Professional Documents

Culture Documents

Core Permit Seeds

Uploaded by

VALERIE Y. DIZONCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Core Permit Seeds

Uploaded by

VALERIE Y. DIZONCopyright:

Available Formats

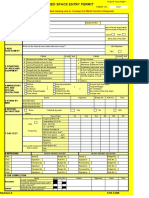

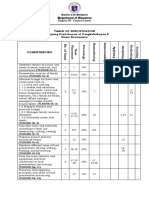

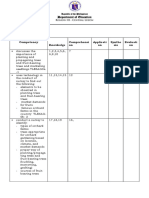

CO R E PE RM I T SEEDS

CORE Permit #:

Initials Date # permits

EMERGENCY PHONE A S S E M B LY

NUMBER: LO C AT I O N :

1. PEOPLE

Permit issuer PRINT SIGN Phone number

Plant/facility Number of people working under this permit

Co-signature PRINT SIGN Name(s) of people working under this permit P R I N T N A M E S o r AT TA C H L I S T

Issuer transferred to PRINT SIGN Receiver transferred to PRINT SIGN

Permit receiver PRINT SIGN Company Date

On-site inspection required by issuer YES NO Start time AM/PM End time AM/PM

Work limited to the following JOB SCOPE / DESCRIPTION / TASKS & AREA / EQUIPMENT & BOUNDARIES Additional Attachments:

All people working under this permit have the necessary site training and/or orientations YES N/A

Emergency procedures have been reviewed and are understood (alarms, locations of assembly points and evacuation routes) YES N/A 2. ENVIRONMENT

Emergency equipment has been located and reviewed

(Examples include, but are not limited to: nearest safety shower, eye wash, fire extinguisher and telephone and/or intercom) YES N/A Potential environmental impact & procedures for N/A

addressing impact: spills and/or leaks

The scope and boundaries of any other work in the area that could impact this permitted work has been reviewed and is understood YES N/A

Other workers in the area have been notified that this permitted work could impact their work, including the locations of any barricades YES N/A

All equipment to be worked on has been properly prepared and identified and is ready to work on YES N/A Waste disposal & housekeeping requirements: N/A

All energy sources, including radiation, are isolated, tagged and confirmed YES N/A

For demolition and renovation work, has the work area been inspected for asbestos YES N/A

A procedure is in place and reviewed for tasks as required by department Procedure Use Policy (PUP) YES N/A Special atmospheric monitoring requirements: N/A

Line of fire hazards have been discussed and mitigation techniques will be in place YES N/A

Fall hazards are present and an additional assessment will need to be completed (ladders, scaffold) YES N/A

Job site inspection required see standard for exceptions. Extended use/additional inspection needed YES N/A

Ergonomic concerns & safeguards: N/A

Job site inspector Mon___ Tues___ Wed___ Thur___ Fri___ Sat___ Sun___

Start time AM/PM End time AM/PM Start time AM/PM End time AM/PM

3. ENERGY 4. EQUIPMENT 5. CHEMICAL

For the scope of work, check the appropriate permit List the hazards of the area, the work and the List below any contained process chemical(s) or

below. Fill out the checklist or permit and attach it to this N/A N/A job specific chemical(s). See Safety Data Sheet(s) N/A

equipment for the specific task.

CORE Permit using the same number as the CORE permit. for review of safety & health hazards.

Line/Equipment Opening Permit Excavation Noise Pinch Points Radiation

Hot Work Permit Hydroblasting Thermal burn Sharp edges Inert atmosphere

Confined Space Entry Permit Pressure washing Flash fire Heat stress Asbestos

Critical Elevated Work Permit Energized electrical work Pressure extreme Flying debris Vibrations HAZARDS

Crane Operation Permit Rigging Permit Falls Dust type: _____________

Isolations of Energy (IOE) IOE master #: _________ ___________ Flammable Inhalation Toxic Skin absorption

Electrical/high voltage

______________ Skin irritant Corrosive Reactive _____________

Protection required for hazards - list personal protective equipment, precautions and safeguards

6. PROTECTION required to protect against hazards. place an asterisk (*) beside any personal protective equipment

with specific requirements/upgrade/downgrade, then define in section below.

