Professional Documents

Culture Documents

Welding Safety Procedures

Uploaded by

AdilMunirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Safety Procedures

Uploaded by

AdilMunirCopyright:

Available Formats

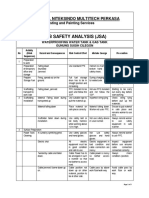

JOB TITLE: PAGE: DATE: TIME:5.

30 am Emergency TELEPHONE

Welding Grinding Fitting Gouging 1 of 2

roof plates 4748888

TITLE OF PERSON WHO DOES JOB: SUPERVISOR: /FOREMAN ANALYSIS BY: )

JOB SAFETY Welder Chipper I Fitter Operator RIAZ AHMED NEHME FARAH

ANALYSIS

LOCATION: DEPARTMENT OR PROJECT: CONTRACT NUMBER: 153130

IC 3 TANKAGE PEARL GTL PROJECT

REQUIRED AND/OR RECOMMENDED PERSONAL PROTECTIVE EQUIPMENT: Hard hat Safety glasses /shoes APPROVED BY: NEHME FARAH

working and welding gloves face shield Welding hood safety goggles ALL PPE

SEQUENCE OF BASIC JOB STEPS POTENTIAL HAZARDS RECOMMENDED ACTION OR PROCEDURE

Welding and cutting roof plates Fire hazard Fire extinguisher ever work area proper house keeping and

remove the flammable material which can cause fire

Defective tools Tools should be checked on a daily basis and should be color

coded use the right tools for the right job

Tripping slipping hazards -Proper house keeping and observing the surrounding hazards

-Arrange materials in and around the lifting/set down area in an

orderly and neat manner.

-Keep scaffolds access free of materials.

-Materials should be kept inside the tool baskets for proper

storage. Welding cable and air hoses should properly lined on

the wind girders

Working at heights Workers are required to use the CB&I approved safety harnesses

with shock absorber (deceleration device) and 2 lanyards.

-When working at heights 1.5m or above workers are required to

be 100% tied off at all times.

Hand lines top and mid rail should be properly tensioned (no

more than 3 inches of deflection under hand pressure at mid

span) and should be clamped properly using approved Crosby

cable clips.

-If necessary the workers are required to use independent line

tied to an approved anchorage point.

Flying debris/dust Wear double eye protection [face shield and goggles]for grinding

/welding hood with correct lens

Pinch point Proper body position do not put your hands between the plates

and pieces of material

Body positioning The involved crew should be observant where their position is

Printed in USA SAF 55 (FRONT) NOV 95

Use of defective tools Do not use any improvised tools

WELDING under the wind girder use rolling Falling object All loose tools put in side cage prior to use rolling scaffold the

scaffold gouging and grinding wheels should be locked to avoid unnecessary movements

area barricades must be installed at least 1.5m from the shell

under the scaffold the barricade must be complete around the

tank

Damaged grinder All tools including grinder to be inspected for any defects prior to

use

In line of fire CO worker to be protected from the grinding sparks Inform your

co worker when your start the grinder and position so as to

protect other worker from sparks

Welding of nozzles and Support shell and roof Working at heights Worker are required to use the CBI approved safety harnesses

attachments other with shock absorber and two lanyards

Working in heights using man basket Prior to lifting man basket should be tested with the test

plate .Man basket should have a bypass man basket should

have an independent lifeline for anchorage of the workers

Wind effect of to the man basket There should be a designated man to hold or control the man

basket with rope

Static effect to the man basket and crane wile Man basket should be grounded

welding

Working inside the confined space Hazardous atmosphere Do gas monitoring every morning prior to entry and after

lunch

Make sure that non permit required confined space is posted on

the site and check the gas testing on that

Provide ventilation on the pontoon man hole if required

Insufficient light Provide lights inside the pontoon for work

SIGNATURES REQUIRED ON BACK OF JSA

Printed in USA SAF 55 (FRONT) NOV 95

JSA TRAINING ATTENDANCE

PRINT NAME HERE SIGNATURE

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Recommended Improvements in JSA:

