Professional Documents

Culture Documents

TIE2208200005 Engineering Design Applications II

Uploaded by

Patrick NdlovuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TIE2208200005 Engineering Design Applications II

Uploaded by

Patrick NdlovuCopyright:

Available Formats

1

NATIONAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

FACULTY OF INDUSTRIAL TECHNOLOGY

DEPARTMENT OF INDUSTRIAL ENGINEERING

PART III – ENGINEERING DESIGN APPLICATIONS – TIE 2208

SECOND SEMESTER EXAMINATION – APRIL/MAY 2000

Time Allowed: 3 Hours

Answer ALL Questions

Qu. 1 Design a belt drive to transmit 150kW for a system consisting of two pulleys

of diameters 90cm and 120 cm, center distance of 360 cm, a belt speed 20

m/sec, coefficient of friction 0.3, a slip of 1.2% at each pulley and 5% friction

loss at each shaft, 20% over load. Assume leather belt with density of

1gm/cm2. [25]

Qu. 2 A steel solid shaft transmitting 20kW at 200 rpm is supported on two bearings

750 mm apart and has two gears keyed to it. The pinion having 30 teeth of

5mm module is located 100 mm to the left of the right hand bearing and

delivers power horizontally to the right. The gear having 100 teeth of 5mm

module is located 150 mm to the right of the left-hand bearing and receives

power in a vertical direction from below. Using an allowable stress of 540MPa

in shear, determine the diameter of the shaft. [25]

Qu. 3 A mild steel shaft transmits 23 kW at 200 rpm. It carries a central load of

900N and is simply supported between the bearings 2.5 metres apart.

Determine the size of the shaft, if the allowable shear stress is 42 N/mm2 and

the maximum tensile or compressive stress is not to exceed 56 N/mm2. What

size of the shaft will be required if it is subjected to gradually applied loads?

[25]

Qu. 4 A pair of straight teeth spur gears is to transmit 20kW when the pinion

rotates at 300 rpm. The velocity ratio is 1:3. The allowable static stresses for

the pinion and gear materials are 120 and 100 N/mm2 respectively. The

pinion has 15 teeth and its face width is 14 times the module. Determine:

Module, face width and pitch circle diameters of both the pinion and the gear

from the stand point of strength only, taking into consideration the effect of

the dynamic loading. The tooth form factor can be taken as:

0.912

Y = 0.154 −

No. of teeth

and the velocity factor Cv as

3

Cv =

3+V

where v is expressed in m/s. [25]

You might also like

- Assignment 2Document1 pageAssignment 2pethuraNo ratings yet

- Design spur gears transmit powerDocument3 pagesDesign spur gears transmit powerMohammed YunusNo ratings yet

- Integrated Mechanical Design Questions For Practice 2003Document4 pagesIntegrated Mechanical Design Questions For Practice 2003Mohammedraffic Noor MohamedNo ratings yet

- Design of Transmission Systems Question BankDocument10 pagesDesign of Transmission Systems Question BankDesejo SozinandoNo ratings yet

- Register Number NIT Mechanical Design Machine Elements ExamDocument2 pagesRegister Number NIT Mechanical Design Machine Elements ExamdharaniventhanNo ratings yet

- Dme Imp QuestionsDocument9 pagesDme Imp QuestionsCAD With RaoNo ratings yet

- Mechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Document4 pagesMechanical Engineering Department Tutorial Sheet Machine Design-I, M-503Harpinder GotraaNo ratings yet

- Design of Transmission System Question BankDocument18 pagesDesign of Transmission System Question BankAravind50% (2)

- Machine Design Answer KeyDocument16 pagesMachine Design Answer KeyK.KESAVARAJ HICET STAFF MCTSNo ratings yet

- SSM Institute Design of Transmission System TutorialDocument1 pageSSM Institute Design of Transmission System TutorialRama SamyNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsGowtham RajNo ratings yet

- Possible Exercise On Machine Element Two Flat BeltDocument4 pagesPossible Exercise On Machine Element Two Flat BeltAbebaw AyeleNo ratings yet

- Me3601 As01Document2 pagesMe3601 As01Arjun RanaNo ratings yet

- Me-1352 Design of Transmission SystemDocument7 pagesMe-1352 Design of Transmission Systemshujai cruise100% (1)

- MGM College of Engineering Assignment on Machine Design ProblemsDocument1 pageMGM College of Engineering Assignment on Machine Design ProblemsmrinalsinghrawatNo ratings yet

- MD ConventionalDocument8 pagesMD ConventionalBipin KumarNo ratings yet

- Anna University ME2303 Design of Machine Elements Exam QuestionsDocument3 pagesAnna University ME2303 Design of Machine Elements Exam QuestionssathurvedhaNo ratings yet

- 3.1.belt and Belt DrivesDocument17 pages3.1.belt and Belt DrivesVignesh ShenoyNo ratings yet

