Professional Documents

Culture Documents

Mix Design - M 20

Uploaded by

Vijay JamadarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mix Design - M 20

Uploaded by

Vijay JamadarCopyright:

Available Formats

PAGE 1 OF 4

MIX DESIGN FOR A CONCRETE OF M-20

1. Design Stipulation

a) Characteristic Compressive Strength required =20

in the field at 28 days (N/mm2)

b) Maximum Size of Aggregate, MSA, mm =20

c) Degree of workability =100+ 20

d) Degree of quality control =Good

e) Type of exposure =Severe

2. Test data for Materials

a) Cement used =CPJ-CEM II_B 32.5

b) Specific Gravity of Cement =2.75

c) Specific Gravity

### Fine Aggregate(Crushed Sand) =2.81

### Coarse Aggregate-I =2.75

### Coarse Aggregate-II =2.78

d) Water Absorption

### Fine Aggregate(Crushed Sand) =3.20

### Coarse Aggregate-I =1.64

### Coarse Aggregate-II =1.22

e) Free Surface Moisture

### Fine Aggregate =---

### Coarse Aggregate-I =---

### Coarse Aggregate-II =---

f) Chemical Admixure =-NA

Specific Gravity of admixure =-NA

g)

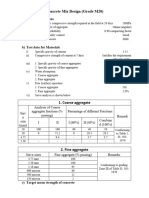

h) Sieve Analysis

###

h) Coarse Aggregate

IS Sieve % Passing % of Different Fraction Remark

size (mm) CA I CA II I ( 45 ) II ( 55) Combined

20 100 89.55 45.00 49.25 94.25 Conforming

10 86.91 0.00 39.11 0.00 39.11 to table-2

4.75 1.99 0.00 0.90 0.00 0.90 of IS.

2.36 0 0.00 0.00 0.00 0.00 383-1970

###

ii) Fine Aggregate(Crushed Sand) PAGE 2 OF 4

IS Sieve % Passing Remarks

size (mm)

20 100.00 Conforming to Gradation

10 100.00 Zone-I of table-4 of

4.75 93.40 IS. 383-1970

2.36 79.50

1.18 56.30

0.600 36.40

0.300 19.10

0.150 7.70

3 Target Mean strength of Concrete

a)

Characteristic Compressive Strength of cubes =20

@ 28 days,fck(N/mm )2

b)

Accepted proportion of low results % =4 (Ref. IS. 10262-2009)

A statistical constant (t) =1.65 (Table-1, Page-2)

c)

control (V.Good=V/Good=G/Fair=F) =Good

Standard Deviation (S) =4.0

d)

Target mean strength of cube =26.60

@ 28 days (f 'ck) = fck + (t x s)

7 days strength of cement (N/mm 2) =

e)

28 days strength of cement (N/mm 2) =

Grade of Cement (A/B/C/D/E/F) =E

4 Selection of Water Cement Ratio

a)

from w/c Vs 28 days Strength graph =0.45

b)

Client Defined = AS per IS

From Table 5 of IS 456,

maximum water-cement

Adopted Water Cement Ratio =0.52

ratio (see Note under

4.1)=0.45.

Adopted Water Cement Ratio =0.52 0.52 < 0.45,hence,O.K.

5 Selection of Water & Coarse Aggregate Content

Nominal Water Coarse (Ref. IS. 10262-2009)

size of Content Aggregate (Table-2, Page-3) for Water Content

aggregate (Ref. IS. 10262-2009)

(mm) (kg) (%) (Table-3, Page-3) for Coarse Aggregate

20 186 60

* Estimated Water Content for 100 + 20 mm slump =186+(6/100*186)

=197.16 litre

a) Hence,the arrived water content =197.16 x 0.85 PAGE 3 OF 4

=167.59 litre

*Required Coarse Aggregate content (%) =62

* =62

For concrete Coarse Aggregate should be

* Fine Aggregate(Crushed Sand) % = 100 - 60

=38

6 Determination of Cement Content

### Water Cement ratio = 0.52

### Water = 167.59

Cement Material = 320

From Table 5 of IS 456,

minimum cement

### contentfor

'SEVERE'exposure

condition =320 kg/m3

a) Cement (100 %) = 320 320 kg/m3 > 320 kg/m3,

hence,O.K.

