Professional Documents

Culture Documents

Risk Assmeeint Cable Pulling

Uploaded by

noorOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assmeeint Cable Pulling

Uploaded by

noorCopyright:

Available Formats

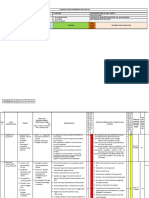

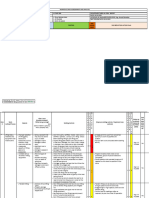

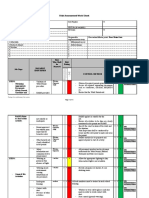

RISK ASSESSMENT AND ANALYSIS

Risk Assessment (Baseline and full RA)

WORKPLACE/TASK/ACTIVITY/PROCESS NAME: MSF BUILDING - UNIT NO. DEPARTMENT/AREA: HFO TANK AREA - STAGE -1/ Desal 5

RA Number: REV. 0 DATE:

RA TEAM(Names) 1. APPROVED BY Manager / Supervisor:

2.

3. NEXT REVIEW DATE:

HAZARD IDENTIFICATION CONTROL RISK ASSESSMENT RISK REDUCTION ACTION PLAN

C C

L L

o o

i i

n R n R

k k

Risks Issue s a s a

(Possible incident) e R e R Follow up by Controls

e n e n

Item Workplace/ [What can go wrong] l i (Improve existing controls / implement new l i Whom (name) Implem

Hazards Existing Controls q k q k

# Activity/Process i s controls) i s & By When ented

u i u i

(Accident/ill health to persons, h k h k (date) Yes/No

fire or property loss) e n e n

o o

n g n g

o o

c c

d d

e e

1. USING PROPER METHOD TO AVOID ANY INJURY,

2. TBT TALK, TRANING ,, GOOD COMMUNICATION,

USING PROPER TOOLS

3- Awareness of maximum permitted cable pulling

tensions and minimum bending radii.

1. NECK SYNDROME 4-Sufficient numbers of well supervised operatives

2.PHYSICAL INJURY 1. PPE - ,TRANING ,, GOOD to share the manual handling and include training

Cable Pulling(Manual

2 Rotator Cuff Tendonitis 3-Injury from Contact with COMMUNICATION,RESPIRATORY PROTECTION; 3 3 9 in suitable techniques when the method statement 3 1 3 JOB SUPERVISOR YES

Handling) Winches, Pulleys and Cable GLOVES is explained. 5-

Suitably maintained drum roller frames, jacks,

rollers and operatives controlled to ensure hands

are clear when cable is moving.

6 • One person designated to control the pull to

ensure all cable pullers are working as a team and

share the load.

You might also like

- 27.2 RISK ASSESSMENT and Analysis Cable Tray InstallationDocument3 pages27.2 RISK ASSESSMENT and Analysis Cable Tray InstallationsalmanNo ratings yet

- Growing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyFrom EverandGrowing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyNo ratings yet

- 10 ManliftDocument3 pages10 ManliftBalongNo ratings yet

- 5 CraneDocument3 pages5 CraneBalongNo ratings yet

- Risk Assessment Access Ladder, Cable Rack&PaintingDocument3 pagesRisk Assessment Access Ladder, Cable Rack&PaintingsalmanNo ratings yet

- 5-Star Safety and Health Management System: Risk RegisterDocument3 pages5-Star Safety and Health Management System: Risk RegistersalmanNo ratings yet

- Hazard Identification Control Risk Assessment Risk Reduction Action PlanDocument4 pagesHazard Identification Control Risk Assessment Risk Reduction Action PlannoorNo ratings yet

- Energy Isolation High Voltage Electricity Work at Height Floor/Handrail Removal Confined Space Hot Work Excavation/Penetration Lifting/CraneageDocument4 pagesEnergy Isolation High Voltage Electricity Work at Height Floor/Handrail Removal Confined Space Hot Work Excavation/Penetration Lifting/CraneageJoanne Marie LagusNo ratings yet