- Dme-II Question BankDocument4 pagesDme-II Question BankenggsantuNo ratings yet

- DTS Question BankDocument21 pagesDTS Question BankSam TirshathNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine Elementsdsathiya0% (1)

- PART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESDocument12 pagesPART-B QUESTIONS STEADY STRESSES AND VARIABLE STRESSESMadhu MithaNo ratings yet

- DMM Question BankDocument2 pagesDMM Question Bankzubair ahmedNo ratings yet

- Imp Qoestions MDDocument3 pagesImp Qoestions MDvenuedNo ratings yet

- Design of Machine ElementsDocument10 pagesDesign of Machine ElementsMahalingam NanjappanNo ratings yet

- Tutorial Sheet Unit V 3Document3 pagesTutorial Sheet Unit V 3rakesh507No ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Design and Selection of Belt, Rope and Chain DrivesDocument7 pagesDesign and Selection of Belt, Rope and Chain DrivesenggsantuNo ratings yet

- Assignment On Shaft DesignDocument2 pagesAssignment On Shaft DesignRitesh SinghNo ratings yet

- D MDocument9 pagesD MMuthu KumarNo ratings yet

- Machine Design Tutorial Sheet QuestionsDocument3 pagesMachine Design Tutorial Sheet Questionsabhishek chaurasiyaNo ratings yet

- Me2303 - Design of Machine ElementsDocument14 pagesMe2303 - Design of Machine ElementsThulasi RamNo ratings yet

- 13 ME AssignmentDocument2 pages13 ME AssignmentMuhammad Sharif JamaliNo ratings yet

- Strength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyDocument3 pagesStrength of Materials Unit 3 Question Bank: Jansons Institute of TechnologyVasanth KumarNo ratings yet

- Design ProblemsDocument13 pagesDesign ProblemsAristotle RiveraNo ratings yet

- Design ExercisesDocument13 pagesDesign ExercisesBookieeNo ratings yet

- Reg. No. IV SEMESTER B.TECH. (MECHATRONICS ENGINEERING) END SEMESTER EXAMINATIONS, JUNE 2018 DESIGN OF MACHINE LEMENTS MTE 2202Document3 pagesReg. No. IV SEMESTER B.TECH. (MECHATRONICS ENGINEERING) END SEMESTER EXAMINATIONS, JUNE 2018 DESIGN OF MACHINE LEMENTS MTE 2202MeghaNo ratings yet

- 12ME5DCDM2Document3 pages12ME5DCDM2Abhyudaya SinghNo ratings yet

- Belt Drive Assignment Problems SolvedDocument2 pagesBelt Drive Assignment Problems SolvedNevil ModiNo ratings yet

- Me8593 Iq R17Document4 pagesMe8593 Iq R17Vaideesh LJNo ratings yet

- Machine Designe - IIDocument2 pagesMachine Designe - IIAndrea DouglasNo ratings yet

- Assignment 3Document2 pagesAssignment 3vishalNo ratings yet

- ASSIGNDocument1 pageASSIGNksahilkNo ratings yet

- DME QB All UnitsDocument11 pagesDME QB All UnitsPrakash ThangavelNo ratings yet

- 12 Me 5dcdm2Document3 pages12 Me 5dcdm2Abhyudaya SinghNo ratings yet

- Design of Transmission Systems Question BankDocument26 pagesDesign of Transmission Systems Question BankJennifer WilsonNo ratings yet

- TutorialDocument1 pageTutorialAtul GaurNo ratings yet

- Assignment - IIDocument3 pagesAssignment - IIRamaswamy SubbiahNo ratings yet

- DMM 1 Assignment Questions FinalDocument2 pagesDMM 1 Assignment Questions FinalSrimanthula SrikanthNo ratings yet

- ME-311 Belt 2018Document2 pagesME-311 Belt 2018VishnuNo ratings yet

- Design of Transmission Systems-Question BankDocument28 pagesDesign of Transmission Systems-Question BankAlfred Franklin V100% (1)

- Assignmnt TOS QnsDocument2 pagesAssignmnt TOS QnsNANDINI S DEV 200571No ratings yet

- gupta PG - No:176) Exercise 9Document3 pagesgupta PG - No:176) Exercise 9mahendra babu mekalaNo ratings yet

- PVP Siddhartha Mech Engineering III Sem HomeworkDocument2 pagesPVP Siddhartha Mech Engineering III Sem HomeworkNarayanarao PalagaraNo ratings yet

- Design of Curved Beams and SpringsDocument11 pagesDesign of Curved Beams and SpringsAnonymous utfuIcnNo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Small Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsFrom EverandSmall Dynamos and How to Make Them - Practical Instruction on Building a Variety of Machines Including Electric MotorsNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- O level Physics Questions And Answer Practice Papers 2From EverandO level Physics Questions And Answer Practice Papers 2Rating: 5 out of 5 stars5/5 (1)

