Professional Documents

Culture Documents

Job Risk Assessment JRA No: CE/QTLM/SCF/IS/0522/074

Uploaded by

8916290 ratings0% found this document useful (0 votes)

46 views8 pagesThe document is a job risk assessment form for erecting and dismantling scaffolding. It identifies potential hazards such as lack of training, equipment failure, permit violations, falls, and falling materials. Control measures specified include ensuring all employees are fit for work and properly trained, conducting inspections of equipment, adhering to permit to work procedures, maintaining vigilance on site, and keeping work areas clear of hazards. The form rates risks before and after mitigation on a scale of 1 to 4.

Original Description:

Original Title

ISOLATION Scaffolding JRA

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a job risk assessment form for erecting and dismantling scaffolding. It identifies potential hazards such as lack of training, equipment failure, permit violations, falls, and falling materials. Control measures specified include ensuring all employees are fit for work and properly trained, conducting inspections of equipment, adhering to permit to work procedures, maintaining vigilance on site, and keeping work areas clear of hazards. The form rates risks before and after mitigation on a scale of 1 to 4.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views8 pagesJob Risk Assessment JRA No: CE/QTLM/SCF/IS/0522/074

Uploaded by

891629The document is a job risk assessment form for erecting and dismantling scaffolding. It identifies potential hazards such as lack of training, equipment failure, permit violations, falls, and falling materials. Control measures specified include ensuring all employees are fit for work and properly trained, conducting inspections of equipment, adhering to permit to work procedures, maintaining vigilance on site, and keeping work areas clear of hazards. The form rates risks before and after mitigation on a scale of 1 to 4.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 8

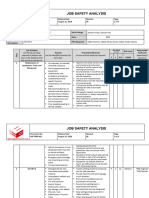

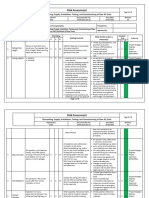

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 1 of 8

Job Risk Assessment JRA No: CE/QTLM/SCF/IS/0522/074

Company Name: Cape East Prepared by : Date:

Group : Central Maintenance Approved by : Deepak Purkuti Date:

Department :

Job Location : Equipment:

Title of Job : To erect and dismantle Scaffolding for

Mandatory PPE required:

Risk Score Residual

Sequence of Job Steps Potential Hazards Potential Effects before Control Measures

Risk

mitigation after mitigation

Fitness to work Injury / Illness to the Ensure All Employees to be fit to work.

Mobilization and demobilization of 4-L 1–L

Lack of knowledge individual. Only personnel having appropriate training

manpower and equipment to and from job

site. Wrong practices and Resulting to error and and certifications to be mobilized for the

procedures confusing leading to scope of activities.

Equipment failure serious injury or fatality All personnel shall complete Client

Damage /loss to property induction to be familiar with the site, scope,

Damaged to equipment / hazards, Cape/ Client expectations.

property loss Conduct pre-mobilization checks for the

equipment and inspection by QATALUM

personnel (where applicable)

Where applicable, equipment shall be

inspection by QATALUM and only

mobilize equipment with valid certification.

All personnel being mobilized shall be

issued with appropriate PPE for their

specific task.

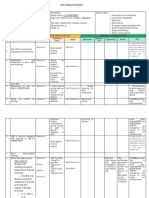

Access to Workplace Permit Violation Injury / illness to the Qatalum PTW together with the applicable

4-L 2–L

Hazards related to process individual JSA shall be strictly adhered for entering

Mechanical Hazards Incident potentially cause inside the plant area.

Slips, Trip and Falls damage Ensure where applicable, gas test is

6/11/2022 Uncontrolled when printed 1

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 2 of 8

Risk Score Residual

Sequence of Job Steps Potential Hazards Potential Effects before Control Measures

Risk

mitigation after mitigation

Falling Materials Material Damage / loss conducted by Client representative and the

Damage to plant and area released is free from hazards.

equipment’s Personnel shall be familiar with the Permit

Controls, Hazards and controls as per JRA

and the scope of work covered.

Maintain high degree of vigilance whilst

moving around site. Do not interfere with

sensitive parts.

As far as is reasonably practicable, all work

areas shall be kept free from trailing cables,

timber packing, tools, equipment and waste

cleared away as soon as possible.

Do not block the plant access and

emergency equipment.

Barricading by means of hazard tape

around material/ equipment mobilized on

site.

