Professional Documents

Culture Documents

Copper Alloy Data: Chemical Composition

Uploaded by

lizethOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Copper Alloy Data: Chemical Composition

Uploaded by

lizethCopyright:

Available Formats

Copper Alloy Data

C36000

C36000

Tradename: Free-Cutting Brass

Designation:

Active? True

Inactive Date:

US EPA Registered Antimicrobial? False

Chemical Composition

Element

Cu Pb Zn Fe

(1)

Min (%) 60.0 2.5

Max (%) 63.0 3.0 Rem 0.35

(1) Cu + Sum of Named Elements 99.5% min.

Alloy C36000 Page 1 of 19

Mechanical Properties*

Ultimate

Tensile

Shear Fatigue Reduction Strength in Section Cold

Temper Tensile Strength YS-0.5% Ext Elongation Rockwell B Rockwell Strength Strength** of Area Shear Size Work

Form Temper Code (ksi) (ksi) (%) scale F scale (ksi) (ksi) (%) (ksi) (in) (%)

H02 45 Min for Standard 17 Min for Standard 15 Min for Standard 60 Typ 1.5

H02 40 Min for Standard 15 Min for Standard 20 Min for Standard 1.5

1/2 Hard H02 40 Min for Standard 15 Min for Standard 20 Min for Standard 3

Bar H02 50 Min for Standard 25 Min for Standard 10 Min for Standard 65 Typ <0.50

H02 45 Min for Standard 17 Min for Standard 15 Min for Standard <0.50

O60 44 Min for Standard 18 Min for Standard 20 Min for Standard <1

Soft Anneal

O60 40 Min for Standard 15 Min for Standard 25 Min for Standard 22 Typ 1.5

Flat

1/2 Hard H02 56 Typ 45 Typ 20 Typ 62 Typ 33 Typ 0.25 11

Products

H02 57 Typ 25 Typ 7 Typ 65 Typ 32 Typ 20 Typ <0.50

H02 50 Min for Standard 20 Min for Standard 15 Min for Standard 65 Typ 1.5

H02 45 Min for Standard 15 Min for Standard 20 Min for Standard 55 Typ 3.0

25 Min for

H02 40 Min for Standard 15 Min for Standard 20 Min for Standard 4.5

Standard

1/2 Hard

34 Min for

H02 55 Min for Standard 25 Min for Standard 10 Min for Standard 70 Min 0.75

Standard

H02 58 Typ 45 Typ 25 Typ 50 Typ 34 Typ 1 20

H02 55 Typ 44 Typ 32 Typ 52 Typ 32 Typ 2 18

Rod

H02 68 Typ 52 Typ 18 Typ 48 Typ 38 Typ 0.24 25

Annealed O61 49 Typ 18 Typ 53 Typ 58 Typ 30 Typ 1

H04 65 Min for Standard 30 Min for Standard 6 Min for Standard 0.625

Hard H04 70 Min for Standard 35 Min for Standard 4 Min for Standard 78 Typ 34 Typ 0.375

H04 80 Min for Standard 45 Min for Standard 80 Typ 38 Typ 0.25

O60 48 Min for Standard 20 Min for Standard 15 Min for Standard 28 Typ 30 Typ <1

Soft Anneal O60 44 Min for Standard 18 Min for Standard 20 Min for Standard 1.5

O60 40 Min for Standard 15 Min for Standard 25 Min for Standard 2.5

Alloy C36000 Page 2 of 19

Ultimate

Tensile

Shear Fatigue Reduction Strength in Section Cold

Temper Tensile Strength YS-0.5% Ext Elongation Rockwell B Rockwell Strength Strength** of Area Shear Size Work

Form Temper Code (ksi) (ksi) (%) scale F scale (ksi) (ksi) (%) (ksi) (in) (%)

H01 56 Typ 45 Typ 20 Typ 62 Typ 33 Typ 0.5 11

1/4 Hard

H01 56 Typ 45 Typ 20 Typ 33 Typ 15

Shapes

M30 49 Typ 18 Typ 50 Typ 68 Typ 30 Typ 0.5

As Hot

Extruded

M30 49 Typ 18 Typ 50 Typ 30 Typ

* Measured at room temperature, 68°F (20°C). ** Fatigue Strength: 100 x 10 cycles, unless indicated as [N] x 10 .