- Design of SpringsDocument32 pagesDesign of SpringsPatrick NdlovuNo ratings yet

- Chain drive transmits 15 kW powerDocument19 pagesChain drive transmits 15 kW powerPatrick NdlovuNo ratings yet

- NUEST Bachelor Engineering Design Applications ExamDocument4 pagesNUEST Bachelor Engineering Design Applications ExamPatrick NdlovuNo ratings yet

- Part 2 Design AssignmentsDocument3 pagesPart 2 Design AssignmentsPatrick NdlovuNo ratings yet

- When To Challenge Petrographic Reports - tcm45-347346Document4 pagesWhen To Challenge Petrographic Reports - tcm45-347346Dan TranNo ratings yet

- Dodge Sleevoil Series)Document17 pagesDodge Sleevoil Series)spadafora77No ratings yet

- Naval Base Kitsap Location For UAS/NTAT RegulationsDocument5 pagesNaval Base Kitsap Location For UAS/NTAT RegulationsKING 5 NewsNo ratings yet

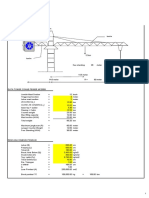

- Dokumen - Tips - Perhitungan Pondasi TCDocument7 pagesDokumen - Tips - Perhitungan Pondasi TCAlex MartiknoNo ratings yet

- Metallurgical Changes in Steels by Cryogenic ProcessingDocument16 pagesMetallurgical Changes in Steels by Cryogenic ProcessingAjit BeheraNo ratings yet

- FM200 SpecificationDocument13 pagesFM200 Specificationsechoo100% (2)

- ANSI Pad Mounted (Draft)Document8 pagesANSI Pad Mounted (Draft)Samer Abdulaziz SadaqaNo ratings yet

- Non Conventional System of ConstructionDocument4 pagesNon Conventional System of ConstructionPeach CreamNo ratings yet

- SikaCor VEMYDocument5 pagesSikaCor VEMYboyzesNo ratings yet

- Z Blokrefractoryfibremodulesenglish New PDFDocument2 pagesZ Blokrefractoryfibremodulesenglish New PDFOswaldo GuerraNo ratings yet

- Construction Industry KPI Report FINAL PDFDocument78 pagesConstruction Industry KPI Report FINAL PDFAbdulrahmanNo ratings yet

- Don Tomas Bautista Mapua: First Registered Filipino ArchitectDocument2 pagesDon Tomas Bautista Mapua: First Registered Filipino ArchitectEXTRA VIDEOSNo ratings yet

- 6 Virat e Khalsa PDFDocument28 pages6 Virat e Khalsa PDFesamridhNo ratings yet

- 2018 Waste Water Collection Systems - EugeneDocument51 pages2018 Waste Water Collection Systems - EugeneKwaku frimpongNo ratings yet

- CES Tutorial 3 Derivation of Performance Indices (Feb 2014)Document3 pagesCES Tutorial 3 Derivation of Performance Indices (Feb 2014)Zamri NasirNo ratings yet

- Poor Quality Cost in Construction Literature ReviewDocument77 pagesPoor Quality Cost in Construction Literature Reviewmatrixworld20100% (1)

- Test Certificate: CM/L-NO:5200036277Document10 pagesTest Certificate: CM/L-NO:5200036277TARUNKUMARNo ratings yet

- Research ProposalDocument6 pagesResearch ProposalAbdalla Mohamed Abdalla100% (3)

- 05thjan Assignment Abroad TimesDocument8 pages05thjan Assignment Abroad TimesSameer ShaikNo ratings yet

- SGP Stress Analysis ReportDocument14 pagesSGP Stress Analysis ReportDenstar Ricardo Silalahi100% (2)

- Zoned Earth Fill DamDocument8 pagesZoned Earth Fill DamRahul KolateNo ratings yet

- Utilization of Plastic Waste For MakingDocument4 pagesUtilization of Plastic Waste For MakingObaNo ratings yet

- Rubber Isolator 1921Document10 pagesRubber Isolator 1921Mario Daniel MLNo ratings yet

- The S-Curve For Forecasting Waste Generation in Construction Projects Lu, Peng, Chen, Skitmore, ZhangDocument12 pagesThe S-Curve For Forecasting Waste Generation in Construction Projects Lu, Peng, Chen, Skitmore, ZhangisenefretNo ratings yet

- Daylight Design RulesDocument9 pagesDaylight Design Rulesmehak guptaNo ratings yet

- AC inspection checklist titleDocument1 pageAC inspection checklist titlezahid_497No ratings yet

- STEM1-06 FinalPaperDocument21 pagesSTEM1-06 FinalPaperReuben Wei PalmaresNo ratings yet

- X Ride Part Catalogue PDFDocument46 pagesX Ride Part Catalogue PDFMahful Irvay MukhlisNo ratings yet

- Study and Analysis of Failure Analysis of Wire RopeDocument6 pagesStudy and Analysis of Failure Analysis of Wire RopeInternational Journal of Technology and Emerging Sciences (IJTES)No ratings yet