Professional Documents

Culture Documents

Method Statement House Building in NCR

Uploaded by

Kishore kumar MatchaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement House Building in NCR

Uploaded by

Kishore kumar MatchaCopyright:

Available Formats

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Safety General

1 Refer to Chapter 3, MS 12 & 13, Chapter 4, MS1, Chapter 6, Page 1 for general

provisions on safety discipline in addition to those included with various method

statements on this Chapter

2 Relevant point should be extracted from description in line to requirements on relevant

activities

3 It is to be noted that safety standards vary from organization to organization, company to

company & client to client

4 Just consideration of economy on project cannot exclusively, be a criterion to avoid or

reduce safety measures

5 A minimum level of safety measures installations should be made a ‘must’ for a site

supervise to ensure that workforce ‘must’ work safely

6 It is preferable to work with acceptable level of safety rather than loosening lives of

workers

Method Statement

Chapter 10

House building in NCR

Part1

Scope

1 Purpose of this method statement is to describe in brief, procedures that were adopted for

one house construction in NCR Delhi long back 2008/2009

2 Synopsis of engineering construction provides brief details later

3 Basement/Ground/First/Second floors/Penthouse

4 All RCC structures constituted from basement to pent house, including RCC basement

walls. No bricks were included in foundations

5 Walls in bricks at all levels for cladding & not for any load bearing

6 Doors windows-Aluminum framed glazing

7 Existing old structure about 80 SQM with wooden doors, RCC structures

8 Design of whole building all disciplines, including connection to old building

Part 2

Design methods/procedures

1 All design disciplines for addition were conducted self, without any aid from architect

2 Off sets/zoning, architectural plans, elevations, sections & detailing were conducted self

3 Structural analysis were conducted using Kani’s rotation contribution method, for which,

self formulized excel templates were used to reach moments, shear force, deflections,

seismic impacts etc.

4 Designing was also, conducted, using custom self formulized excel templates for beam,

columns, foundations etc.

5 Bar bending schedules were prepared using excel sheet, duly formulized in line &

consideration to BS 4466 shape codes, which is now replaced by BS 8866

Part 3

Safety

Page 1 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

1 Access ramp was profiled for ingress & egress to & from foundation pit, used by

personnel & donkeys workers both

2 Scaffolding was procured in form of pipes as well as, wooden ballies/props

3 Timber safety railing was used on sides to prevent falls into basement excavation

4 PPEs were used to requirement (it is unfortunate to note that workers in NCR do not

respect use of PPE)

References

1 Drawings- Included within synopsis

2 Specifications- General international & national

Part 4

Materials

1 Local materials from various sources procured for all activities

2 Structural materials/ingredients were procured from NCR Pali crushers/queries

3 Reinforcing bars procured in full length 12/14 meters, without being bent. Extra payment

was made to distributor for trailer transport

4 All reinforcing bars were fabricated on site only under my direct supervision, for steel

fixer vendor did not accept to protect steel bars

5 Concrete was mixed on site, since RMC was not consistent in quality & RMC vendor

failed to answer my queries

6 Formwork was designed, using marine plywood & wooden scantling battens, both hard

wood & softwood

Part 5

Methods

Surveys

1. Setting out was done by old methods of formation of a right angle triangle, instead of

using a Theodolite.

2. All references regarding grids & levels were established on existing walls around

excavated area

Excavation

1 Existing soil type is silt/y clay with sand strata @ 20 m depth

2 No dewatering was required, since water table is much below

3 JCB equipment was utilized for excavations up to limited depth & limited setting out

4 Reason being that on 3 sides, buildings existed, which did not permit full excavation by

machine, requiring manual means for further work

5 Donkeys with masters were used for remaining excavation to reach formation level

6 Excavated material was removed from site immediately, as & when, it was dropped into

truck or on to tractor trolley to transport to temporary stockpile or deliver to someone

else, for some activity

7 Sides of excavation were protected from erosion by covering with polythene sheet, so

that rain water could not help, loosen strength in this case

8 Horizontal/inclined bracings/supports were not required, due to nature of soil

Page 2 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Blinding

1 Since, soil bearing capacity is not safe to allow heavy structure on this formation, soil

improvement was conducted, by including below formation level, an improved layer 300

mm deep, as explained later

2 This layer composed of aggregate & coarse dust, duly watered & compacted, so that it

should also, function, as a coarse graded strata

3 On this layer, an application of Tapecrete coatings was carried out for concrete protection

4 Coatings of Tapecrete was covered with a plaster screed for protection

5 Preparation for blinding was effected & blinding concrete laid to whole area

6 Blinding was cured to requirement of 3 days

Foundation

1 Setting out foundations bases, a part of foundation beams was conducted

2 Concrete Spacers were cast on location. Thickness 50mm, 40mm, 30mm, 20mm

3 16mm dia. Tie bolts for concrete beams were procured fabricated from mechanical shop,

using 550N special steel

4 Preparation of beams, included placing fabricated reinforcement, fixing of forms to sides

of proposed beams, fixing spacers, cleaning whole RCC space etc.

5 Special waterproofing compound was procured to be mixed with concrete for areas,

where a water tank portion, required to be included, within portions of beams itself

6 Concrete mixing & pouring was carried out in one day successfully, followed by

application of wooden finish & continuous curing for required number of days

7 Work started for upright part of foundation beam, which included all activities, respecting

forms fabrication & fixing, reinforcing bars fabrication & fixing, inclusion respecting box

outs/inserts for services, water tank slab etc, were prepared to be ready for inspection

8 Concrete was mixed for this pour added with self leveling concrete compound. Concrete

for water tank beams & bases were cast monolithically, because PVC waterbar could not

be procured

9 During all foundation beams pour, one sectional beam side tried to open, but

immediately, it was controlled by pressing back to alignment within tolerance limit.