6 6

Alloy C36000 Page 3 of 19

Physical Properties

Melting Point - Liquidus°F 1650

Melting Point - Solidus°F 1630

Densitylb/cu in. at 68°F 0.307

Specific Gravity 8.5

Electrical Conductivity% IACS at 68°F 26

Thermal ConductivityBtu/ sq ft/ ft hr/ °F at 68°F 67

Coefficient of Thermal Expansion 68-57210⁻⁶ per °F (68 – 572°F) 11.4

Specific Heat CapacityBtu/ lb /°F at 68°F 0.09

Modulus of Elasticity in Tensionksi 14000

Modulus of Rigidityksi 5300

Alloy C36000 Page 4 of 19

Fabrication Properties

Technique Suitability

Soldering Excellent

Brazing Good

Oxyacetylene Welding Not Recommended

Gas Shielded Arc Welding Not Recommended

Coated Metal Arc Welding Not Recommended

Spot Weld Not Recommended

Seam Weld Not Recommended

Butt Weld Fair

Capacity for Being Cold Worked Fair

Capacity for Being Hot Formed Fair

Machinability Rating 100

Alloy C36000 Page 5 of 19

Common Fabrication Processes

Machining

Roll Threading and Knurling

Alloy C36000 Page 6 of 19

Thermal Properties

Treatment Minimum* Maximum*

Annealing 800 1100

Hot Treatment 1300 1450

Temperature is measured in Fahrenheit.

*

Alloy C36000 Page 7 of 19

Typical uses

Product Category Product Reason Category Reason

Terrazzo Strip Appearance Color

Terrazzo Strip Corrosion Resistance Corrosion Resistance

Architecture

Terrazzo Strip Corrosion Resistance Corrosion Resistance to Chemicals

Terrazzo Strip Friction & Wear Properties Wear Resistance

Fluid Connectors Corrosion Resistance Corrosion Resistance

Fluid Connectors Machining Characteristics Machinability

Fluid Connectors Mechanical Properties Moderate Strength

Sensor Bodies Corrosion Resistance Corrosion Resistance

Sensor Bodies Machining Characteristics Machinability

Automotive

Sensor Bodies Mechanical Properties Moderate Strength

Thermostat Parts Corrosion Resistance Corrosion Resistance

Thermostat Parts Machining Characteristics Machinability

Thermostat Parts Mechanical Properties Moderate Strength

Threaded Inserts for Plastic Machining Characteristics Machinability

Fittings Appearance Appearance

Fittings Corrosion Resistance Corrosion Resistance

Fittings Machining Characteristics Machinability

Fittings Mechanical Properties Ductility

Fittings Mechanical Properties Moderate Strength

Hardware Appearance Appearance

Builders Hardware Hardware Corrosion Resistance Corrosion Resistance

Hardware Machining Characteristics Machinability

Hardware Mechanical Properties Moderate Strength

Lock Bodies Appearance Appearance

Lock Bodies Corrosion Resistance Corrosion Resistance

Lock Bodies Machining Characteristics Machinability

Lock Bodies Mechanical Properties Moderate Strength

Hot Combs (to Straighten Hair) Conductivity (Thermal) Thermal Conductivity

Hot Combs (to Straighten Hair) Corrosion Resistance Corrosion Resistance to Chemicals