Printed in USA SAF 55 (BACK) NOV 95

You might also like

- Builder Hoist Erection JSA HSE ProfessionalsDocument2 pagesBuilder Hoist Erection JSA HSE ProfessionalsMAM ENERGINDONo ratings yet

- 12 scaffolding workDocument5 pages12 scaffolding workKoneti JanardhanaraoNo ratings yet

- CS Sub Station JsaDocument4 pagesCS Sub Station JsaEHS Unit IINo ratings yet

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RNo ratings yet

- Jsa For - SRPDocument3 pagesJsa For - SRPVijay chauhanNo ratings yet

- JSP For Electrical and HV TestingDocument4 pagesJSP For Electrical and HV TestingmohammedNo ratings yet

- Ene Risk AssessmentDocument1 pageEne Risk AssessmentSanjeet SinghNo ratings yet

- Job Hazard Analysis for Erection of Field InstrumentsDocument8 pagesJob Hazard Analysis for Erection of Field Instrumentsசேகர் வேதாரண்யம்No ratings yet

- Project: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control MeasuresDocument3 pagesProject: Job Title:Suspended Rope Platform S.No Activities Hazard Risk Control Measureskhaja asifuddin100% (1)

- Job Hazard Analysis For Crane DismantlingDocument2 pagesJob Hazard Analysis For Crane DismantlingKamlesh Bule Lonari100% (2)

- Structural Fabrication _ Erection JSA HSE ProfessionalsDocument1 pageStructural Fabrication _ Erection JSA HSE Professionalsm.rehanhseNo ratings yet

- Job Safety for PlumbersDocument2 pagesJob Safety for PlumbersNaresh KumarNo ratings yet

- Aea 1305 WC El MS 0001Document12 pagesAea 1305 WC El MS 0001Adil HasanovNo ratings yet

- Safe Plan of Action Ramsu EnterpriseDocument5 pagesSafe Plan of Action Ramsu EnterpriseSanjeev Kumar100% (1)

- JOB HAZARD ANALYSIS AND CONTROL Grinding-JHADocument4 pagesJOB HAZARD ANALYSIS AND CONTROL Grinding-JHAlipNo ratings yet

- Sunmow Jha 001Document3 pagesSunmow Jha 001Douglas DellyNo ratings yet

- JsaDocument13 pagesJsaArnold Roy Coballes Manalo100% (1)

- JSA PlumberDocument2 pagesJSA PlumberSyed Yousuf AliNo ratings yet

- Pole Unit Install JhaDocument2 pagesPole Unit Install JhafatimahNo ratings yet

- Job Safety Analysis (Jsa) : Pt. Niteksindo Multitech PerkasaDocument3 pagesJob Safety Analysis (Jsa) : Pt. Niteksindo Multitech PerkasalukiNo ratings yet

- JHA 15-Work at Height Using ScaffoldingDocument3 pagesJHA 15-Work at Height Using ScaffoldingWte SB100% (7)

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- FPS 008 - WeldingREV1Document3 pagesFPS 008 - WeldingREV1grantNo ratings yet

- Final Steam Blowing PermitF03Document4 pagesFinal Steam Blowing PermitF03Mostafa AbdullahNo ratings yet

- Fixing of Glass at Bridge JSA HSE ProfessionalsDocument1 pageFixing of Glass at Bridge JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Temporary Sheds JSA HSE ProfessionalsDocument1 pageTemporary Sheds JSA HSE ProfessionalsAli KaziNo ratings yet

- Shuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaDocument5 pagesShuttring, Deshuttering, Steel Fixing, P.C.C and R.C.C Work JsaAKBAR ALINo ratings yet

- Scffolding Erection and Dismanatel JsaDocument5 pagesScffolding Erection and Dismanatel Jsakhaja asifuddinNo ratings yet

- Fixing of glass at bridge JSA HSE ProfessionalsDocument1 pageFixing of glass at bridge JSA HSE Professionalsm.rehanhseNo ratings yet