- Failure Mode Effect of Failure Cause of Failure Cause Prevention Severity Ranking Occurrence Ranking Detection Ranking Risk Priority Number (RPN)Document7 pagesFailure Mode Effect of Failure Cause of Failure Cause Prevention Severity Ranking Occurrence Ranking Detection Ranking Risk Priority Number (RPN)Arvind SharmaNo ratings yet

- Fmea 2017Document2 pagesFmea 2017GoKart 2017No ratings yet

- Risk Assessment (2.8) - Ra For Substation - Latest For Final Jizan City-2Document266 pagesRisk Assessment (2.8) - Ra For Substation - Latest For Final Jizan City-2Shah MuzzamilNo ratings yet

- HIRA 4r Utility Identification CMRL 09.05.17Document3 pagesHIRA 4r Utility Identification CMRL 09.05.17mahesh naikNo ratings yet

- Hazard Identification, Risk Assessment and Determining Control AnalysisDocument6 pagesHazard Identification, Risk Assessment and Determining Control AnalysisKhaty JahNo ratings yet

- Retaining Wall Construction WorkDocument12 pagesRetaining Wall Construction WorkRohit Singh90% (10)

- Amef Marcha de Un Número NissanDocument1 pageAmef Marcha de Un Número NissanTom WilberNo ratings yet

- Amef Nissan MarchDocument1 pageAmef Nissan MarchTom WilberNo ratings yet

- AMEF - Bomba Ensival de Efluentes de PWADocument1 pageAMEF - Bomba Ensival de Efluentes de PWATom WilberNo ratings yet

- Noteshub - Co.In - Download Android App: Scanned by CamscannerDocument32 pagesNoteshub - Co.In - Download Android App: Scanned by CamscannerAccidental AceNo ratings yet

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Document4 pagesStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderNo ratings yet

- Risk Assessment For BorescopeDocument14 pagesRisk Assessment For BorescopeJayson Escamillan100% (1)

- Risk Assessment And Analysis/رطاخﻤلا م يقﺗDocument3 pagesRisk Assessment And Analysis/رطاخﻤلا م يقﺗNaveen GladsonNo ratings yet

- AMEF REDUCTOR FALK 21620 - Wilbert PeraltaDocument1 pageAMEF REDUCTOR FALK 21620 - Wilbert PeraltaTom WilberNo ratings yet

- Collate CS Unit-1 Notes PDFDocument33 pagesCollate CS Unit-1 Notes PDFApoorvNo ratings yet

- FMEA WorksheetDocument3 pagesFMEA WorksheetrlwersalNo ratings yet

- Failure Mode and Effects Analysis: (Project FMEA)Document2 pagesFailure Mode and Effects Analysis: (Project FMEA)Akaristide AristideNo ratings yet

- User Experience Process: ScopeDocument1 pageUser Experience Process: ScopeThottempudi uday tejaNo ratings yet

- Air Conditioning Unit SystemDocument11 pagesAir Conditioning Unit SystemZubair Ahmed KhaskheliNo ratings yet

- Template Process FMEADocument1 pageTemplate Process FMEABittuNo ratings yet

- Task Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Faizan ShabbirNo ratings yet

- MBCC-1140-TS-MS-031 FOR Gypsum False CeilingDocument10 pagesMBCC-1140-TS-MS-031 FOR Gypsum False Ceilinglarrypanlican411No ratings yet

- 6-Transformer Installation PDFDocument3 pages6-Transformer Installation PDFAhmed ZaiNo ratings yet

- RUP Roles and Responsibilities MatrixDocument3 pagesRUP Roles and Responsibilities MatrixLuis RochollNo ratings yet

