Professional Documents

Culture Documents

Experimental study on properties of concrete with bottle cap fibers

Uploaded by

Sajjad AhmadOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experimental study on properties of concrete with bottle cap fibers

Uploaded by

Sajjad AhmadCopyright:

Available Formats

IJETST- Volume||01||Issue||08||Pages 1335-1341||October||ISSN 2348-9480 2014

International Journal of Emerging Trends in Science and Technology

Experimental Study on the Hardened Properties of Concrete by Using

Soft Drink Bottle Caps as Partial Replacement for Coarse Aggregates

Authors

Darshan N1, Rajani V Akki 2, Sharath B P3

1

M.Tech in Construction Technology, Department of Civil Engineering, Karavali Institute of

Technology, Mangalore, Karnataka, India

Email: narayana.darshan89@gmail.com

2

M.Tech in Construction Technology, Department of Civil Engineering, Karavali Institute of

Technology, Mangalore, Karnataka, India

Email: rajni.akki@gmail.com

3

B.Tech in Civil Engineering, Department of Civil Engineering, NMAM Institute of Technology,

Udupi, Karnataka, India

Email: sharathbp21@gmail.com

ABSTRACT

Cement concrete is the most extensively used construction material in the world because of its great

workability and can be moulded to any shape. Ordinary cement concrete possesses a very low tensile

strength, limited ductility and little resistance to cracking because of the presence of internal micro

cracks, which leads to failure of the concrete. In this modern age, civil engineering constructions have

their own structural and durability requirements, depending upon its purpose and for this, modification

in traditional cement concrete is must. Addition of different types of fibers to concrete in specific

percentage improves the mechanical properties, durability and serviceability of the structure. It is learnt

that Steel Fiber Reinforced Concrete (SFRC) has its superior resistance to cracking and crack

propagation. Hence an attempt is made to study the influence of cut bottle caps as a steel fiber concrete

as partial replacement for coarse aggregates and studying the parameters like compressive strength,

split-tensile and flexural strength of conventional and steel fiber reinforced concrete Therefore it can be

seen that compressive, split-tensile and flexural strength of fiber reinforced concrete has been increased

as compared to conventional concrete by replacing coarse aggregates with bottle caps.

Key Words: Bottle Caps, Steel fibers, fiber reinforced concrete, compressive, split-tensile and flexural

strength.

1. INTRODUCTION Concrete is weak in tension and has a brittle

Initially, fibers are used to prevent and control character. The concept of using fibers to

plastic and drying shrinkage in the concrete. improve the characteristics of construction

After the research and improvement, it has been materials is very old. Alternatively, introduction

understood that the addition of fiber materials in of fibers in discrete form in plain or reinforced

the concrete can also improve the other concrete concrete may provide a better solution [1]. Fiber

properties such as flexural toughness, flexural reinforcement is now considered as the most

strength fatigue resistance, impact resistance, effective way of improving the resistance of

and post-crack strength. concrete to cracking. During the last two

Darshan N1, Rajani V Akki 2, Sharath B P3 www.ijetst.in Page 1335

IJETST- Volume||01||Issue||08||Pages 1335-1341||October||ISSN 2348-9480 2014

decades, numerous fiber types made from many 2.4 Fiber material:

different materials (steel, polypropylene, nylon, Bottle caps of soft drink bottles were collected

carbon, etc.) have been developed and and cut into small pieces. They are similar to the

successfully used to reinforce concrete. While steel fibres but they don’t have any regular

the primary purpose of fiber reinforcement has shape and size. The dimension varies with

so far been to improve the toughness and energy nature of sources and upon the type of

absorption of concrete, it is becoming apparent industries. Scraps considered in this work are

that the real benefit of fiber reinforcement may 0.5 mm thick, 3 mm approximate width which

in fact be in improving the physical and are added to the concrete as steel fibers as

durability properties of concrete. [2] shown in figure 1.

Experimental studies proved that fibers improve

the mechanical properties of concrete such as

flexural strength, compressive strength, tensile

strength, creep behavior, impact resistance and

toughness [3]

2. MATERIALS

2.1 Cement:

Ordinary Portland cement of Grade 43 [Birla

gold] conforming to IS: 8112-1989 was adopted

in this work [4], The properties of the same are

given in Table 1.

2.2 Coarse aggregates:

The aggregates used in this project are mainly of

basalt rock which comes under normal weight

category. The aggregates are locally available.