- Welding Works JSA HSE ProfessionalsDocument1 pageWelding Works JSA HSE ProfessionalsAli Kazi100% (1)

- Erection of Tanks JSADocument4 pagesErection of Tanks JSASalah Abd EldayemNo ratings yet

- Ahu Unit Install JhaDocument3 pagesAhu Unit Install JhafatimahNo ratings yet

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- Job Safety Analysis New ReviseDocument12 pagesJob Safety Analysis New ReviseAnonymous YmINeSIFNo ratings yet

- Excavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)Document11 pagesExcavation (Company Name) : Safe Work Plan (SWP) /phase Hazard Analysis (Pha)PABITRA PANDANo ratings yet

- Hazard Identification PlanDocument11 pagesHazard Identification PlanjavithNo ratings yet

- Personal Protective Equipment (PPE) Policy: PPE Requirements Used in These SituationsDocument3 pagesPersonal Protective Equipment (PPE) Policy: PPE Requirements Used in These SituationsHelp Tubestar Crew100% (1)

- Welding Works JSA HSE ProfessionalsDocument1 pageWelding Works JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Marker Post Installation JSADocument10 pagesMarker Post Installation JSAShahid BhattiNo ratings yet

- Masonary Pitching Works JSA HSE ProfessionalsDocument2 pagesMasonary Pitching Works JSA HSE ProfessionalsSamadov 13No ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)midozotyNo ratings yet

- JSA For Welding of HVACDocument4 pagesJSA For Welding of HVACMohammed Minhaj100% (1)

- Shuttering For Beam - Slab JSA HSE ProfessionalsDocument1 pageShuttering For Beam - Slab JSA HSE ProfessionalsSamadov 13No ratings yet

- JSA for Drain Line ReplacementDocument5 pagesJSA for Drain Line ReplacementMadhan KannanNo ratings yet

- JSA 03-Rev.02 - BlindingDebliding under Nitrogen purgingDocument2 pagesJSA 03-Rev.02 - BlindingDebliding under Nitrogen purginggolusinghdataNo ratings yet

- CMPL and MVPL Vent-Line Connectivity JHADocument4 pagesCMPL and MVPL Vent-Line Connectivity JHASiddhant choudharyNo ratings yet

- nrcs144p2 042421Document3 pagesnrcs144p2 042421Mohd AleemNo ratings yet

- Annexure - B Safety SOP ChecklistDocument4 pagesAnnexure - B Safety SOP ChecklistANUJ SHAHNo ratings yet

- R.A FOR Condensate PitDocument5 pagesR.A FOR Condensate PitResearcherNo ratings yet

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Document4 pages0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- Fabrication Work Risk AssessmentDocument11 pagesFabrication Work Risk Assessmentstansilous100% (1)

- Jsa Water Proofing For DHADocument13 pagesJsa Water Proofing For DHAAnonymous YmINeSIFNo ratings yet

- Majeestech JSP for Scaffolding and Working at HeightDocument3 pagesMajeestech JSP for Scaffolding and Working at HeightkrishnakumarNo ratings yet

- Hirarc Unioil ProjectDocument3 pagesHirarc Unioil ProjectJason CuisonNo ratings yet

- Job Safety Analysis: Printed in USA Saf 55 (Front) Nov 95Document2 pagesJob Safety Analysis: Printed in USA Saf 55 (Front) Nov 95AdilMunirNo ratings yet

- Use of 110v Tools B 05Document1 pageUse of 110v Tools B 05cardyNo ratings yet

- Roofing Sheeting Cladding Works JSA HSE ProfessionalsDocument1 pageRoofing Sheeting Cladding Works JSA HSE ProfessionalsSamadov 13No ratings yet

- Job Safety Analysis: Printed in USA Saf 55 (Front) Nov 95Document2 pagesJob Safety Analysis: Printed in USA Saf 55 (Front) Nov 95AdilMunirNo ratings yet