- Risk SummaryDocument3 pagesRisk SummaryHan Htun OoNo ratings yet

- Risk SummaryDocument3 pagesRisk SummaryHan Htun OoNo ratings yet

- Failure Mode and Effects Analysis: (Design FMEA)Document1 pageFailure Mode and Effects Analysis: (Design FMEA)AbhishekChowdhuryNo ratings yet

- Template Quarterly KRADocument5 pagesTemplate Quarterly KRASuba SriramNo ratings yet

- HARCDocument8 pagesHARCYaqoob IbrahimNo ratings yet

- BIRT: The Eclipse Reporting Framework: Krishna VenkatramanDocument22 pagesBIRT: The Eclipse Reporting Framework: Krishna VenkatramancasabalanNo ratings yet

- Birt The Eclipse Reporting FrameworkDocument22 pagesBirt The Eclipse Reporting FrameworkAditya BhuyanNo ratings yet

- Design Fmea Sae j1739Document1 pageDesign Fmea Sae j1739Tarek SanNo ratings yet

- UntitledDocument16 pagesUntitledvishnu jNo ratings yet

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Document4 pagesMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaNo ratings yet

- Meenakshi Molding Private Limited Process FMEA: O C C U RDocument4 pagesMeenakshi Molding Private Limited Process FMEA: O C C U Rilaya raja100% (1)

- Gantry Crane Installation 2Document6 pagesGantry Crane Installation 2angelaNo ratings yet

- New Doc 2018-03-15Document6 pagesNew Doc 2018-03-15Syed Anas SohailNo ratings yet

- 5-Pole Erection & Stringing PDFDocument2 pages5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- RUP Roles and Responsibilities MatrixDocument3 pagesRUP Roles and Responsibilities MatrixSantosh Rajvanshi100% (1)

- API RP 585 Pressure Equipment Integrity Incident InvestigationDocument43 pagesAPI RP 585 Pressure Equipment Integrity Incident InvestigationKYAW100% (1)

- System & Equipment Reliability Prioritization (SERP)Document2 pagesSystem & Equipment Reliability Prioritization (SERP)nasrunNo ratings yet

- Img 20220523 0001Document1 pageImg 20220523 0001Christian PorlucasNo ratings yet

- Risk Assessment - Rebar Shifting Using BHDocument4 pagesRisk Assessment - Rebar Shifting Using BHLeoniv Arviz LiboroNo ratings yet

- D80149GC11 sg1 PDFDocument340 pagesD80149GC11 sg1 PDFNestor Torres PachecoNo ratings yet

- AIAG - Failure Mode and Effects Analysis (FMEA) Reference Manual - 3ed, 2001 (95, 93)Document88 pagesAIAG - Failure Mode and Effects Analysis (FMEA) Reference Manual - 3ed, 2001 (95, 93)Luis Gustavo PachecoNo ratings yet

- FMEADocument88 pagesFMEAapi-26802090100% (3)

- Workshop Layout/Bookkeeping NC Iii: Bulletin BoardDocument1 pageWorkshop Layout/Bookkeeping NC Iii: Bulletin BoardKyah PengNo ratings yet

- Ch4-Multiple Radio AccessDocument60 pagesCh4-Multiple Radio AccessAmal AlhamadNo ratings yet

- Potential of A Production DI Two-Stroke Engine Adapted For Range Extender and Motorcycle ApplicationsDocument24 pagesPotential of A Production DI Two-Stroke Engine Adapted For Range Extender and Motorcycle ApplicationsManuelLentiNo ratings yet

- Part Catalogo RMZ250Document67 pagesPart Catalogo RMZ250jesus moralesNo ratings yet

- Banasthali Vidyapith: Bachelor of Arts and Bachelor of LawsDocument172 pagesBanasthali Vidyapith: Bachelor of Arts and Bachelor of Lawssimranrai122002No ratings yet

- 5E Lesson Plan Template: TeacherDocument6 pages5E Lesson Plan Template: Teacherapi-534260240No ratings yet