50% of the aggregate used are of 10-12mm size

and remaining 50% are of 20mm size. The

impact value and crushing value is 7.49% and

24.40% respectively. Specific gravity is 2.67,

Figure 1: Sources of bottle caps and sample of

and fineness modulus is 7.2 and all are under

fiber

limits and were tested in accordance to Indian

Standard specifications IS: 383-1970 [5].

3. Methodology

2.3 Fine Aggregates:

3.1 Concrete Mix Design

Clean River sand is used as fine aggregate. The

In the present study, M20 grade with nominal

specific gravity and fineness modulus were

mix as per IS 10262-2009 is used as per [6]. The

found to be 2.63 and 2.64 respectively. Sieve

concrete mix proportion (cement: fine

analysis was done to find out fineness modulus

aggregate: coarse aggregate) is 1: 1.5: 3 by

which is obtained as 3.14% which is under

volume and a water cement ratio of 0.5.

limits as per IS 383-1970. The properties are

tested as per [5]

Darshan N1, Rajani V Akki 2, Sharath B P3 www.ijetst.in Page 1336

IJETST- Volume||01||Issue||08||Pages 1335-1341||October||ISSN 2348-9480 2014

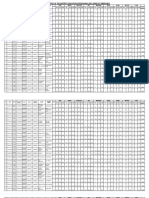

3.2 Experimental programs Table 2: Details of specimen

Totally 45 cubes, 45 cylinders and 45 beams

were casted. Metal caps were partially replaced

with coarse aggregates in concrete in 5 different S.No Specimen Name of No. of

percentages starting from 0%, and increasing the Details speciman Specimen

mixing of metal caps up to 4%, at an interval of

Normal

1.0%. For each percent of metal cap fiber

1 Concrete (N N1 3

addition, 3 cubes, 3 cylinders and 3 beams were

casted. Final strength of cubes, cylinders and C) + 0% fiber

beams were tested after 7, 28 and 45 days of

N C + 1% of

curing. Compression testing machine was used 2 N2 3

Fiber

for testing the compressive strength of cubes

[150 X 150 X 150] mm, split tensile strength of N C + 2% of

cylinders [Ø 150 mm, height 300 mm] and 3 N3 3

Fiber

flexural strength test on beams of size [100X

100 X 100 mm] by Universal Testing Machine. N C + 3% of

4 N4 3

Specimen details are given in table 2. [7, 8, 9, Fiber

10]

N C + 4% of

5 N5 3

Fiber

Table 1: Cement test results

Experimental As per IS

S. No Characters

Value 8112:1989 Table 3: Test Results of 7, 28 and 45 - Days

compressive Strength of Concrete

Consistency

1 31.0% -

of Cement

Average strength at 7, 28

Specific % of and 45 days in (N/mm2)

2 3.13 3.15 Name of bottle

Gravity 7-day 28-day 45-day

Specimen caps

Initial used strength strength strength

3 Setting 36min >30min (MPa) (MPa) (MPa)

Time 21.81 2.22 27.54

N1 0

Final 24.52 27.51 30.83

N2 1

4 Setting 472min <600min

Time N3 2 27.74 32.91 33.18

Fineness of N4 3 25.42 31.32 31.57

5 9% 10%

Cement

N5 4 22.54 32.79 31.95

Darshan N1, Rajani V Akki 2, Sharath B P3 www.ijetst.in Page 1337

IJETST- Volume||01||Issue||08||Pages 1335-1341||October||ISSN 2348-9480 2014

0% 1% 2% 3% 4%

0% 1% 2% 3% 4% 6

35

Split Tensile Strength (N/mm2)

Compressive Strength (MPa)

30 5

25

4

20

15 3

10

2

5

1

0

7 days 28days 45days

Age 0

7 days 28days 45days

Age

Graph 1: Compressive strength of SFRC at

different addition levels for 7, 28 and 45-days

The Graph 1 indicates that the compressive Graph 2: Split-tensile strength at different

strength of 45-days is more than that of 28-days. additions levels for 7, 28 and 45-days

The optimum strength gained is at 2%

replacement of coarse aggregates by bottle caps The Graph 2 indicates that the compressive

as fibers to concrete and lowest strength at 0% strength of 45-days is more than that of 28-days.