- Job Safety Analysis: Radiography of Annular Plates 1 OF 2 July 07, 2009 0Document2 pagesJob Safety Analysis: Radiography of Annular Plates 1 OF 2 July 07, 2009 0AdilMunirNo ratings yet

- ASME VIII (Version 1)Document17 pagesASME VIII (Version 1)AdilMunirNo ratings yet

- Shifting and Loading Unloading of MaterialDocument4 pagesShifting and Loading Unloading of MaterialAdilMunirNo ratings yet

- Arc Welding Safe Work ProcedureDocument3 pagesArc Welding Safe Work ProcedureAdilMunirNo ratings yet

- BGAS Theory PaperDocument22 pagesBGAS Theory PaperAdilMunir100% (3)

- Welding Variables for Qualification of Base Metals and Filler MetalsDocument3 pagesWelding Variables for Qualification of Base Metals and Filler MetalsAdilMunirNo ratings yet

- Power PointDocument16 pagesPower PointAdilMunirNo ratings yet

- API 570 QBank3Document31 pagesAPI 570 QBank3Mohammad RizwanNo ratings yet

- Radiography Weld Defects GuideDocument50 pagesRadiography Weld Defects GuideAdilMunir100% (2)

- ASME B31.3 Process Piping ExamDocument2 pagesASME B31.3 Process Piping ExamMichael Albuquerque100% (1)

- WIS 10 Interp ExeDocument67 pagesWIS 10 Interp Exelembugs100% (1)

- API 571 For API 570 ExamDocument28 pagesAPI 571 For API 570 ExamAdilMunir100% (1)

- SMC Pneumatics PDFDocument507 pagesSMC Pneumatics PDFgigiuNo ratings yet

- Guided Wave Final ITECHDocument23 pagesGuided Wave Final ITECHAdilMunirNo ratings yet

- A2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFDocument53 pagesA2U8A2 - KBR Quality Plan For Phase Two Mechanical and Electrical Work PDFMOST PASONNo ratings yet

- Bench - Mark Ouiz: ASME B 31.3 Process PipingDocument4 pagesBench - Mark Ouiz: ASME B 31.3 Process PipingMichael AlbuquerqueNo ratings yet

- Radiography Weld Defects GuideDocument50 pagesRadiography Weld Defects GuideAdilMunir100% (2)

- Chandio PDFDocument3 pagesChandio PDFAdilMunirNo ratings yet

- Itp Piping PDFDocument4 pagesItp Piping PDFdashNo ratings yet

- Ammar Ahmad: Welding InspectorDocument4 pagesAmmar Ahmad: Welding InspectorAdilMunirNo ratings yet

- Floating Head Heat Exchanger Maintenance PDFDocument15 pagesFloating Head Heat Exchanger Maintenance PDFAdilMunirNo ratings yet

- Chemical Cleaning of Thermal Power StationsDocument8 pagesChemical Cleaning of Thermal Power StationsAdilMunirNo ratings yet

- ARAMCO-Welding Inspector DutiesDocument73 pagesARAMCO-Welding Inspector DutiesAdilMunir100% (4)

- Division 4 - MasonryDocument4 pagesDivision 4 - MasonryDiaszNo ratings yet

- List of JSA Documents for Construction ProjectDocument1 pageList of JSA Documents for Construction ProjectMARIA MANOJNo ratings yet

- FM Review Letter & Form 2688: Massachusetts Department of Transportation Highway DivisionDocument8 pagesFM Review Letter & Form 2688: Massachusetts Department of Transportation Highway DivisionVidyadhar BommeriNo ratings yet

- Ibuyan Joseph Me150-2 E02 Quiz3Document5 pagesIbuyan Joseph Me150-2 E02 Quiz3joseph ibuyan100% (1)

- Understanding BMD in RCC Beams (And Advantages of Continuous Beams)Document6 pagesUnderstanding BMD in RCC Beams (And Advantages of Continuous Beams)Niket Pai100% (1)

- The Drawing Board (September 2020)Document1 pageThe Drawing Board (September 2020)C HillNo ratings yet