7 Determination

MIX CALCULATION

of Cementitious Content

a) Volume of concrete = 1 m3

b) Volume of cement = Mass of cement 1

x

Specific gravity of cement 1000

= 320 1

x

2.75 1000

= 0.116 m3

c) Volume of water = Mass of water 1

x

Specific gravity of water 1000

= 167 1

x

1.00 1000

= 0.167 m3

PAGE 4 OF 4

d) Volume of all in aggragate = { a - (b+c) }

= { 1 - (0.116+0.167) }

= 0.717 m3

e) Mass of Fine aggregate = f x vol.of fine aggregate x Sp.gravity of fine aggregate x 1000

= 0.717 x 0.38 x 2.81 x 1000

= 766 kg

f) Mass of coarse aggregate-I = f x vol.of coarse aggregate I x Sp.gravity of coarse aggregate I x 1000

= 0.717 x 0.28 x 2.75 x 1000

= 552 kg

g) Mass of coarse aggregate-I = f x vol.of coarse aggregate II x Sp.gravity of coarse aggregate II x 100

= 0.717 x 0.32 x 2.78 x 1000

= 638 kg

35 Liter farma Size Length 27

Mix Proportion for 1 M 3

Mix Proportion for 1 bag of cement Breadth 27 Cm/ Heighth 48

Cement (kg) =320 Cement (kg) =50 1 bag

Curshed Sand (kg) =766 Curshed Sand (kg) =120 71.43

CA-I (kg) =552 CA-I (kg) =85 58.22

CA-II (kg) =638 CA-II (kg) =99.68 67.35

Water (ltr.) =167 Water (ltr.) =26 26 liter

Water/cement ratio =0.52 Water/cement ratio =0.52

* Actual Slump (mm)

a) 0 min

b) 30 min --

c) 60 min --

d) 120 min --

NOTE :

Aggregates should be used in saturated surface dry condition.If otherwise,when computing the requirement of

mixing water,allowable shall be made for the free(surface)moisture contributed by the fine & coarse aggregates.

egate I x 1000

regate II x 1000

Size Length 27cm/

m/ Heighth 48 cm

1bag

2.041

1.663

1.924

26 liter

You might also like

- Concrete Mix Design Using Crushed SandDocument22 pagesConcrete Mix Design Using Crushed SandOlaolu Olalekan50% (2)

- Design of An Industrial BuildingDocument7 pagesDesign of An Industrial BuildingAbhishek KaushikNo ratings yet

- MNE Consultant engineering services profileDocument15 pagesMNE Consultant engineering services profileDavid PuenNo ratings yet

- List of Materials ConstructionDocument1 pageList of Materials ConstructionMaan GalangNo ratings yet

- How Do Fixed and Pinned Connections Between Piles and Pile Caps Affect The Load Carrying Capacity of PilesDocument1 pageHow Do Fixed and Pinned Connections Between Piles and Pile Caps Affect The Load Carrying Capacity of PilesthakrarhitsNo ratings yet

- Rib Beam 1Document2 pagesRib Beam 1sabahpmNo ratings yet

- Penang Bridge International Marathon 2010 Starting ListDocument1,972 pagesPenang Bridge International Marathon 2010 Starting ListstelzertNo ratings yet

- Sieve Analysis For 20 MMDocument26 pagesSieve Analysis For 20 MMShesha ShayanNo ratings yet

- M40 Mix DesignDocument2 pagesM40 Mix DesignHajarath Prasad Abburu100% (1)

- ACI Mix Design CalculationsDocument5 pagesACI Mix Design CalculationsHaris AlamNo ratings yet

- Mix Designs PFADocument8 pagesMix Designs PFAasif razaNo ratings yet

- Concrete Slabs On GradeDocument4 pagesConcrete Slabs On Grademr.KramNo ratings yet