Consumer

Hot Combs (to Straighten Hair) Machining Characteristics Machinability

Hot Combs (to Straighten Hair) Mechanical Properties Retains Strength

Bolts Corrosion Resistance Corrosion Resistance

Bolts Machining Characteristics Machinability

Bolts Mechanical Properties Ductility

Bolts Mechanical Properties Moderate Strength

Nuts Corrosion Resistance Corrosion Resistance

Fasteners

Nuts Machining Characteristics Machinability

Nuts Mechanical Properties Moderate Strength

Screws Corrosion Resistance Corrosion Resistance

Screws Machining Characteristics Machinability

Screws Mechanical Properties Moderate Strength

Alloy C36000 Page 8 of 19

Product Category Product Reason Category Reason

Adapters Corrosion Resistance Corrosion Resistance

Adapters Machining Characteristics Machinability

Adapters Mechanical Properties Ductility

Adapters Mechanical Properties Moderate Strength

Adapters Solderability Solderability

Automatic Screw Machine Parts Corrosion Resistance Corrosion Resistance

Automatic Screw Machine Parts Machining Characteristics Machinability

Automatic Screw Machine Parts Mechanical Properties Ductility

Automatic Screw Machine Parts Mechanical Properties Moderate Strength

Faucet Components Corrosion Resistance Corrosion Resistance

Faucet Components Machining Characteristics Machinability

Faucet Components Mechanical Properties Moderate Strength

Fluid Connectors Corrosion Resistance Corrosion Resistance

Fluid Connectors Machining Characteristics Machinability

Fluid Connectors Mechanical Properties Moderate Strength

Gauges Corrosion Resistance Corrosion Resistance

Gauges Friction & Wear Properties Wear Resistance

Gauges Machining Characteristics Machinability

Gauges Mechanical Properties Moderate Strength

Gears Corrosion Resistance Corrosion Resistance

Gears Friction & Wear Properties Wear Resistance

Gears Machining Characteristics Machinability

Gears Mechanical Properties Ductility

Gears Mechanical Properties Moderate Strength

Nozzles Corrosion Resistance Corrosion Resistance

Nozzles Friction & Wear Properties Wear Resistance

Nozzles Machining Characteristics Machinability

Industrial Nozzles Mechanical Properties Moderate Strength

Pinions Corrosion Resistance Corrosion Resistance

Pinions Friction & Wear Properties Wear Resistance

Pinions Machining Characteristics Machinability

Pinions Mechanical Properties Ductility

Pinions Mechanical Properties Moderate Strength

Pneumatic Fittings Corrosion Resistance Corrosion Resistance

Pneumatic Fittings Machining Characteristics Machinability

Pneumatic Fittings Mechanical Properties Moderate Strength

Screw Machine Products Corrosion Resistance Corrosion Resistance

Screw Machine Products Machining Characteristics Machinability

Screw Machine Products Mechanical Properties Moderate Strength

Unions Corrosion Resistance Corrosion Resistance

Unions Machining Characteristics Machinability

Unions Mechanical Properties Moderate Strength

Unions Solderability Solderability

Valve Seats Corrosion Resistance Corrosion Resistance

Valve Seats Friction & Wear Properties Wear Resistance

Valve Seats Machining Characteristics Machinability

Valve Seats Mechanical Properties Moderate Strength

Valve Stems Corrosion Resistance Corrosion Resistance

Valve Stems Friction & Wear Properties Wear Resistance

Valve Stems Machining Characteristics Machinability

Valve Stems Mechanical Properties Moderate Strength

Valve Trim Corrosion Resistance Corrosion Resistance

Valve Trim Friction & Wear Properties Wear Resistance

Valve Trim Machining Characteristics Machinability

Valve Trim Mechanical Properties Moderate Strength

Alloy C36000 Page 9 of 19

Product Category Product Reason Category Reason

Faucet Seats Appearance Appearance

Faucet Seats Corrosion Resistance Corrosion Resistance

Faucet Seats Machining Characteristics Machinability - Best of Lead Brasses

Faucet Stems Appearance Appearance

Faucet Stems Corrosion Resistance Corrosion Resistance

Faucet Stems Forming Characteristics Roll Threading

Plumbing

Faucet Stems Machining Characteristics Machibability

Faucet Stems Machining Characteristics Machinability - Best of Lead Brasses

Plumbers' Brass Goods Corrosion Resistance Corrosion Resistance

Plumbing Fittings Appearance Appearance

Plumbing Fittings Corrosion Resistance Corrosion Resistance

Plumbing Fittings Machining Characteristics Machinability - Best of Lead Brasses

Alloy C36000 Page 10 of 19

Applicable Specifications

Form System Standard Description

AMS 4610 BRASS BARS AND RODS, FREE CUTTING, HALF-HARD

ASTM B16/B16M FREE-CUTTING BRASS ROD, BAR AND SHAPES FOR USE IN SCREW MACHINES

Bar

SAE J461 WROUGHT AND CAST COPPER ALLOYS

SAE J463 WROUGHT COPPER AND COPPER ALLOYS

AMS 4610 BRASS BARS AND RODS, FREE CUTTING, HALF-HARD

ASTM B16/B16M FREE-CUTTING BRASS ROD, BAR AND SHAPES FOR USE IN SCREW MACHINES

Rod

SAE J461 WROUGHT AND CAST COPPER ALLOYS

SAE J463 WROUGHT COPPER AND COPPER ALLOYS

ASTM B16/B16M FREE-CUTTING BRASS ROD, BAR AND SHAPES FOR USE IN SCREW MACHINES

Shapes SAE J461 WROUGHT AND CAST COPPER ALLOYS

SAE J463 WROUGHT COPPER AND COPPER ALLOYS

Valves MILITARY MIL-V-18436 VALVES, CHECK, BRONZE

Wire ASTM B16/B16M FREE-CUTTING BRASS ROD, BAR AND SHAPES FOR USE IN SCREW MACHINES

Alloy C36000 Page 11 of 19

Corrosion Properties

Environmental

Category Specific Environment Resistance Level Corrosion notes

Excellent Resistant at cryogenic and room temperatures

Aluminum Hydroxide Excellent Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Ammonium Hydroxide Poor Reduced corrosion resistance due to soluble complex ion formation

Barium Carbonate Excellent Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Barium Hydroxide Good Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Black Liquor, Sulfate Process Poor Severe dezincification

Calcium Hydroxide Good Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Lime Excellent Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Lime-Sulfur Good Corrosion rate increases at elevated temperatures or with traces of moisture

Alkali Magnesium Hydroxide Excellent Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Potassium Carbonate Good Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Potassium Hydroxide Fair Susceptible to dezincification.

Sodium Bicarbonate Fair Susceptible to dezincification.

Sodium Carbonate Good Corrosion increases at elevated temperatures and in presence of oxidizers such as chromates or hypochlorates

Sodium Hydroxide Fair Susceptible to dezincification.

Sodium Phosphate Good

Sodium Silicate Good Susceptible to dezincification.