10 Continuous Curing was effected for required number of days

Basement Walls/Columns/Stairs

1 Setting out respecting walls & columns was given & verified

2 Work of columns commenced, as it was to be part, within RCC walls

3 Works of columns included formwork fabrication, rebar fabrication & provision of

electrical inserts, all to be carried out in stages, depending on number of form sets

4 Work of RCC walls fabrication for basement started immediately, after, beams were

completed

5 Works of staircase also, started in parallel from basement level to its first landing

6 Setting out of staircase was given on site, using details from Autocad, so that no error

should result on site by contractor

7 Basement walls were required to be poured in stages, due to fact that formwork for 2

walls were only fabricated

8 One by one all elements were prepared & poured followed by required number days of

curing application

Page 3 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Ground Floor Level Slab/Basement Cover

1 Preparation for ground floor slab/basement suspended slab was initiated for which, steel

props procured for centering along with hard wood 50 x 100 mm section for grid support

to formwork

2 Drawings were provided to lead steel fixers & lead formwork carpenters

3 Setting out & levels were monitored regularly, so as not to cause certain error

4 Reinforcement was placed on suspended slab, beams & up stands

5 Electrical conduits were laid in line to drawings, meeting requirement of all electrical

supply points such as light, fans &others

6 Slab concrete was poured continuously, followed by both immediate or instant curing &

regular curing for required number of 7/10 days

7 Application was moved with Haryana Urban Development Authority/Municipal

Corporation of Faridabad to inspect & issue DPC certificate, a statutory requirement

8 Inspection was conducted by concerned officials & DPC issue was cleared

Ground Floor & Above/Superstructure

1 Superstructure between ground floor & first floor included columns, suspended slabs &

staircase, within extended portion

2 Superstructure on existing structure included dismantling of existing parapet, exposing

reinforcing dowels for upper columns & further work from that level up to second floor

3 Also, required joining of old structure to new structure at first floor level

4 Setting out respecting columns at ground floor was conducted

5 Access scaffolding to work around columns was erected

6 Ground floor columns were to be prepared for double heights, within hall portion

7 Steel reinforcing bars were placed in positions, according to drawings

8 Electrical conduits with switch panel boxes were placed/fixed in columns, where required

9 Kickers were prepared & poured for better alignment controls

10 Form for all sides were fabricated & erected, using plywood & battens

11 Supports were fixed, alignment checked & plumb checked

12 Concreting was done for columns in decided sequence

13 Work of stairs were prepared in parallel, which sequences, as carrying out basement

landing to first slab, pour with basement slab

14 Works for first flight from ground to first landing were carried out accordingly, along

with steps for monolithic casting

15 Works for first floor suspended slab were carried out, using steel props specially rented

16 Preparations for first floor slab were completed with all services, pertinent to electrical

discipline inserted

17 Block outs for other services as well, were also, placed in

18 Reinforcement fabrication & placing for slab as well as, 1800 mm continuous

balcony/1000 mm continuous balcony were also, carried out

19 When all activities for preparation were over, clearance for pouring was given

20 Slab concrete was poured in one day, followed by intensive curing for 10 days

21 Works for second slab started along with staircase as well as, works on old portion

22 Columns on old portion were carried out along with added stability floor beams

23 Double stage supporting system was used for area covering, double height slab

Page 4 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

24 Forms for beams & slabs were fixed, followed by steel reinforcing bars fixing

25 All works respecting forms & reinforcing bars continued & completed as required

26 All inserts & block outs/box outs were fixed in to meet requirement as indicated

27 All electrical conduits were placed in, following requirements & locations of electrical

light points/ceiling fan points & wall points

28 Adequate provisions for air conditioning box outs were also, included

29 Provision for allowance for garbage chute too were made on slab

30 When preparatory works were ready for pouring concrete, inspection were conducted &

pouring clearance granted, followed by concrete pour in one day

31 Columns, beams & slabs were poured accordingly, followed by required number of days

curing

32 Application of waterproofing/concrete protection coating was made around whole

basement external surfaces up to plinth level/finished ground level. Polymerised cement

coating was included for application for concrete protection

33 Meanwhile, backfilling was being conducted around basement in 2 vertical layers

34 Earth boring was carried out at one location up to 30 m depth, followed by drilling

required pipes & coal etc. so that a connection, using copper wire could be given to

distribution board

35 First layer in contact with RCC walls was to be filled with 100 mm river sand, while

remaining layer with ordinary soil

36 Later, on all following sequential items, such as brick walling, electrical services first fix,

plastering, rendering, ceramic tiling, sanitary fixtures, water tank placement &

connection, painting, flooring, lighting etc. continued, until all works were completed, so

that it facilitated to move an application to obtain an Occupation Certificate from

authorities, which is a statutory requirement, prior to occupying constructed building

Part 6

Reference

House Construction on Plot 430 Sector 21 B, NCR India, Faridabad

Construction Synopsis

1 Construction commenced 12.11.2008

2 Structure completed 9.7.2009

3 Please refer to plates from 1 to 26 giving entire views of structural construction.

4 Cost on RCC 500 rupees per square foot

Figures 1 to 8 below give certain details for your immediate, reference.

