Professional Documents

Culture Documents

Dme Mid1 Question Paper

Uploaded by

PavaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dme Mid1 Question Paper

Uploaded by

PavaniCopyright:

Available Formats

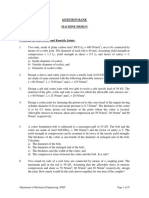

AVANTHI'S St.

THERESSA INSTITUTE OF ENGINEERING & TECHNOLOGY GARIVIDI

DEPARTMENT OF MECHANICAL

DIPLOMa MID-I SUBJECT : PD MARKS:40M

PART – A

Answer all the questions 4 X 5 = 20M

1. (a) Define Principal Stress

(b) Define Pitch of a thread

(c) Define Throat of a weld

(d) Define transverse pitch of riveted joint

2. State Rankine theory of elastic failure and its mathematical statement

3. Draw (i) ACME, (ii)Buttress and (iii) Square threads forms

4. Draw the double riveted, double strap zigzag butt joint

5. Write any three advantages and disadvantages of welded joints over other joints

PART – B

Instructions: Part B consists of 3 Units. Answer any one full question from each unit. Each question

carries 8 marks and may have sub questions.

6. The cylinder head is connected to cylinder flange by means of 16 bolts. The bore of the cylinder is 400mm. The

maximum pressure inside the cylinder is 1.25 N/mm2. The material of bolts is plain carbon steel having yield

strength in tension is 400 N/mm2 and factor of safety is 5. Find the size of bolts by considering the effect of

initial tightening and the stiffness factor as 0.6.

(OR)

Find the induced tensile stress in a boiler stay supporting an area 400 mm X 300 mm of the flat end surface. The

nominal diameter of the stay is 60 mm and the pressure inside the boiler is 1.2 MPa. Consider the effect of initial

tightening and the stiffness factor is 0.6.

7. Explain different ways of the failures in riveted joints.

(OR)

Two tie-bar plates of a bridge structure, 250 mm wide and 20 mm thick, are to be connected by a double-strap butt

joint. The rivets and the plates are made of steel. The permissible stresses in tension, shear and compression are 80,

60 and 120 N/mm2 respectively.

(i) Determine the diameter of the rivet by using the following empirical relationship, d = 6 √t

where t is the plate thickness and efficiency of the joint.

8. A plate, 75 mm wide and 10 mm thick, is joined with another steel plate by means of

single transverse and double parallel fillet welds, as shown in Fig. The joint is

Courseed to a maximum tensile force of 55 kN. The permissible tensile and shear

stresses in the weld material are 70 and 50 N/mm2 respectively. Determine the

required length of each parallel fillet weld.

(OR)

A steel plate, 100 mm wide and 10 mm thick, is joined with another steel plate by means of single transverse and double parallel

fillet welds, as shown in Fig. The strength of the welded joint should be equal to the strength of the plates to be joined. The

permissible tensile and shear stresses for the weld material and the plates are 70 and 50 N/mm2 respectively. Find the length of

each parallel fillet weld. Assume the tensile force acting on the plates

You might also like

- Question Bank MD IDocument15 pagesQuestion Bank MD IvsambardekarNo ratings yet

- Dme-22 6 15Document8 pagesDme-22 6 15VIGNESH L RNo ratings yet

- Simulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysysDocument7 pagesSimulation of Dehydration - Regeneration Plant For Natural Gas Processing Using Aspen HysyseduryuNo ratings yet

- Designing An AirshipDocument100 pagesDesigning An AirshipFrik van der Merwe100% (2)

- Toshiba X-Ray Tube Product InfoDocument10 pagesToshiba X-Ray Tube Product InfoJairo ManzanedaNo ratings yet

- Tender Status Report Delhi-Mumbai Expressway 10.01.19Document66 pagesTender Status Report Delhi-Mumbai Expressway 10.01.19chtrp100% (2)

- Question Bank Disign of MachineDocument11 pagesQuestion Bank Disign of Machinedipzbarma5No ratings yet

- Design of Machine Elements Exam QuestionsDocument8 pagesDesign of Machine Elements Exam Questionsslv_prasaadNo ratings yet

- Machine Design Question PaperDocument2 pagesMachine Design Question Papersushil.vgi100% (1)

- Snist Dom Previous PaperDocument9 pagesSnist Dom Previous PaperKapil Siddhant DevulapalliNo ratings yet

- Ashok Dmm1Document4 pagesAshok Dmm1Praveen KumarNo ratings yet

- Rr312404 Design of Machine ElementsDocument9 pagesRr312404 Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Question Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle JointsDocument25 pagesQuestion Bank Machine Design A: Numerical Problems: Problems On Pin, Cotter and Knuckle Jointsamol pogakeNo ratings yet