- Cs Supply ChainDocument7 pagesCs Supply ChainJoy MartinezNo ratings yet

- Likelihood Ratio Tests: Instructor: Songfeng ZhengDocument9 pagesLikelihood Ratio Tests: Instructor: Songfeng ZhengRIZKA FIDYA PERMATASARI 06211940005004No ratings yet

- Lecture 16 - Bernoulli Applications 3Document14 pagesLecture 16 - Bernoulli Applications 3يوسف عادل حسانين100% (1)

- Physiology of LactationDocument5 pagesPhysiology of LactationJosephNo ratings yet

- Practical 9: Enthalpy Change of ReactionDocument4 pagesPractical 9: Enthalpy Change of ReactionJulia QistinaNo ratings yet

- SimNowUsersManual4 6 1Document271 pagesSimNowUsersManual4 6 1MichelleNo ratings yet

- UNIT 2 - LESSON 1 - Overview To Qualitative ResearchDocument31 pagesUNIT 2 - LESSON 1 - Overview To Qualitative ResearchmikkaellaNo ratings yet

- Revised EstimateDocument2 pagesRevised EstimateMd. Abdul HaiNo ratings yet

- Protein MetabolismDocument78 pagesProtein MetabolismU2002862 STUDENTNo ratings yet

- 2011 07 IDIP Unit A Past PaperDocument4 pages2011 07 IDIP Unit A Past Paperfh71No ratings yet

- Ecosystem ScriptDocument7 pagesEcosystem ScriptGeraldine Co TolentinoNo ratings yet

- Lenovo Ideapad V110-15AST - LV114A (15270-1 08A03)Document64 pagesLenovo Ideapad V110-15AST - LV114A (15270-1 08A03)Mahmut KaralarNo ratings yet

- Index of Appendices: Pmo - ConfidentialDocument149 pagesIndex of Appendices: Pmo - Confidentialonize mosesNo ratings yet

- Program Istp17Document17 pagesProgram Istp17pverma4622No ratings yet

- How To Product ManualDocument250 pagesHow To Product ManualAmith M DNo ratings yet

- How Satisfied Are Students of Royal High School With The Lunch Services Offered by The School CanteenDocument5 pagesHow Satisfied Are Students of Royal High School With The Lunch Services Offered by The School CanteenMonique GayleNo ratings yet

- Defence10 BookDocument58 pagesDefence10 BookYash ChanneNo ratings yet

- Grlweap 2005Document3 pagesGrlweap 2005José RuizNo ratings yet

- A&D MGMU End Sem Exam Paper (2022-23) Part-IDocument5 pagesA&D MGMU End Sem Exam Paper (2022-23) Part-IAzar BargirNo ratings yet

- Goat Fattening Rs. 0.85 MillionDocument18 pagesGoat Fattening Rs. 0.85 MillionZakir Ali100% (1)

- How Fractions, Decimals and Percentages Work TogetherDocument9 pagesHow Fractions, Decimals and Percentages Work TogetherjohnteecubeNo ratings yet

- Adenosine Deaminase: Quantitative Determination of Adenosine Deaminase (ADA) in Serum and Plasma SamplesDocument1 pageAdenosine Deaminase: Quantitative Determination of Adenosine Deaminase (ADA) in Serum and Plasma Samplesmark.zac1990No ratings yet

- Electrothermal Industries PDFDocument10 pagesElectrothermal Industries PDFAna Marie AllamNo ratings yet

- VedicReport2 28 202412 53 08PMDocument55 pagesVedicReport2 28 202412 53 08PM처곧ᄉJimmyNo ratings yet

- Fibre Optic Cable SplicingDocument33 pagesFibre Optic Cable SplicingAmax TeckNo ratings yet

- Holmstrom1982 Moral Hazard in TeamsDocument18 pagesHolmstrom1982 Moral Hazard in TeamsfaqeveaNo ratings yet