legendary Performance With Next-Level ComfortDocument8 pagesLegendary Performance With Next-Level ComfortSaraNo ratings yet

- Kuri CONQUERORDocument16 pagesKuri CONQUERORJosh WhiteNo ratings yet

- Gear Synt TDL 75W-90: Lubricant For Heavily Loaded Transmissions and Long Drain Service. 100% SyntheticDocument1 pageGear Synt TDL 75W-90: Lubricant For Heavily Loaded Transmissions and Long Drain Service. 100% SyntheticManuel GironNo ratings yet

- Cuplaje ElasticeDocument27 pagesCuplaje ElasticeAndrei VictorasNo ratings yet

- Demag pillar and wall-mounted slewing jib cranes guideDocument30 pagesDemag pillar and wall-mounted slewing jib cranes guidevedranNo ratings yet

- Product Manual for Tyre-Flex CouplingDocument28 pagesProduct Manual for Tyre-Flex CouplingJason Wei Han LeeNo ratings yet

- 0901d19680abfc1d 18845 EN - SuPB Brochure For Driven Tools - TCM - 12 559623Document8 pages0901d19680abfc1d 18845 EN - SuPB Brochure For Driven Tools - TCM - 12 559623a04205No ratings yet

- Rugged Disc Brake SolutionsDocument4 pagesRugged Disc Brake SolutionsNelsonParedesNo ratings yet

- 27 - Hofmann - Slew Bearings Brochure - A4Document2 pages27 - Hofmann - Slew Bearings Brochure - A4Jorge VillalobosNo ratings yet

- Technoroll BrosureDocument13 pagesTechnoroll BrosurephitokrioNo ratings yet

- Approval Material / Product Request: Tongar Hydropower Project - Civil Works PLTM TongarDocument5 pagesApproval Material / Product Request: Tongar Hydropower Project - Civil Works PLTM TongarimronNo ratings yet

- D90KS/1190E: Rotary Blast Hole DrillsDocument12 pagesD90KS/1190E: Rotary Blast Hole DrillsPeMar León ChangNo ratings yet

- sl2023 745Document2 pagessl2023 745iodinecoil02No ratings yet

- Shell Gadus S2 OG 40: Performance, Features & BenefitsDocument2 pagesShell Gadus S2 OG 40: Performance, Features & BenefitsAmanNo ratings yet

- Shell Gadus S2 OG 85Document2 pagesShell Gadus S2 OG 85Anonymous oAbjbl4HNo ratings yet

- High Density CycloneDocument2 pagesHigh Density CycloneEdson CastelliNo ratings yet

- Hydraulic Rock Breakers GuideDocument4 pagesHydraulic Rock Breakers GuideJose Andres Pari VilcaNo ratings yet

- PG 0451Document50 pagesPG 0451Tayfun SezişNo ratings yet

- PG 0251Document50 pagesPG 0251Tayfun SezişNo ratings yet

- PG 0301Document50 pagesPG 0301Tayfun SezişNo ratings yet

- PG 0401Document50 pagesPG 0401Tayfun SezişNo ratings yet

- PG 0351Document50 pagesPG 0351Tayfun SezişNo ratings yet

- Kavlico ProductoverviewDocument26 pagesKavlico ProductoverviewTayfun SezişNo ratings yet

- 22 Mounting SystemDocument6 pages22 Mounting SystemTayfun SezişNo ratings yet

- Air ducting component listDocument15 pagesAir ducting component listTayfun SezişNo ratings yet

- Industrial SolutionGuideDocument39 pagesIndustrial SolutionGuideTayfun SezişNo ratings yet

- 17-2 Starting EquipmentDocument1 page17-2 Starting EquipmentTayfun SezişNo ratings yet

- June 22Document2 pagesJune 22Tayfun SezişNo ratings yet

- Norgren Express Catalog PDFDocument330 pagesNorgren Express Catalog PDFTayfun SezişNo ratings yet