- NR-310305-Design of Machine ElementsDocument9 pagesNR-310305-Design of Machine ElementsSrinivasa Rao GNo ratings yet

- Design of Machine Elements IDocument8 pagesDesign of Machine Elements Imesab100No ratings yet

- 08 r05310305 Design of Machine Members IDocument9 pages08 r05310305 Design of Machine Members IKrupanandareddyYarragudiNo ratings yet

- Som I Iat Ques 2019Document3 pagesSom I Iat Ques 2019Siva RamanNo ratings yet

- PTU - B Tech - 2018 - 3rd Semester - Dec - 56004 SOLID MECHANICSDocument2 pagesPTU - B Tech - 2018 - 3rd Semester - Dec - 56004 SOLID MECHANICSSHAIK NASEER AHMED 160419736120No ratings yet

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Document10 pagesMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsNo ratings yet

- Lbs College of Engineering, KasaragodDocument2 pagesLbs College of Engineering, KasaragodJithesh VNo ratings yet

- TUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignDocument8 pagesTUK University Exams June 2016 Mechanical Engineering Technology Advanced Machine DesignCharles OndiekiNo ratings yet

- 3-1 DMM1 (Nov 2009 Regular)Document9 pages3-1 DMM1 (Nov 2009 Regular)micmechNo ratings yet

- MTP 5Document4 pagesMTP 5tinku singhNo ratings yet

- Dme Question BankDocument4 pagesDme Question BankRavi Patil100% (1)

- Som Assignments PDFDocument12 pagesSom Assignments PDFLaxmi HattiholiNo ratings yet

- DME AssignmentDocument2 pagesDME Assignmentchirag sanghaniNo ratings yet

- Mech Btech PapersDocument7 pagesMech Btech PapersThanatos XNo ratings yet

- DMM 1Document9 pagesDMM 1andhracollegesNo ratings yet

- ME201 Mechanics of Solids Model ExamDocument3 pagesME201 Mechanics of Solids Model ExamSijuKalladaNo ratings yet

- R7310305 Design of Machine Members - IDocument1 pageR7310305 Design of Machine Members - IsivabharathamurthyNo ratings yet

- Mechanics of Solids exam questionsDocument10 pagesMechanics of Solids exam questionsgalehNo ratings yet

- Answer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameDocument2 pagesAnswer Any Three Full Questions, Each Carries 10 Marks: Reg No.: - NameavinashNo ratings yet

- Design of machine elements exam questions and solutionsDocument3 pagesDesign of machine elements exam questions and solutionsvikaskumar1986No ratings yet

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IDocument9 pagesDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- 34412501-Design of MC ElementDocument8 pages34412501-Design of MC Elementsmg26thmayNo ratings yet

- QB Unit-1,2Document5 pagesQB Unit-1,2Agranshu BhardwajNo ratings yet

- ME 352 - All Problem Class - 14-18 BatchDocument125 pagesME 352 - All Problem Class - 14-18 BatchEntertainment GamingNo ratings yet

- Question Bank - DMEDocument6 pagesQuestion Bank - DMEBdhdhshNo ratings yet

- Rr310305 Design of Machine Members IDocument8 pagesRr310305 Design of Machine Members ISrinivasa Rao GNo ratings yet

- Finolex Academy Machine Design I Bolted, Riveted, Welded Joint AssignmentDocument4 pagesFinolex Academy Machine Design I Bolted, Riveted, Welded Joint AssignmentRitesh SinghNo ratings yet

- Machine Design I - ME501 - Sup 011Document2 pagesMachine Design I - ME501 - Sup 011Saurav JainNo ratings yet

- Mechanical PapersDocument23 pagesMechanical PapersSachin AgrawalNo ratings yet

- Scheme – E Sample Question PaperDocument4 pagesScheme – E Sample Question PaperBinyamin ChinikamwalaNo ratings yet

- DESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperDocument8 pagesDESIGN OF MACHINE MEMBERS - I Nov 2007 Question PaperelimelekNo ratings yet

- B.Tech Exam Design of Machine Members QuestionsDocument8 pagesB.Tech Exam Design of Machine Members Questionsprk74No ratings yet

- CE8301-Strength of Materials IDocument4 pagesCE8301-Strength of Materials Isyed1188No ratings yet

- Dme Home Assignment 2019-20Document4 pagesDme Home Assignment 2019-20VenkateshNo ratings yet

- Assignment No. 3 &4 B.Tech Mechanical Engineering Third YearDocument4 pagesAssignment No. 3 &4 B.Tech Mechanical Engineering Third Yearharish_kumar201301No ratings yet

- Winsem2015 16 Cp3870 Qz01qst Dme Tee QP ModelDocument3 pagesWinsem2015 16 Cp3870 Qz01qst Dme Tee QP ModelyashvantNo ratings yet