replacement for all 7, 28 and 45 days period of The optimum strength gained after 28 and 45-

curing. days curing period is at 2% addition and the

lowest strength at 0% addition of bottle caps as

Table 4: Split Tensile strength at 7, 28 and 45- fiber to concrete.

days for various additions of bottle caps

% of 45-day

7-day 28-day

Bottle strength

strength strength

Caps (MPa)

(MPa) (MPa)

Used

0% 2.43 2.83 2.90

1% 3.30 3.35 3.35

2% 3.75 4.80 4.91

3% 3.43 4.31 4.29

4% 2.77 3.50 3.56

Figure 2: Typical compressive failure pattern of

concrete Cubes

Darshan N1, Rajani V Akki 2, Sharath B P3 www.ijetst.in Page 1338

IJETST- Volume||01||Issue||08||Pages 1335-1341||October||ISSN 2348-9480 2014

Table 5: Flexural strength at 7, 28 and 45-days optimum strength gained after both 28 and 45-

for various additions of bottle caps days curing period is at 2% addition and the

% of lowest strength at 0% addition of bottle caps as

7-day 28-day fiber to concrete.

Bottle 45-day

strength strength

Caps strength

(MPa) (MPa)

Used (MPa)

0% 2.33 3.42 3.43

1% 2.55 3.91 3.93

2% 3.08 4.52 4.54

3% 2.82 4.24 4.2

4% 2.65 3.85 3.88

5 0

%

4.5

4 1

Flexural Strength (N/mm2)

3.5 %

3 Figure 3: Typical Tensile Failure pattern of

2 concrete Cubes

2.5 %

2

1.5 3

%

1

0.5

4

0 %

7 days 28days 45days

Age

Graph 3: Flexural strength at different additions

levels for 7, 28 and 45-days

Figure 4: Typical Flexure Failure pattern of

The Graph 3 indicates that the flexural strength

concrete Cubes

of 45-days is more than that of 28-days. The

Darshan N1, Rajani V Akki 2, Sharath B P3 www.ijetst.in Page 1339

IJETST- Volume||01||Issue||08||Pages 1335-1341||October||ISSN 2348-9480 2014

5. Results and Discussion concrete is more as compared to its

compressive strength.

It can be observed from the Graphs 1, 2, The results indicated that the

4 that, the compression, split tensile and compressive, split-tensile and flexural

flexural strength of concrete can be strength of fiber reinforced concrete has

increased by increasing the percentage of been increased when compared to the

fibres added to it. The above graph conventional concrete at 2% addition of

indicates that the compressive strength of steel fiber reinforced concrete (SFRC).

45-days is more than that of 28-days.

Since, bottle caps of soft drinks are

The optimum strength gained is at 2%

easily available, they can be easily

replacement of coarse aggregate by

collected and cut into fibers and the

bottle caps as fiber to concrete and

compressive strength can be increased to

lowest strength at 0% replacement for all

it some extent.

7, 28 and 45 days period of curing.

The Graph 2 indicates that the

References

compressive strength of 45-days is more 1. Ramada, J.P. and Batson, G.B., ‘The

than that of 28-days. fiber Mechanics of Crack Arrest in Concrete’,

The Graph 3 indicates that the flexural Journal of the Engineering Mechanics

strength of 45-days is more than that of Division, ASCE, 89:147-168 (June,

28-days. The optimum strength gained 1983).

after both 28 and 45-days curing period 2. N. Banthia ‘Durability enhancements in

is at 2% addition and the lowest strength concrete with fiber reinforcement’. The

at 0% addition of bottle caps as fiber to University of British Columbia,

concrete. Vancouver, Canada

3. Mukesh Shukla (2011). ‘Behaviour of

6. Conclusion Reinforced Concrete Beams with Steel

The conclusions that can be drawn from this Fibres under Flexural Loading’. ISSN

research based on the experimental results are as 0974-5904, Volume 04, No 06 SPL,

follows: October 2011, pp 843-846

Addition of steel fibers increases flexural 4. IS: 8112-1989. Specifications for 43

and compressive strength of concrete to grades Portland cement, Bureau of

larger extent Indian Standards, New Delhi, India.