For detailed review of plans, refer to chapter 13, sketch # 66 to 108

1 Purpose of this file is an exclusive indicative information exchange.

Page 5 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Structural

7 72

4 50

level

2 47 2

5750 1 00 0

1 25 0

level

7 50

8 00 1 50

1 50

5 750 1 2 50

2 00 1 50 15 0

1 78 9 600

60 0

1 60 0 16 6 1 3 00 60 0 1 50

3 00 1 43

385 20 0 16 77 30 0

7 14 14 94

2 50 0 2 00

H a ll Entry Le ft Si de ba lc ony 4 64 14 9 4

R ight S ide ba lcon y

St ai r r ai l o n beam

C 2 00 x 3 00

20 0 x 30 0 D

A B

1 7 83 2 00 x 3 00 200

1 50 0 2 00 x 30 0 2 00 x 30 0

20 0 3 00 x 2 00

1 1 00 0

6 00 F2 20 0 x 3 0 0

300

47 49 51 53 55 57 59

1 4 00

2 4 72

2 00 x 3 0 0 1 80 0 72 70 66 64 62 60

1 0 00 2 00 x 4 00

F2 7 72

2 F2 u p st an d

20 0 x 3 0 0

30 0

3 00 x 30 0 x

6 00 600

80 0 F11

F9 14 00

1 80 0 2 00 x 3 00 2 3 00

Bal co n y l i nk /Rai li n g

1 00 0 3 20 0 x 30 0

10 00 6 00

2 00

30 0 x 3 0 0

2 00 x 3 00

2 00

10 00 3 00 x 30 0

578

39 7 7 F12

2 00 x 3 00

F9 20 0 1 20 0 27 77

2 00 x 3 00

4 30 0 x

F4 F4 5 89

6 00 4 00

2 00 x 3 00 3 00

F9 F9 F13

2 00 2 00 x 3 00 2 4 99

2 00 x 3 00

20 0 x 30 0 30 0 x 20 0 3 00 x

5 F5 6 00 60 0 F5

1 00 0 F8 F8 F8 F8 F8 F8

1 8 00 17 20 1 72 0 18 50 1 90 0 18 5 1 18 0 0

2 00 x 30 0 2 00 x 3 00 2 00 x 3 00 2 00 x 3 00

2 00 x 30 0

2 00 200 20 0 20 0 20 0 20 0

11 7 8 3 59 1 60 51

1 50

300

4 50

1 378

1000

F1, F2 , F4, F5/3 00 x 60 0 m m deep, F3 do n ot exis t

F6, F7 , F8, F9/20 0 x 3 00 mm d eep

F10, F11, F12, F13/2 00 x 300 m m deep

Fir st Str uc tu ra l Fr a ming Le vel Ha ll Por tion

40 0 4 00 4 00 4 00 40 0 40 0 4 00 40 0 4 00

40 0 4 00

20 0

I nt er na l Bal con y/ Ra il in g

400

Bal con y p as sa ge/Rail in g

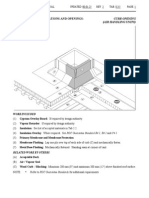

Figure 1 Plan

1 Plot Size 420 SQM

2 Basement below drawing room hall portion

3 Ground coverage 55 %

4 Total coverage added 540 SQM

Str uctu ral

450

772

24 72

level

57 50 10 00

1250

level

750

8 00 15 0

150

575 0 1250

200 150 150

60 0

1789 6 00

150

1600 1 661 30 0 600

300 1 43

38 5 200 1 677 3 00

714 1494

250 0 200

H all E ntr y Left S id e b alcon y

4 64 1494

Righ t S ide balcon y

bea ms

C 200 x 300 m m D

A B 200 x 300

200 x 300

2 00 x 30 0 200

17 83

1500 200 x 300 200 x 300

300 x

1 1000

200

600 F2

200

200 x 300

300

47 49 51 53 55 57 59

1400

247 2

2 00 x 30 0

10 00 18 00 72 70 66 64 62 60 200 x 4 00

2 F2 772

ups ta nd

F2 200 x 300

300

300 x 300 x

600 600

800 F 11

1 400

F9

1800 200 x 3 00 230 0

10 00 3 2 00 x 300

1 000

600

200

200 x 300

20 0

3 00 x 3 00

1000 39 77

578 F 12

200 x 300

F9 2 00 12 00 277 7

200 x 3 00

4 300 x

F4 600

F4 589

200 x 300

300

F9 F9 F 13

200 2 00 x 30 0 249 9

200 x 3 00

2 00 x 300 300 x 200 300 x

5 F5 600 600 F5

1000

F8 F8 F8 F8 F8 F8

1800 1 720 1 720 1850 1 900 1 851 1 800

2 00 x 300 200 x 300 200 x 300 200 x 3 00

200 x 300

200 200 200 200 2 00 200

1178 3591 6 051

1 50

300

450

13 78 1 00 0

F1, F 2, F4, F 5/300 x 600 m m de ep, F3 do not e xist

F6, F7, F8, F9/200 x 300 mm deep

F10, F11, F 12, F13/200 x 300 m m dee p

Fir st Str u ctur al Fra ming Level H a ll Por tion

Figure 2 Plan

Salient features of construction carried out:

1 Front portion double height drawing room or hall

2 Rear portion Bed Room area in three stories

3 Ground floor portion 75 SQM previously constructed in year 2000

4 Soil Silt/y Clay with high affinity to water & white ants.

5 Depth of formation level (-3.4 m) for basement.

6 Excavation carried out by JCB partly & then used donkey stock for a total excavation

quantity of 550 cum.

Page 6 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

7 Excavated soil removed from site using trucks/tractor trolleys.

Part 7

Soil improvement activity below formation level as defined below:

1 Soil improvement by filling/laying 40 mm size graded aggregate 250 mm thick, followed

by placing 20 &10 mm graded aggregate, one after other to fill voids & then on that

layer, placed graded machine dust to completely pack fill voids.

2 Above mix was compacted dry as well as, wet to get placed mix material dense for both

to improve/enhance bearing capacity & to reduce possible settlement.

3 I had observed one pit 1 M x 1 M x 2 M deep for about six months to understand soil

conduct, observations of which were utilized for designing foundations.

4 There was no problem in excavation & there was no need of any shoring during

excavation that indicates that soil was self supporting, due to having no angle of internal

friction, but due to possessing high value of cohesion.

5 Substrata did not have any water table, but certain moisture content % very nominal.

6 It appears that land was used for purpose of agriculture in long past & for development of

area, Development authority acquired land for urbanization around Delhi.

7 Soil definitely contained certain organic chemicals that had to be avoided to impart

adverse affect to proposed building.

8 I judged SBC of soil to be around, 5 to 10 T /SQM based on my experience, yet, it did

not meet building requirement, due to unforeseen conduct of Clays, that could have

contended minerals like Montmorillonite or Illite or some others, which could help soil,

either to swell, while being in contact with water or to loosen entire shear

strength/resistance.

9 Proposal was to include one equal size basement that caused me a cause of concern.

10 I decided to avoid construction of isolated foundations on existing soil, even at cost of

additional expenses.

11 Fortunately, I have experienced during my career extensively on RCC building projects

as well as, on industrial onshore projects, both in office engineering, as well as, in field

engineering.

12 Based on my experience earning, I could solve proposal easily, which I did comfortably

with full confidence successfully.

13 A decision was made to apply soil improvement technique in easiest way, so that bearing

capacity as well as, permeability of soil below formation is sustainable.

14 Water should not affect foundation, if it is allowed to move beneath foundation

structures, because mobility of water can result in various chemical changes within soil &

also, can impact other adjacent structures.

15 Clay soil had to be isolated from building substructures for purpose of RCC protection.

16 To meet requirement, I decided to form a road type WBM structure below foundation

formation, without involving any cementing material, but to be included just water

bound.

17 Some person suggested to include lime also, to mix with soil for soil stabilization, but it

did not convince me, since lime is not a reliable material in moist environment.

18 I went ahead to excavate about 300 mm additional depth to accommodate proposed soil

improvement to a minimal meeting.

Page 7 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

19 It could be more thick but, I did not intend to take risk more than that, due to excessive

depth of excavation, where on two sides of proposed building, existing building/s up to

three story are located.

20 Formation was prepared & 40m size aggregate, which is called Vapisi (40mm aggregate)

in Delhi term, was used to be placed first.

21 20 mm size aggregate was placed on 40 mm size layer, so that voids within 40 mm size

aggregate to be filled packed with 10 mm size aggregates.

22 Later, additional layer of machine graded dust was placed, so that voids within 10 mm

size aggregate to be filled packed with mechanically produced dust.

23 All laid dry mix was watered & compacted, just as it is done on a water bound Macadem

road structure formation.

24 I noticed after compaction that formation was very strong & there was much

improvement on SBC.

25 Foregoing fill has to respond to work as a permeable medium also, for down flowing

water as well as, to allow a break for upward flowing water in future that could be a

result of heavy rains/water table rise or by whatsoever reason, it could be.