Sodium Sulfide Good Corrosion rate increases at elevated temperatures or with traces of moisture

Affected by pollutants and other environmental factors. Hydrogen sulfide causes rapid tarnishing. Sulfur dioxide, nitrogen oxides and ammonia may cause

Atmosphere, Industrial Good

stress corrosion cracking.

Atmosphere

Atmosphere, Marine Good Protective green basic copper chloride or carbonate patina. Sulfur dioxide, nitrogen oxides and ammonia may cause stress corrosion cracking.

Atmosphere, Rural Excellent Low corrosion rates, no localized attack

Carbon Tetrachloride, Dry Excellent Susceptible to dezincification.

Carbon Tetracholoride, Moist Poor Severe dezincification

Chloroform, Dry Excellent Corrosion rate increases at elevated temperatures or with traces of moisture

Chlor. organic Ethyl Chloride Fair Susceptible to dezincification.

Methyl Chloride, Dry Excellent Corrosion rate increases at elevated temperatures or with traces of moisture

Trichlorethylene, Dry Excellent Corrosion rate increases at elevated temperatures or with traces of moisture

Trichlorethylene, Moist Fair Susceptible to dezincification.

Alloy C36000 Page 12 of 19

Environmental

Category Specific Environment Resistance Level Corrosion notes

Oleic Acid Fair Susceptible to dezincification.

Fatty acid Palmitic Acid Fair Susceptible to dezincification.

Stearic Acid Fair Susceptible to dezincification.

Beer Good Susceptible to dezincification.

Beet Sugar Syrups Good Susceptible to dezincification.

Cane Sugar Syrups Good Susceptible to dezincification.

Carbonated Beverages Fair Susceptible to dezincification.

Carbonated Water Fair Susceptible to dezincification.

Cider Fair Susceptible to dezincification.

Coffee Excellent Susceptible to dezincification.

Food/beverage

Corn Oil Good Susceptible to dezincification.

Cottonseed Oil Good Susceptible to dezincification.

Fruit Juices Poor Susceptible to dezincification.

Gelatine Excellent Susceptible to dezincification.

Milk Good Susceptible to dezincification.

Sugar Solutions Good Susceptible to dezincification.

Vinegar Poor Susceptible to dezincification.

Ammonia, Absolutely Dry Excellent Rapid corrosion increases with traces of moisture

Ammonia, Moist Poor More corrosion resistant in dry gas

Carbon Dioxide, Dry Excellent Corrosion increases with trace of moisture

Gas

Carbon Dioxide, Moist Fair More corrosion resistant in dry gas

Hydrogen Excellent Copper and copper alloys containing copper oxide susceptible to attack

Oxygen Excellent Scaling at elevated temperatures

Bromine, Dry Excellent Rapid corrosion increases with traces of moisture

Bromine, Moist Poor More corrosion resistant in dry gas

Halogen gas

Chlorine, Dry Excellent Rapid corrosion increases with traces of moisture

Chlorine, Moist Poor More corrosion resistant in dry gas

Alloy C36000 Page 13 of 19

Environmental

Category Specific Environment Resistance Level Corrosion notes

Acetylene Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Asphalt Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Benzine Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Benzol Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Butane Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Creosote Good Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Crude Oil Fair Careful consideration must be given to specific contaminants when selecting materials for this complex environment

Freon Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Hydrocarbon Fuel Oil Good Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Gasoline Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Hydrocarbons, Pure Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Kerosene Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Natural Gas Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Paraffin Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Propane Excellent Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Tar Not Recommended Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Turpentine Good Contaminants such as water, sulfides, acids and various organic compounds can increase corrosion significantly

Boric Acid Good Susceptible to dezincification.

Carbolic Acid Good Susceptible to dezincification.

Hydrobromic Acid Poor Susceptible to dezincification.

Hydrochloric Acid Poor Susceptible to dezincification.

Inorg. acid non-ox. Hydrocyanic Acid Poor Reduced corrosion resistance due to soluble complex ion formation

Hydrofluoric Acid Poor Susceptible to dezincification.

Hydrofluosilicic Acid Poor Susceptible to dezincification.

Phosphoric Acid Poor Susceptible to dezincification.

Sulfuric Acid Poor Not suitable for hot concentrated solutions

Chromic Acid Poor Severe oxidizing environment.

Inorg. acid ox. Nitric Acid Poor Severe oxidizing environment.

Sulfurous Acid Poor Susceptible to dezincification.

Liquid metal Mercury Poor Severe liquid metal embrittlement

Alloy C36000 Page 14 of 19

Environmental

Category Specific Environment Resistance Level Corrosion notes

Glue Good Low corrosion rates, no localized attack

Linseed Oil Good Low corrosion rates, no localized attack

Rosin Excellent Low corrosion rates, no localized attack

Miscellaneous

Sewage Fair Susceptible to dezincification.

Soap Solutions Good Dezincification may occur.

Varnish Excellent Low corrosion rates, no localized attack

Alum Poor

Alumina Excellent Low corrosion rates, no localized attack

Aluminum Chloride Poor Severe dezincification

Aluminum Sulfate Poor Susceptible to dezincification.