- Dome 6TH Sem. SP - 09Document7 pagesDome 6TH Sem. SP - 09neelesh singhNo ratings yet

- GTU BE Semester IV Machine Design & Industrial Drafting ExamDocument3 pagesGTU BE Semester IV Machine Design & Industrial Drafting ExamhukNo ratings yet

- Machine Elements Design ProblemsDocument3 pagesMachine Elements Design ProblemsHanan ShayiboNo ratings yet

- S. E. (Mechanical / Mechanical - SW / Automobile) 2012 CourseDocument3 pagesS. E. (Mechanical / Mechanical - SW / Automobile) 2012 CourseTejas AdakNo ratings yet

- Problems 4012 PDFDocument8 pagesProblems 4012 PDFjonthemesNo ratings yet

- 9A01302 Strength of Materials - IDocument8 pages9A01302 Strength of Materials - IsivabharathamurthyNo ratings yet

- Prestressed ConcreteDocument8 pagesPrestressed ConcreteYeswanth RaghavendraNo ratings yet

- Pre Stressed ConcreteDocument8 pagesPre Stressed Concretevamsi_rsNo ratings yet

- 07 r05310305 Design of Machine Members IDocument8 pages07 r05310305 Design of Machine Members IandhracollegesNo ratings yet

- Cyclic Plasticity of Engineering Materials: Experiments and ModelsFrom EverandCyclic Plasticity of Engineering Materials: Experiments and ModelsNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- CATIA Lab ManualDocument79 pagesCATIA Lab ManualPavaniNo ratings yet

- B.tech Mech IV-II Time Table r19Document5 pagesB.tech Mech IV-II Time Table r19PavaniNo ratings yet

- Unit 1Document24 pagesUnit 1PavaniNo ratings yet

- FES Lab Experiment NumberDocument2 pagesFES Lab Experiment NumberPavaniNo ratings yet

- ManuscriptDocument3 pagesManuscriptPavaniNo ratings yet

- DMM - 2 R16 - Unit-2Document32 pagesDMM - 2 R16 - Unit-2PavaniNo ratings yet

- Unit - 1Document59 pagesUnit - 1PavaniNo ratings yet

- 286 293, Tesma409, IJEASTDocument8 pages286 293, Tesma409, IJEASTPavaniNo ratings yet

- DMM - 2 R16 - Unit-3Document16 pagesDMM - 2 R16 - Unit-3PavaniNo ratings yet

- Structural and Thermal Analysis of Disc Brake Using Solidworks and AnsysDocument11 pagesStructural and Thermal Analysis of Disc Brake Using Solidworks and AnsysIAEME PublicationNo ratings yet

- DMM - 2 R19 - UNIT-4 (Ref-2)Document39 pagesDMM - 2 R19 - UNIT-4 (Ref-2)PavaniNo ratings yet

- DMM - 2 R16 - Unit-6Document22 pagesDMM - 2 R16 - Unit-6PavaniNo ratings yet

- CamScanner App Scans Documents EasilyDocument2 pagesCamScanner App Scans Documents EasilyPavaniNo ratings yet

- 3d Printed Prosthetic HandDocument70 pages3d Printed Prosthetic HandDavid CorpadeanNo ratings yet

- JNTUK ME SyllabusDocument9 pagesJNTUK ME Syllabusg rajuNo ratings yet

- Mech Engg 3-1 CS & Syllabus - UG - R20Document102 pagesMech Engg 3-1 CS & Syllabus - UG - R20PavaniNo ratings yet

- St.Theressa AM Mid-Exam QuestionsDocument2 pagesSt.Theressa AM Mid-Exam QuestionsPavaniNo ratings yet

- Casting and Welding GuideDocument27 pagesCasting and Welding GuidePavaniNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument21 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For Scientistsmohmmad mahmoodNo ratings yet

- 3D PrintingDocument14 pages3D PrintingDorian VujnovićNo ratings yet

- c20 Dme Printby Sbtet 27092021Document465 pagesc20 Dme Printby Sbtet 27092021PavaniNo ratings yet

- Design and Fabrication of 3-Axes Mini CNC Milling MachineDocument15 pagesDesign and Fabrication of 3-Axes Mini CNC Milling MachinePavaniNo ratings yet

- (Original For Recipient) : Sl. No Description Unit Price Discount Qty Net Amount Tax Rate Tax Type Tax Amount Total AmountDocument1 page(Original For Recipient) : Sl. No Description Unit Price Discount Qty Net Amount Tax Rate Tax Type Tax Amount Total AmountPavaniNo ratings yet

- Design, Development and Construction of A Fuel Cell Vehicle-Hercules ProjectDocument14 pagesDesign, Development and Construction of A Fuel Cell Vehicle-Hercules ProjectPavaniNo ratings yet