7. WORK ENVIRONMENT

Head / Face Hands Arms / Body Respiratory Feet / Legs Elevated Work

Access Prevention Protection

Hard hat/bump cap Chemical resistant Chemical suit type: Supplied air Safety shoes

Welding hood gloves type: _____________________ Ladder Guardrail Harness w/ lanyard

_____________________ Full face purifying Closed Toed Shoes

Chemical hood type: Tyvek type: Mobile scaffold Restraint line Vertical lifeline

_______________ _____________________ Powered air purifying Rubber boots - ankle

Mechanical Welding Aerial lift devices Retractable lifeline Safety net

Hearing protection 1/2 face purifying Rubber boot - calf high

Leather Thermal Nomex (FRPC) Flash suit Scaffold Designated area: Horizontal lifeline

Double hearing protection Dust mask Metatarsal protection

Welding jacket _______________ ______________ Defined anchor point:

Face shield Electrical Gauntlet Cartridge type:

Apron type: Knee pads _______________

Chemical goggles Cut resistant - level: _____________________ _____________________

Safety glasses with _____________________ _____________________ Thigh protection Barricades Caution/Danger tape Physical _________________

side shields Lab coat Long sleeve

Safety glasses - foam seal _____________________ High visability/reflective _____________________ _____________________ Additional requirements Signage

_____________________ _____________________ _____________________ _____________________ _____________________ ___________

Electrical GFCI Written operating procedure

Comments: Reason for upgrading or downgrading PPE Communication type: Safety attendant(s) required: ___________

__________________ Name: ________________

___________

Limited time exposure: Fire extinguisher

(breaks, etc) ___________

__________________ ______________________

8. TRAINING 9. CORE PERMIT RECEIVER 10. RESPONSIBILITIES

Workers have specialty training as required: N/A The Core Permit Receiver will ensure that all workers: Responsibilities communicated to permit receiver:

Equipment PPE use Understand the hazards of the area, equipment and work and the safeguards in place. Conditions for work stoppage

Understand potential environmental impact and procedures for addressing this. Reporting changes that affect job safety

Powered industrial truck Competent person

Understand and follow Personal Protective Equipment requirements. Crew accountability & addressing workers’ concerns

Aerial work platform Hazwoper

Have the necessary skills and knowledge to do the permitted work safety.

PCB, PMN, 5e Certified Reporting a change in the permit receiver

Know emergency procedures, alarm and assembly points.

_____________________

Asbestos Qualified person Know the location of and how to use emergency equipment.

Lead _________________ Know the scope of other work that could impact this work. Permit receiver:

Understand the scope of this permitted work. Initials Phone #

11. CHANGE 12. CLOSEOUT

Scope changed Hazards changed Control measures changed Closeout job site inspection completed? YES N/A Receiver closeout: Issuer closeout:

Status of job and equipment reviewed? YES N/A

STOP WORK - notify permit issuer for review! SIGNATURE SIGNATURE

Additional paperwork reconciled? YES N/A

If suspended, reauthorize permit to continue work!

Special instruction, precautions, limitations, remarks: Date Time

Issuer SIGNATURE

AM/PM

Receiver SIGNATURE

Date Time AM/PM CORTEVA. CORE PERMIT. LAST UPDATED MAY 2019.

You might also like

- 7 - HSE-SOP-007 Radiography Permit FormDocument2 pages7 - HSE-SOP-007 Radiography Permit FormEngr. Muhammad Hassan AzizNo ratings yet

- 001 - Safe Work Permit Form - R2Document2 pages001 - Safe Work Permit Form - R2John Renz Caling RetiroNo ratings yet

- Lifting Work PermitDocument1 pageLifting Work PermitRadha BuildtechNo ratings yet

- 02 - Radiography Certificate (4022802 - v1)Document1 page02 - Radiography Certificate (4022802 - v1)Ali.N AlsaadyNo ratings yet

