Professional Documents

Culture Documents

Working at Heights Checklist: Part A

Uploaded by

gopal kumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Working at Heights Checklist: Part A

Uploaded by

gopal kumarCopyright:

Available Formats

This hazard control checklist shall be completed

WHS-12A if working at heights is identified in the

preparation of a Job Safety and Environment

WORKING AT HEIGHTS CHECKLIST: PART A Analysis (JSEA).

Description of work at heights task: Work order number:

Location: Asset name:

EWP, Crane, Scissor lift, Forklift type: Pre-start Log Book completed by:

Work at heights type: 2m or greater fall height possible <2m into an area containing a hazard

Existing platform, walkway, access way Erection of scaffolding

Means of access to location at height: Fixed ladder, stairway or portable ladder Elevated work platform (EWP), including scissor lift

Other (crane or forklift work box, etc):

WORKING AT HEIGHT CONTROLS:

BARRICADE PREVENTION OF FALLING OBJECTS

Solid barrier with top rail, mid rail and kick boards (mandatory above 2m) Erection of toe boards, infill, mesh guards, etc on all edge protection

Soft barrier wet and slippery surfaces accounted for Erection of containment sheeting on work platforms and scaffolds

PERSONAL FALL PROTECTION Erection of overhead protection

Fall restraint system Establishment of an exclusion zone below the work area via barricades and signs

Fall arrest system Fragile and wet surfaces/rooftops

Anchorage inspected and approved for use Other:

Safety observer PERSONAL PROTECTIVE EQUIPMENT (PPE)

Tool restraints Safety helmet Safety glasses Safety Harness Lanyard

RESCUE/RETRIEVAL CONSIDERATIONS: The following controls should be considered in situations involving the use of fall arrest harness systems

Personnel involved in the work are competent to perform rescue/retrieval Any additional requirements for rescue/retrieval are able to be enacted immediately

Additional retrieval/rescue equipment is available at the immediate work location Other:

Name: Signed: Date:

Prepared/Authorised by: Supervisor: Signed: Date:

Safety Observer: Signed: Date:

G-OHS-12A Working at Heights Checklist V3 Page 1 of 2 Document Owner: WHS Specialist

Reviewed: Sept 2014 Document Sponsor: Chief Executive Officer

WHS-12A This equipment Inspection checklist shall be filled out

covering all Working at Heights equipment to be used. Any

WORKING AT HEIGHTS CHECKLIST: PART B Defective equipment shall be removed from service and

tagged immediately

Type of equipment: (Harness, lanyard etc) Equipment Manufacturer: Serial Number Year of Manufacture: Remove from service date:

Harnesses, Lanyards and associated equipment

No deterioration due to

No damage due to contact No activation of fall

Webbing: No cuts or tears No abrasion damage rotting, mildew or UV

with heat, oils or chemicals. indicators where fitted.

exposure

Snap Hooks

No distortion of hook or Free from dirt or other No cracks or wear at No free movement of the No broken, weak or

and

latch. obstructions. swivels and latch points. latch over its full travel. missing latch springs.

Carabiners:

No excessive vertical No cracks, especially at the joins No distortion or other No excessive loss of

D-Rings:

movement of the D-ring of straight and curved sections. physical damage of the D-ring cross section due to wear.

Buckles and No distortion or other

No cracks No bent tongues

adjusters: physical damage

No broken, cut or worn No damage or weakening of No signs of contact with

Stitching:

threads. threads. heat, oils or other chemicals.

No damage due to

No deterioration due to

Ropes: No cuts No abrasion or fraying No stretching contact with heat, oils or

UV’s or mildew

chemicals.

Fall Arrest Devices

Rope or No damage due to contact No excessive dirt or No activation of fall

No cuts No Fraying or abrasion

Webbing: with heat, oils or chemicals. grease/oil impregnation indicators where fitted.

Mounting No physical damage or No wear or damage

No cracks, especially in corners Check mounting security

Ring: wear around pivot points

No significant dents, No foreign bodies such as Correct use labels and

No loose or missing screws, nuts

Device Body: distortion, corrosion or small stones within the body service label/tag is present

or bolts (external check only)

cracks (To be checked without dismantling) and legible.

Hardware: Check the condition and locking action of any associated snap hooks, links and the condition of anchorage points to be used.