26 This provision has also, affected as a barricade for clay soil to be in contact with

foundations.

27 In addition to above, on sides of fixed retaining RCC walls, built between main columns,

fill material used is river sand, so that it allows water to permeability, since clay does not

possess this property, but considerable porosity.

28 Virtually, foundations built are soil contact free & portions, between all RCC beams

foundations joining columns in both directions, an exclusively river sand was used, as a

filling material to avoid cumbersome work on compaction of soils, either to be taken

selectively from site or to be imported from selected source.

29 I think that work has been done economically, in all respects, inducing to foundation,

what it necessitated from practical engineering construction viewpoints.

Part 8

Structural:

1 On prepared soil improvement base, a 50 mm thick layer of blinding concrete was laid.

2 Surface of blinding concrete waterproofed using CICO Tapecrete coating, protected by

CM plastering like on coating.

3 Analysis of structures was done using Kani’s Rotation Contribution Method, a very old

method of moment distribution, but yet useful

4 Analysis of foundation framed matting done by purpose made worksheets.

5 Sketch shows details of foundation section 400 x 1200 mm beam, with 800 mm wide

spreader embedded in full 200 mm thick RCC matting under all beams in both directions.

6 Columns were revealed for stubs/full columns from beams

7 One 16000 litres capacity water storage tank has also, been provided, below basement

accommodated, between foundation beams to contain 600 deep water.

8 Between beams, river sand filling provided in place of soil, since it is difficult to compact

available soil, which could also, deteriorate concrete protection, applied in solution form

as cement based coating.

Page 8 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

9 Externally, 450 mm wide portion filled with river sand, while remaining soil butts with

450 mm line, for which prosecution used form plywood & battens were used to erect

temporary formwork between soil & sand layers.

10 Contractor was not happy to carry out such dual filling for which, extra payment, based

on day basis work was made.

11 There was allowed no contact, between soil & foundations anywhere.

12 Sole criteria had been to keep water permeability working below & around foundations,

so that a virtual filter functions permanently.

13 In general, anti termite treatment is applied on all buildings in NCR zone, but no such

application was made, due to fact that termite cannot bite concrete

400.00

Foun dation Beam

1000.00

200.00

300.00

Soil I mpr ovemen t

Figure 3 Foundation beam

1 Retaining walls 200 mm thick provided around foundations to hold fill.

2 Wall reinforced with 8 mm reinforcing bars @ 200 centers both ways.

3 Main hall portion allowed 12 columns 1000 x 400 mm 4 # columns, while 600 x 400 mm

8 # columns.

4 Span between columns being 11 M in two frames, while 8 M in three frames.

5 Certain frames are located in double height area.

6 Front allows 1800 mm wide balconies, while sides 1000 mm.

7 Six beams provided in front balconies at both levels.

8 Main beams permitted 300 mm x 600 mm section for stability resolution.

9 Cross beams included 200 x 300 mm section.

10 Stair waste provided 200 mm thick with reinforcing bars meshing in top & bottom layers.

11 All suspended slabs included with 8 mm reinforcing bars @ 200 mm centers both top &

bottom.

12 Rear bed rooms’ portion constructed with 11 # columns 300 mm x 450 mm sections for

spans do not exceed 5m.

13 A quantity of 250 cum RCC constructed using M 30/25, all onsite mixing done.

14 Form support systems employed using rented props.

15 Form material employed 12 mm thick ply & timber scantlings/battens 50 mm x 75 mm &

50 mm x 100 mm.

16 A total quantity of reinforcing bars used 22000 kg.

Page 9 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

17 Up to ground level 8000 kg & above ground 14000 kg.

18 Labour workforce element contractor did not include curing element, which consequently

I had to do this activity/part myself.

19 I did not find any problem for suspended slab curing, but for columns & brick walls, I

conducted hard job.

20 Water supply & distribution to kitchen & wet areas has been arranged to be supplied

from tank below basement, located between foundation beams, which has a capacity

about 16000 litres

21 Water is delivered to this tank by gravity from municipal supply main, from where, it is

pumped to roof located 4 # numbers water tanks/tank farm 1000 litres each

22 Delivery to/intake @ tank is integrated, while basement pump supplies water to 2 # roof

tanks only, from where water is automatically, moved to other two tanks as well & then

from there/all tanks, water is distributed down to all floors excepting basement

23 Though proposed use of building is for residential purpose per local authority, yet visitors

put building not as residential in look, but either commercial or any office.

24 A platform was also, constructed to mount Sai Baba statute

25 Finishing items constituted plastering, rendering, marble stone flooring, ceramic tiling on

walls, marble paint coating, wooden cupboards, roofing etc.

Major activities can be summarized as follows:

1 Excavation of whole area, which can be referred to chapter 13, sketch # 105

2 Soil improvement on all formation areas with structure graded fill/engineered fill

3 Blinding concrete on whole prepared & compacted areas

4 Application of concrete protection coating over blinding layer

5 Protection mortar layer over waterproofing/concrete protection coating

6 Steel rebar fixing for thin so called raft part of foundation beams frame

7 Formwork installation for thin raft part of foundation beams

8 Pouring thin raft part of foundations beam frame

9 Steel fixing for beams part of foundations

10 Formwork for beams part of foundations

11 Services’ inserts installations, within foundation beams

12 Pouring foundation beams, using self leveling compound mixed with concrete

13 Preparatory works for suspended slab for water tank cover

14 Pouring water tank suspended slab

15 Preparatory works for basement columns

16 Preparatory works for basement retaining walls one by one

17 Preparatory works for stairs basement first flight & pouring

18 Preparatory works for basement cover slab or ground slab & pouring

19 Columns for ground floor in sequence

20 Stair flight for ground to first floor

21 Suspended slab works for ground floor cover or first floor level slab

22 & similarly, all structural activities for whole remaining elements completed

23 Then, brick walling, plaster, render, roofing, flooring, marble stone flooring, painting,

wood work services etc all items

24 Installation of services fixes & commissioning all services

Page 10 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Part 10

Observations:

1 I tried to apply all efforts to extract a good quality of structure from workers used to

system in NCR but, I was successful to certain extent only.

2 It necessitates a lot of training to be imparted with skilled workers, as well as, self styled

contractors & foreman.

3 Most significant part that requires training is about, what should be real procedures of

producing, transporting & placing concrete mix, within right defined duration.

4 QA system is slackening on use of structural concrete.

5 Generally, RMC suppliers think that cube results only, dominate concrete.

6 There is no call in Bharat India to mandatory drill cores post concreting to ensure

accuracy or genuine sampling of cubes.

7 Concrete pouring gangs do work efficiently, but compliance with requirement raises a

question mark on various projects.