- The Use of Slurry Walls in ConstructionDocument13 pagesThe Use of Slurry Walls in ConstructionMallela SrikanthNo ratings yet

- EPC Schedule 168 To 183Document108 pagesEPC Schedule 168 To 183Muani HmarNo ratings yet

- 1.1 Subject Information: Statical Calculation For Masonry Abutment DesignDocument10 pages1.1 Subject Information: Statical Calculation For Masonry Abutment DesignabadittadesseNo ratings yet

- Application of Interior Gypsum Plaster1 C842-05 (2021)Document9 pagesApplication of Interior Gypsum Plaster1 C842-05 (2021)Evan AzerNo ratings yet

- Liberty Mercian Limited Vs Cuddy Civil Engineering LimitedDocument51 pagesLiberty Mercian Limited Vs Cuddy Civil Engineering LimitedMuhammad ArslanNo ratings yet

- Fineness of Cement by Sieve AnalysisDocument2 pagesFineness of Cement by Sieve AnalysisAminul Haque50% (2)

- Surat KetidaksanggupanDocument3 pagesSurat KetidaksanggupanAzie Taufiq RahmanNo ratings yet

- Municipal Street Lighting Standards - City of PortlandDocument45 pagesMunicipal Street Lighting Standards - City of Portlandabdulbasit88No ratings yet

- 8491-Article Text-32930-1-10-20151225 PDFDocument7 pages8491-Article Text-32930-1-10-20151225 PDFChetali SinghNo ratings yet

- Barrel Coupling PDFDocument1 pageBarrel Coupling PDFRajendra PagarNo ratings yet

- TDS Nitoflor Hardtop Standard India2Document4 pagesTDS Nitoflor Hardtop Standard India2widi atmakaNo ratings yet

- Slab and load calculations for 3-story building under 40 charsDocument52 pagesSlab and load calculations for 3-story building under 40 charsJohn Paul Hilary Espejo100% (1)

- Building Workshop No. 1Document2 pagesBuilding Workshop No. 1JUN TING SEOWNo ratings yet

- 80 Egg Crate Return Grille CatalogDocument7 pages80 Egg Crate Return Grille CatalogekahNo ratings yet

- Nexans - Corflex-KDocument24 pagesNexans - Corflex-KReza AbadiNo ratings yet

- NAPA IS 143 BMD ResourceGuide PublicationDocument62 pagesNAPA IS 143 BMD ResourceGuide PublicationALBERTO ROCHERNo ratings yet

- Contract ManagementDocument184 pagesContract ManagementBikila M. Kejela100% (1)

- Use of Recyclable Materials in Sustainable Civil Engineering ApplicationsDocument77 pagesUse of Recyclable Materials in Sustainable Civil Engineering Applicationsmochammad baagilNo ratings yet

- School of Building and Civil Engineering: Cest-SbceDocument11 pagesSchool of Building and Civil Engineering: Cest-SbceVishwaleen RamNo ratings yet

- Top Level Cross Road Cross Road: Wearing Coat 65mm Thk. Deck Slab FRL Kerb FRL 2.5% 2.5% Center Line of RoadDocument1 pageTop Level Cross Road Cross Road: Wearing Coat 65mm Thk. Deck Slab FRL Kerb FRL 2.5% 2.5% Center Line of RoadPraveen CyssanNo ratings yet

- P-3138 - UL1007 - 24ga 7strd - TC - InduDocument1 pageP-3138 - UL1007 - 24ga 7strd - TC - InduTrần Long VũNo ratings yet

- A3c-Acs VS AcsrDocument1 pageA3c-Acs VS AcsrAlif Maulana FirdausNo ratings yet

- APEX STRUCTURE PVT - Presentation For Mumbai (7012021)Document18 pagesAPEX STRUCTURE PVT - Presentation For Mumbai (7012021)SHEKHAR DHOTENo ratings yet

- Corform BrochureDocument6 pagesCorform BrochureWJW_totalNo ratings yet