In flexure the specimen with soft drink 5. IS: 383-1970. Specifications for coarse

bottle caps as waste material was found and fine aggregates from natural sources

to be good. By the addition of scrap steel for concrete, Bureau of Indian Standards,

fibers, the flexure strength was found to New Delhi, India.

increase to a greater extent than that of 6. IS: 10262-2009.Recommended

the conventional concrete. guidelines for concrete mix design,

The various percentage of fiber at a Bureau of Indian Standards, New Delhi,

dosage of 1%, 2%, 3% and 4%, the India.

compression, tensile and flexural 7. ASTM D790: Standard Test Methods for

strength has been altered compared to Flexural Properties of unreinforced and

normal concrete. Reinforced Plastic.

The percentage increase in tensile 8. ASTM C496 / C496M - 11 Standard

strength of steel scrap fiber reinforced Test Method for Splitting Tensile

Darshan N1, Rajani V Akki 2, Sharath B P3 www.ijetst.in Page 1340

IJETST- Volume||01||Issue||08||Pages 1335-1341||October||ISSN 2348-9480 2014

Strength of Cylindrical Concrete

Specimens.

9. ASTM C39 / C39M - 12a Standard Test

Method for Compressive Strength of

Cylindrical Concrete Specimens.

10. ASTM C1609 / C1609M - 12 Standard

Test Method for Flexural Performance of

Fiber-Reinforced Concrete (Using Beam

With Third-Point Loading).

11. IS 456-2000, Indian standard plain and

reinforced concrete-code of practice, 4th

revision, and 1st reprint Sep-2000.

12. R.Saravanakumar, Gabriela Rajan,

N.Ragavan, G.Murali and B.Mohan

“Effect of Soft Bottle Caps Fiber on

Concrete Structures”. International

Journal of Advanced Scientific Research

and Technology Issue 2, Volume 3

(June- 2012)

Darshan N1, Rajani V Akki 2, Sharath B P3 www.ijetst.in Page 1341

You might also like

- Bamboo Reinforced ConcreteDocument7 pagesBamboo Reinforced ConcreteIJRASETPublicationsNo ratings yet

- Materials Today: Proceedings: S. Sangeetha, N. Sakthieswaran, O. Ganesh BabuDocument5 pagesMaterials Today: Proceedings: S. Sangeetha, N. Sakthieswaran, O. Ganesh BabuShaik Abdul RaheemNo ratings yet

- A Study On Steel Fiber Reinforced Normal PDFDocument5 pagesA Study On Steel Fiber Reinforced Normal PDFZindagiDeeNo ratings yet

- Study On The Strength of Stainless-Steel Fiber Rein-Forcement ConcreteDocument6 pagesStudy On The Strength of Stainless-Steel Fiber Rein-Forcement ConcreteIJRASETPublicationsNo ratings yet

- Experimental Investigation of Steel Fiber Reinforced ConcetreDocument6 pagesExperimental Investigation of Steel Fiber Reinforced ConcetreJETLYNo ratings yet

- FIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanDocument8 pagesFIBRE REINFORCED CONCRETE USING DOMESTIC WASTE PLASTICS AS FIBRES by R. Kandasamy and R. MurugesanIvan KotNo ratings yet

- Experimental Study On The Steel Fiber Reinforcement ConcreteDocument6 pagesExperimental Study On The Steel Fiber Reinforcement ConcreteIJRASETPublicationsNo ratings yet

- Effect of Steel Fiber and Glass Fiber On Mechanical Properties of ConcreteDocument6 pagesEffect of Steel Fiber and Glass Fiber On Mechanical Properties of ConcreteIJSTENo ratings yet

- Concrete StrengthDocument4 pagesConcrete StrengthJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- A Study On Effect of Mechanical Properties of Recron 3S Fibre Concrete On Different Grades Exposed To Elevated TemperaturesDocument6 pagesA Study On Effect of Mechanical Properties of Recron 3S Fibre Concrete On Different Grades Exposed To Elevated TemperaturesIJIRSTNo ratings yet

- Study On Mechanical Properties of Steel Fibre Reinforced ConcreteDocument5 pagesStudy On Mechanical Properties of Steel Fibre Reinforced ConcreteShikha SachanNo ratings yet

- Experimental study enhances concrete flexural strength with small steel fibersDocument9 pagesExperimental study enhances concrete flexural strength with small steel fibersSal SaadNo ratings yet

- WPFRC 7Document13 pagesWPFRC 7Tesema LegeseNo ratings yet

- Performance of Steel Fiber Reinforced Self Compacting ConcreteDocument5 pagesPerformance of Steel Fiber Reinforced Self Compacting ConcreteInternational Journal of computational Engineering research (IJCER)No ratings yet