Ammonium Chloride Poor Reduced corrosion resistance due to soluble complex ion formation

Ammonium Sulfate Poor Reduced corrosion resistance due to soluble complex ion formation

Barium Chloride Poor Severe dezincification

Barium Sulfate Excellent Low corrosion rates, no localized attack

Barium Sulfide Good Corrosion affected by salt concentration, temperature, velocity, dissolved oxygen content and pollutants.

Calcium Chloride Poor Severe dezincification

Carbon Disulfide Excellent Corrosion affected by salt concentration, temperature, velocity, dissolved oxygen content and pollutants.

Magnesium Chloride Poor Severe dezincification

Magnesium Sulfate Fair Susceptible to dezincification.

Neutral/acid salt

Potassium Chloride Poor Severe dezincification

Potassium Cyanide Poor Reduced corrosion resistance due to soluble complex ion formation

Potassium Dichromate Acid Poor Highly oxidizing under acidic conditions

Potassium Sulfate Good Susceptible to dezincification.

Sodium Bisulfate Poor Severe dezincification

Sodium Chloride Poor Severe dezincification

Sodium Cyanide Poor Low corrosion rates, no localized attack

Sodium Dichromate, Acid Poor Highly oxidizing under acidic conditions

Sodium Sulfate Good Susceptible to dezincification.

Sodium Sulfite Poor Severe dezincification

Sodium Thiosulfate Good Corrosion affected by salt concentration, temperature, velocity, dissolved oxygen content and pollutants.

Zinc Chloride Poor Severe dezincification

Zinc Sulfate Poor Severe dezincification

Alloy C36000 Page 15 of 19

Environmental

Category Specific Environment Resistance Level Corrosion notes

Acetone Excellent Resistant up to 200F unless contaminated by water, acids, alkalies or salts

Alcohols Excellent Resistant up to 200F unless contaminated by water, acids, alkalies or salts

Amyl Acetate Good

Amyl Alcohol Excellent

Butyl Alcohol Excellent Resistant up to 200F unless contaminated by water, acids, alkalies or salts

Org. solvent Ethers Excellent Resistant up to 200F unless contaminated by water, acids, alkalies or salts

Ethyl Acetate Good

Ethyl Alcohol Excellent Resistant up to 200F unless contaminated by water, acids, alkalies or salts

Lacquer Solvents Excellent Resistant up to 200F unless contaminated by water, acids, alkalies or salts

Methyl Alcohol Excellent

Toluene Excellent Resistant up to 200F unless contaminated by water, acids, alkalies or salts

Acetic Acid Poor Susceptible to dezincification.

Acetic Anhydride Poor Susceptible to dezincification.

Benzoic Acid Good Susceptible to dezincification.

Butyric Acid Fair Susceptible to dezincification.

Chloracetic Acid Poor Susceptible to dezincification.

Citric Acid Fair Susceptible to dezincification.

Organic acid

Formic Acid Fair Susceptible to dezincification.

Lactic Acid Fair Susceptible to dezincification.

Oxalic Acid Fair Susceptible to dezincification.

Tannic Acid Good Susceptible to dezincification.

Tartaric Acid Fair Susceptible to dezincification.

Trichloracetic Acid Poor Susceptible to dezincification.

Aniline Fair Stree corrosion cracking possible.

Aniline Dyes Fair Stree corrosion cracking possible.

Castor Oil Excellent Low corrosion rates, no localized attack

Ethylene Glycol Good Dezincification may occur.

Organic comp. Formaldehyde Fair Dezincification may occur.

Furfural Fair Dezincification may occur.

Glucose Excellent Low corrosion rates, no localized attack

Glycerine Excellent Low corrosion rates, no localized attack

Lacquers Excellent Low corrosion rates, no localized attack

Alloy C36000 Page 16 of 19

Environmental

Category Specific Environment Resistance Level Corrosion notes

Ammonium Nitrate Poor Reduced corrosion resistance due to soluble complex ion formation

Bleaching Powder, Wet Poor Severe dezincification

Borax Excellent Low corrosion rates, no localized attack

Bordeaux Mixture Good Susceptible to dezincification.

Calcium Bisulfite Poor Severe dezincification

Calcium Hypochlorite Poor Severe dezincification

Copper Chloride Poor Severe oxidizing environment.

Copper Nitrate Poor Severe dezincification

Copper Sulfate Poor Severe dezincification

Ferric Chloride Poor Severe oxidizing environment.

Ferric Sulfate Poor Severe oxidizing environment.

Oxidizing salt

Ferrous Chloride Poor Severe dezincification

Ferrous Sulfate Poor Severe dezincification

Hydrogen Peroxide Fair Susceptible to dezincification.

Mercury Salts Poor May cause liquid metal embrittlement

Potassium Chromate Excellent Suitable for neutral or alkaline conditions

Silver Salts Poor Noble metal salt, plates on copper surface

Sodium Bisulfite Poor Susceptible to dezincification.