- PTW-Revised New R3Document11 pagesPTW-Revised New R3anasgour883No ratings yet

- Biopolis TBM 17 Feb 2024Document3 pagesBiopolis TBM 17 Feb 2024SelvamNo ratings yet

- Phalaborwa - ZBS Upgrade Project S&D ConsortiumDocument2 pagesPhalaborwa - ZBS Upgrade Project S&D Consortiumcontrax8No ratings yet

- PTW GZR-304Document1 pagePTW GZR-304sasidharan syamNo ratings yet

- General or Cold PTWDocument2 pagesGeneral or Cold PTWVijayakumar KarunanidhiNo ratings yet

- Ptwno 26: 571al ExpiryDocument2 pagesPtwno 26: 571al Expirysufiyan sskNo ratings yet

- Reactive Repair Job Ticket C1034Document5 pagesReactive Repair Job Ticket C1034MukeshLagadhirNo ratings yet

- Confined Space Entry PermitDocument4 pagesConfined Space Entry PermitradhouaNo ratings yet

- Cold WP PWIE 27 - 10 - 20 Access ControlDocument2 pagesCold WP PWIE 27 - 10 - 20 Access ControlHBHJBMNNo ratings yet

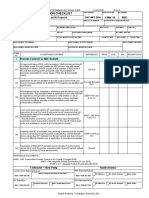

- Joint Job Site Inspection When Issuing and or Closing Out Work Permit Is RequiredDocument3 pagesJoint Job Site Inspection When Issuing and or Closing Out Work Permit Is Requiredradhoua0% (1)

- Permit To Excavation Work NewDocument2 pagesPermit To Excavation Work NewSaleh AlomariNo ratings yet

- Risk Assesment FOR TERMITE TREATMENTDocument1 pageRisk Assesment FOR TERMITE TREATMENTindunilNo ratings yet

- Format PTW-Revised 00Document17 pagesFormat PTW-Revised 00yogesh.divekar8941No ratings yet

- Pre Job Hazard Assessment: Our Goal Is Injuries in The WorkplaceDocument1 pagePre Job Hazard Assessment: Our Goal Is Injuries in The WorkplaceNadya ShintaNo ratings yet

- 4.2.11 PTW General WorksDocument2 pages4.2.11 PTW General Works2830093188No ratings yet

- General PermitDocument1 pageGeneral Permitanasgour883No ratings yet

- SICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Document2 pagesSICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Farrukh IjazNo ratings yet

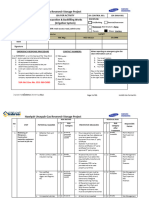

- SIM ARABIA - JSA For Excavation and Backfilling Works (Irrigation System)Document11 pagesSIM ARABIA - JSA For Excavation and Backfilling Works (Irrigation System)Rana AhmedNo ratings yet

- Pipeline Relocation Contract Gas Testing PermitDocument2 pagesPipeline Relocation Contract Gas Testing PermitFarrukh Ijaz0% (1)

- SICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Document1 pageSICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Farrukh EjazNo ratings yet

- GMs Drill Deep Read Across MatrixDocument10 pagesGMs Drill Deep Read Across MatrixJohn Oo100% (1)

- Contractors Site Induction ChecksheetDocument2 pagesContractors Site Induction ChecksheetPhelelani NkabindeNo ratings yet

- Phalaborwa - ZBS Upgrade ProjectDocument3 pagesPhalaborwa - ZBS Upgrade Projectcontrax8No ratings yet

- Eil Permit For Energy Isolation & De-IsolationDocument1 pageEil Permit For Energy Isolation & De-IsolationAvesh ChauahanNo ratings yet

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- EBENCO Facility General Work Permit (GWP)Document3 pagesEBENCO Facility General Work Permit (GWP)Lateef RaifuNo ratings yet

- HSEP12F06 - Radiation Work PermitDocument2 pagesHSEP12F06 - Radiation Work Permitasheshdas189No ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- Confined Space Entry Permit DetailsDocument3 pagesConfined Space Entry Permit DetailsHSE Health Safety EnvironmentNo ratings yet