- A Study On Properties of Recycled Coarse Aggregate and It's ConcreteDocument11 pagesA Study On Properties of Recycled Coarse Aggregate and It's ConcreteJenish PatelNo ratings yet

- Effect of Lathe Waste Review 1Document22 pagesEffect of Lathe Waste Review 1dreamboy87No ratings yet

- Strength Behavior of Bamboo Reinforced CDocument9 pagesStrength Behavior of Bamboo Reinforced CBRYLLE KYLLE OIDEMNo ratings yet

- Steel Nail ConcreteDocument3 pagesSteel Nail ConcreteDaniel Alexfre Juarez VictorioNo ratings yet

- Experimental Investigation On Flexural Strength of RC Beam Using Sisal Fiber and Comparing With Conventional ConcreteDocument7 pagesExperimental Investigation On Flexural Strength of RC Beam Using Sisal Fiber and Comparing With Conventional ConcretereenaNo ratings yet

- Comparative study of strengthening circular concrete columns with softFRPDocument7 pagesComparative study of strengthening circular concrete columns with softFRPmasud0768No ratings yet

- Ehab, Debaiky, RedaDocument8 pagesEhab, Debaiky, RedaAhmed S DebaikyNo ratings yet

- Deformation Characteristics of Basalt Reinforced Concrete With SuperplasticizerDocument7 pagesDeformation Characteristics of Basalt Reinforced Concrete With SuperplasticizerBanNo ratings yet

- Reinforced Concrete Strength Using Glass & Steel FibersDocument5 pagesReinforced Concrete Strength Using Glass & Steel FibersLebo.emx MathosaNo ratings yet

- Study of Strength Property of Concrete Using Waste Plastics and Steel FiberDocument3 pagesStudy of Strength Property of Concrete Using Waste Plastics and Steel FibertheijesNo ratings yet

- 2017 - FC2015 - Effect of The Loading Rate On Fibre Reinforced Concrete BeamsDocument7 pages2017 - FC2015 - Effect of The Loading Rate On Fibre Reinforced Concrete BeamsJuhász KPNo ratings yet

- To Improve The Strength of Concrete by Using Carbon Nanotubes (CNTS)Document7 pagesTo Improve The Strength of Concrete by Using Carbon Nanotubes (CNTS)IJRASETPublicationsNo ratings yet

- CivilDocument2 pagesCivilShiyaNo ratings yet

- Effect of Lathe Waste in Concrete As ReinforcementDocument6 pagesEffect of Lathe Waste in Concrete As ReinforcementAnkit GuptaNo ratings yet

- Comparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass FiberDocument19 pagesComparative Study On Durability Properties of Engineered Cementitious Composites With Polypropylene Fiber and Glass Fiberci_balaNo ratings yet

- Welcome To The Presentation: Presented by MD Nasir Uddin Reg: 1101060006D & Amzad Hussain Reg: 1101060023DDocument13 pagesWelcome To The Presentation: Presented by MD Nasir Uddin Reg: 1101060006D & Amzad Hussain Reg: 1101060023DAhmed TashvikNo ratings yet

- Strengthening of RCC Beams With FRPDocument6 pagesStrengthening of RCC Beams With FRPGRD JournalsNo ratings yet

- Paper 7Document9 pagesPaper 7RakeshconclaveNo ratings yet

- International Journal of Chemtech Research: A.R.Krishnaraja, S.KandasamyDocument7 pagesInternational Journal of Chemtech Research: A.R.Krishnaraja, S.KandasamyZrar IsqeliNo ratings yet

- Experimental Work For Mechanical Properties of Brick and Masonry PanelDocument8 pagesExperimental Work For Mechanical Properties of Brick and Masonry PanelHadi Iz'aanNo ratings yet

- Experimental Behaviour of Steel Fiber Reinforced Concrete With Partial Replacement of Fly Ash and MetakaolinDocument4 pagesExperimental Behaviour of Steel Fiber Reinforced Concrete With Partial Replacement of Fly Ash and MetakaolinEditor IJTSRDNo ratings yet

- Material Properties of FRC With Recycled Aggregate: Jiřina TRČKOVÁ and Petr PROCHÁZKADocument7 pagesMaterial Properties of FRC With Recycled Aggregate: Jiřina TRČKOVÁ and Petr PROCHÁZKAShruthi IyengarNo ratings yet