- Bearing Capacity Estimation from SPT and Settlement CalculationDocument14 pagesBearing Capacity Estimation from SPT and Settlement CalculationmazharNo ratings yet

- ThesisDocument151 pagesThesisRajeshwari NarayanamoorthyNo ratings yet

- Mix DesignDocument6 pagesMix DesignAjinNo ratings yet

- Concrete Pull Out Check PDFDocument1 pageConcrete Pull Out Check PDFMaliki MuhammedNo ratings yet

- Japanese Seismic Design and Construction Practices After the 1995 Kobe EarthquakeDocument11 pagesJapanese Seismic Design and Construction Practices After the 1995 Kobe EarthquakeHelen WangNo ratings yet

- Column Shear DesignDocument2 pagesColumn Shear DesignArnel DodongNo ratings yet

- Tank Design Class Notes 009Document68 pagesTank Design Class Notes 009Abdullah SahlyNo ratings yet

- WLG2445 - Chain Link FenceDocument38 pagesWLG2445 - Chain Link FenceIho1No ratings yet

- CT Lab ManualDocument26 pagesCT Lab ManualJagathChandraNo ratings yet

- Coconut Shell Ash As Partial Replacement of Ordinary Portland Cement in Concrete ProductionDocument4 pagesCoconut Shell Ash As Partial Replacement of Ordinary Portland Cement in Concrete ProductionHumanyx SajaNo ratings yet

- Earth Dam Design and Soil SelectionDocument6 pagesEarth Dam Design and Soil SelectionAngel HasnaNo ratings yet

- Concrete Mix Design ExampleDocument4 pagesConcrete Mix Design ExampleTheke MarkNo ratings yet

- Lab Manual.1pdfDocument31 pagesLab Manual.1pdfAshish KumarNo ratings yet

- Concrete Mix Design and PropertiesDocument8 pagesConcrete Mix Design and PropertiesTomNo ratings yet

- Municipal Wastewater Treatment GuideDocument48 pagesMunicipal Wastewater Treatment GuideMonika AcharyaNo ratings yet

- SDMF Question Paper 1Document2 pagesSDMF Question Paper 1G. SASIDHARA KURUPNo ratings yet

- Sand Cushion: 1. IntroductionDocument2 pagesSand Cushion: 1. Introductionlokesh nandinaNo ratings yet

- PE 13 Slope StabilityDocument12 pagesPE 13 Slope StabilityGreg KeldjianNo ratings yet

- POTENTIAL USES OF WASTE FLY-ASH IN CERAMICS AND CONSTRUCTIONDocument1 pagePOTENTIAL USES OF WASTE FLY-ASH IN CERAMICS AND CONSTRUCTIONPiyushKumarNo ratings yet

- Optimization Workflow for Flat Slab Systems Using Parametric DesignDocument120 pagesOptimization Workflow for Flat Slab Systems Using Parametric DesignKatherine StuartNo ratings yet

- Design of Pinned Base Plate:-: Max Axial Case Max Uplift CaseDocument3 pagesDesign of Pinned Base Plate:-: Max Axial Case Max Uplift CaseYELLAMANDA SANKATINo ratings yet

- Front Elevation Rear Elevation Side Elevation: Reception Table 01Document1 pageFront Elevation Rear Elevation Side Elevation: Reception Table 01Niyati ThakarNo ratings yet

- Considerations For Design of Concrete Structures Subjected To Fatigue LoadingDocument25 pagesConsiderations For Design of Concrete Structures Subjected To Fatigue LoadingMr Polash100% (1)

- Concrete Lab TestsDocument54 pagesConcrete Lab TestsAxumawi Ebuy TekaNo ratings yet

- ACI Method of Mix DesignDocument11 pagesACI Method of Mix DesignCivilax.comNo ratings yet

- Application of Aesthetics in Architecture and Design: Exploring Architecture As An Art FormDocument4 pagesApplication of Aesthetics in Architecture and Design: Exploring Architecture As An Art FormChristdel VivarNo ratings yet

