Professional Documents

Culture Documents

Configurable Dosing Tank Station: Storing and Dosing Liquid Chemicals

Uploaded by

Mostafa RaedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Configurable Dosing Tank Station: Storing and Dosing Liquid Chemicals

Uploaded by

Mostafa RaedCopyright:

Available Formats

grundfos Water Treatment

DTS dosing tank station

Configurable Dosing Tank Station

Storing and dosing liquid chemicals

General • PE or PVC discharge line (10 m)

Dosing is precision work and one of the main tasks • Drain valve

in chemical and process engineering as well as water • Filling armature with ball valve (for all tank sizes) or

treatment. Thus dosing requires precise adjustment of dissolving hopper (from 200 l)

the pump and its accessories to the process parameters of

• Multi-function valve

the respective application. DIGITAL DOSING™ pumps are

delivering an optimal performance in these application • Prepared for the installation of a dosing pump DDA, DDC,

fields. DDE, DMX 221 or DDI 60-10 including necessary assembly

material (connectors, click-plate and screws depending on

As they are easy to install, DTS dosing tank stations are the pump type)

first choice in the matter of economic efficiency when adding

liquids such as coagulants, disinfectants or neutralising Note:

agents to a process in a precise and controlled way. Dosing pumps are not comprised in a standard delivery. They

have to be ordered separately.

DTS dosing tank stations are intended for storing and dosing

liquids. Many different configurations can be selected flexibly Applications

to fulfil various dosing tasks. Due to the use of high-quality • Dosing of biocides and inhibitors into cooling water

materials, DTS dosing tank stations can be employed for • Dosing of lyes and acids for pH regulation

diverse dosing liquids. The selection of materials can be

• Dosing of coagulants, such as ferric(II)chloride or ferric(III)

adapted via the configuration.

chloride, for waste water treatment

Components and features • Dosing of hypochlorite

• Chemically resistant tank made of UV-stabilised, • Dosing of cleaning agents and disinfectants (CIP, cleaning

semitransparent or black polyethylene, machines)

in 6 sizes from 60 to 1000 litres,

with embossed litre scale and PE screw cover

• PE collecting tray

• Handheld mixer or electric stirrer (230 V, 50 Hz) with level

switch for dry-running protection

• Rigid suction lance or foot valve made of PE, with 2-step

level switch for dry-running protection, suction line to the

dosing pump

• PVC or PP injection unit with G 1/2 process connection

Type key

Example DTS 100 T 1 0 3 4 RE E 4 A 1 H

Product type Multi-function valve

DTS Dosing Tank Station A Without

G Multi-function valve PV/V

Tank size H Multi-function valve PV/E

60 60 litres I Multi-function valve PV/T

100 100 litres

200 200 litres Filling device

300 300 litres 0 Without

500 500 litres 1 Filling armature PVC/E with ball valve

1000 1000 litres 2 Dissolving hopper

Tank colour Drain valve (not with collecting tray)

T Transparent A Without

B Black B Drain valve PVC/E

ECM: 1139925

Collecting tray Injection unit (G 1/2 process connection)

0 Without 0 Without

1 Collecting tray 1 Injection unit PVC/V/C

2 Injection unit PP/V/C

Screw cover 3 Injection unit PVC/E/C

95715959 0914

0 Black screw cover without lock 4 Injection unit PP/E/C

5 Injection unit PVC/T/C

Mixer or stirrer

0 Without Discharge line

1 Handheld mixer, PE A Without

2 Electric stirrer, stainless steel B 10 m of PE hose 4/6 mm (up to 7.5 l/h)

3 Electric stirrer, PP, with sealing flange C 10 m of braided PVC hose 6/12 mm (up to 30 l/h)

D 10 m of PE hose 9/12 mm (up to 60 l/h)

The name Grundfos, the Grundfos logo, and be think innovate are registered trademarks owned by Grundfos Holding A/S or Grundfos A/S, Denmark. All rights reserved worldwide.