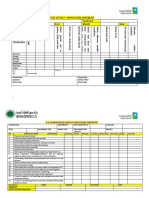

- SAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTDocument2 pagesSAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTArjun RawatNo ratings yet

- Piping Inspection RequestDocument2 pagesPiping Inspection RequestRadj SoLoNo ratings yet

- Permit To WorkDocument1 pagePermit To WorkIshtiaq AhmadNo ratings yet

- Cme Iraq CF Oi 5 1 Cold Work PermitDocument1 pageCme Iraq CF Oi 5 1 Cold Work Permitmurtadanajem1999No ratings yet

- PPC Lifting PermitDocument2 pagesPPC Lifting Permitimranul haqNo ratings yet

- Hindustan Urvarak and Rasayan Limited Confined Space Entry PermitDocument2 pagesHindustan Urvarak and Rasayan Limited Confined Space Entry PermitThakur Vikash SharmaNo ratings yet

- 89 Gas and Oilfield Safety Inspection ChecklistDocument14 pages89 Gas and Oilfield Safety Inspection Checklistdilip matalNo ratings yet

- Work Permit-Form PDFDocument1 pageWork Permit-Form PDFNijo JosephNo ratings yet

- Daily Work Permit ChecklistDocument1 pageDaily Work Permit ChecklistIndraNo ratings yet

- Inspection & Testing Plan For Installation of GRP PipesDocument3 pagesInspection & Testing Plan For Installation of GRP Pipessandeep reshmaNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- CheckList Daily Inspection of Manlift Rev.1Document1 pageCheckList Daily Inspection of Manlift Rev.1shabeermhNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- WorkPermitDetails 20 09 2023Document3 pagesWorkPermitDetails 20 09 2023gulamsafiNo ratings yet

- Construction Permit To Work SystemDocument3 pagesConstruction Permit To Work SystemZubair KhanNo ratings yet

- JSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformDocument6 pagesJSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformRaju KhalifaNo ratings yet

- JSA For Scaffolding and Shed ErectionDocument1 pageJSA For Scaffolding and Shed ErectionAnonymous voA5Tb0No ratings yet

- Updated Lifting Work PermitDocument2 pagesUpdated Lifting Work PermitSaleh AlomariNo ratings yet

- Att Job Safety Assessment (Jsa) Rev F Dated 9-22-15Document2 pagesAtt Job Safety Assessment (Jsa) Rev F Dated 9-22-15Brandon Moore0% (1)

- Safety Daily Site Checklist Mastoura co-SA-1-12Document12 pagesSafety Daily Site Checklist Mastoura co-SA-1-12LawrenceNo ratings yet

- Working at Heights PermitDocument3 pagesWorking at Heights PermitNguyen Tai TuongNo ratings yet

- JSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyDocument10 pagesJSP For OHTL No. 19 Excavation Works For Tower Foundation Pad and ChimneyJaafar LagayanNo ratings yet

- 4.2.11 PTW General WorksDocument2 pages4.2.11 PTW General Works2830093188No ratings yet

- Permit of WorkDocument24 pagesPermit of WorkSantanu SharmaNo ratings yet

- Ptw-Kec - Final v3 - SparkDocument1 pagePtw-Kec - Final v3 - SparkXiang JintaoNo ratings yet

- JSA Hot TappingDocument7 pagesJSA Hot TappingsagarauceNo ratings yet

- He 6 TosDocument2 pagesHe 6 TosVALERIE Y. DIZON100% (1)

- LESSON-EXEMPLAR-in ICT GRADE6 - JESSEL ANN C. PERALTADocument8 pagesLESSON-EXEMPLAR-in ICT GRADE6 - JESSEL ANN C. PERALTAVALERIE Y. DIZONNo ratings yet

- LESSON-EXEMPLAR-in-EPP-HE 6 CATHERINE CARONONGANDocument11 pagesLESSON-EXEMPLAR-in-EPP-HE 6 CATHERINE CARONONGANVALERIE Y. DIZONNo ratings yet

- DLL - English 6 - Q4 - W2Document4 pagesDLL - English 6 - Q4 - W2VALERIE Y. DIZONNo ratings yet