- Utilization of Waste Plastics As A Fiber in Concrete: January 2017Document6 pagesUtilization of Waste Plastics As A Fiber in Concrete: January 2017Excel MigsNo ratings yet

- jESE Vol4 No3 p123 134 2014Document12 pagesjESE Vol4 No3 p123 134 2014mochocerNo ratings yet

- DEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonDocument9 pagesDEVI, OLYVIA, EDI - Pengaruh Penambahan Serat Kawat Bendhrat Terhadap Kuat Tekan Dan Kuat Tarik BetonExcellenza Nafidzun AzzamNo ratings yet

- Effect of Corrosion On The Shear Transfer Behavior of Shear StudDocument8 pagesEffect of Corrosion On The Shear Transfer Behavior of Shear StudOsamaNo ratings yet

- Strength Aspects of Glass Fibre Reinforced Concrete PDFDocument5 pagesStrength Aspects of Glass Fibre Reinforced Concrete PDFTushar SharmaNo ratings yet

- Suitability of Glass Fibers in High Strength Recycled Aggregate Concrete-An Experimental InvestigationDocument10 pagesSuitability of Glass Fibers in High Strength Recycled Aggregate Concrete-An Experimental InvestigationSuresh KomurajuNo ratings yet

- 1 s2.0 S2214785320407217 MainDocument4 pages1 s2.0 S2214785320407217 MainSamuel NkereuwemNo ratings yet

- Characteristic Strength of Concrete Using Steel Slag As A Fine AggregateDocument8 pagesCharacteristic Strength of Concrete Using Steel Slag As A Fine AggregateIJRASETPublicationsNo ratings yet

- Irjet V5i4297Document2 pagesIrjet V5i4297Cornelia BaeraNo ratings yet

- Experimental Study On Partial Replacement of Coarse Aggregate by Crown CapsDocument3 pagesExperimental Study On Partial Replacement of Coarse Aggregate by Crown CapsFE3056 NAGARAJ.SNo ratings yet

- Use of Industrial Waste and Recron 3s Fiber to Improve Concrete PropertiesDocument34 pagesUse of Industrial Waste and Recron 3s Fiber to Improve Concrete PropertiesPavan Kalyan Yadav100% (1)

- Post-Cracking Behaviour of Steel and Macro-Synthetic Fibre-Reinforced ConcretesDocument10 pagesPost-Cracking Behaviour of Steel and Macro-Synthetic Fibre-Reinforced ConcretesDan MaceNo ratings yet

- Study On Strength and Durability Properties of Polypropylene and Carbon Fiber Reinforced Concrete CompositeDocument6 pagesStudy On Strength and Durability Properties of Polypropylene and Carbon Fiber Reinforced Concrete CompositeIJRASETPublicationsNo ratings yet

- An Investigation of Steel Fiber Reinforced Concrete With Fly AshDocument5 pagesAn Investigation of Steel Fiber Reinforced Concrete With Fly AshmaheshNo ratings yet

- Experimental Study On The Structural Retrofitting of RC Beam Using Synthetic Steel Mesh Fiber and High Strength Aramid Kevlar Fiber Reinforced in Concrete BeamDocument7 pagesExperimental Study On The Structural Retrofitting of RC Beam Using Synthetic Steel Mesh Fiber and High Strength Aramid Kevlar Fiber Reinforced in Concrete BeamInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteDocument9 pagesComparison Study of Basalt Fiber and Steel Fiber As Additives To ConcreteIJRASETPublicationsNo ratings yet

- Strength Properties of Polypropylene Fiber Reinforced ConcreteDocument5 pagesStrength Properties of Polypropylene Fiber Reinforced ConcreteVarun ChandraNo ratings yet

- Mechanical properties of fibrous concrete using waste materialsDocument5 pagesMechanical properties of fibrous concrete using waste materialsIbukunoluwa Aborisade ErunkuluNo ratings yet

- Ferrocement JointsDocument8 pagesFerrocement JointsSulaiman Mohsin AbdulAzizNo ratings yet

- 11 X October 2023Document35 pages11 X October 2023Sohail ShaikhNo ratings yet

- Strength Characteristics of Hybrid Fiber Reinforced Concrete Produced With Different Aspect RatiosDocument12 pagesStrength Characteristics of Hybrid Fiber Reinforced Concrete Produced With Different Aspect RatiosIJRASETPublicationsNo ratings yet