Sodium Chromate Excellent Suitable for neutral or alkaline conditions

Sodium Hypochlorite Poor Severe dezincification

Sodium Nitrate Fair Susceptible to dezincification.

Sodium Peroxide Poor Susceptible to dezincification.

Hydrogen Sulfide, Dry Excellent Corrosion increases with trace of moisture

Hydrogen Sulfide, Moist Fair More corrosion resistant in dry gas

Sulfur Chloride, Dry Excellent Rapid corrosion increases with traces of moisture

Sulfur Dioxide, Dry Excellent Scaling at elevated temperatures

Sulfur comp.

Sulfur Dioxide, Moist Poor Mixed oxide and sulfide scale forms

Sulfur Trioxide, Dry Excellent Corrosion increases with trace of moisture

Sulfur, Dry Excellent Corrosion rate increases at elevated temperatures

Sulfur, Molten Poor Forms non-protective copper sulfide

Alloy C36000 Page 17 of 19

Environmental

Category Specific Environment Resistance Level Corrosion notes

Increased corrosion with oxidizers, e.g. oxygen (air), chlorine, hypochlorites and ferric ions. Susceptible to dezincification with nitrates, sulfates, chlorides.

Brines Poor

Refer to specific salt solution rat

Mine Water Poor Acidic waters containing oxidizers are highly corrosive.

Water

Sea Water Fair Corrosion affected by salt concentration, temperature, velocity, dissolved oxygen content and pollutants. Dezincification may occur.

Steam Fair Dezincification may occur.

Water, Potable Fair Corrosion affected by water chemistry (mineral content, acidity) system design and fabrication. Dezincification may occur.

Alloy C36000 Page 18 of 19

Alloy C36000 Page 19 of 19

You might also like

- Chemical Composition: Copper Alloy DataDocument22 pagesChemical Composition: Copper Alloy Datajose_ruben_64No ratings yet

- C12200 AlloyDocument26 pagesC12200 AlloyviniciusschwabNo ratings yet

- Copper Alloy C26800Document13 pagesCopper Alloy C26800fernandoincesaNo ratings yet

- Capsun (Radial Thru-Hole) SL4 SeriesDocument2 pagesCapsun (Radial Thru-Hole) SL4 Serieshes545No ratings yet

- ASTM F1554: Supplementary TestingDocument4 pagesASTM F1554: Supplementary TestingSamsuNo ratings yet

- Copper Alloy Data for Heat ExchangersDocument9 pagesCopper Alloy Data for Heat ExchangersNut AssanaiNo ratings yet

- CS 60001 72401 LA FERTE BERNARD cedex France CuZn40Al2 HR3 Alloy Data SheetDocument1 pageCS 60001 72401 LA FERTE BERNARD cedex France CuZn40Al2 HR3 Alloy Data SheetEminent RishNo ratings yet

- Common Mode Filters: For General Signal Line/power LineDocument3 pagesCommon Mode Filters: For General Signal Line/power LineJozefNo ratings yet

- Capsun (SMD) VEN SeriesDocument2 pagesCapsun (SMD) VEN Serieshes545No ratings yet

- Heco Product Sheet 6302 DIN 11864 DIN 11853 Flange Connections Aseptic DIN 11864 2 O RingsDocument2 pagesHeco Product Sheet 6302 DIN 11864 DIN 11853 Flange Connections Aseptic DIN 11864 2 O RingsUroš ČampragNo ratings yet

- Capxon: Conductive Polymer Aluminum Solid CapacitorDocument40 pagesCapxon: Conductive Polymer Aluminum Solid CapacitorDz CapssoulaNo ratings yet

- Aluminum Electrolytic Capacitors Radial Lead Type ADocument12 pagesAluminum Electrolytic Capacitors Radial Lead Type AYaraNo ratings yet

- FHP Pressure FiltersDocument10 pagesFHP Pressure Filtersfrancis_15in100% (1)

- Material Comparison Aisi 1006, SWRM6, Swch18a, Swch22aDocument1 pageMaterial Comparison Aisi 1006, SWRM6, Swch18a, Swch22aCahyo ArdoyoNo ratings yet

- HCGF5ASERIESDocument3 pagesHCGF5ASERIESPalmNo ratings yet

- A302 Grade B Steel Plate Specs and Mechanical PropertiesDocument2 pagesA302 Grade B Steel Plate Specs and Mechanical PropertiesOwais Manzoor MalikNo ratings yet

- SCK05052LDocument19 pagesSCK05052Lcasa1233333No ratings yet

- Tugas Membrane - PGBDocument17 pagesTugas Membrane - PGBRika Budi NoviawatiNo ratings yet

- RGB LED Diode Technical Data SheetDocument8 pagesRGB LED Diode Technical Data SheetEko SutjiptoNo ratings yet