- Pro1040 Pro1050 BS5609 Section3 Sept2017Document10 pagesPro1040 Pro1050 BS5609 Section3 Sept2017Tayfun SezişNo ratings yet

- Main and Auxiliary PTO Systems Technical DocumentationDocument16 pagesMain and Auxiliary PTO Systems Technical DocumentationTayfun SezişNo ratings yet

- Coolant System ComponentsDocument99 pagesCoolant System ComponentsTayfun SezişNo ratings yet

- 18 Lubricating Oil SystemDocument31 pages18 Lubricating Oil SystemTayfun SezişNo ratings yet

- 21 Electric Power SupplyDocument12 pages21 Electric Power SupplyTayfun SezişNo ratings yet

- Letter of Origin For Pro1040 Pro1050 Series DevicesDocument1 pageLetter of Origin For Pro1040 Pro1050 Series DevicesTayfun SezişNo ratings yet

- 11 Charge Air CoolingDocument10 pages11 Charge Air CoolingTayfun SezişNo ratings yet

- OKI FACTORY TEST REPORT E135780-A105-CB-1-Amendment-1Document19 pagesOKI FACTORY TEST REPORT E135780-A105-CB-1-Amendment-1Tayfun SezişNo ratings yet

- 14 Exhaust SystemDocument21 pages14 Exhaust SystemTayfun SezişNo ratings yet

- EMC Pro1040 Pro1050 2No363A PV701 Pro1050 40 N36201B 0B X SignedDocument10 pagesEMC Pro1040 Pro1050 2No363A PV701 Pro1050 40 N36201B 0B X SignedTayfun SezişNo ratings yet

- 10-2 Exhaust TurbochargerDocument1 page10-2 Exhaust TurbochargerTayfun SezişNo ratings yet

- Oil System Parts ListDocument38 pagesOil System Parts ListTayfun SezişNo ratings yet

- EMC Pro1040 Pro1050 2No363A PV701 Pro1050 40 N36201B 0B X SignedDocument10 pagesEMC Pro1040 Pro1050 2No363A PV701 Pro1050 40 N36201B 0B X SignedTayfun SezişNo ratings yet

- EMC Pro1040 Pro1050 2182013 ODCùl ENDocument75 pagesEMC Pro1040 Pro1050 2182013 ODCùl ENTayfun SezişNo ratings yet

- Optimized Accessories Parts ListDocument14 pagesOptimized Accessories Parts ListTayfun SezişNo ratings yet

- EMC Pro1040 Pro1050 2no363 PV701 Pro1050 Pro1040 N36201B N36200BDocument10 pagesEMC Pro1040 Pro1050 2no363 PV701 Pro1050 Pro1040 N36201B N36200BTayfun SezişNo ratings yet

- HJ 274 3 Product ManualDocument1 pageHJ 274 3 Product ManualTayfun SezişNo ratings yet

- 13 Oil PumpDocument8 pages13 Oil PumpTayfun SezişNo ratings yet

- Experimental Investigation and Prediction On Pressure Drop During Flow Boiling in Horizontal MicrochannelsDocument17 pagesExperimental Investigation and Prediction On Pressure Drop During Flow Boiling in Horizontal MicrochannelsdewianzaniNo ratings yet

- Pronunciation test with circle the wordDocument5 pagesPronunciation test with circle the wordĐỗ Cát TiênNo ratings yet

- MRT - Belitung Oil TerminalDocument26 pagesMRT - Belitung Oil TerminalMohammadNo ratings yet

- ST MicroInverter SchemeticDocument12 pagesST MicroInverter Schemeticpuspendu janaNo ratings yet

- 8587ctts 330v 2i 1178 182Document5 pages8587ctts 330v 2i 1178 182Haresh RaisinghaniNo ratings yet