All personnel are to maintain a safe

working distance from others working

overhead.

Personnel are not to walk / work under

suspended loads.

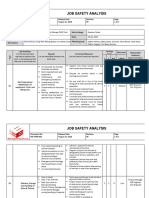

Hazardous environment Exposure to Environmental Ensure PTW and supporting documents

4-L 2-L

Equipment failure incident potentially cause including appropriate JHA and Method

Work Preparation including PPE. damage Statement are available for the scope of

Falling of materials Damaged to equipment / work to be carried

property loss Review JSA for the specific scope and

Material Damage / loss ensure controls are adequate prior to start

the work.

Conduct recorded toolbox talk prior to job

start to explain job specific hazards and

control measures to the work crew.

Carry out inspection of all equipment

including PPE prior to donning to ensure

no visible damages.

Periodic review of equipment inspection

certification to ensure validity and fit for

purpose.

Ensure material shifted to workface is in

6/11/2022 Uncontrolled when printed 2

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 3 of 8

Risk Score Residual

Sequence of Job Steps Potential Hazards Potential Effects before Control Measures

Risk

mitigation after mitigation

good serviceable condition and enough to

complete the scope for the shift.

No excess material shall be left unattended

at workface.

Identify the requirements of workplace

control including barricading and arrange

as appropriate where required.

PSTA shall be carried out by each

individual.

Competent and trained personnel to be

12-H 3-L

assigned for the task.

Arrange storage of materials near

workplace using mechanical handling

Erection and Dismantle of scaffolding Wrong Manual Handling Exposure to Manual Handling (where practical) to reduce manual

incident/injury. handling.

Maintain manual handling techniques for

shifting / lifting of scaffold materials.

Whilst raising tubes and boards company

manual handling assessment and procedure

shall be followed.

Adequate supervision at site by performing

party always.

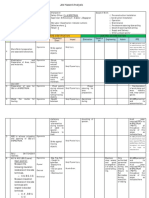

Dropped Objects. Damage to plan and Dropped object management procedure to

12-H 3-L

equipment’s be followed.

Property loss Ensure personnel are trained on dropped

object prevention.

Incident injury

Exclusion / drop zone shall be identified,

and adequate barricading provided to

prevent unauthorized access.

Ensure all tools tied up with lanyard.

Use tools Bag / Pouches to transport

scaffolding tools.

Use certified lifting bags or basket in

serviceable condition for shifting scaffold

materials to and from high elevation.

Hand balling may be used for shifting tubes

and boards.

Ensure gin wheels are attached to the

scaffolding structure and secured at both

6/11/2022 Uncontrolled when printed 3

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 4 of 8

Risk Score Residual

Sequence of Job Steps Potential Hazards Potential Effects before Control Measures

Risk

mitigation after mitigation

ends with double / swivel couplers.

Rope to be used shall be long enough

without knots and kinks.

Establish Twist to confirm technique to

communicate/Co-ordinate with scaffolding

crew during hand transfer operation.

Lowering and raising scaffolding materials

will be performed safe and steady manner,

and at controlled speed.

Inspect all scaffolds pertaining to design

drawings

Ensure toe boards placed and platforms

closely boarded & secured without gaps.

Do not leave loose materials at scaffolding

platform.

Carry out dropped object inspection as per

procedure

Slip / Trips / Falls. Injury / Injury to the Good Standard of House Keeping shall be

12-H 3-L

individual. maintained. (A place for everything and

Higher Risk of Serious everything in its place always).

incident injury / Fatality Materials stored away from access without

obstructions.

Falling from height Use full body harness with double lanyard

Working at height. 12-H 3-L

Higher Risk of Serious whilst working above 2 meters and ensure

incident injury / Fatality 100% tie –off.

Use Chin Strap for helmet while working at

height.

Ensure harness is hooked on safe

anchorage point and hooked above waist

height as practicably possible.

Anchorage point shall be of load bearing

and structure of adequate strength.

Clear platform & no gap between boards.

Handrails & Mid rails rigidly secured to

prevent fall.

Secure ladders ensure 3-point contact

whilst climbing and descending ladders.

Scaffolding work will be suspended in case

of high wind / adverse weather condition.