- Asme PTC 25-2014Document6 pagesAsme PTC 25-2014euisNo ratings yet

- SKD11, D2, SKH59, M42Document2 pagesSKD11, D2, SKH59, M42QA LAB ISMNo ratings yet

- CB-8391 CBND Technical Data - Specifications PDFDocument43 pagesCB-8391 CBND Technical Data - Specifications PDFcoyuncoNo ratings yet

- Copper Alloy C95200Document11 pagesCopper Alloy C95200Lin DouaiNo ratings yet

- Direct Mount IGBT Snubber Capacitor Modules for High dV/dt ApplicationsDocument4 pagesDirect Mount IGBT Snubber Capacitor Modules for High dV/dt ApplicationsYoughorta TirNo ratings yet

- Data CIDocument1 pageData CIMajdi JerbiNo ratings yet

- Pulse Transformers/SMD Type: Features Shapes and DimensionsDocument3 pagesPulse Transformers/SMD Type: Features Shapes and DimensionsRajan RajpootNo ratings yet

- Outokumpu Machining Guidelines For Forta DX2205Document2 pagesOutokumpu Machining Guidelines For Forta DX2205chavico113No ratings yet

- Acon (Radial Thru-Hole) LKF SeriesDocument1 pageAcon (Radial Thru-Hole) LKF Seriesser4595No ratings yet

- AbcDocument2 pagesAbcsurendarNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Raj RajeshNo ratings yet

- 12.SD QMS Qa 12 (R5) Tech - SpecDocument2 pages12.SD QMS Qa 12 (R5) Tech - Specindah dwi wahyuniNo ratings yet

- Jis C3771Document2 pagesJis C3771bkprodhNo ratings yet

- Datasheet Sandvik Saf 2205 en PDFDocument12 pagesDatasheet Sandvik Saf 2205 en PDFYuriy NesterovNo ratings yet

- PP - Sasol - HKR 102Document2 pagesPP - Sasol - HKR 102Luis ArciaNo ratings yet

- Diaphragm Pressure SwitchesDocument2 pagesDiaphragm Pressure SwitchesUssamaNo ratings yet

- Duplex Filters Max. 200 L/min. 40 Bar: Cast Iron Duplex Filter For Marine ApplicationsDocument4 pagesDuplex Filters Max. 200 L/min. 40 Bar: Cast Iron Duplex Filter For Marine ApplicationshidagamersNo ratings yet

- Acon (Radial Thru-Hole) NF SeriesDocument1 pageAcon (Radial Thru-Hole) NF Seriesser4595No ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- Loctite HF 212Document3 pagesLoctite HF 212Mahir AlsadiNo ratings yet

- 1050 Data Sheet: Chemical CompositionDocument1 page1050 Data Sheet: Chemical CompositionMiguel Angel Rocca HuaytaNo ratings yet

- FMP PereesureDocument10 pagesFMP Pereesuremohsen alvaniNo ratings yet

- FO Connector Catalogue-2009 - LX.5 PDFDocument104 pagesFO Connector Catalogue-2009 - LX.5 PDFMaster22No ratings yet

- Arcanol Technical Datasheet Load LubricantDocument5 pagesArcanol Technical Datasheet Load LubricantJoan HoyosNo ratings yet

- Raffmetal: UNI EN 1676 and 1706Document2 pagesRaffmetal: UNI EN 1676 and 1706Jonathan Getial CruzNo ratings yet

- Commercial-Purity Aluminium1050Document1 pageCommercial-Purity Aluminium1050SiyabulelaNo ratings yet

- Non Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% MinimumDocument1 pageNon Heat Treatable Commercial-Purity Aluminium 1050 A: Chemical Composition Limits (In %) Aluminium 99,5% Minimumprivate 2No ratings yet

- Commercial Purity Aluminium1050Document1 pageCommercial Purity Aluminium1050HermanNo ratings yet

- Capsun (Radial Thru-Hole) SPF SeriesDocument2 pagesCapsun (Radial Thru-Hole) SPF Serieshes545No ratings yet

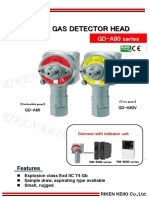

- Riken Gas Detector Head: GD-A80 SeriesDocument2 pagesRiken Gas Detector Head: GD-A80 SerieswahyunurrizkyNo ratings yet

- Capsun (SMD) VWC SeriesDocument2 pagesCapsun (SMD) VWC Serieshes545No ratings yet

- Series 2000: Hercules EncodersDocument2 pagesSeries 2000: Hercules EncodersJose Abdel Rujana MontealegreNo ratings yet

- ZPD & ZRD Copeland Scroll Digital Compressor Range For R410A and R407CDocument3 pagesZPD & ZRD Copeland Scroll Digital Compressor Range For R410A and R407CmilivojNo ratings yet

- Acon (Radial Thru-Hole) LF SeriesDocument1 pageAcon (Radial Thru-Hole) LF Seriesxyz99No ratings yet