- Mix DesignsDocument1 pageMix DesignssohanpmeharwadeNo ratings yet

- Experiment Atterberg Limits: PurposeDocument8 pagesExperiment Atterberg Limits: PurposefoidsNo ratings yet

- Physical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachDocument8 pagesPhysical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachSEP-PublisherNo ratings yet

- Tests Determine Aggregate PropertiesDocument9 pagesTests Determine Aggregate PropertiesRuthra ManickamNo ratings yet

- Pile Fixity-38Document3 pagesPile Fixity-38Bilal MuhammadNo ratings yet

- Ce 5660: Design of Metal Structures Term Project: Design of A Pipe RackDocument10 pagesCe 5660: Design of Metal Structures Term Project: Design of A Pipe RackFayaz HabeebNo ratings yet

- Floor Slab System PDFDocument34 pagesFloor Slab System PDFNayan MulkiNo ratings yet

- ASD Specification (Volumn 1 Corrigendum)Document0 pagesASD Specification (Volumn 1 Corrigendum)Agnon FungNo ratings yet

- C.T. Lab Manual 2019-20 New1Document52 pagesC.T. Lab Manual 2019-20 New1James DNo ratings yet

- Final Report RC Group 12 Sec 1 - CompressedDocument187 pagesFinal Report RC Group 12 Sec 1 - CompressedAnas Akmal Bin AzharNo ratings yet

- Problem LossesDocument5 pagesProblem LossesArvee GavinoNo ratings yet

- Design of Prestressed Concrete Tank A ReviewDocument3 pagesDesign of Prestressed Concrete Tank A ReviewNada AL-Sabah AlsabahNo ratings yet

- Evaluation of Concrete Chimney With Liner: Stack: BrickDocument12 pagesEvaluation of Concrete Chimney With Liner: Stack: Brickcaojin259No ratings yet

- Runoff Calculations Using Rational MethodDocument17 pagesRunoff Calculations Using Rational MethodManish SinghNo ratings yet

- Ultimate Load Capacity of Circular Hollow Sections Filled With HiDocument266 pagesUltimate Load Capacity of Circular Hollow Sections Filled With Hipatricklim1982No ratings yet

- Carbonation Test PrinciplesDocument16 pagesCarbonation Test Principlesjoechengsh100% (1)

- Concrete Mix Design M25Document9 pagesConcrete Mix Design M25ramkrishnaNo ratings yet

- Concrete Mix DesignDocument6 pagesConcrete Mix DesignWilliamray PabloNo ratings yet

- Concrete Mix Design For MembersDocument27 pagesConcrete Mix Design For MembersTaaNo ratings yet

- 14 - Appendix 1 PDFDocument7 pages14 - Appendix 1 PDFAnonymous qAPTE8REmnNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix Designtangudusrikanth513gmNo ratings yet

- Aggregate Testing ReportDocument16 pagesAggregate Testing ReportVijay JamadarNo ratings yet

- CALCULATION of Concrete and Shuttering FOR THE FOUNDETIONDocument8 pagesCALCULATION of Concrete and Shuttering FOR THE FOUNDETIONVijay JamadarNo ratings yet

- GSM Steel Quantity - XLSX REVISEDDocument6 pagesGSM Steel Quantity - XLSX REVISEDVijay JamadarNo ratings yet

- Test Report No. & DateDocument2 pagesTest Report No. & DateVijay JamadarNo ratings yet

- Land Surveying (Seven-Day Course)Document2 pagesLand Surveying (Seven-Day Course)Vijay JamadarNo ratings yet

- Global Archer Construction and Engineering LLP: P P P P P P P P A A A A A A A ADocument3 pagesGlobal Archer Construction and Engineering LLP: P P P P P P P P A A A A A A A AVijay JamadarNo ratings yet

- GSM Steel Quantity - XLSX REVISEDDocument6 pagesGSM Steel Quantity - XLSX REVISEDVijay JamadarNo ratings yet