6/11/2022 Uncontrolled when printed 4

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 5 of 8

Risk Score Residual

Sequence of Job Steps Potential Hazards Potential Effects before Control Measures

Risk

mitigation after mitigation

SIMOPS Failure Collations between two team Job safety risk assessments to be cascaded

9-M 3-L

Booster bus Bar potential to cause incident to all operatives and followed at all times.

Electrical /Injury Any changes in environment causing

Electrocution / electric additional risks will lead to immediate

shocked stoppage of work and review of current

Injury / illness Risk assessment.

SIMOPs endangering each other to be

Working near the electrical Lack of awareness avoided jobs designated priority wise.

Equipment Resulting to error and

confusing leading to serious Ensure no other works are ongoing in the

injury or fatality. same area without adequate SIMOPs plan.

Do not extend any materials to buster bus

bar area.

Do not extend any material beyond

Working in energize area Electrical Shock Electrocution / electric basement fens

shocked

All personnel shall have completed the

Injury / Illness to the Qatalum HSE site induction

individual.

Risk assessment Method of statement and

Higher Risk of Serious work permit briefing and task prestart talk

incident injury / Fatality to all persons connected with the activity.

Proper and close coordination with

operations personnel.

Apply the personal padlock before entering

and start the work. Follow the isolation

procedure.

Do not operate any electrical Equipment.

Proper isolation (Lock out / Tagout) system

by authorize person only.

Apply the personal padlock before entering

and start the work. Follow the isolation

procedure.

Don’t operate any equipment.

Adverse weather Heat stress Higher Risk of Serious Illness Rest Shelter and Ablutions at Site

12-H 3-L

Sun Stroke / Fatality Awareness

Hot Weather Working

Dehydration Erratic Behavior Regular Breaks, Drink Water

Poor physical fitness Weakness, Unsteady Gait Provide Adequate Drinking Water Nearby

Exhibiting symptoms of Body Temperature elevated & Implement Appropriate Work Rest

fatigue Convulsions Scheme

Loss of Consciousness Operatives Are Given Information on Heat

Stress and Exhaustion During Tbt.

6/11/2022 Uncontrolled when printed 5

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 6 of 8

Risk Score Residual

Sequence of Job Steps Potential Hazards Potential Effects before Control Measures

Risk

mitigation after mitigation

Operatives Are Instructed to Take Regular

Breaks and Drink Water as Per Project

Heat Stress Index.

Provide adequate cold water on site at all

times. Always provide adequate shelter on

site. Water flasks to be provided to all

operatives

Reduce, as much as possible, the number of

activities performed outdoors

Ensure that workers remain well hydrated

Higher Risk of Serious Illness Maintain personal hygiene

COVID - 19 COVID19 Infection / Spread 9-M 3-L

/ Fatality / Environmental Masks and gloves are mandatory for self as

of Virus / Transmission

Conditions that may affect well other precautionary.

exposure Avoid sharing tools & equipment.

Adhere to social distancing 1.5 m.

Try to be paperless for procedures.

Ensure all the team who involved in the job

should have good health.

Report to senior if anyone feeling sick or

fever.

Follow MOPH as well as Qatalum

guidelines for self and others awareness

Area cleaning Ongoing at all times as you work, the area

shall be cleaned and unwanted materials to

be removed.