- Rizal School Mid-Year Assessment ResultsDocument3 pagesRizal School Mid-Year Assessment ResultsVALERIE Y. DIZONNo ratings yet

- Mapeh 6 Mya TosDocument4 pagesMapeh 6 Mya TosVALERIE Y. DIZONNo ratings yet

- Sses 6 ArpanDocument41 pagesSses 6 ArpanVALERIE Y. DIZONNo ratings yet

- ATT New FormatDocument1 pageATT New FormatVALERIE Y. DIZONNo ratings yet

- Mapeh Vi ArtsDocument6 pagesMapeh Vi ArtsVALERIE Y. DIZONNo ratings yet

- ENYEDocument1 pageENYEVALERIE Y. DIZONNo ratings yet

- EPSON L120 Series Advanced Driver SettingsDocument1 pageEPSON L120 Series Advanced Driver SettingsEco Generasi BiruNo ratings yet

- Agri 6 TosDocument2 pagesAgri 6 TosVALERIE Y. DIZONNo ratings yet

- Onward Real Estate Inc. Luisita Industrial Park San Miguel, Tarlac CityDocument1 pageOnward Real Estate Inc. Luisita Industrial Park San Miguel, Tarlac CityVALERIE Y. DIZONNo ratings yet

- Gold 6 ArpanDocument42 pagesGold 6 ArpanVALERIE Y. DIZONNo ratings yet

- Regional diagnostic test analysisDocument17 pagesRegional diagnostic test analysisVALERIE Y. DIZONNo ratings yet

- Answer Key - RDA - Grade 5 EnglishDocument1 pageAnswer Key - RDA - Grade 5 EnglishVALERIE Y. DIZONNo ratings yet

- Lesson 3 Buying and Selling Products BasDocument5 pagesLesson 3 Buying and Selling Products BasVALERIE Y. DIZONNo ratings yet

- Sses 6 ArpanDocument41 pagesSses 6 ArpanVALERIE Y. DIZONNo ratings yet

- PMS Aircon ChecklistDocument1 pagePMS Aircon ChecklistVALERIE Y. DIZONNo ratings yet

- Prequalification Application FormDocument3 pagesPrequalification Application FormVALERIE Y. DIZONNo ratings yet

- Epp Teachers ProfileDocument1 pageEpp Teachers ProfileVALERIE Y. DIZONNo ratings yet

- Participate in Video Conferences SafelyDocument17 pagesParticipate in Video Conferences SafelyVALERIE Y. DIZONNo ratings yet

- Health FormDocument1 pageHealth FormVALERIE Y. DIZONNo ratings yet

- Lesson 4 SELLING PRODUCTS BASED ON NEEDSDocument8 pagesLesson 4 SELLING PRODUCTS BASED ON NEEDSVALERIE Y. DIZONNo ratings yet

- Safe and Responsible Use of ICTDocument33 pagesSafe and Responsible Use of ICTVALERIE Y. DIZONNo ratings yet

- Online Survey Tools Advantages & DisadvantagesDocument13 pagesOnline Survey Tools Advantages & DisadvantagesVALERIE Y. DIZONNo ratings yet

- Certificate of Employment: To Who May ConcernDocument1 pageCertificate of Employment: To Who May ConcernVALERIE Y. DIZONNo ratings yet

- Lesson 10 FUNCTIONS AND FORMULAS IN AN EDocument23 pagesLesson 10 FUNCTIONS AND FORMULAS IN AN EVALERIE Y. DIZON100% (1)

- Lesson 5 Posting and Sharing Materials oDocument30 pagesLesson 5 Posting and Sharing Materials oVALERIE Y. DIZONNo ratings yet

- Philippines Elementary School Health Protocol ChecklistDocument2 pagesPhilippines Elementary School Health Protocol ChecklistVALERIE Y. DIZONNo ratings yet

- Evaluation of Stroke Rehabilitation Services in The In-Hospital Phase: Findings From A Tertiary Care Centre in IndiaDocument15 pagesEvaluation of Stroke Rehabilitation Services in The In-Hospital Phase: Findings From A Tertiary Care Centre in IndiaIJAR JOURNALNo ratings yet