- Annex To The CPT Name Quantity Price On GNF: Laboratory Sieve Diameter in MM DN 250Document15 pagesAnnex To The CPT Name Quantity Price On GNF: Laboratory Sieve Diameter in MM DN 250Vijay JamadarNo ratings yet

- Global Archer Construction & Engineering Sarl: GACE Training Syllabus of Lab Schedule and Time TableDocument4 pagesGlobal Archer Construction & Engineering Sarl: GACE Training Syllabus of Lab Schedule and Time TableVijay JamadarNo ratings yet

- Cryogenic Techno Works: Half Cell Potentiometer Test ReportDocument2 pagesCryogenic Techno Works: Half Cell Potentiometer Test ReportVijay JamadarNo ratings yet

- Bar Bending Schedule For Pile: Total Weight: 1021.307 KgsDocument3 pagesBar Bending Schedule For Pile: Total Weight: 1021.307 Kgsdrsmani08100% (1)

- Notification15032013 PDFDocument10 pagesNotification15032013 PDFYuvraj AtholeNo ratings yet

- MODE / TYPE OF INSPECTION FOR STEEL PLATE AND UNDERGROUND TANKDocument3 pagesMODE / TYPE OF INSPECTION FOR STEEL PLATE AND UNDERGROUND TANKVijay JamadarNo ratings yet

- Report On Laboratory and Site Visit 2Document9 pagesReport On Laboratory and Site Visit 2Vijay JamadarNo ratings yet

- Energies 12 01565Document17 pagesEnergies 12 01565Vijay JamadarNo ratings yet

- Cea - Standard Technical Specification For Main Plant Package (2 500 MW)Document1,011 pagesCea - Standard Technical Specification For Main Plant Package (2 500 MW)vasudevapavanNo ratings yet

- Ultrasonic Pulse Velocity Test Report for Muktidham Co. Op Hsg. SocDocument2 pagesUltrasonic Pulse Velocity Test Report for Muktidham Co. Op Hsg. SocVijay JamadarNo ratings yet

- Complete RCC Design Very ImportantDocument41 pagesComplete RCC Design Very ImportantAmal PremachandranNo ratings yet

- Civil Engineers GuideDocument46 pagesCivil Engineers GuideSrinivasan Reddy88% (17)

- Test Pile Loading RecordDocument14 pagesTest Pile Loading RecordCivilax.com100% (1)

- Test Pile Loading RecordDocument14 pagesTest Pile Loading RecordCivilax.com100% (1)

- BuildinginspectionreportformatbyDr I P Sonar PDFDocument15 pagesBuildinginspectionreportformatbyDr I P Sonar PDFDavinder BajajNo ratings yet

- Planned As Per CP R5 Actual Achieved: Daily Progress Report - Berth No. 4Document55 pagesPlanned As Per CP R5 Actual Achieved: Daily Progress Report - Berth No. 4Vijay JamadarNo ratings yet

- Workbook-WPS Office 5Document5 pagesWorkbook-WPS Office 5Vijay JamadarNo ratings yet

- Complete RCC Design Very ImportantDocument41 pagesComplete RCC Design Very ImportantAmal PremachandranNo ratings yet

- Corrections in DrawingDocument2 pagesCorrections in DrawingVijay JamadarNo ratings yet

- Safety ManualDocument180 pagesSafety ManualVijay Jamadar100% (1)

- Safetey Manual: GuineaDocument90 pagesSafetey Manual: GuineaVijay Jamadar100% (1)

- Vol 6.1.137 15 052 3.1 280 Resident Block f3 Proposed Elevations South EastDocument1 pageVol 6.1.137 15 052 3.1 280 Resident Block f3 Proposed Elevations South EastVijay JamadarNo ratings yet

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimNo ratings yet

- Experiment 4 PDFDocument7 pagesExperiment 4 PDFsaiNo ratings yet

- DampingDocument4 pagesDampingMARIA RHODORA BITBITNo ratings yet

- Vibration Analysis Field Balancing 70 MW Gas Turbine RotorDocument46 pagesVibration Analysis Field Balancing 70 MW Gas Turbine Rotori.kamalNo ratings yet