Preparation for dosing pump E 10 m of PE hose 6/9 mm (up to 30 l/h)

0 Without

1 Preparation for DMX 221 up to 50 l/h Suction line

3 Preparation for DDI 60-10 WO Without

4 Preparation for SMART Digital DDA, DDC, DDE RV Rigid suction lance PE/V

RE Rigid suction lance PE/E

RT Rigid suction lance PE/T

FV Foot valve with flexible suction line PE/V

FE Foot valve with flexible suction line PE/E

FT Foot valve with flexible suction line PE/T

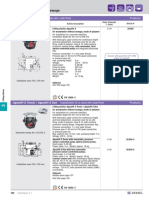

Components overview

9.2

3.2 6 7

9.1

3.1 10 1 Tank

1 2 Collecting tray

4 3.1 Handheld mixer

3.2 Electric stirrer

3.3 Level switch for electric stirrer

2 4 Installation material

5.1 Rigid suction lance with connection

to the pump

5.2

5.2 Foot valve with flexible suction line

5.1

6 Discharge line

7 Injection unit

8 Drain valve

9.1 Filling armature with ball valve

3.3 9.2 Dissolving hopper

10 Multi-function valve

8

GRUNDFOS Holding A/S

Poul Due Jensens Vej 7

DK-8850 Bjerringbro

Tel: +45 87 50 14 00

www.grundfos.com

You might also like

- Configurable Dosing Tank Stations: Storing and Dosing Liquid ChemicalsDocument2 pagesConfigurable Dosing Tank Stations: Storing and Dosing Liquid ChemicalsAgustynho MagimbaNo ratings yet

- Grundfosliterature 5269322Document20 pagesGrundfosliterature 5269322Norbert MeyerNo ratings yet

- Grundfos DSB Dosing Station Data SheetDocument2 pagesGrundfos DSB Dosing Station Data SheetMuhammad Abdurrokhim ANo ratings yet

- Solenoid Valve For Aggressive Fluids, Direct Acting: Type 131Document6 pagesSolenoid Valve For Aggressive Fluids, Direct Acting: Type 131Francisco Mones RuizNo ratings yet

- Ken40 316 PDFDocument1 pageKen40 316 PDFArjun BharambeNo ratings yet

- Dosapack Max: Automatic Powder Reagent Preparation EquipmentDocument2 pagesDosapack Max: Automatic Powder Reagent Preparation EquipmentreinpolyNo ratings yet

- Twin Mac CQ ArcoDocument5 pagesTwin Mac CQ ArcoNitin SeenauthNo ratings yet

- Dyonics 25Document4 pagesDyonics 25api-19808945No ratings yet

- FT Statie Pompare Ape UzateDocument6 pagesFT Statie Pompare Ape UzateDemyGhermanNo ratings yet

- 593Document4 pages593Bijan ChoudhuryNo ratings yet

- Tenant Valve PlusDocument2 pagesTenant Valve Pluspaul coffeyNo ratings yet

- Hobart: Versatility RulesDocument2 pagesHobart: Versatility RulesRicardo PalaciosNo ratings yet

- Tech Sheet Series CDocument2 pagesTech Sheet Series CLalu Adam Akmal IsnenNo ratings yet

- Give Your Family 100% Safe & Tasty WaterDocument2 pagesGive Your Family 100% Safe & Tasty WaterAnupam JadhavNo ratings yet

- Mini Vitaq - 022858Document4 pagesMini Vitaq - 022858Ahmed SalemNo ratings yet

- Saniflo Sanitop Installation GuideDocument9 pagesSaniflo Sanitop Installation GuideSmoKingBuds HD (SKB)No ratings yet

- TOO Catalog File 2022 - 30.10.22Document6 pagesTOO Catalog File 2022 - 30.10.22Hen BenjaminNo ratings yet

- LubrilineDocument20 pagesLubrilinekaniappan sakthivelNo ratings yet

- Filter Press 1200sqft DFP1200Document2 pagesFilter Press 1200sqft DFP1200silroy d'saNo ratings yet

- Industrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesDocument2 pagesIndustrial Grade Sealed Unit: PVC & CPVC Compact Ball ValvesPoro ChanNo ratings yet

- Esytank Eng - 0Document8 pagesEsytank Eng - 0Ajie McNo ratings yet

- Axial Piston Variable Pump A2VKDocument12 pagesAxial Piston Variable Pump A2VKAkbarmoradiNo ratings yet

- 2 - Reflex - Pressure Tank - 300 LitreDocument4 pages2 - Reflex - Pressure Tank - 300 LitreMeenakshisundaram SenthilveluNo ratings yet

- For Wastewater Without Sewage: Lifting StationsDocument2 pagesFor Wastewater Without Sewage: Lifting StationsehsanNo ratings yet

- Diverter Valve Wam BrochureDocument4 pagesDiverter Valve Wam BrochureEzequiel Guillermo Trejo NavasNo ratings yet

- Vtpsewage PDFDocument6 pagesVtpsewage PDFDóriclo FernandesNo ratings yet

- 54450b13e6c55 Dutypoint Dosing Pots DetailsDocument2 pages54450b13e6c55 Dutypoint Dosing Pots DetailsMohammed KhaledNo ratings yet