8 Absence of qualified engineers on supervision also, raises eyebrows. Public seems to be

ignorant & non serious about required quality of good concrete & very few understand

durability of concrete, as a basic property.

9 What is seen by eyes is considered building work, but, real technological requirements do

not reach builder or general public.

10 Promoters or builders befool consumers in name of international standards & make

profits from innocent buyers.

11 For further reference to understand this construction, many sketches have been attached

within chapter 13, sketch # 66 to 108, which I think should be useful to reader.

12 All these sketches are detailed well in architectural, structural, building services etc,

which can be referred to for grasping requirements on professional projects drawings &

documents issues.

13 I have experienced that contractors & engineers avoid preparation all detailed documents

for sake of time or cost, but I do not know exactly about what reason is behind that

neglecting approach

14 Interestingly, double mesh both ways reinforcing bars were included on suspended slabs

& almost all being 8 T, excepting certain cantilever beams.

15 Steel fixer contractor was scared to include 8 T only, but it was done to his surprise.

16 Similarly, 12 T reinforcing bars were included in many beams with span 11M, which

surprised many builders.

17 Steel contractor was surprised to see that polythene sheet was used to cover reinforcing

bars which were in store or others that had been placed on job.

18 Bars in store were used to be covered all days & only bars to be fabricated were

withdrawn & after, withdrawal, again polythene sheet covered.

19 Some reinforcing bars were due to rain, which rust was removed from bars by steel

brushing for many days.

20 It was also, surprising that workers removing loose rust did not feel happy to do task.

21 Brick walls were carried out, after slab formwork struck completely.

22 Elevation drawings were issued to contractor for walls windows areas, for parapet areas

23 No lintel was included, due to reverted design of windows

24 Reverted design means, top width being more than middle & middle width more than

lowest as all windows resembled stepping in two steps on all elevations

Page 11 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

25 Purpose of had been to allow lesser loads from walls, as well as, to allow natural lights

to a maximum extent possible at least during day sunny hours.

26 Special design was drawn for roofing item utilizing used plywood, battens, polystyrene

etc, so that roof is thermally insulated, as well as, act acoustic.

27 It has also, been experienced that for such buildings, structures are not allowed, due

weight to design applications as architects or layman builders dominate such low profile

private clients market

28 Every unqualified in engineering person experienced as mason or carpenter, self appoints

as a builder or a promoter or a contractor winning jobs either @ labour element rate or as

a lump sum or item rate based, which results in carrying out designs, based on no design

calculations, while owners are misled in such situation

29 Owners are advised to save cost by not including design based structural elements

30 Conventional old tradition workers carry out their own assumed or practiced designs &

deliver non professional buildings, but well decorated from internal & external envelopes

keeping owner pleased

31 Such buildings are not even based on direct load calculations, forget about bending

moments, deflection or seismic shear altogether, while builder provides a guaranteed

verbatim statement to owner, pertinent to hundreds years long life of delivered building

32 Even higher dia. Steel reinforcing bars are included within suspended slabs, while,

required beams & columns are overlooked or neglected altogether

33 Generally, 225x225mm columns are added to certain locations, but within block walls

raised together to slab level followed by slab work

34 Curing got no specific meaning in such builder’s vocabulary, while some leave first day

post formwork striking surface of columns & others to natural curing by air!!!

35 Hope public could understand engineering & requirement of a well designed building

Page 12 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Righ t Elevation

Arch itectur al

Elevation

500

2125

8.85 sqm 1.56

5 25 59 5

297297297297

594 47 5 475 475 47 5 300

738

3250

3250

738

738

3.0

737 300

3.24

52 5

3250

3250

73 8 3.4

437

100 300

750

1625 1.37

2.35 O WNE RS- SURAJ SINGH & SUMI TRA

2500

F O R Submiss ion

875

PLO T 43 0/1 A, SECTOR 2 1B, FARIDABAD-HUDA ARE A

Figure 4

Elevation

Arch itectu ral

500

P LOT 4 30 /1 A, SECTOR 21 B, FARIDABAD-HUD A AREA

3 250

1000

OWNER S- SURAJ SINGH & SUM ITR A

3 250

3 250

FO R Su b mission

3 250

3 750

300

1250

3 250

200 0 20 00

Left Elevation

Page 13 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Figure 5

200 400 250 400 250 400 200

1378 800 1200 935 935 1200 1200 935 935 1200 800

PL OT 430/1A, SE CTO R 21B, FARIDABAD -H UD A ARE A

800

200

300

349 698 349 228

1.82

OWN E RS- SURAJ SING H & SU MIT RA

1.82

F O R S ubmi ssi on

349

349 228 2000

666

667

650

650

Fr on t Eleva tion

Ar ch itectu ral Eleva tion

Figure 6

FO R Su bmission

OWNER S- SURAJ SI NGH & SUMIT RA

PLOT 430 /1A, SE CTOR 2 1B, FARI DABAD-HUDA AREA

1371 37 59

V1

80 3

Arch itectu ral D1

BED

55 59

W1

2450 3 507 4 764

D2

D

900 850 9 00 900

V

V3 W

W2

524 D5 D4

900 D3

300

SF L+ 1 2' 0 "

pra yer

Ba th

4200 44 99

BED

1 000 850 W4

D8 D10

V5 90 0 2052

650 75 0

12 00 W1 5 D11 1 200

118 0

2 50

927 802

W5 47 49 51 53 55 57 59

10 70 V6

72 70

927 66 64 62 60

20 00

W6 800

10 00 W14

W7 1 500

1000

D ouble H eight

20 00 W8 W13 2000

SFL + 14'-6"

1500

W9

800 W12 15 00

D 13

2791 200 0

W10 W1 1 1800

First Floor pla n Sca le 1 : 50

Page 14 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Figure 7

A B C 40 0

3 00

2 00

D

T ypic al2 00

2 00

2 00 1 00

2 00

1 80 0

6 / 16 Ø ea ch in 3 l ayer s 4 Leg ged /8 Ø r in gs @2 0 0 c/c 6 / 16 Ø in 1 l ayer , 4 oth e r layer 1000

6 / 12 Ø in 1 laye r, 4 ot h er la ye r

6 / 1 2 Ø i n 1 la yer

2472

2 4 / 12 Ø ea ch in 2 layer s 6 / 12 Ø ea ch in 3 l ayer s 4 Leg ged /8 Ø r in gs @2 0 0 c/c 6 / 1 2 Ø eac h in 3 la yers