- Gpe EpeDocument15 pagesGpe EpeMiles BarrozoNo ratings yet

- Lecture Notes Conductors, Insulators, and SemiconductorsDocument2 pagesLecture Notes Conductors, Insulators, and Semiconductorsoduleke davidNo ratings yet

- UPS Battery Maintenance 101 - EC&MDocument6 pagesUPS Battery Maintenance 101 - EC&MZiad BadrNo ratings yet

- JKM460 480N 60HL4 (V) F1 enDocument2 pagesJKM460 480N 60HL4 (V) F1 enFriedrichNo ratings yet

- Process Applications: Selecting EvaporatorsDocument8 pagesProcess Applications: Selecting EvaporatorsRaul TejedaNo ratings yet

- 12'34RPS-FM-02 OIS Application Form' With Younew' With YouDocument8 pages12'34RPS-FM-02 OIS Application Form' With Younew' With YouManoj BhandariNo ratings yet

- Peraturan Dan Undang-Undang Alam Sekitar (Rcra)Document7 pagesPeraturan Dan Undang-Undang Alam Sekitar (Rcra)Iser100% (1)

- Module 9Document8 pagesModule 9ENSANO, RHYNS G.No ratings yet

- Currentwatch Current Sensors 1: DescriptionDocument52 pagesCurrentwatch Current Sensors 1: DescriptionFlorin MNo ratings yet

- Catalog D-1 Reg Sol and 3-Way Heat Reclaim ValvesDocument60 pagesCatalog D-1 Reg Sol and 3-Way Heat Reclaim ValvesviniciusschwabNo ratings yet

- Manual de Servicio Autoclave Steelco VS 12Document41 pagesManual de Servicio Autoclave Steelco VS 12Wilito Corona100% (1)

- PffeguidDocument18 pagesPffeguidPrakash VasudevanNo ratings yet

- 3U-3UB - Iom1 (BOMBA)Document16 pages3U-3UB - Iom1 (BOMBA)Paris AnabelNo ratings yet

- Efficiency Analysis of The Solar Tracking PV SysteDocument10 pagesEfficiency Analysis of The Solar Tracking PV Syste2K20A526 AmanVermaNo ratings yet

- E32 Usermanual EN v1.30-10Document1 pageE32 Usermanual EN v1.30-10Sergey SevruginNo ratings yet

- IC Engines GuideDocument47 pagesIC Engines GuidearulNo ratings yet

- Fault Detection and Protection Strategy For Islanded Inverter-Based MicrogridsDocument13 pagesFault Detection and Protection Strategy For Islanded Inverter-Based MicrogridsIEEE PROJECTS MICANS INFOTECHNo ratings yet

- Photovoltaic Maximum Power Point Tracking Using Artificial Neural Network and PI ControllerDocument12 pagesPhotovoltaic Maximum Power Point Tracking Using Artificial Neural Network and PI ControllerHocine AbdelhakNo ratings yet

- Training Course Power System Protection: About DNVDocument2 pagesTraining Course Power System Protection: About DNVlisusedNo ratings yet

- Part 1: The Structure of ATP: ND RDDocument5 pagesPart 1: The Structure of ATP: ND RDkate corveraNo ratings yet

- Essay Competition - Mochammad Rafli Sholehudin Randy - PKTJ Tegal DasdasdasdasdDocument9 pagesEssay Competition - Mochammad Rafli Sholehudin Randy - PKTJ Tegal DasdasdasdasdGenshin DefNo ratings yet

- Fire Fighting Panel Design SummaryDocument52 pagesFire Fighting Panel Design SummarySuvendu Sekhar SabatNo ratings yet

- New 2024 Hyundai N Vision 74Document2 pagesNew 2024 Hyundai N Vision 74luxury life wishesNo ratings yet

- Product Catalogue 188 192Document5 pagesProduct Catalogue 188 192Anand PuntambekarNo ratings yet

- HydraulicsDocument234 pagesHydraulicsChristine CastroNo ratings yet