- Middy CCTV Case StudyDocument2 pagesMiddy CCTV Case StudyLucas StacheckiNo ratings yet

- 6 135Document6 pages6 135Ashok LenkaNo ratings yet

- Csec Physics Sbaform ModerationDocument1 pageCsec Physics Sbaform Moderationapi-248240402No ratings yet

- Alu DrossDocument10 pagesAlu DrossfahmiNo ratings yet

- Inb 372Document3 pagesInb 372SunnyNo ratings yet

- Schemes of Government of Rajasthan in HealthDocument67 pagesSchemes of Government of Rajasthan in HealthKamal ShuklaNo ratings yet

- LanoLip Power Point PresentationDocument12 pagesLanoLip Power Point PresentationWalter Sanchez EscobarNo ratings yet

- E.Coli Essay FINAL PDFDocument8 pagesE.Coli Essay FINAL PDFSaraturituriNo ratings yet

- D&D 5E - Homebrew - Class ProfligateDocument7 pagesD&D 5E - Homebrew - Class Profligate19931214No ratings yet

- Acute Respiratory InfectionsDocument26 pagesAcute Respiratory InfectionsSuneel SagareNo ratings yet

- CHAPTER 1 Nursing As A ProfessionDocument3 pagesCHAPTER 1 Nursing As A ProfessionKarl ZacariasNo ratings yet

- Malignant Self LoveDocument7 pagesMalignant Self LoveMarjoryStewartBaxterNo ratings yet

- Midwife 2Document65 pagesMidwife 2jancyraniJNo ratings yet

- A Case Study of Hypertensive Cardiovascular Disease (HCVD) : School of Nursing and MidwiferyDocument13 pagesA Case Study of Hypertensive Cardiovascular Disease (HCVD) : School of Nursing and Midwiferyhsiria100% (2)

- Value patterns of prospective teachersDocument13 pagesValue patterns of prospective teachersUtpal Kalita0% (1)

- Wa0002.Document9 pagesWa0002.SojiNo ratings yet

- Florence Nightingale TheoryDocument44 pagesFlorence Nightingale TheoryAnsu MaliyakalNo ratings yet

- 5th Grade Reading Comprehension Worksheets - Fifth Grade Week 4Document2 pages5th Grade Reading Comprehension Worksheets - Fifth Grade Week 4Julius CesarNo ratings yet

- Relationship of Mothers' Knowledge and Socio-Culture to Motivation for MR ImmunizationDocument10 pagesRelationship of Mothers' Knowledge and Socio-Culture to Motivation for MR ImmunizationHanaNo ratings yet

- Galway All Products Price ListDocument3 pagesGalway All Products Price ListRishikesh Kumar Ray madhaipurNo ratings yet

- Social Studies Sba 2020 2Document23 pagesSocial Studies Sba 2020 2Petreene BaileyNo ratings yet

- Annotated BibliographyDocument20 pagesAnnotated BibliographyautumnemilymaddyNo ratings yet

- Frist Aid PPT For Pharm PDFDocument257 pagesFrist Aid PPT For Pharm PDFAbdulwhab MohammedNo ratings yet

- Eyelid Disorders: Hordeolum, Chalazion, Blepharitis, TrichiasisDocument19 pagesEyelid Disorders: Hordeolum, Chalazion, Blepharitis, TrichiasisWulan NeenNo ratings yet

- Systematic Literature Review Thematic AnalysisDocument4 pagesSystematic Literature Review Thematic Analysishyz0tiwezif3100% (1)

- Personal Protective Equipment - GustinaDocument24 pagesPersonal Protective Equipment - GustinaHidayatullah HidayatullahNo ratings yet

- NAVTA Ovt Nov17 CERadiographDocument8 pagesNAVTA Ovt Nov17 CERadiographabazanhasan6705No ratings yet

- PhobiasDocument4 pagesPhobiasOti VuraNo ratings yet

- 의약품동등성시험기준 해설서 요약Document137 pages의약품동등성시험기준 해설서 요약Travis JeonNo ratings yet