6 / 1 6 Ø ea ch i n 3 la yer s

6 / 12 Ø in 1 layer

6 / 1 6 Ø e ach in 3 layer s

2300

3 4 / 12 Ø ea ch in 2 layer s 6 / 1 2 Ø e ach in 2 layer s 4 L egge d/8 Ø r in g s @ 20 0 c/c 6 / 12 Ø

6 / 16 Ø ea ch in 3 l ayer s

6 / 12 Ø in 1 l ayer , 4 in a n oth er r

6 / 1 6 Ø e ach in 4 la ye rs

2777

4 6 / 12 Ø

6 / 1 2 Ø e ach in 3 la ye rs

6 / 16 Ø ea ch in 3 l ayer s 4 Leg ged /8 Ø r in gs @2 0 0 c/c 4 / 1 2 Ø in 2 layer s

6 / 1 2 Ø ea ch in 3 layer s

2499

4 / 1 2 Ø i n 1 la yer

5 6 / 12 Ø 6 / 16 Ø ea ch in 3 l ayer s 4 Leg ged /8 Ø r in gs @2 0 0 c/c 4 / 1 2 Ø in 2 layer s

Fou ndations Beams Rebars P lan

Page 15 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

Figure 8

OWNE RS- SUR AJ SINGH & SUM ITR A

S elect objects:

Area = 156403737, Length = 53010 P LOT 43 0/1A, S ECTOR 2 1B, FAR IDABAD-HUDA AR EA

8851

A B C 29'0"

D

1000

8'2"

1 2472

1000

15'8"

4768

4'6" 1378 3390 11'2"

2472

2

4'6"1378

2300

3 1000

12848

17'0" 42'1.5"

E xcavat ion Level -3.125 M

103765177 2777

34'0" 4

2499

5 2699

8'10"

1000

12241

40'2"

13619

44'8"

Foun da tions Exca va tion s Pla n

H a ll por tion Area 156 sqm

Part 11

Quality Systems: Lessons Learnt & Conclusions

1 Quality Requirement is More Significant than Quality Awareness.

2 Quality requirement must be binding leaving chalta he or quality last attitude written

off for ever to be replaced by thik karo or quality must attitude.

3 Quality Systems Requirement must be adherently, applied from Designs to Tendering to

Award to Supervision to Execution of Construction Operations, as well as, post

construction maintenance.

4 Merely, signing off documents is not sufficient, but, carrying out of activities & cent per

cent inspections or examinations are mandatory.

5 Those personnel involved with quality system operations, must be themselves quality

competent, as well as, quality supportive & must campaign for its realty achievement by

encouraging other department’s personnel. Responsibility ignoring personnel spoil whole

system quality.

6 Lapse on quality cannot be digested in any case, whether activity belongs to pre

earthquake preventive measures or belongs to a post earthquake disaster management.

7 Loss of lives due to negligence cannot be compromised. Generally, it has been

experienced in almost all spheres that after quality system introduction for decades,

products quality has not resulted as expected consequently, by inefficient compliance of

quality system.

8 Lapse of quality on performance & its inefficiency cannot be allowed to be digested with

any disaster mitigation scenario whether, it has to be in operation or it has to be as

supporting resources or as involving leading authorities, whosoever & howsoever big one

may be.

9 Hard work input, determination, dedication, commitment, implementation, post

implementation scrutiny or audits, are all a must & must be seen, duly performing in

addition to approved or recognized agreements.

10 Bare talks & statements would not work to give required results. Real action must be seen

doing by one & by all members of all departments teams.

Page 16 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

11 No leniency should be accepted on doing any activity to requirement in any department

or section.

12 Safety first & Quality must attitude must be adopted, as a strong potential slogan.

13 Can we understand this?

14 Since world has been changing then Bharat/India has to change otherwise, there would be

no way to escape from due responsibility & legal liability.

15 Know safety, no pain versus No safety, Know pain.

16 Can we understand it?

Other buildings

1 Chapter 13, sketch # 63 & 64 an officer’s apartment/flat & an administrative building

respectively, provide more proposals for construction purpose

2 As described in foregoing, similar, sequence for respective activities should be followed

3 All such buildings are RCC structures with internal & external finished on same pattern

or scheme

4 Sketch # 61 shows a central control building, which constitutes a part of major facilities

project with wide dimensions

5 Purpose of such building is to house all central controls that are required to control all

processes trains on a chemical processing plant

6 Since, this type of building is located in off sites of processing areas, such structure must

be blast resistant/resilient, due to fact that its distance of extreme corner lies within in

200/600 m of process area location for which, sketch # 20 indicative facility layout could

be referred

7 Sketch does not show complete details of settings out but, only that part, which requires

blast resistance that can be provided including RCC walls on periphery allowing blast

resistant steel thick doors on indicated locations or if so required, on other locations as

well.

8 CCB type building should have IT access room, with raised floor system to contain

optical networking supporting arrangements cabling

9 CCB must have devised with all equipment that would be required for total processing

controls & should have adequate accommodation capacity, as well as, internal circulation

areas from safety & ergonomics viewpoint

10 Entry locations should be provided with air lock doors/entries

11 Internal controls should be provided with access card system or other security &

surveillance system

12 CCB must have integration with CCTV network/SCADA controls etc.

13 Sketch # 62 indicates a line plan for a substation building, which requires blast resilience

or resistant design provisions

14 When such building is located within 200 M from process area, it should be blast

resistant & accordingly RC walls & slabs should be provided, while no precast elements

preferred on such buildings

15 When located, between 200 to 600 M, it could be blast resilient

16 When located more than 600 m, it could be non blast building/an ordinary structure

involving normal loads, wind loads & seismic shears applications

17 Substation constitutes cable cellar, high voltage switch gear area, transformer area,

control offices areas

Page 17 of 18 2012 Int. P Eng (India) Suraj Singh

Buildings Practice For Professionals

Construction Method Statements

Chapter 10 House Building in NCR

18 Walls should be RCC constructed for blast resistant case in addition to RCC roof

19 RCC Columns should be constructed for blast resilience case in addition to RCC roof

20 Walls should be concrete block with normal reinforcement in voids/horizontal alternative

courses constructed for blast resilience or non blast areas

21 Precast slabs or walls should not be used for blast impact locations, due to no viability

22 Transformers party walls should be RCC constructed for blast, as well as, for fire loading

23 For all such critical buildings in process areas or in off sites, adequate provisions should

be made for loss prevention utilizing either FM 200 system or Inergen gas system, which

performs on basis of consideration that during fire, area in scope, is sealed in seconds

allowing no fire spread

24 Sketch #65 show a general arrangement, pertinent to a sectional tank, respecting water

storage tank in plant areas, where no single unit tank can be useful due to certain reasons

25 Single unit tank does not allow continuation of water service, in case of problem is

involved with tank but, sectional design, can allow continuation by holding affecting

sectional cube

26 Tank is shown in 4 # vertical layers or row as, while it has 15 # units horizontally in each

row, which arrangement capacitates to defined quantity

27 Tanks has to rest on ground for which, foundation is required

28 Foundation beams have been located to bear load in such a way that end beams carry

weight/load from one unit mount or stack only, while intermediate beams, carry from two

unit mounts or stack

29 Whole area require excavation in shallow depths, compaction, blinding, concrete

protection, protection concrete, formworks for beams, steel placing, concrete pouring etc.