6/11/2022 Uncontrolled when printed 6

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 7 of 8

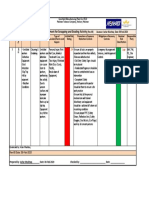

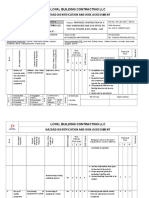

Likelihood or probability

1 2 3 4 5

Rare Unlikely Moderate Likely Almost certain

Property damage Might well be

Practically

Injury/illness Environmental Quite possible or expected or

(actual loss, USD) impossible, has Unlikely, but has Possible or has

has been has been

never occurred been occurred in been occurred

occurred once a occurred more

in similar similar industry in Qatalum

year in Qatalum than once per

industry

year in Qatalum

Minor incident but no

1 Insignificant immediate signs of No effect to environment < 5,000 1–L 2–L 3–L 4–L 5–L

injury/illness

Environmental incident

2 Minor First Aid Case 5,000 – 25,000 2–L 4–L 6–M 8–M 10 – M

potentially cause damage

LTI temp. disability

Environmental incident

3 Moderate Restricted Work Case 25,000 – 100,000 3–L 6–M 9–M 12 – H 15 – H

resulting minor damage

Medical Treatment Case

4 Major Single fatality Environmental incident 100,000 – 1,000,000 4–L 8–M 12 – H 16 – H 20 – H

resulting major damage to

6/11/2022 Uncontrolled when printed 7

GOV-ST-41-1-APP02

Rev. date : 1 Sep 2020

Job Risk Assessment Form Rev. no. 03

Page : 8 of 8

Severity or

LTI perm. disability Qatalum

Multiple fatality Environmental incident

5 Catastrophic Perm. disability > 10 people resulting major damage to > 1,000,000 5–L 10 – M 15 – H 20 – H 25 – H

surrounding community

Risk = Severity x Likelihood L = Low Risk (≤ 5) M = Medium Risk (6 – 10) H = High risk (≥ 11)

MANAGING RISKS

6/11/2022 Uncontrolled when printed 8

You might also like

- (General Scaffolding JRADocument7 pages(General Scaffolding JRA891629No ratings yet

- Silo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment FormDocument9 pagesSilo - JRA Stack Scaffolding 11.05.2021 GOV-ST-41-1-APP02 Job Risk Assessment Form891629100% (1)

- Jha New Format-Painting Revision)Document8 pagesJha New Format-Painting Revision)Kenny Hassan100% (1)

- JSA-009 Sand Blasting - Coating 2Document6 pagesJSA-009 Sand Blasting - Coating 2Omar DhiebNo ratings yet

- Risk Assesment Excavation & BackfillingDocument5 pagesRisk Assesment Excavation & BackfillingMuhammad Jamshid100% (3)

- Jha - Transformer Installation PDFDocument6 pagesJha - Transformer Installation PDFperquino oasan0% (1)

- JHA - MSPECTRUM-PMFTC-ABB Project PDFDocument6 pagesJHA - MSPECTRUM-PMFTC-ABB Project PDFperquino oasanNo ratings yet

- Control System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Document4 pagesControl System Integration Project: CONTRACT NO.: EDC 13-228/GC113-036Jayson EscamillanNo ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- RA Pump TemoraryDocument12 pagesRA Pump TemoraryCarlos ImmanuelNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Hot Work JSA FSDDocument3 pagesHot Work JSA FSDfiazhussaindbxNo ratings yet

- Jha Clarke Engine PumpDocument4 pagesJha Clarke Engine Pumpperquino oasanNo ratings yet

- Jha John Deere Fire Engine PumpDocument4 pagesJha John Deere Fire Engine Pumpperquino oasanNo ratings yet

- 27 - Drainage WorksDocument4 pages27 - Drainage WorksRafee Pie100% (5)

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgNo ratings yet

- Risk Assessment For Earth Works (Excavation Back Filling) Require...Document13 pagesRisk Assessment For Earth Works (Excavation Back Filling) Require...khalid khan100% (1)

- JHA - MSPECTRUM-PMFTC-ABB Project PDFDocument6 pagesJHA - MSPECTRUM-PMFTC-ABB Project PDFperquino oasanNo ratings yet

- Jha Solar Transformer ProjectDocument6 pagesJha Solar Transformer Projectperquino oasanNo ratings yet

- RA Construction For Sub-Base & Road Base WorksDocument17 pagesRA Construction For Sub-Base & Road Base WorksBleep NewsNo ratings yet

- Risk AssessmentDocument14 pagesRisk AssessmentApm FoumilNo ratings yet

- Al-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassDocument11 pagesAl-Nafay Engeenering Solution Co. BSPM Kasur: Description: Risk Assessment of General Maintenance Work On Bio MassMuhammad Muneeb Naeem NaeemNo ratings yet

- 12.hse - Risk AssessmentDocument9 pages12.hse - Risk Assessmentsandeep reshmaNo ratings yet

- Appendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical AnchorDocument13 pagesAppendix 3 Risk Assessment of Post Fixed Rebar Drill & Fix With Chemical Anchormohsin.meizaNo ratings yet

- Positif Jsa HMCFDDocument4 pagesPositif Jsa HMCFDBryant TorresNo ratings yet

- Jha JOHN DEERE Engine PumpDocument4 pagesJha JOHN DEERE Engine Pumpperquino oasanNo ratings yet

- JHA ISO Container Lifting Point MPI InspectionDocument7 pagesJHA ISO Container Lifting Point MPI InspectionMohamedNo ratings yet