- HSS Taps PDFDocument26 pagesHSS Taps PDFRavipawarNo ratings yet

- SCK SeriesDocument17 pagesSCK SeriestahirianNo ratings yet

- NIC Components NACL SeriesDocument3 pagesNIC Components NACL SeriesNICCompNo ratings yet

- Portable X-Ray Flaw DetectorDocument16 pagesPortable X-Ray Flaw Detectorhunggul amelNo ratings yet

- Moly WhiteDocument1 pageMoly WhiteLuis EduardoNo ratings yet

- Chemistry Folio Form 4Document14 pagesChemistry Folio Form 4navinaNo ratings yet

- A. BRFDocument14 pagesA. BRFIrish MercadoNo ratings yet

- Maintenance-Free Design 8DABDocument5 pagesMaintenance-Free Design 8DABrjk941-1No ratings yet

- Philippines Clean Air Act of 1999Document29 pagesPhilippines Clean Air Act of 1999mcdale100% (4)

- KMT plans to re-treat tailings for copper and cobalt recoveryDocument70 pagesKMT plans to re-treat tailings for copper and cobalt recoveryKazem MirjaliliNo ratings yet

- Wet MillingDocument9 pagesWet MillingMinh VõNo ratings yet

- GI-700 Brochure en HRE-2883ADocument4 pagesGI-700 Brochure en HRE-2883APustinjak SaharicNo ratings yet

- Cse18 Rscarchive 2016 6Document23 pagesCse18 Rscarchive 2016 6Harwinder Singh KhanguraNo ratings yet

- Grade 9 Chemistry PT 2 Paper 2Document7 pagesGrade 9 Chemistry PT 2 Paper 2Naisha ParekhNo ratings yet

- Computation of Equilibria in Models of Flue Gas Washer Plants (Desch, W Et Al.)Document9 pagesComputation of Equilibria in Models of Flue Gas Washer Plants (Desch, W Et Al.)jesus_manrique2753No ratings yet

- HAZ-SCANNER™ Model HIM-6000: Hazardous Incident Air Quality Monitoring SystemDocument3 pagesHAZ-SCANNER™ Model HIM-6000: Hazardous Incident Air Quality Monitoring SystemJonathanNo ratings yet

- Sulfinol PDFDocument25 pagesSulfinol PDFcandra_zakaria4416No ratings yet

- Reductive Pyrolysis Study of Sulfur Compounds in Different Tabas Coal Samples (Iran)Document7 pagesReductive Pyrolysis Study of Sulfur Compounds in Different Tabas Coal Samples (Iran)DadanNo ratings yet

- Towards Partial Fulfillment of The Requirements For TheDocument28 pagesTowards Partial Fulfillment of The Requirements For TheShivamPandeyNo ratings yet

- Catalyst RegenerationDocument57 pagesCatalyst RegenerationSyed Abdul RehmanNo ratings yet

- Gas Insulated Substation Control and MonitoringDocument33 pagesGas Insulated Substation Control and MonitoringMaharajaNo ratings yet

- Sulphuric Acid AceDocument2 pagesSulphuric Acid AceLam Wen HongNo ratings yet

- Anorganic Chemistry: You Want To Gain The "Prize", The B. EngDocument44 pagesAnorganic Chemistry: You Want To Gain The "Prize", The B. EngArinaNo ratings yet

- 10Document13 pages10Henry TangNo ratings yet

- Met Wet FGD PaperDocument19 pagesMet Wet FGD Paperopenid_ZrfbXb06No ratings yet

- Treatment of Air Pollutants and Control MethodsDocument17 pagesTreatment of Air Pollutants and Control MethodsWonda 005No ratings yet

- NP Coaxial Pulsed Corona DischargeDocument5 pagesNP Coaxial Pulsed Corona DischargeKin Wai CheahNo ratings yet

- Types of PollutionDocument5 pagesTypes of PollutionShah JeeNo ratings yet

- Uses of Sulphuric Acid: SulphurDocument6 pagesUses of Sulphuric Acid: SulphurHumphrey JinuinNo ratings yet

- So2b4 11 13Document2 pagesSo2b4 11 13Omar SaaedNo ratings yet

- Top 10 World'S Air Polluted Countries: 1-ChinaDocument5 pagesTop 10 World'S Air Polluted Countries: 1-ChinaPRINTDESK by DanNo ratings yet

- Project Report On Oleum: Guided By: Yamini S. PatelDocument51 pagesProject Report On Oleum: Guided By: Yamini S. PatelPatel RajNo ratings yet

- Sulphur Burning and The Formation of So3Document16 pagesSulphur Burning and The Formation of So3rubcarvNo ratings yet

- Free Radical ChlorinationDocument3 pagesFree Radical ChlorinationShailesh GhediyaNo ratings yet

- C9 Enthalpy PowerpointDocument135 pagesC9 Enthalpy PowerpointHanaa KhaldiNo ratings yet