30 A pump shed is also, required to be constructed adjacent to this tank by installing a pump

plinth or base based on machine design calculations

Page 18 of 18 2012 Int. P Eng (India) Suraj Singh

You might also like

- Technical ReportDocument16 pagesTechnical ReportBrahammanand BairwaNo ratings yet

- Method Statement For ScribbDocument12 pagesMethod Statement For ScribbAmirul ShazwanNo ratings yet

- Proposed Method Statement For Yangon CCRDocument31 pagesProposed Method Statement For Yangon CCRMyo Lwin100% (1)

- Methodology: I TitleDocument10 pagesMethodology: I TitleGuedjeo SuhNo ratings yet

- Faculty of Civil EngineeringDocument12 pagesFaculty of Civil EngineeringAnang SdjNo ratings yet

- Practical Training: B. Tech. Semester VIIDocument53 pagesPractical Training: B. Tech. Semester VIIRakshit Gp Goyal100% (1)

- BALJOT IndustrialDocument44 pagesBALJOT IndustrialHarmeet Singh100% (1)

- Quality Procedure For ConcreteDocument12 pagesQuality Procedure For ConcreteEdrian DiazNo ratings yet

- ED-E-MS-500 Rev 01 (Method Statement Solid Blockwork, 26-10-16)Document7 pagesED-E-MS-500 Rev 01 (Method Statement Solid Blockwork, 26-10-16)Nalin SenadeeraNo ratings yet

- Specification of Soil NailingDocument11 pagesSpecification of Soil NailingdonnyNo ratings yet

- Construction of Block WallDocument2 pagesConstruction of Block WallWai Fai WongNo ratings yet

- Method of Construction of Segmental Concrete BridgeDocument72 pagesMethod of Construction of Segmental Concrete BridgemarioestructuraNo ratings yet

- DCM Construction MethodDocument12 pagesDCM Construction MethodHaryadi WirawanNo ratings yet

- Method Statement For PCC & RCC WorksDocument11 pagesMethod Statement For PCC & RCC WorkspoovazhaganNo ratings yet

- Repair & Rehabilitation of Distressed Structures (Repair & Retrofitting)Document26 pagesRepair & Rehabilitation of Distressed Structures (Repair & Retrofitting)sahilkaushikNo ratings yet

- Method Statement For Temporory Works For Trench Area in South E2 TowerDocument10 pagesMethod Statement For Temporory Works For Trench Area in South E2 TowerSilajit Rony DasguptaNo ratings yet

- Method of Statement For Concrete Surface RepairDocument13 pagesMethod of Statement For Concrete Surface RepairMohd MuksinNo ratings yet

- Lecture AllDocument58 pagesLecture Alldwk100% (2)

- Master Specification - Part St-Re-C2 - Soil NailingDocument10 pagesMaster Specification - Part St-Re-C2 - Soil NailingHugo FernandezNo ratings yet

- How To Construct Concrete Column in A Simple WayDocument5 pagesHow To Construct Concrete Column in A Simple WayKishore KumarNo ratings yet

- Grade Beam Procedures Rev 3Document2 pagesGrade Beam Procedures Rev 3Rose ManipolNo ratings yet

- Checklists For Quality Control For RCC WorkDocument4 pagesChecklists For Quality Control For RCC Workwaimaung100% (1)

- CE2045 Prefabricated Structures PDFDocument124 pagesCE2045 Prefabricated Structures PDFGauthami Kesavan100% (4)

- Precast Technology With The Case Study of BWSLDocument93 pagesPrecast Technology With The Case Study of BWSLer_hvpatelNo ratings yet

- Method Statement For Hardscape WorksDocument12 pagesMethod Statement For Hardscape WorksAnish ElmoNo ratings yet

- 2 - Introduction To Precast Concrete PDFDocument16 pages2 - Introduction To Precast Concrete PDFPreciousNo ratings yet

- CE6016 PS Unit 4 NotesDocument12 pagesCE6016 PS Unit 4 NotesCarlos OrozcoNo ratings yet

- Method Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Document32 pagesMethod Statement With Job Safety Analysis For Road Drains Culverts Road Crossover Final 16 07 2019Imranuddin SyedNo ratings yet

- An Mol Final ReportDocument35 pagesAn Mol Final ReportShweta JaiswalNo ratings yet

- D345-MS For Block Work - 05.01.2023Document7 pagesD345-MS For Block Work - 05.01.2023naseerdropboxNo ratings yet

- MOS - Concrete Works 07.18 R-0Document9 pagesMOS - Concrete Works 07.18 R-0RABIE EL MAGHWRY ABDELKHALEK ELGHAMRYNo ratings yet

- 9.BOX CulDocument3 pages9.BOX CulPMC HYTPLNo ratings yet

- RajatDocument23 pagesRajatShah PriyamNo ratings yet

- Ms of Rectify The MEP Pipe Opening On Slab-Stair LandingDocument13 pagesMs of Rectify The MEP Pipe Opening On Slab-Stair LandingBON KIMSONGNo ratings yet

- Wood FlooringDocument5 pagesWood FlooringYunitaNo ratings yet

- Const. MethodologyDocument11 pagesConst. MethodologyTekton Construction Corp.No ratings yet

- Concrete Works For Foundation (PC-RC) - 1Document7 pagesConcrete Works For Foundation (PC-RC) - 1Mohamed GamalNo ratings yet

- Module 8 - Structure ItemDocument8 pagesModule 8 - Structure Item2023804106No ratings yet

- CS Comments - Method Statement For GRC WorksDocument6 pagesCS Comments - Method Statement For GRC Worksmohamedelnoby254No ratings yet

- Construction Methods in IndiaDocument5 pagesConstruction Methods in IndiaVishal ShahNo ratings yet

- Ms Block WorksDocument3 pagesMs Block WorksjaladeepNo ratings yet

- Work Procedure For Construction of Chemical Storage ShelterDocument10 pagesWork Procedure For Construction of Chemical Storage ShelterResearcherNo ratings yet

- Special Specification 4657 MicropilingDocument8 pagesSpecial Specification 4657 Micropilingyamanta_rajNo ratings yet