G-OHS-12A Working at Heights Checklist V3 Page 2 of 2 Document Owner: WHS Specialist

Reviewed: Sept 2014 Document Sponsor: Chief Executive Officer

You might also like

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- Work at Height ChecklistDocument2 pagesWork at Height ChecklistBRC HSE Dept.100% (3)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Job Safety Analysis - Rope AccessDocument2 pagesJob Safety Analysis - Rope AccessMathavaraj Dharmaraj75% (4)

- JSA Steel Erection ManliftsDocument1 pageJSA Steel Erection Manliftsrudygoot100% (1)

- W@H PermitDocument2 pagesW@H PermitJixtha SaintNo ratings yet

- Risk Assessment For External Façade & Canopies CleaningDocument6 pagesRisk Assessment For External Façade & Canopies Cleaningjulius0% (1)

- JSA DrillingDocument4 pagesJSA DrillingAmalNo ratings yet

- JSA SK Erection DismantlingDocument1 pageJSA SK Erection DismantlingSamuel Hugos100% (4)

- Safety: JOB AnalysisDocument4 pagesSafety: JOB AnalysisAjay kumar100% (1)

- JSA Painting Aut Tranformer Unit 3 OutageDocument7 pagesJSA Painting Aut Tranformer Unit 3 OutageMarhendraNo ratings yet

- DFo 2 1Document15 pagesDFo 2 1Donna HernandezNo ratings yet

- L02-02 Lifting Plan (Non Crane)Document2 pagesL02-02 Lifting Plan (Non Crane)Fabio CastroNo ratings yet

- Scaffolding Work Permit New FORMDocument1 pageScaffolding Work Permit New FORMRaka NusantaraNo ratings yet

- Emergency Plan For LiftDocument8 pagesEmergency Plan For LiftScribdTranslationsNo ratings yet

- STARRT CardDocument2 pagesSTARRT Cardsanny100% (1)

- Roofing WorkDocument5 pagesRoofing WorkSsenyonjo EricNo ratings yet

- JSA Mobile CranesDocument2 pagesJSA Mobile CranesAmanya DickallansNo ratings yet

- Operation of Vehicle Mounted Crane: Safe Work Method StatementDocument9 pagesOperation of Vehicle Mounted Crane: Safe Work Method StatementMuhd AqibNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Job Hazard Environment Analysis - BenchmarkDocument8 pagesJob Hazard Environment Analysis - BenchmarkStansilous Tatenda Nyagomo100% (1)

- Cutting DrillingDocument4 pagesCutting DrillingKoneti JanardhanaraoNo ratings yet

- Working at Heights SwmsDocument11 pagesWorking at Heights Swmssyed khaja misbhuddinNo ratings yet

- Ehv SWP Form Lifting Lowering Operation PDF NewDocument3 pagesEhv SWP Form Lifting Lowering Operation PDF NewSn AhsanNo ratings yet

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- JSA - Installation, Operation and Maintenance of VSM 300 ShakerDocument5 pagesJSA - Installation, Operation and Maintenance of VSM 300 ShakerjinaNo ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplateJUAN NICANOR ALIAGA GIRONNo ratings yet

- SWMS (Cable Glanding and Termination )Document6 pagesSWMS (Cable Glanding and Termination )PRIYESH . K. PRIYANNo ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- Genie Scissor Lift GS 2632 - SWP Nov 12 2013Document5 pagesGenie Scissor Lift GS 2632 - SWP Nov 12 2013Cvijic DejanNo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- Genie E Series Slab Scissor Lift OperationDocument11 pagesGenie E Series Slab Scissor Lift OperationSanket Arun MoreNo ratings yet

- Concrete Placement Finishing Swms 10064-7Document12 pagesConcrete Placement Finishing Swms 10064-7JamesNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- Work PermitsDocument11 pagesWork PermitsAbdul RasheedNo ratings yet

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATEPrakash PavuralaNo ratings yet

- Job Safety Analysis - Cone ErectionDocument6 pagesJob Safety Analysis - Cone ErectionEslam lotfy- Eslam elsadatNo ratings yet

- JHA 02 Lifting and SlingingDocument4 pagesJHA 02 Lifting and Slingingadil khanNo ratings yet

- Work at Height Permit FormDocument3 pagesWork at Height Permit FormEbenezer OpuniNo ratings yet

- Jsa Water Proofing For DHADocument13 pagesJsa Water Proofing For DHAAnonymous YmINeSIFNo ratings yet

- ENG20016-QAFM-007 Rev.0 - Excavation PermitDocument3 pagesENG20016-QAFM-007 Rev.0 - Excavation PermitElmer BellenNo ratings yet

- Fall PreventionsDocument16 pagesFall PreventionsRajesh gp100% (1)

- Construction Job Hazards Analysis: This Is A TEMPLATEDocument1 pageConstruction Job Hazards Analysis: This Is A TEMPLATEcrnkarlosNo ratings yet

- Crane LiftsDocument1 pageCrane LiftsJasonNo ratings yet

- SWMS Piling Machine Assembly RKDocument14 pagesSWMS Piling Machine Assembly RKrakeshkhanna78100% (1)