- Tax Invoice for 3D Printer StickerDocument1 pageTax Invoice for 3D Printer StickerPavaniNo ratings yet

- EV Single Page Brochure1Document29 pagesEV Single Page Brochure1PavaniNo ratings yet

- Modeling and Simulation of Mechatronic Systems Using SimscapeDocument42 pagesModeling and Simulation of Mechatronic Systems Using SimscapePavaniNo ratings yet

- MATERIAL TESTING and Matallographic LAB MANUALDocument37 pagesMATERIAL TESTING and Matallographic LAB MANUALPavaniNo ratings yet

- Basic Simulation Laboratory Manual B.Tech (Ii Year - I Sem) (2021-22)Document56 pagesBasic Simulation Laboratory Manual B.Tech (Ii Year - I Sem) (2021-22)PavaniNo ratings yet

- Excerpt: "Railroaded" by Richard WhiteDocument38 pagesExcerpt: "Railroaded" by Richard Whitewamu885No ratings yet

- Chetan Tour and Travel: Pickup Spot: Destination SpotDocument2 pagesChetan Tour and Travel: Pickup Spot: Destination SpotRahulNo ratings yet

- Macalintal v. PETDocument5 pagesMacalintal v. PETJazem AnsamaNo ratings yet

- Uti MF v. Ito 345 Itr 71 - (2012) 019taxmann - Com00250 (Bom)Document8 pagesUti MF v. Ito 345 Itr 71 - (2012) 019taxmann - Com00250 (Bom)bharath289No ratings yet

- Bangladesh Premier League 2024 Schedule, Live Scores and ResultsDocument5 pagesBangladesh Premier League 2024 Schedule, Live Scores and Resultsmoslahuddin2022No ratings yet

- Pengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriDocument15 pagesPengembangan Lembar Kegiatan Siswa Berbasis Online Berbantuan Geogebra Book Untuk Siswa SMA Kelas X Pada Materi TrigonometriNovita Rizki YustianiNo ratings yet

- The Influence of Culture Subculture On Consumer BehaviorDocument55 pagesThe Influence of Culture Subculture On Consumer Behaviorvijendra chanda100% (12)

- Design of Grounding System For GIS Indoor SubstationDocument4 pagesDesign of Grounding System For GIS Indoor Substationzerferuz67% (3)

- Slimline F96T12 DX Alto: Product Family Description T12 Single Pin Linear Fluorescent LampsDocument2 pagesSlimline F96T12 DX Alto: Product Family Description T12 Single Pin Linear Fluorescent LampsJon GosnellNo ratings yet

- MObile InvoiceDocument1 pageMObile Invoicechandra kiran KodavatiNo ratings yet

- Fazaia College of Education For WomenDocument10 pagesFazaia College of Education For WomenZahra TahirNo ratings yet

- 2003 June Calc Paper 6 (H)Document20 pages2003 June Calc Paper 6 (H)abbasfazilNo ratings yet

- TU20Document6 pagesTU20Manikumar KNo ratings yet

- Global Service Learning: M325D MH / M325D L MH Material HandlersDocument52 pagesGlobal Service Learning: M325D MH / M325D L MH Material Handlersanon_828943220100% (2)

- Affidavit Defends Wife's InnocenceDocument6 pagesAffidavit Defends Wife's InnocenceGreggy LawNo ratings yet

- Document 10Document5 pagesDocument 10Filza FatimaNo ratings yet

- Welcome To All: Fundamental Analysis Economic AnalysisDocument11 pagesWelcome To All: Fundamental Analysis Economic AnalysisMD.RUMON BAKSHINo ratings yet

- Indexed Addressing & Flow Rate AveragingDocument5 pagesIndexed Addressing & Flow Rate AveragingMestrecal MeloNo ratings yet

- IsotopesDocument35 pagesIsotopesAddisu Amare Zena 18BML0104No ratings yet

- Baja2018 Unisa Team3 Design ReportDocument23 pagesBaja2018 Unisa Team3 Design ReportDaniel MabengoNo ratings yet

- Dhi-Ehs-Hsm-028 Work Over Water Rev0Document5 pagesDhi-Ehs-Hsm-028 Work Over Water Rev0Phạm Đình NghĩaNo ratings yet

- Aproximaciones Al Concepto de Grupos y Tipos de GruposDocument16 pagesAproximaciones Al Concepto de Grupos y Tipos de GruposM. CNo ratings yet

- Kami Export - Exercise Lab - Mini-2Document3 pagesKami Export - Exercise Lab - Mini-2Ryan FungNo ratings yet

- Gek 106852aDocument10 pagesGek 106852awednetoxNo ratings yet