- Document Control Sheet: MahagencoDocument6 pagesDocument Control Sheet: MahagenconileshwarkeNo ratings yet

- Nitto CatalogoDocument114 pagesNitto Catalogojacerosiete2952No ratings yet

- System - Rated - Plus - W - Sub - 150 Water Hammer PPPDocument2 pagesSystem - Rated - Plus - W - Sub - 150 Water Hammer PPPJeffry GabilanNo ratings yet

- pv212 - Datasheet - Bomba GEDocument4 pagespv212 - Datasheet - Bomba GECesarNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet: Double Seat ValvesDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet: Double Seat Valvesمیلاد قاسمیNo ratings yet

- Hawe Connection Blocks Type B For Hydraulic Power PacksDocument11 pagesHawe Connection Blocks Type B For Hydraulic Power Packsdriss echanchniNo ratings yet

- Hydreco V3A4013 Brochure 2014Document8 pagesHydreco V3A4013 Brochure 2014Montes JorgeNo ratings yet

- MTC 1000 SpecDocument2 pagesMTC 1000 SpecJuan José Tovar PérezNo ratings yet

- Dosing PumpDocument2 pagesDosing PumpElectrical JKFMNo ratings yet

- HPLC User Maintenance and TroubleshootingDocument49 pagesHPLC User Maintenance and TroubleshootingFelipe AndrinoNo ratings yet

- Product Data Sheet Damcos Local Power Unit Double en 60572Document12 pagesProduct Data Sheet Damcos Local Power Unit Double en 60572yongmin seoNo ratings yet

- Model 2-Way, Direct-Acting, Solenoid-Operated Directional Blocking Poppet Valve (740 Series)Document3 pagesModel 2-Way, Direct-Acting, Solenoid-Operated Directional Blocking Poppet Valve (740 Series)Anurag JainNo ratings yet

- Chem Dosing SystemsDocument12 pagesChem Dosing Systemshemanta_12No ratings yet

- HDU 27 Product SheetDocument6 pagesHDU 27 Product SheetHazim SofianNo ratings yet

- Tap Water Reverse Osmosis Systems For Small Flow: 100 L/H 200 L/HDocument3 pagesTap Water Reverse Osmosis Systems For Small Flow: 100 L/H 200 L/HalexandraNo ratings yet

- Alfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletDocument7 pagesAlfa Laval Unique Mixproof Tank Outlet Valve Unique To Product LeafletAnonymous KdnOsd9No ratings yet

- TanksDocument6 pagesTankslokeshNo ratings yet

- R DCP P TDSDocument1 pageR DCP P TDSemanuel775No ratings yet

- Final Besgo PL 2022 - English PDFDocument16 pagesFinal Besgo PL 2022 - English PDFBla BleNo ratings yet

- KUBOTACI CatalogueDocument56 pagesKUBOTACI CatalogueLong Luong HoangNo ratings yet

- Cartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMDocument2 pagesCartridge Filters: Rugged, Low-Cost Cartridge Design For Flow Rates To 100 GPMJulio Enrique Oliver CuelloNo ratings yet

- Technical SHEET 15349/000/04NL 1 Sbo14 Universal Machine: SSO 14 #11001 Ring HsinDocument7 pagesTechnical SHEET 15349/000/04NL 1 Sbo14 Universal Machine: SSO 14 #11001 Ring HsinphongNo ratings yet

- Overfill Prevention Spill ContainmentDocument11 pagesOverfill Prevention Spill Containmentwarung1bensinNo ratings yet

- Flojet 4405 SN8386377Document4 pagesFlojet 4405 SN8386377Stathis MoumousisNo ratings yet

- CODA Full en Us LetterDocument2 pagesCODA Full en Us Lettercesar5984No ratings yet

- PI1508enA 9125527 Water Make-Up Systems Water Treatment PG Extract WebDocument20 pagesPI1508enA 9125527 Water Make-Up Systems Water Treatment PG Extract Webkepe81No ratings yet

- Schwab Product Catalogue 2015 (53 - 0112 - 14) PDFDocument100 pagesSchwab Product Catalogue 2015 (53 - 0112 - 14) PDFRobert Nito100% (1)

- Catalogo Industria HidraulicaDocument36 pagesCatalogo Industria HidraulicaEdwing GuerreroNo ratings yet

- 2 KESSEL Lifting StationsDocument20 pages2 KESSEL Lifting StationsAhmed HakamNo ratings yet