- QRC-RA-013-Removal of Existing Road StructureDocument10 pagesQRC-RA-013-Removal of Existing Road StructureKallem RajashekarNo ratings yet

- Jesa-Construction of Chemical Storage Shelter For CPP RegenDocument28 pagesJesa-Construction of Chemical Storage Shelter For CPP RegenResearcherNo ratings yet

- Rare GusterDocument16 pagesRare Gusterreemy sarkNo ratings yet

- Job Safety Analysis & Risk Assessment For Scrapping and Grading ActivityDocument1 pageJob Safety Analysis & Risk Assessment For Scrapping and Grading ActivityAzhar Mushtaq100% (1)

- GGH Basket RemovelDocument9 pagesGGH Basket Removeltamoor sarwarNo ratings yet

- Risk Assessment For Installation of A New AC UnitDocument9 pagesRisk Assessment For Installation of A New AC Unitservice.amepNo ratings yet

- Jesa FGDDocument26 pagesJesa FGDResearcherNo ratings yet

- Risk Assessment Erection Steel StructureDocument10 pagesRisk Assessment Erection Steel StructureTubagus DikaNo ratings yet

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- 3 - JSA Loading Off LoadingDocument5 pages3 - JSA Loading Off LoadingAijaz AhmedNo ratings yet

- RA 02 - Earth WorkDocument38 pagesRA 02 - Earth WorkAnonymous kWfNFb100% (2)

- Qrc-Ra-004 - Re-Routing of Electrical CableDocument14 pagesQrc-Ra-004 - Re-Routing of Electrical CableKallem RajashekarNo ratings yet

- Excavation Work RISK ASSESSMENTDocument8 pagesExcavation Work RISK ASSESSMENTVimal ViswanathNo ratings yet

- Mob DemobDocument6 pagesMob DemobMohammad Irfan Kiki IsmailNo ratings yet

- Tra ExcavationDocument7 pagesTra ExcavationBilal50% (2)

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- Job Hazard Analysis (Jha) WorksheetDocument4 pagesJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNo ratings yet

- Vehicle & Equipment Movement JSADocument3 pagesVehicle & Equipment Movement JSAfiazhussaindbxNo ratings yet

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- Paint Work Using Mobile Crane PSO FSD.Document5 pagesPaint Work Using Mobile Crane PSO FSD.fiazhussaindbxNo ratings yet

- Co2 Cylinder House-JesaDocument24 pagesCo2 Cylinder House-JesaResearcherNo ratings yet

- 1 RA Water Works (Revised)Document21 pages1 RA Water Works (Revised)Muhammad Shahid Iqbal0% (1)

- Shear Wall Jumping Platform R A - 50Document6 pagesShear Wall Jumping Platform R A - 50Saranlal M0% (1)

- Risk Assessment For Kerb Stones, Wheel Stopper and Paving InterlocksDocument4 pagesRisk Assessment For Kerb Stones, Wheel Stopper and Paving Interlockspete chiz91% (22)

- RA For Installation of Fuel SystemDocument7 pagesRA For Installation of Fuel SystemAdel MorsyNo ratings yet

- JHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLDocument8 pagesJHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLOmkar MishraNo ratings yet

- Civil Works For BORF SHELTER FOR PPTEP'S PRODUCTIONDocument6 pagesCivil Works For BORF SHELTER FOR PPTEP'S PRODUCTIONMohammad Irfan Kiki IsmailNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectiondeepakkumaryadav841441No ratings yet

- 43 Equipment Erection (Static and Rotary)Document5 pages43 Equipment Erection (Static and Rotary)Hamza DhariwalNo ratings yet

- Tra 002Document6 pagesTra 002Bilal0% (1)

- Jsa 14Document6 pagesJsa 14Abhi SandiNo ratings yet

- Backfilling, Leveling RISK ASSESSMENTDocument6 pagesBackfilling, Leveling RISK ASSESSMENTVimal ViswanathNo ratings yet

- Guidance On Planning An Application of The Common Safety Method On Risk Evaluation and AssessmentDocument17 pagesGuidance On Planning An Application of The Common Safety Method On Risk Evaluation and AssessmentBernyke ContracyNo ratings yet