- Surface tension forces induce convection cells in thin liquid filmsDocument12 pagesSurface tension forces induce convection cells in thin liquid filmsChong Jen Haw100% (1)

- EDEXCEL JAN 2020 M1 [ QP + MS ]Document40 pagesEDEXCEL JAN 2020 M1 [ QP + MS ]1234567890 UnknownNo ratings yet

- Report Robot WeldingDocument23 pagesReport Robot WeldingKishan Singh100% (3)

- 1st Floor Slab Design Sample PDFDocument5 pages1st Floor Slab Design Sample PDFSanjeev SanjeevNo ratings yet

- Spectrophotometry FundamentalsDocument15 pagesSpectrophotometry FundamentalschipulinoNo ratings yet

- ES 122 NotesDocument4 pagesES 122 NotesronieNo ratings yet

- Arch348 - Term Project-Central Heating SystemDocument17 pagesArch348 - Term Project-Central Heating Systemmert avlarNo ratings yet

- Guide To ODDocument2 pagesGuide To ODlb_BotsNo ratings yet

- V0l 1-Manual For Structure Part-Doosan STSDocument37 pagesV0l 1-Manual For Structure Part-Doosan STSJohn Milton100% (1)

- Locating and Operating Industrial PlantsDocument2 pagesLocating and Operating Industrial PlantsMartyn PereiraNo ratings yet

- KD-131 Asme Viii Div3Document2 pagesKD-131 Asme Viii Div3comar85No ratings yet

- Differential DistillationDocument8 pagesDifferential DistillationIsuru Lakmuthu MudannayakeNo ratings yet

- Mechanical Engineering PPT of AltafDocument10 pagesMechanical Engineering PPT of AltafAltaf HussainNo ratings yet

- 4140 Final Exam Fa16Document2 pages4140 Final Exam Fa16AdamNo ratings yet

- 4.IJAEST Vol No 6 Issue No 2 Comparision of QUAC and FLAASH Atmospheric Correction Modules On EO 1 Hyperion Data of Sanchi 178 186Document9 pages4.IJAEST Vol No 6 Issue No 2 Comparision of QUAC and FLAASH Atmospheric Correction Modules On EO 1 Hyperion Data of Sanchi 178 186Enver Leoned Melgarejo RomeroNo ratings yet

- Methods For Design & Sability Ug ExcavationDocument67 pagesMethods For Design & Sability Ug Excavationbishal pradhanNo ratings yet

- Astm D87 - 04Document3 pagesAstm D87 - 04mpisjrkkhtoiiqfsuuNo ratings yet

- Design of Stringer (Road Way Bridges)Document10 pagesDesign of Stringer (Road Way Bridges)Karim NasserNo ratings yet

- Clear Air TurbulanceDocument2 pagesClear Air TurbulanceAchmad Arifudin HidayatullohNo ratings yet

- Waves on a String Activity QuestionsDocument11 pagesWaves on a String Activity Questionskaushik247No ratings yet

- Table 1 and 2 Solubility Experiment ResultsDocument3 pagesTable 1 and 2 Solubility Experiment ResultsShara MorialNo ratings yet

- GRE Formula SheetDocument5 pagesGRE Formula SheetHumberto GilmerNo ratings yet

- Design of Steel Structures To EurocodesDocument46 pagesDesign of Steel Structures To EurocodesFlorin VladNo ratings yet

- EVAPORATIONDocument11 pagesEVAPORATIONEmmanuel AtakosNo ratings yet

- Tension Anchors1.3 - Rock BoltsDocument5 pagesTension Anchors1.3 - Rock Boltsibnmessaoud10No ratings yet

![EDEXCEL JAN 2020 M1 [ QP + MS ]](https://imgv2-2-f.scribdassets.com/img/document/719807553/149x198/696dcb63b1/1712183779?v=1)