- GDocument2 pagesGdomo32No ratings yet

- Ken32 276 PDFDocument1 pageKen32 276 PDFashishtanjeaaNo ratings yet

- FLEXI LeafletDocument2 pagesFLEXI Leafletinternational@kishorpumps.comNo ratings yet

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- Cyrille MATH INVESTIGATION Part2Document18 pagesCyrille MATH INVESTIGATION Part2Jessie jorgeNo ratings yet

- PD750-01 Engine Data Sheet 12-29-20Document4 pagesPD750-01 Engine Data Sheet 12-29-20Service Brags & Hayes, Inc.No ratings yet

- Test Cases: Project Name: Virtual ClassroomDocument5 pagesTest Cases: Project Name: Virtual ClassroomTina HernandezNo ratings yet

- Expansions Meet Health Care Needs: Economists Question Trump Plan FiguresDocument10 pagesExpansions Meet Health Care Needs: Economists Question Trump Plan FiguresThe Daily Tar HeelNo ratings yet

- EHR StandardsIndia - August 2013-32630521Document54 pagesEHR StandardsIndia - August 2013-32630521kartiksinhNo ratings yet

- Amplificadores Automotivos PyramidDocument13 pagesAmplificadores Automotivos Pyramidedusf1000No ratings yet

- Helical Coil FlowDocument4 pagesHelical Coil FlowAshish VermaNo ratings yet

- HBS - Zara Fast Fashion Case Write UpDocument4 pagesHBS - Zara Fast Fashion Case Write Upaaronhwalton100% (1)

- Stating Like and DislikesDocument2 pagesStating Like and DislikesDavid ArdiantoNo ratings yet

- Asme Bladder Accumulator DatasheetDocument3 pagesAsme Bladder Accumulator DatasheetSamad A BakarNo ratings yet

- Arrhythmia - WikipediaDocument76 pagesArrhythmia - WikipediaJamesNo ratings yet

- Scale Aircraft Modelling 01.2019Document100 pagesScale Aircraft Modelling 01.2019Nikko LimuaNo ratings yet

- Welding and Heat Treatment Requirements For Equipment and PipingDocument34 pagesWelding and Heat Treatment Requirements For Equipment and Pipingonur gunesNo ratings yet

- Machine DesignDocument627 pagesMachine DesignlucarNo ratings yet

- Cell Structure, Cellular Respiration, PhotosynthesisDocument14 pagesCell Structure, Cellular Respiration, PhotosynthesisAmr NasserNo ratings yet

- 1.6 FSI Inlet Manifold Removal Guide - Audi A2 Owners' ClubDocument3 pages1.6 FSI Inlet Manifold Removal Guide - Audi A2 Owners' Clubdusan jovanovicNo ratings yet

- Market Challengers StrategiesDocument19 pagesMarket Challengers Strategiestobbob007100% (20)

- Sample Spec For AWWA HDPE Pipe Fittings 6.02revDocument6 pagesSample Spec For AWWA HDPE Pipe Fittings 6.02revmg4myNo ratings yet

- 88 Year Old Man Missing in SC - Please ShareDocument1 page88 Year Old Man Missing in SC - Please ShareAmy WoodNo ratings yet

- No Experience ResumeDocument2 pagesNo Experience ResumeNatalia PantojaNo ratings yet

- A Review On Different Yogas Used in The Management of Mandali Damsa Vrana W.S.R. To KriyakaumudiDocument11 pagesA Review On Different Yogas Used in The Management of Mandali Damsa Vrana W.S.R. To KriyakaumudiTiya TiwariNo ratings yet

- U04 Fxs of Humeral ShaftDocument88 pagesU04 Fxs of Humeral Shaftadrian_mogosNo ratings yet

- El Nino 3Document8 pagesEl Nino 3nisAfiqahNo ratings yet

- Pointers in CDocument25 pagesPointers in CSainiNishrithNo ratings yet

- CfoDocument13 pagesCfocarmen pirvanNo ratings yet

- Sample Hum RepDocument21 pagesSample Hum RepPritam PiyushNo ratings yet

- 234567890Document37 pages234567890erppibuNo ratings yet

- Tema & Htri by Bert BoxmaDocument5 pagesTema & Htri by Bert Boxmabloodterry2284No ratings yet

- Loan Agreement: Acceleration ClauseDocument2 pagesLoan Agreement: Acceleration ClauseSomething SuspiciousNo ratings yet

- Towards A Brighter Ecological Future: Group 2Document24 pagesTowards A Brighter Ecological Future: Group 2As YangNo ratings yet