- Shear Behaviour of RC BEAMDocument14 pagesShear Behaviour of RC BEAMSridhar PeriasamyNo ratings yet

- An Experimental Approach For The Study On Mechanical Properties of M30 Grade Concrete When The SteelDocument6 pagesAn Experimental Approach For The Study On Mechanical Properties of M30 Grade Concrete When The SteelIJRASETPublicationsNo ratings yet

- Lecture 06 Design of RC Beam for Shear Updated 01-06-2023Document47 pagesLecture 06 Design of RC Beam for Shear Updated 01-06-2023Sajjad AhmadNo ratings yet

- CementDocument55 pagesCementSajjad AhmadNo ratings yet

- Surveying Lecture OverviewDocument38 pagesSurveying Lecture OverviewSajjad AhmadNo ratings yet

- Density and Specific Gravity of Fine AggregateDocument16 pagesDensity and Specific Gravity of Fine AggregateSajjad AhmadNo ratings yet

- District Education Officer Male Dir Lower TimargaraDocument112 pagesDistrict Education Officer Male Dir Lower TimargaraSajjad AhmadNo ratings yet

- Provisional Merit List of Lecturer Physics BPS 17 With Interview DateDocument5 pagesProvisional Merit List of Lecturer Physics BPS 17 With Interview DateSajjad AhmadNo ratings yet

- Durability Properties of Banana Fibre ReDocument7 pagesDurability Properties of Banana Fibre ReSajjad AhmadNo ratings yet

- Ce 80Document6 pagesCe 80Sajjad AhmadNo ratings yet

- A Study On Water Absorption and Sorptivity of Geopolymer ConcreteDocument9 pagesA Study On Water Absorption and Sorptivity of Geopolymer ConcreteSajjad AhmadNo ratings yet

- Civil Engineering Department: Cecos University of It and Emerging Sciences PeshawarDocument8 pagesCivil Engineering Department: Cecos University of It and Emerging Sciences PeshawarSajjad AhmadNo ratings yet

- Personal Profile: I Am Young Enthusiastic Qualified Skilled and Self-Motivated With A StrongDocument1 pagePersonal Profile: I Am Young Enthusiastic Qualified Skilled and Self-Motivated With A StrongSajjad AhmadNo ratings yet

- Sajjad RM PresentationDocument8 pagesSajjad RM PresentationSajjad AhmadNo ratings yet

- Sajjad Assign 2 Research MethodogyDocument6 pagesSajjad Assign 2 Research MethodogySajjad AhmadNo ratings yet

- CURINGDocument6 pagesCURINGAzriNo ratings yet

- A Review of Relation Between Cube Strength and Core Strength of Hardened Concrete in The Light of IS456:2000and IS516:1959Document4 pagesA Review of Relation Between Cube Strength and Core Strength of Hardened Concrete in The Light of IS456:2000and IS516:1959Rohit RaiNo ratings yet

- ST4010 - Design of Industrial StructuresDocument17 pagesST4010 - Design of Industrial Structurescharvi shinyNo ratings yet

- Wax Emulsions for Coatings: Understanding Surface EffectsDocument7 pagesWax Emulsions for Coatings: Understanding Surface Effectssriatul2006No ratings yet

- Ec6 1 1 10-2001 PDFDocument123 pagesEc6 1 1 10-2001 PDFvdgiNo ratings yet

- MCX U Turn Slot - BILL OF QUANTITIESDocument3 pagesMCX U Turn Slot - BILL OF QUANTITIESJelian GraceNo ratings yet

- Engineering Structures: Fabrizio Gara, Laura Ragni, Davide Roia, Luigino DeziDocument12 pagesEngineering Structures: Fabrizio Gara, Laura Ragni, Davide Roia, Luigino DeziRodrigo LameirasNo ratings yet

- Act PDFDocument61 pagesAct PDFBindu SrirangamNo ratings yet

- Detalles Tipicos de Viga AashtoDocument13 pagesDetalles Tipicos de Viga AashtoCarlos SaldanaNo ratings yet

- A contractor's guide to restoring a house after flood damageDocument10 pagesA contractor's guide to restoring a house after flood damageDmacNo ratings yet

- KidanDocument84 pagesKidanGebrekidan100% (1)