- S.No Job Steps Hazards Preventative Measures Responsible PersonDocument3 pagesS.No Job Steps Hazards Preventative Measures Responsible Personmd_rehan_2No ratings yet

- Whs f014 Safe Work Method Statement FormDocument9 pagesWhs f014 Safe Work Method Statement FormTamo Kim ChowNo ratings yet

- 2040-00-HFRM-004 - 4 Working at Heights PermitDocument8 pages2040-00-HFRM-004 - 4 Working at Heights Permitelliotadjeiacheampong2No ratings yet

- Al-Khalij 4X350 MW Power Plant Project Job Safety Analysis WorksheetDocument5 pagesAl-Khalij 4X350 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Earthmoving Attachment Maintenance: Safe Operational ProcedureDocument3 pagesEarthmoving Attachment Maintenance: Safe Operational ProcedureJamesNo ratings yet

- TLC Skyhook JSA 2Document2 pagesTLC Skyhook JSA 2Mohamed Amine ZemouriNo ratings yet

- Work at Height ChecklistDocument3 pagesWork at Height ChecklistThillai8975No ratings yet

- Point of Work Lifting Assessment POWLA 1 1Document1 pagePoint of Work Lifting Assessment POWLA 1 1Samier MohamedNo ratings yet

- FRM Cach Eng 00028Document5 pagesFRM Cach Eng 00028john macpNo ratings yet

- WAH ChecklistDocument2 pagesWAH ChecklistLiko A. PaddingtoneNo ratings yet

- 1 - Lifting FDocument2 pages1 - Lifting FSuryaNo ratings yet

- Job Safety Analysis 14 For Cable Laying and PullingDocument4 pagesJob Safety Analysis 14 For Cable Laying and PullingBishop Ojonuguwa Ameh100% (1)

- JSA #19 - Heavy Lifting in Hazardous AreaDocument1 pageJSA #19 - Heavy Lifting in Hazardous AreaMock ProjectNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- Campaign ETADocument11 pagesCampaign ETAgopal kumarNo ratings yet

- Jha IbfDocument4 pagesJha Ibfgopal kumarNo ratings yet

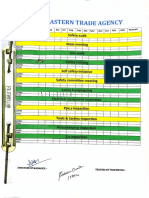

- Rate-Sheet ETADocument10 pagesRate-Sheet ETAgopal kumarNo ratings yet

- Application Slip 11025497Document2 pagesApplication Slip 11025497gopal kumarNo ratings yet

- ETA CSMS ScoreDocument6 pagesETA CSMS Scoregopal kumarNo ratings yet

- NCERT Class 9 Political Science4Document1 pageNCERT Class 9 Political Science4gopal kumarNo ratings yet

- NCERT Class 6 Political Science1Document1 pageNCERT Class 6 Political Science1gopal kumarNo ratings yet

- St. Xavier'S School Doranda, Ranchi SYLLABUS FOR 2021-2022 English I Std. I Terms Months Chapters Terminal Exam First Term AprilDocument7 pagesSt. Xavier'S School Doranda, Ranchi SYLLABUS FOR 2021-2022 English I Std. I Terms Months Chapters Terminal Exam First Term Aprilgopal kumarNo ratings yet

- Infection Control Checklist Housekeeping DepartmentDocument3 pagesInfection Control Checklist Housekeeping Departmentgopal kumar100% (2)

- NCERT Class 8 Political Science3Document1 pageNCERT Class 8 Political Science3gopal kumarNo ratings yet

- 250kva Quotation ETA RevisedDocument8 pages250kva Quotation ETA Revisedgopal kumarNo ratings yet

- NCERT Class 7 Political Science2Document1 pageNCERT Class 7 Political Science2gopal kumarNo ratings yet

- Book List For 2021 2022 KG VDocument7 pagesBook List For 2021 2022 KG Vgopal kumarNo ratings yet

- Acharyakulam Tata Road, Near Namkum Thana, Namkum, Ranchi-10Document3 pagesAcharyakulam Tata Road, Near Namkum Thana, Namkum, Ranchi-10gopal kumarNo ratings yet

- Terracotta JaliDocument1 pageTerracotta Jaligopal kumarNo ratings yet

- Rfq/Nit Detail: Attribute (S)Document3 pagesRfq/Nit Detail: Attribute (S)gopal kumarNo ratings yet

- GeM Bidding 2553337Document12 pagesGeM Bidding 2553337gopal kumarNo ratings yet

- Flir t540 Professional Thermal CameraDocument12 pagesFlir t540 Professional Thermal Cameragopal kumarNo ratings yet