- Ideal QRA PDFDocument81 pagesIdeal QRA PDFOMKAR BHAVLENo ratings yet

- JHA - MCY Upgrade Preparation For Salman Phase 1 (Drainage&Scaffolding)Document5 pagesJHA - MCY Upgrade Preparation For Salman Phase 1 (Drainage&Scaffolding)hairol uisbNo ratings yet

- DEPED - DRRMS Strategic Plan and AchievementsDocument82 pagesDEPED - DRRMS Strategic Plan and AchievementsAdelio RicoNo ratings yet

- A. Appropriate Ballast Water ManagementDocument3 pagesA. Appropriate Ballast Water ManagementjomariNo ratings yet

- Hcs 3000Document167 pagesHcs 3000api-20084589183% (6)

- Risk RangerDocument26 pagesRisk Rangershailu178No ratings yet

- Rueda de NertneyDocument9 pagesRueda de NertneyEdgardo Ismael Ramos PumacahuaNo ratings yet

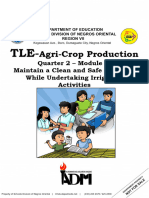

- AFA 10 Agri-Crop-Q2W5Document18 pagesAFA 10 Agri-Crop-Q2W5Rene Rulete MapaladNo ratings yet

- GE8071 Disaster ManagementDocument10 pagesGE8071 Disaster ManagementAnonymous dIhhKA0% (1)

- Bank Erosion Hazard Index (Behi)Document10 pagesBank Erosion Hazard Index (Behi)AvirupNaskarNo ratings yet

- HSG38 Lighting at WorkDocument71 pagesHSG38 Lighting at WorkthelaceNo ratings yet

- RA-LBC-007 Risk Assessment Concrete WorksDocument8 pagesRA-LBC-007 Risk Assessment Concrete Worksjones100% (1)

- Leadership: SafetyDocument7 pagesLeadership: SafetyAbdurrahim RafsanjaniNo ratings yet

- LPG Project 3Document13 pagesLPG Project 3Jehirul IslamNo ratings yet

- Assessment of The Implementation On TheDocument82 pagesAssessment of The Implementation On TheKevin ArnaizNo ratings yet

- Diagnostic-3rd Quarter-Work-ImmersionDocument6 pagesDiagnostic-3rd Quarter-Work-ImmersionMarian AlfonsoNo ratings yet

- Shepherdville College: What Are The Elements of A Flowchart?Document10 pagesShepherdville College: What Are The Elements of A Flowchart?Den SeguenzaNo ratings yet

- Risk Assessment - Working in or Near WaterDocument5 pagesRisk Assessment - Working in or Near WaterabogadieNo ratings yet

- BDRRM PLAN BRGY. San PedroDocument41 pagesBDRRM PLAN BRGY. San PedrowingpinNo ratings yet

- Health Hazards and Occupational RisksDocument14 pagesHealth Hazards and Occupational RisksCelina JuanNo ratings yet

- MSDS Cocoa Powder PDFDocument3 pagesMSDS Cocoa Powder PDFkemang 35No ratings yet

- Safety Measures in Chemical Process IndustriesDocument35 pagesSafety Measures in Chemical Process IndustriesDevendra Sharma75% (8)

- Barista Module 3Document5 pagesBarista Module 3Irene SitjarNo ratings yet

- Group-Activity-2 Valentino Ponciano Basilio Stem-12-ADocument2 pagesGroup-Activity-2 Valentino Ponciano Basilio Stem-12-AGanilyn PoncianoNo ratings yet

- TIR-A15-14 Design Wind Load DeterminationDocument31 pagesTIR-A15-14 Design Wind Load Determinationjay kimNo ratings yet

- Lloyd S Register Energy Guidance Notes For Risk Based Ana PDFDocument22 pagesLloyd S Register Energy Guidance Notes For Risk Based Ana PDFankitalalwaniNo ratings yet

- Community Based Disaster Risk Management (CBDRM) in ActionDocument26 pagesCommunity Based Disaster Risk Management (CBDRM) in ActionREY MUTIANo ratings yet

- Maintain Occupational Health and Safety AwarenessDocument21 pagesMaintain Occupational Health and Safety Awarenesskhiluag74No ratings yet

- DISASTER RESPONSE AND RISK REDUCTION - Q3 - SLM11-without Answer KeyDocument15 pagesDISASTER RESPONSE AND RISK REDUCTION - Q3 - SLM11-without Answer KeyDeceree Mae RemeticadoNo ratings yet