- Schedule Using PrimaveraDocument7 pagesSchedule Using Primaverabraveknight9475% (4)

- An Experimental Study On Soil Stabilization by Using Bio EnzymesDocument7 pagesAn Experimental Study On Soil Stabilization by Using Bio EnzymesEditor IJTSRDNo ratings yet

- 5 Quick Guide ACI 212.3 PRAN Vs PRAH CHPT 15 Explained 2pgsDocument2 pages5 Quick Guide ACI 212.3 PRAN Vs PRAH CHPT 15 Explained 2pgsOvenbird Ingeniaria AvanzadaNo ratings yet

- 214.3R - 88simplified Version of The Recommended Practice For Evaluation of Strength Test Results of Concrete PDFDocument8 pages214.3R - 88simplified Version of The Recommended Practice For Evaluation of Strength Test Results of Concrete PDFWaleed AhmedNo ratings yet

- CT2 2006 Foundation Analysis DesignDocument4 pagesCT2 2006 Foundation Analysis DesignKroya HunNo ratings yet

- Manual Torcret SikaDocument90 pagesManual Torcret SikaAdrian DargauNo ratings yet

- C1646C1646MDocument3 pagesC1646C1646MRajesh KumarNo ratings yet

- Masterprotect 180: A Non-Toxic Solvent Free High Build, Protective Epoxy Resin CoatingDocument3 pagesMasterprotect 180: A Non-Toxic Solvent Free High Build, Protective Epoxy Resin CoatingEngTamerNo ratings yet

- Project Presentation: Department of Civil Engineering Government Engineering College, Ajmer Session:-2019-2020Document18 pagesProject Presentation: Department of Civil Engineering Government Engineering College, Ajmer Session:-2019-2020PrinceNo ratings yet

- Influence of Specific Surface Area of Cement On Mechanical Properties of RCCDocument6 pagesInfluence of Specific Surface Area of Cement On Mechanical Properties of RCCJian-Tong DINGNo ratings yet

- Concrete Design MixDocument4 pagesConcrete Design Mixsubhashchandra chandruNo ratings yet

- Astm C150 C150M.1629Document9 pagesAstm C150 C150M.1629willyrcf100% (3)

- Ce Review Nov 2021: (310mm) (155mm) (220mm) (7.21 In.)Document2 pagesCe Review Nov 2021: (310mm) (155mm) (220mm) (7.21 In.)Ice DelevingneNo ratings yet

- BlackSeal Plus NZ - PDSDocument3 pagesBlackSeal Plus NZ - PDSAnonymous jbvNLNANLINo ratings yet

- Nilson-Transformed Area MethodDocument45 pagesNilson-Transformed Area MethodAhmer MehmoodNo ratings yet

- Precast Concrete Manholes from Shaw PipeDocument34 pagesPrecast Concrete Manholes from Shaw Pipemanjubd1No ratings yet

- Fosroc Construction Grout SolutionsDocument9 pagesFosroc Construction Grout Solutionshareesh13hNo ratings yet

- Design Guidelines For K-UHPCDocument96 pagesDesign Guidelines For K-UHPCPhát Nguyễn TiếnNo ratings yet

- Assess Structural Condition & Risk FactorsDocument23 pagesAssess Structural Condition & Risk FactorsYudi Agung NugrohoNo ratings yet

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetFrom EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetRating: 4.5 out of 5 stars4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Summary of Neil Postman's Amusing Ourselves to DeathFrom EverandSummary of Neil Postman's Amusing Ourselves to DeathRating: 4 out of 5 stars4/5 (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeFrom EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeRating: 4.5 out of 5 stars4.5/5 (59)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisFrom EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisRating: 5 out of 5 stars5/5 (3)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansRating: 4.5 out of 5 stars4.5/5 (21)

- Methodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaFrom EverandMethodology for Estimating Carbon Footprint of Road Projects: Case Study: IndiaNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- Principles of Forensic Engineering Applied to Industrial AccidentsFrom EverandPrinciples of Forensic Engineering Applied to Industrial AccidentsNo ratings yet

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingFrom EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingNo ratings yet

- Engineering Rock Mass Classification: Tunnelling, Foundations and LandslidesFrom EverandEngineering Rock Mass Classification: Tunnelling, Foundations and LandslidesRating: 4 out of 5 stars4/5 (5)