- Enquiry Details: Click To Show/Hide Enquiry DescriptionDocument5 pagesEnquiry Details: Click To Show/Hide Enquiry Descriptiongopal kumarNo ratings yet

- HSCC SRH 0705 PDFDocument1 pageHSCC SRH 0705 PDFBhawna KapoorNo ratings yet

- Brigade Product Catalogue Edition 20 EnglishDocument88 pagesBrigade Product Catalogue Edition 20 EnglishPelotudoPeloteroNo ratings yet

- Practising Modern English For Life Sciences Students Caiet Exercitii-1Document77 pagesPractising Modern English For Life Sciences Students Caiet Exercitii-1Robert BobiaNo ratings yet

- Retail Banking Black BookDocument95 pagesRetail Banking Black Bookomprakash shindeNo ratings yet

- Roxas City For Revision Research 7 Q1 MELC 23 Week2Document10 pagesRoxas City For Revision Research 7 Q1 MELC 23 Week2Rachele DolleteNo ratings yet

- 82686b - LOAD SHARING MODULEDocument2 pages82686b - LOAD SHARING MODULENguyễn Đình ĐứcNo ratings yet

- Gomez-Acevedo 2010 Neotropical Mutualism Between Acacia and Pseudomyrmex Phylogeny and Divergence TimesDocument16 pagesGomez-Acevedo 2010 Neotropical Mutualism Between Acacia and Pseudomyrmex Phylogeny and Divergence TimesTheChaoticFlameNo ratings yet

- Biology Key Stage 4 Lesson PDFDocument4 pagesBiology Key Stage 4 Lesson PDFAleesha AshrafNo ratings yet

- Advertising II Marathi VersionDocument91 pagesAdvertising II Marathi VersionHarsh Sangani100% (1)

- Knee JointDocument28 pagesKnee JointRaj Shekhar Singh100% (1)

- Math 9 Quiz 4Document3 pagesMath 9 Quiz 4Lin SisombounNo ratings yet

- Stentofon Pulse: IP Based Intercom SystemDocument22 pagesStentofon Pulse: IP Based Intercom SystemCraigNo ratings yet

- CORP2165D Lecture 04Document26 pagesCORP2165D Lecture 04kinzi chesterNo ratings yet

- FpsecrashlogDocument19 pagesFpsecrashlogtim lokNo ratings yet

- Google Tools: Reggie Luther Tracsoft, Inc. 706-568-4133Document23 pagesGoogle Tools: Reggie Luther Tracsoft, Inc. 706-568-4133nbaghrechaNo ratings yet

- Moquerio - Defense Mechanism ActivityDocument3 pagesMoquerio - Defense Mechanism ActivityRoxan MoquerioNo ratings yet

- Prospekt Puk U5 en Mail 1185Document8 pagesProspekt Puk U5 en Mail 1185sakthivelNo ratings yet

- 레벨 테스트Document2 pages레벨 테스트BNo ratings yet

- Switching Simulation in GNS3 - GNS3Document3 pagesSwitching Simulation in GNS3 - GNS3Jerry Fourier KemeNo ratings yet

- Design and Analysis of Modified Front Double Wishbone Suspension For A Three Wheel Hybrid VehicleDocument4 pagesDesign and Analysis of Modified Front Double Wishbone Suspension For A Three Wheel Hybrid VehicleRima AroraNo ratings yet

- Project Management TY BSC ITDocument57 pagesProject Management TY BSC ITdarshan130275% (12)

- Case Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityDocument5 pagesCase Study Single Sign On Solution Implementation Software Luxoft For Ping IdentityluxoftNo ratings yet

- Kapinga Kamwalye Conservancy ReleaseDocument5 pagesKapinga Kamwalye Conservancy ReleaseRob ParkerNo ratings yet

- Ducted Split ACsDocument31 pagesDucted Split ACsHammadZaman100% (1)

- EKRP311 Vc-Jun2022Document3 pagesEKRP311 Vc-Jun2022dfmosesi78No ratings yet

- Numerical Modelling and Design of Electrical DevicesDocument69 pagesNumerical Modelling and Design of Electrical Devicesfabrice mellantNo ratings yet

- Curriculum Guide Ay 2021-2022: Dr. Gloria Lacson Foundation Colleges, IncDocument9 pagesCurriculum Guide Ay 2021-2022: Dr. Gloria Lacson Foundation Colleges, IncJean Marie Itang GarciaNo ratings yet

- Logiq v12 SM PDFDocument267 pagesLogiq v12 SM PDFpriyaNo ratings yet

- Module6 Quiz1Document4 pagesModule6 Quiz1karthik1555No ratings yet