- Construction Method For Precast SystemDocument10 pagesConstruction Method For Precast SystemKenny LiuNo ratings yet

- Method StatementDocument9 pagesMethod Statementtmopeli3130No ratings yet

- 4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1Document7 pages4-Method Statement For Door Frame Fixing, Inspection, Storage and Test 1 - Copy1ABHISHEKNo ratings yet

- Construction Method of StatementDocument11 pagesConstruction Method of Statementperunding thd100% (2)

- General SpecsDocument6 pagesGeneral SpecsLoraine Kristy AlmedillaNo ratings yet

- School Building Analysis Final ReportDocument49 pagesSchool Building Analysis Final ReportNabin Acharya100% (1)

- Mathod Statment RCCDocument4 pagesMathod Statment RCCajay singhNo ratings yet

- Construction Method Statement: Concrete WorksDocument6 pagesConstruction Method Statement: Concrete Worksmohammad_reza_49No ratings yet

- 01DCivil Jab SafetyDocument6 pages01DCivil Jab Safetymd sarfaraz khanNo ratings yet

- MS For Pre - CastDocument14 pagesMS For Pre - CastImho TepNo ratings yet

- School Building Analysis Report Final RebuildDocument51 pagesSchool Building Analysis Report Final RebuildNabin Acharya100% (1)

- Utkarsh Industrial Training ReportDocument39 pagesUtkarsh Industrial Training Reportprosperity facilitation100% (1)

- MS005 Block WorkDocument5 pagesMS005 Block WorkMhando Ignas100% (1)

- ReportDocument15 pagesReportA 33 TECE Shivam NikamNo ratings yet

- Construction of Telecommunication TowersDocument5 pagesConstruction of Telecommunication TowersMarvin ZapataNo ratings yet

- GLPL - NDR (Technical Due - Diligence) ..Document1 pageGLPL - NDR (Technical Due - Diligence) ..Kishore kumar MatchaNo ratings yet

- Recent Work Jan 2024 CompressedDocument48 pagesRecent Work Jan 2024 CompressedKishore kumar MatchaNo ratings yet

- Method Statement For Footing Concrete PouringDocument9 pagesMethod Statement For Footing Concrete PouringKishore kumar MatchaNo ratings yet

- Sr. 557 Submission For Approval of Construction Methodology For Cement Plaster (12mm, 15mm or 20mm Thick)Document17 pagesSr. 557 Submission For Approval of Construction Methodology For Cement Plaster (12mm, 15mm or 20mm Thick)Kishore kumar MatchaNo ratings yet

- Control Valve Interview Questions and AnswersDocument11 pagesControl Valve Interview Questions and Answersakmal100% (2)

- Astm Carbon Steel Pipe and Flange Specifications PDFDocument2 pagesAstm Carbon Steel Pipe and Flange Specifications PDFarunNo ratings yet

- What Is A Slab? 2. Two Types of SlabDocument18 pagesWhat Is A Slab? 2. Two Types of SlabCian ChanNo ratings yet

- Performance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFDocument14 pagesPerformance Analysis of Pressure Vessel With Various Stiffener Using FEA PDFsandeeppandey0789No ratings yet

- Imco End MillsDocument36 pagesImco End MillsgurdeeNo ratings yet

- ZCP Mu13947 PDFDocument36 pagesZCP Mu13947 PDFsugirinNo ratings yet

- FS 2004 A - Rev-7Document78 pagesFS 2004 A - Rev-7Maffone NumerounoNo ratings yet

- Filler Metal - Bestseller - Engl - NT - BohlerDocument29 pagesFiller Metal - Bestseller - Engl - NT - BohlerMaher BmdNo ratings yet

- Plumbing GlossaryDocument45 pagesPlumbing GlossarydonvantuongNo ratings yet

- SSE QC CIV 402 Rev0 PDFDocument2 pagesSSE QC CIV 402 Rev0 PDFBhalsingh JangraNo ratings yet

- Standard Details For Metal Roofing & Siding: Post Frame and Residential StructuresDocument48 pagesStandard Details For Metal Roofing & Siding: Post Frame and Residential Structurespierre_oosthuizenNo ratings yet

- Cross Reference AWG To MM2 - Multi - Cable CorporationDocument1 pageCross Reference AWG To MM2 - Multi - Cable CorporationPankaj RawatNo ratings yet

- Jakarta 2Document120 pagesJakarta 2Anang QosimNo ratings yet

- Kitchen Hood Cleaning Checklist-1-2Document2 pagesKitchen Hood Cleaning Checklist-1-2zaimNo ratings yet

- RCABC Roof Curb Pentrations and OpeningsDocument13 pagesRCABC Roof Curb Pentrations and OpeningsdomcristiniNo ratings yet

- Modelling of Negative Skin Friction On Bored Piles in ClayDocument64 pagesModelling of Negative Skin Friction On Bored Piles in ClayLordM00nNo ratings yet

- Analysis of Alternative Composite Material For High Speed Precision Machine Tool Structures PDFDocument14 pagesAnalysis of Alternative Composite Material For High Speed Precision Machine Tool Structures PDFfunkyNo ratings yet

- VWR 1500 Series ManualDocument28 pagesVWR 1500 Series ManualDanielNo ratings yet

- Project: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedDocument2 pagesProject: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedV U P RaoNo ratings yet

- Tekriwal Website ContentDocument3 pagesTekriwal Website ContentJohn KumarNo ratings yet

- Profiles For Ceramic TilesDocument6 pagesProfiles For Ceramic TilesnasuemilNo ratings yet

- Metal Properties and Destructive TestingDocument84 pagesMetal Properties and Destructive Testingtuvu100% (3)

- Daya Dukung - Pondasi DangkalDocument34 pagesDaya Dukung - Pondasi DangkalRaditya PurnamahadiNo ratings yet

- Stopple ProceduresDocument3 pagesStopple ProceduresBensmatNo ratings yet

- Tyco SprinklerDocument68 pagesTyco SprinklerLuka RadilNo ratings yet

- Ashrae Isbd ReportDocument35 pagesAshrae Isbd ReportLuciano EbangNo ratings yet

- Steel Framing For Service YardDocument1 pageSteel Framing For Service YardNana BarimaNo ratings yet

- (Asce) 1076-0431 (2010) 16 2Document7 pages(Asce) 1076-0431 (2010) 16 2Kausalya AravindNo ratings yet

- Commisioning Files - DVM S HP and HR ChecklistDocument2 pagesCommisioning Files - DVM S HP and HR ChecklistGingubaNo ratings yet

- Meyco Segment HR PDFDocument16 pagesMeyco Segment HR PDFFabioSoaresNo ratings yet